Aim a laser at plastic and the results can be very different: Either you cut out a precise and smooth work of art, or it turns into a disaster that releases toxic gases and damages equipment. The key to success or failure depends on which plastic you choose!

Laser cutting is indeed powerful, with high precision and high speed. It is not a problem to cut complex graphics, and plastic is a commonly used material. But I know in my heart: not all plastics can withstand laser cutting!Some cut out clean and beautiful edges, and the effect is nothing to say. Some are terrible, either burnt and discolored, or smoke and catch fire, or even release toxic gases, which is not a joke.

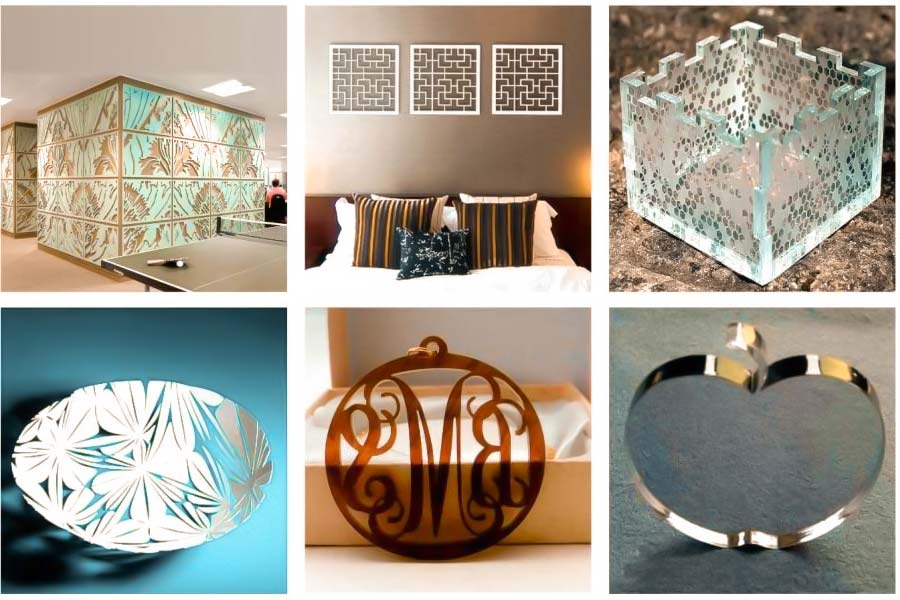

Therefore, choosing the right plastic is the key to success. Whether you are making signs, engraving nameplates, proofing parts, or making shells, if you choose the wrong material, not only will the finished product have a poor effect, but it may also bring danger. If you choose the right one, you will get twice the result with half the effort, the cut surface will be neat, and the efficiency will naturally be high.

This guide is to use our team’s core experience in the field of laser cut plastic to help you avoid minefields, choose the right materials, master the key points of safe operation, and make every cut safe and beautiful.

Core answer:

To put it bluntly, not all plastics can be safely laser cut. To help you quickly avoid risks, we have compiled the following core guidelines:

| Plastic Material | Laser Cuttability | Key Considerations |

| Acrylic/PMMA | ✅ Highly Recommended | The cutting edge is smooth as polishing, producing harmless and special sweet gases. |

| Polyvinyl chloride (PVC) | ❌ Strictly Prohibited | Releasing highly toxic chlorine gas can form hydrochloric acid, severely corroding machines and endangering health. |

| ABS | ⚠️ Not Recommended | Severe melting, poor edge quality, and the production of toxic cyanide gas. |

| Polycarbonate (PC) | ⚠️ Not Recommended | Poor cutting effect, prone to discoloration, melting, and ignition, not suitable for precision cutting. |

| Polyoxymethylene (Delrin/POM) | ✅ Recommended | The cutting edge is clean, with high precision, and requires good ventilation. |

| PETG | ⚠️ Cut with Caution | Easy to melt and adhere, requiring very specific settings and good ventilation. |

| PLA | ⚠️ Cut with Caution | Low melting point, easy to ignite and melt, more suitable for carving rather than cutting. |

This article will answer your questions:

- This guide will give you an in-depth understanding of the performance characteristics of various types of plastics under laser.

