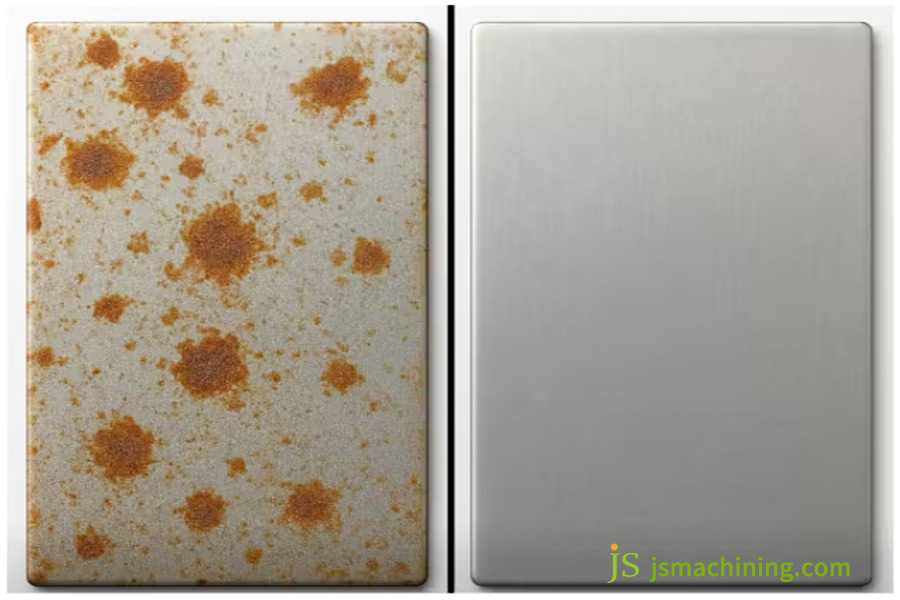

With humid salt spray corrosion,seaside railing project developed unsightly rust in less than a year,completely destroying the quality of the entire project.But the alternative,even though 20% more costly,will last for decades,safeguarding your reputation for your design.

It is not just a choice between 304 vs 316 stainless steel but one for project longevity,total cost of ownership,and company reputation.

This guidebook will enlighten you on the real prices of 304 and 316 stainless steel,enabling you to make the most cost-effective choice.We will also provide you with information about JS’s professional services to supplement your option.

Core Answer Summary

| Comparison Dimension | 304 Stainless Steel | 316 Stainless Steel |

| Core Positioning | Economical all-rounder | Corrosion-resistant specialist |

| Key Difference | Contains chromium and nickel,no molybdenum. | Additional molybdenum(Mo)added. |

| Which is more expensive? | Relatively cheaper | More expensive |

| Current price difference | Base price(please provide specific amount). | Usually 20%-40%more expensive than 304. |

| Why is the price higher? | Basic alloy cost | Cost of molybdenum element and addition process. |

| Preferred Application Scenarios | Indoor furniture,dry environments,general decoration. | Coastal environments,chemical industry,medical equipment,food processing. |

Trust JS: Unveiling The Real Prices Of The Two Stainless Steels

JS has over 10 years of practical experience in stainless steel CNC machining.We have served clients in various industries,including food processing,medical devices,marine engineering,and architectural decoration,and have completed thousands of custom stainless steel parts projects.

For example,we manufacture 316 stainless steel connectors for marine equipment manufacturers,customize 316 surgical instrument accessories for hospitals,and produce 304 stainless steel handrails for general furniture manufacturers.

We understand 304 and 316 stainless steel’s cost and performance profile in different circumstances.We understand when choosing 304 will save us money and when choosing 316 will avoid future loss.

This guide,compiled by the JS team from those actual project experiences,is supported by real-life examples and can help you steer clear of cost traps and arrive at a clear understanding of the actual costs of both stainless steel types.

JS has long professional experience in producing parts through CNC machining and has extensive knowledge of 304 and 316 stainless steel properties and professional selection advice.If you have any requirements,please feel free to contact us to initiate the custom process to achieve the best cost-saving solution.

Common Origins: The Similarities Between 304 And 316

Having gained knowledge of JS’s professional experience,let’s begin with the similarity between the two.They are both austenitic stainless steels,with highly similar basic properties,which is why many people initially struggle to distinguish them.

They share three points in common:

- Excellent corrosion resistance,capable of resisting daily wear and tear from the environment.

- Excellent weldability and formability,can be machined easily into complex shapes in mass CNC machining production with stable post-manufacturing performance.

- Excellent room-temperature mechanical properties,meeting most structural component requirements.

In order to present an easier-to-understand overview,we have summarized the following table:

| Characteristic Category | 304 Stainless Steel | 316 Stainless Steel | Summary of Common Features |

| Material Type | Austenitic stainless steel | Austenitic stainless steel | Belong to the same category with stable crystal structure. |

| Weldability | Good | Good | Not prone to cracks after welding,with high welding strength. |

| Room-temperature Tensile Strength | Approx.515MPa | Approx.515MPa | Basically the same mechanical strength at room temperature. |

| Formability | Excellent | Excellent | Easy to machine into complex parts via CNC machining. |

JS effectively uses the common characteristics of 304 and 316 stainless steel in custom CNC machining manufacturing,ensuring excellent forming performance and stable running.We can actually meet your requirements if you require customized stainless steel products.

The Mystery Of Price: Why Does The Element Molybdenum(Mo)Cause A Huge Price Difference?

Although 304 and 316 stainless steels share a great deal in common,they differ in price as well.The explanation is basic in nature:316 stainless steel includes molybdenum(Mo),but 304 stainless steel does not.This microscopic difference has a directly causal relationship with a macroscopic cost disparity between the two.

Microscopic Differences in Chemical Makeup

We compare the primary chemical makeup of the two(by mass percentage)in this table:

| Element | 304 Stainless Steel | 316 Stainless Steel | Difference Analysis |

| Chromium(Cr) | 18%-20% | 16%-18% | Both contain sufficient chromium to provide basic corrosion resistance. |

| Nickel(Ni) | 8%-10.5% | 10%-14% | 316 has higher nickel content,enhancing toughness and corrosion resistance. |

| Molybdenum(Mo) | 0% | 2%-3% | Molybdenum is unique to 316 and is the key to pitting corrosion resistance. |

| Carbon(C) | ≤0.08% | ≤0.08% | Consistent carbon content to avoid intergranular corrosion during processing. |

Molybdenum forms a denser oxide film on stainless steel surfaces to resist corrosion by chloride ions(seawater,salt,and disinfectant),so 316 is tougher under very corrosive conditions.However,the molybdenum refining challenge and raw materials’cost help raise the price of making 316 stainless steel.

Macroscopic Cost Impact: How large is the market price difference now?

As of Sep 2025,for example,2mm thickness coil with 2B surface,the normal price of 304 steel is $8,000-9,500 per ton,while that of 316 steel is $11,000-13,000 per ton,which is 25%-40% higher than 304.The premium depends on molybdenum and nickel price,supply and demand,and the price of 316 steel increases more when there is molybdenum ore shortage.

JS delves into the cost of 304 vs 316 stainless steel and the root causes of their differences and can provide you with open quotes on CNC machining prices.We’ll recommend the appropriate material to your application scenario to avoid unnecessary cost.

Beyond Material: What Else Does Impact Your Final Quote?

Once you understand the differences in materials,you’ll notice different suppliers charge differently for the same stainless steel.Surface treatment,form,and specifications can differ significantly in terms of price,with over 20% differences in the same material at times.

Specifications and form are controlling factors

In terms of specifications, non-standard specifications with a thickness of less than 0.5mm or greater than 10mm and a width exceeding 2 meters are priced 8% -20% higher than standard specifications (1-3mm thick, 1.22-1.5 meters wide) due to their high processing difficulty and low utilization rate.

In terms of form, the coil material is 5% -8% lower than the same specification board, and the molded parts require additional processing, resulting in a price 30% -50% higher than the raw materials.

Surface Treatment–A Cost Multiplier

Different surface finishes require different machining steps and can result in significant cost differences. These differences are directly reflected in the custom CNC machining manufacturing quote and also affect the CNC machining price.