- And analyze our material selection logic through a real case.

- At the same time, we will also provide clear analysis of common practical problems such as cutting thickness and key equipment parameter settings.

Why Trust JS’s Plastic Cutting Suggestions? We Are Responsible For Your Safety And Project

At JS, laser cutting parts are the core of our daily work, of which plastic parts account for a large proportion. This high-frequency practical operation has allowed us to accumulate valuable “first-hand” experience.

We have witnessed with our own eyes that acrylic (PMMA) is precisely cut by laser, and the edges are crystal-like smooth and transparent. Similarly, we have also handled many maintenance cases where customers misused inappropriate plastics (such as PVC), resulting in the release of corrosive gases, smoked optical lenses, and even triggered equipment safety alarms during cutting – these profound lessons have given us a personal experience of the correlation between material selection and safety.

We not only provide custom laser cutting manufacturing services, but the core engineers of our team have long been focusing on studying the thermal effect characteristics, gas release rules and cutting quality correlation of different plastics under the action of lasers.

We are well aware that the root of an accurate and reasonable laser cutting quotation must be based on an accurate judgment of material safety and processing applicability.

“Herbert A. Simon, a pioneer in materials science and a master of engineering practice, has an insight that the judgment brought by experience cannot be replaced by any precise calculation.”

This guide is the core experience we have gained over the years in avoiding material risks, ensuring the long-term stable operation of equipment, and ultimately ensuring the successful delivery of customer projects. It condenses our dedication to safety and the pursuit of perfect cutting results, and aims to provide truly reliable and practical guidance for your project, so that you can achieve your design goals while effectively controlling costs and risks.

Plastic “Green Light Zone”: Materials Born For Lasers

In actual operation, I found that certain plastics are really natural partners for laser cutting! They can achieve precision and smoothness that other processing methods cannot achieve.

Acrylic (PMMA): The well-deserved first choice!

Why do our engineers love to use it so much?

Because it absorbs the energy of CO2 laser very well. Once the laser is shone on it, the material can be precisely evaporated instantly. The cut edges are very smooth and transparent, like glass. We often joke that it looks like the effect of “flame polishing”.

It is important to choose the right type of acrylic:

Cast acrylic: This is the material we often choose when laser engraving and cutting. The cut edges are super clear and transparent, and the engraved patterns are beautiful matte white with good contrast and ideal effect.

Extruded acrylic: The cut edges are also smooth, but there is a feature that the areas directly engraved by the laser are transparent, unlike cast acrylic which is matte white, so when choosing materials, you have to look at the specific effect you want.

Polyoxymethylene (Delrin / POM): Expert in precision parts!

This engineering plastic is a good helper for us when making small precision parts. Laser cutting it, the edge is extremely clean and straight, the dimensional accuracy is very high, and the deformation is small. It is especially suitable for small parts that need to be tightly fitted and highly functional, such as gears, bearings, buckles, etc.

“Choosing the right material is half the battle of laser cutting parts. Acrylic (especially casting type) can bring amazing surface effects, while polyoxymethylene is a reliable choice for precision functional parts. We have rich experience with laser use of material at JS. If you have specific project requirements, please feel free to contact us to talk about which material can best realize your ideas!”

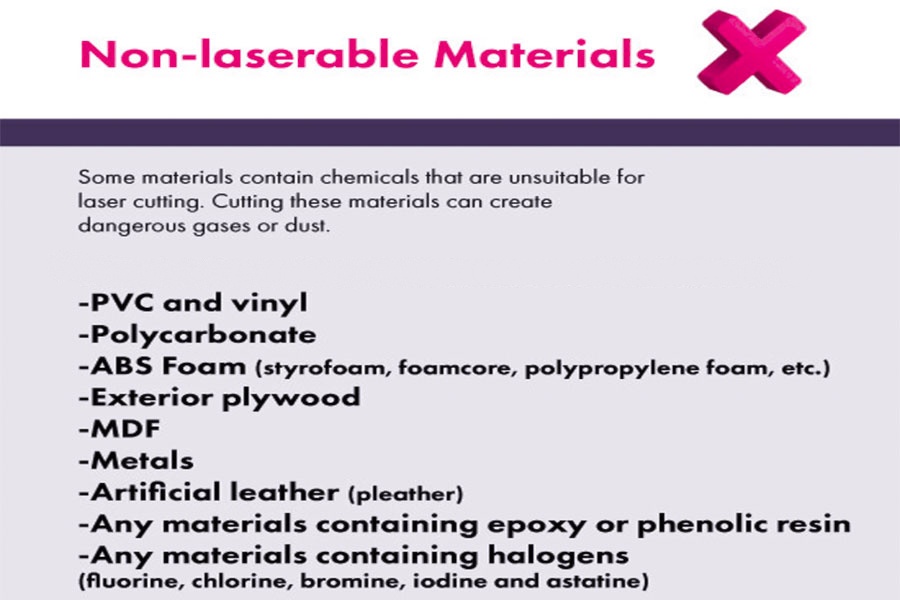

Absolute “Red Light District”: Never Put These Plastics Into The Laser Machine

Now, I must seriously remind you: Some plastics are absolutely forbidden areas for laser processing! Using them indiscriminately will not only mess up your workpiece, but also hurt the machine and people. This is really not to scare you:

PVC (polyvinyl chloride) – absolutely prohibited!

Why absolutely not?

PVC contains chlorine. When the laser burns, it will release highly toxic and pungent chlorine gas. Once the chlorine gas touches the moisture in the air, it immediately turns into highly corrosive acid mist.

How serious are the consequences?

This acid mist will seriously corrode your expensive laser machine: the lens will be blurred, the guide rail will be rusted, and the metal parts will be corroded. It is expensive and troublesome to repair! What’s more terrible is that people who inhale this gas will suffer acute respiratory burns, which is very dangerous!

ABS – poison gas maker + bad effect!

Core risk: When laser cutting ABS, the smoke contains highly toxic gases such as hydrogen cyanide (HCN), which poses a great threat to the health of the operator.

The effect is also very poor: The material is prone to violent melting rather than clean cutting/engraving, resulting in severe carbonization, adhesion, and deformation of the edges, which is a pure waste of materials.

Polycarbonate (PC / bulletproof glass) – not suitable for laser process

Why not? Although it is very hard and impact-resistant (often used to make bulletproof glass), it strongly absorbs near-infrared laser energy (especially CO2 laser), which can easily cause local overheating, yellowing, blistering, and open flame combustion.

The effect is equally bad: the cutting edge will become charred, uneven, or even catch fire, and the desired accuracy and finish will not be achieved at all.

“PVC, ABS and polycarbonate will produce highly toxic gases and highly corrosive substances during laser processing, posing unacceptable risks to personnel health, equipment life and processing quality. JS strictly implements material safety regulations and strongly recommends that customers confirm the suitability of materials with our technical team before starting the project. Avoiding risks and ensuring safety and quality are the basis for successful cooperation.”

Cautious “Yellow Light Zone”: You Can Cut, But You Need To Think Twice

I am doing laser cutting Plastics are very familiar with this type of material: they can indeed be cut, but you have to be extra careful! Melty edges, pungent odors, and frayed cuts are par for the course. Without sophisticated experience and careful control of parameters, the results are often unsatisfactory.

PETG: Excellent strength, but will “stick to the knife”

This material has outstanding toughness, but it melts too easily during laser processing! The melty plastic especially likes to stick back to the cut edges, making the cut grimy. Want to process it successfully? Powerful exhaust and precise airflow assistance (air pressure, angle) are necessary, otherwise the effect is ugly.