The following table summarizes key information for each surface finish:

| Surface Treatment Method | Processing Procedure Description | Cost Increase Compared to 2B Surface | Application Scenario Examples |

| 2B Surface (Basic) | Direct surface treatment after cold rolling. | 0% (Lowest Cost) | General parts with no special surface requirements, such as ordinary structural parts. |

| Brushed Surface | Grinding with sandpaper or a brushing machine to form uniform lines on the surface. | 5% – 10% | CNC machining parts with certain appearance requirements, such as equipment exterior parts. |

| Mirror Polished Surface | Multiple fine grindings to achieve a mirror-like gloss on the surface. | 15% – 25% | High-end decorative parts, precision equipment parts. |

| Passivation Treatment | Forming a protective film on the surface through chemical solution to improve corrosion resistance. | 8% – 12% | Outdoor parts, parts in humid environments. |

If a part requires a combination of surface finishes (for example, brushing followed by passivation), the total cost increase will be compounded on top of the cost increase for each individual finish, and the final quote will increase accordingly. This should be confirmed with the supplier in advance when selecting online CNC machining services.

Timing Of Buying: The Year-End And Beginning Of The Year “Unspoken Price Rules”

Choosing the right material,specifications,and surface finishing,and making the purchases at the correct time are other ways through which you can save a lot of money.This is especially true in the export markets,where prices for stainless steel fluctuate like crazy between the beginning of the year and the end of the year.This is normally referred to as the“unspoken price rules”by insiders.

The procurement cycle in foreign markets is usually linked to annual performance evaluations:

- During November and December of every year,sellers offer 5%-12% discounts for stock clearance and sales volume boosts,leading to lower prices and faster delivery.

- Between January and February of the following year,downstream demand rises upon the restart of production,leading to price increases of 8%-15%,extending delivery cycles to 4-6 weeks and potentially leading to material shortages.

Thus,if your project timeline is not rigid,do year-end buying first.For buying early in the year,sign contracts 2-3 months ahead to confirm prices and delivery dates.

JS understands international stainless steel purchasing timing trends and can provide the most favorable CNC machining price strategy based on your project schedule.If you plan to purchase and machine stainless steel,we can help you catch low prices and reduce overall costs.

Case Analysis: Why A Flawed”Cost-Saving”Decision Double The Cost?

Client Background

An upscale restaurant equipment supplier participated in a tender for the refurbishment of a seafood restaurant,which required 10 bespoke worktops and 5 sinks.JS offered a 316 solution costing a total of $300,000(Including CNC machining fees),while one rival company offered a 304 solution with a total of $225,000(25% lower).The supplier chose the 304 solution in order to win the bid.

Problem

Six months after opening,from exposure to chloride ions(detergents,seawater,salty foods)in the kitchen over a long period of time,large areas of pitting and rust on the 304 countertops appeared,which is a violation of food safety codes.The restaurant was ordered to close down for two weeks for correction and had to pay a claim o f$100,000.

After the supplier had approached JS Precision Manufacturing,we calculated total losses as follows: replacement cost of $180,000(including disassembly and installation),loss of business of $50,000,and claims of $100,000,totaling $330,000,far exceeding the $75,000 saved.

JS Solution

- Implement the use of raw material 316 stainless steel and apply efficient CNC machining technology in order to shorten the processing cycle time of new equipment from the normal 4 weeks to 1 week,restricting the restaurant’s downtime.

- Implement a professional team to dismantle the old equipment and install the new equipment on-site,ensuring that the accuracy of on-site installation meets the demands of kitchen use.

- Offer a 1-year corrosion-resistant warranty for the new equipment to comfort both suppliers and restaurants.

Results

After the new equipment was installed,the restaurant reopened.316 equipment was used for 1 year without rusting.The suppliers regain cooperation and obtain subsequent maintenance orders.This case is evidence that the”low price”of 304 in the inappropriate environment is actually the most expensive price.

JS has helped numerous customers get rid of the problem of the wrong material selection many times in custom CNC machining manufacturing.We will recommend the right stainless steel based on your application and allow you not to get into the”low-price”trap.You can choose our services freely.

Selection Guide: How To Choose The Right 304 Vs.316?