PLA (Common materials for 3D printing): Be careful it burns!

PLA has a very low melting point and is extremely easy to burn during laser processing. It is also easy to turn into a high-viscosity melt, making a mess. It is not very suitable for cutting, with high risks and poor results. If you must use laser processing, low-power shallow engraving is a more realistic option, but you must always keep an eye on fire prevention.

“PETG and PLA laser cutting are dangerous and difficult to handle, requiring rich experience and fine tuning. Don’t try it easily! When choosing materials for a project, it is strongly recommended to talk to our JS engineers first. Using the right materials is worry-free and safe.”

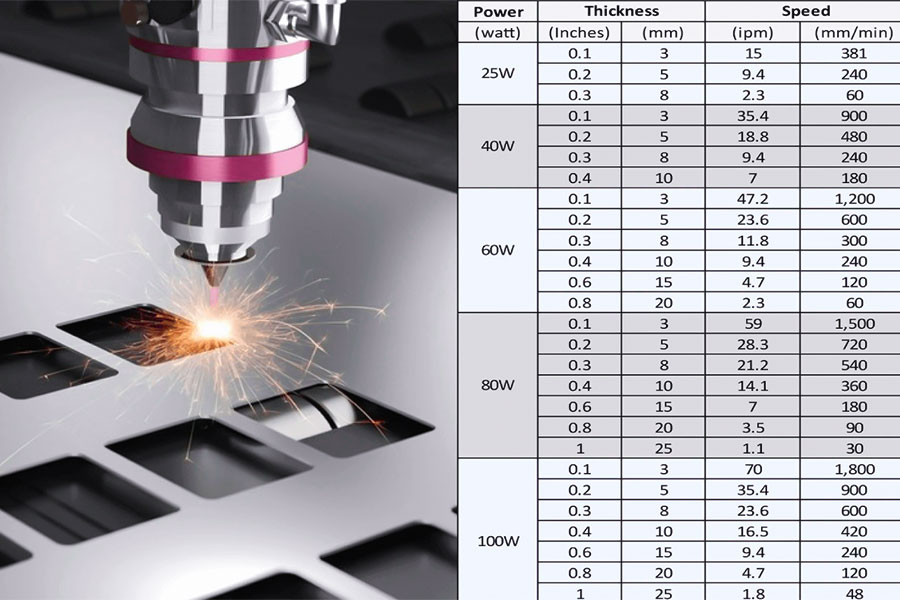

Game Between Thickness And Power: How Thick Plastic Can I Cut?

In daily technical consultation, how thick plastic can this machine cut? It is one of the most common questions. My answer is always: “It depends on how you want to cut”-is it barely penetrating, or is it efficient and high-quality cutting? Thickness is indeed the key, but behind it is a game of power, material and precision requirements.

Power: The cornerstone of cutting capability

Laser power (in W) determines directly the upper boundary of the input energy. The higher the power (e.g. 100W vs. 40W), the larger the volume of material that can be melted/vaporized in theory, and the greater the thickness that can be handled.

Key insight: “Being able to cut” and “being able to cut well” are definitely two different things. High power is a necessary condition for processing thick materials, but not the only condition.

Material: The essential difference that determines energy requirements

Different plastics have different cutting difficulties. For the same 10mm thickness, acrylic (PMMA) requires much higher power and slower speed than Delrin (POM). Acrylic absorbs energy more, and cutting parameters require more precise adjustment. First, get familiar with your material properties to choose the correct parameters.

Quality requirements: Defining the standard for “effective cutting”

In pursuit of perfect cutting of thick plates, the edge of the cut often has a taper (Kerf Taper), which is a physical law. The characteristics of the laser beam cause the cut to be wide at the top and narrow at the bottom. The greater the thickness, the more significant the taper effect.

“As Professor Dr. Reinhart Poprawe of the Fraunhofer Institute for Laser Technology (Fraunhofer ILT) in Germany emphasized in his book: The ultimate pursuit of edge verticality (low taper) and smoothness essentially sets an engineering upper limit for the maximum processable thickness that is far below the physical penetration limit.”

Other quality properties (e.g. heat-affected zone size, bottom dross, cutting speed) also suffer from increased thickness.

Application reference: Focus on top-quality cutting

As per my experience and common international practice (refer ILO and SPIE laser processing standard data), the practical maximum of high-quality cutting of acrylic for typical CO2 laser cutting machines usually ranges from 20-25mm (roughly equal to 1 inch). Beyond this thickness, the cutting speed is either very low or the quality becomes difficult to maintain.

100W CO2 laser high-quality cutting plastic parameters:

| Material type | Maximum thickness for high-quality cutting (mm) | Optimal speed range (mm/min) | Typical edge taper | Key process control points |

| Acrylic (PMMA) | 18 – 23 | 700 – 1100 | 0.7° – 2.2° | Control of melt viscosity and gas purity>99.95%. |

| Polycarbonate (PC) | 12 – 16 | 500 – 800 | 1.2° – 3.5° | Anti yellowing/carbonization, O₂ isolation. |

| HDPE | 6 – 10 | 1200 – 2000 | 2.5° – 6.0°+ | Discharge of molten material and prevention of reattachment. |

| POM (Delrin/Acetal) | 14 – 18 | 900 – 1500 | 1.0° – 2.8° | Prevent excessive melting and optimize air pressure. |

Data source: Comprehensive LIA Technical Reports & SPIE Proceedings Vol. 11674, based on N2-assisted cutting standard process.

“Curious how thick you are able to cut your plastic? Don’t just look at the machine power upper limit. Please let me know your target material, the most critical quality point for you, and your target thickness. Our JS personnel can help you best match the most suitable laser power and fine parameter solution on those.”

Case Analysis: From Wrong PC to Right Acrylic

Here is a real-life case to illustrate how material selection indirectly contributes to the success or failure of laser cutting and the final product value:

Project Challenge: Strong ≠ Laser Processability

We received a design sketch from our start-up business and asked to laser cut polycarbonate (PC) in order to manufacture a transparent device protection plate. They are best characterized by “strong and durable”. It seems reasonable at first sight, PC possesses better impact resistance. But I saw the probable risk immediately as a professional with laser processing: given that the laser cutting characteristics of PC are essentially contrary to its mechanical performances.

JS’s expert action: revealing the trap in “sturdiness”

We engaged with the customer immediately on receiving the drawings and made it clear to them:

(1) Edge yellowing and carbonization: PC has very strong absorption of CO₂ laser (10.6μm) but very low thermal stability. The high temperature in cutting is easy to cause the edges of the cuts to yellow or even to carbonize and leave ugly brown or black spots, completely destroying the visual effect of transparent parts.

(2) Melting and burrs: When PC melts, it is poorly fluid and highly viscous. During the cooling process, it is easy to form rough slag and burrs at the bottom of the cut, requiring a lot of post-processing and with poor results.

(3) Risk of stress cracking: Local high heat input from the laser may induce internal stress in the PC, causing microcracks or even cracking in subsequent use or assembly, which will damage the sturdiness.

Customers expect sturdy and transparent panels, but the results of laser cutting PC are often fragile and ugly, which goes against the core purpose of product prototype display.

JS’s solution and value: Cast Acrylic is recommended

We understand that customers need “sturdiness”, but the core of the prototype stage is fast verification and good display. We recommend cast acrylic:

(1) Good optical performance: The light transmittance is extremely high (about 92%), and the edge after cutting is crystal clear like crystal, which is an ideal choice for display panels.

(2) Laser processing friendliness: Acrylic has high absorption efficiency for CO₂ lasers and can achieve clean gasification cutting. The viscosity is low near the melting point, and with appropriate parameters (especially auxiliary gas), smooth, slag-free, and low heat-affected zone (HAZ) cutting edges can be obtained.