Having seen the above examples,you will understand that 304 or 316 is not always a question of price,it is the application that settles it.We’ve compiled below an easy-to-see and easy-to-understand selection guide to allow you to make the right decision with a glimpse and to avoid the supplier’s trap from the example.

Golden Rules for Selecting 316 Stainless Steel

If your application entails any of the following conditions,316 stainless steel is the way to go:

- Chloride ion-containing environments,such as marine hardware(e.g.,ship parts),building facades in coastal regions,and food processing equipment that comes in contact with brine(e.g.,pickling tanks),

- In the medical field,e.g.,for surgical tools and hospital sterilizers,as 316 stainless steel has higher biocompatibility and lower corrosiveness by disinfectants(e.g.,chlorinated disinfectants),

- For temperatures above 500°C,e.g.,for high-temperature furnace parts,316 offers higher stable high-temperature resistance than 304 and is lower in deformation or oxidation at high temperatures.

Select 304 Stainless Steel with Confidence

If your product will be used in the following environments,choosing 304 stainless steel will meet your needs while also keeping costs under control:

- Indoor,dry environments,such as office stainless steel handrails,stainless steel furniture brackets,and household kitchenware(such as wok handles),

- Low-corrosion environments,such as freshwater treatment equipment(e.g.,water pipes)and interior decorative components(e.g.,stainless steel ceilings),

- Cost-sensitive consumer products with no extreme performance requirements,e.g.,stainless steel water bottles and housing parts for common household appliances.

Best Approach When in Doubt

When the application scenario is special,the best approach is to obtain professional service provider advice,e.g.,JS Precision Manufacturing.We provide free choice consultation based on your environment,budget,etc.,and even perform small-batch sample testing in a bid to reduce decision risk.

FAQs

Q1: Is it worth paying extra for 316?

Whether or not it is worth the extra expense for 316 ultimately depends on where it will be used.If the application is with chloride ions(seawater or heavily salted foods),or is subjected to high heat or medical use,316’s corrosion resistance and stability are far greater than that of 304,preventing the damage caused by rust,repair,or replacement thereafter.For normal indoor applications with dry,low-corrosion environments,304 will suffice,and there is no need to pay a premium for 316.

Q2: Is 316 stainless steel truly rust-proof?

No.316 stainless steel is not entirely rust-proof,it simply has excellent corrosion resistance.Under typical circumstances,316 forms a dense oxide layer on its surface to guard against corrosion.But if the environment is extremely severe(e.g.,high concentration strong acid),or if the oxide layer is damaged by mechanical abrasion or impact and not restored timely,corrosion and rust will occur,although the possibility is much reduced compared with 304 stainless steel.

Q3: I wonder if I can use 304 stainless steel for marine parts.

It is extremely undesirable to use 304 stainless steel for marine parts.Seawater and the sea environment expose marine components to seawater over long periods of time,and the chlorides present in them would quickly etch the oxide film on the surface of 304 stainless steel,leading to pitting and stress corrosion cracking.This not only reduces the strength and service life of the components but also poses a safety hazard.

Q4: Is there any variation in recycling value?

The price of recycling 304 and 316 stainless steel is highly diverse,with 316 generally being more valuable.As the recycling value of stainless steel relies on the metal content it has,316 contains 2%-3% molybdenum,a difficult-to-refine metal with a high market value.304 does not contain molybdenum and less nickel compared to 316.As a result,when recycled,316 generally fetches a price of 15%-25% over 304.

Summary

Choosing between 304 and 316 is far more than price comparison,it’s a cost calculation of the entire lifecycle and an investment in project durability and quality.If you need custom stainless steel CNC machining parts,allow the application and budget determine the choice wherever possible.If you are not sure,always seek the advice of experts.

Don’t be bogged down with difficult material selection!JS always puts customer needs at the core in the manufacturing of CNC machining parts and online CNC machining services, providing precise machining services for 304 and 316 stainless steel.Contact our material experts today for the latest market trends and expert technical advice regarding 304 and 316 stainless steel.

You can also upload your engineering drawings directly to our intelligent quoting system.We will provide you a clear,open,and accurate quote with material certification based on your precise specifications(material,spec,and process)within 1 minute,so that your purchase is easy and secure.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Is A Milling Machine The Same As A CNC Machine? - JUSHENG