(3) Meet the need for the prototype to be strong enough: Although the impact resistance is weaker than PC, it is completely sufficient for protective panels that are not frequently hit, and the dimensional accuracy is extremely high.

Comparison and results of key processing parameters:

| Characteristic | Performance of polycarbonate (PC) laser cutting | Laser cutting performance of Cast Acrylic | Customer value reflection |

| Edge quality | Severe yellowing/carbonization (unacceptable). | Highly transparent and smooth (Ra<3 μm). | The display effect is stunning and does not require secondary polishing. |

| Bottom slag/burrs | Significant presence, difficult to remove. | Very little or no slag. | Save post-processing time and costs. |

| Cutting speed (3mm thick) | Slow (about 500-700 mm/min). | Fast (about 1000-1500 mm/min). | The processing efficiency has been improved by more than 100%, and the cost has been reduced. |

| Yield | Low (<60%, affected by yellowing/cracking). | High (>95%). | Avoid material waste and deliver on time. |

| Final unit price | High (material+low efficiency+high scrap rate+post-treatment cost). | More competitive. | Better budget control. |

Professional value realization:

“The customer took our advice. We cut the panel with precision using acrylic, and the edge effect was far beyond expectations. The customer not only avoided the scrap loss and extra processing fees caused by the wrong material selection, but also obtained a product prototype with a very professional appearance, which accelerated its market verification process. More practically, JS’s laser cutting price advantage was directly converted into a more competitive quotation for the final product.”

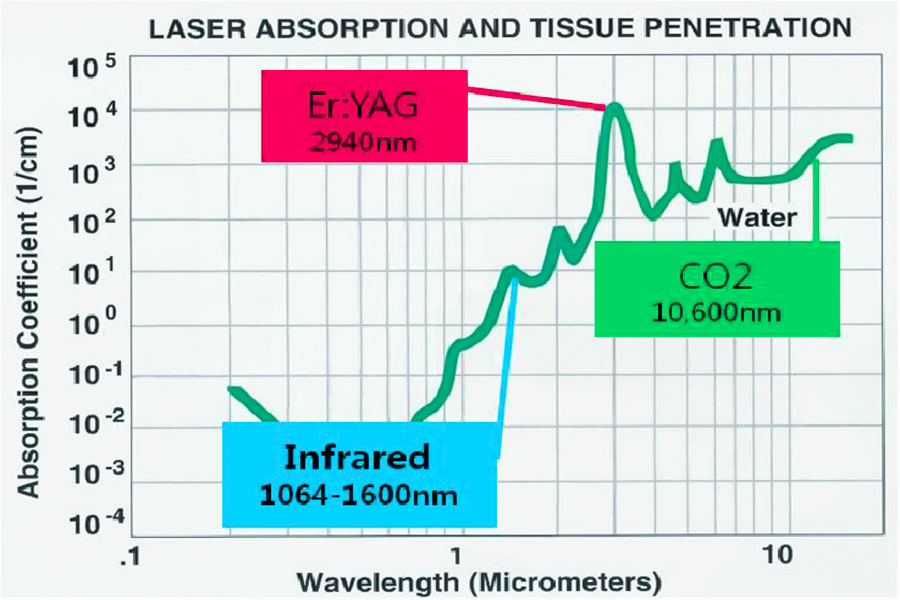

Fiber laser vs. CO2 laser: Which one should I use to cut plastic?

For plastic cutting, should I choose fiber laser or CO₂ laser? Simply put, they are like “seeing” the material with different colors of light, and the effect is very different.

My first choice: CO₂ laser (wavelength is about 10.6 microns)

Most common plastics (such as acrylic/PMMA, polypropylene/PP, ABS, polycarbonate/PC, and non-metallic organics such as wood and leather) can efficiently absorb light energy with a wavelength of 10.6 microns.

After absorbing light energy, the material heats up rapidly, reaching a state of melting or even direct vaporization, thereby achieving clean, smooth and efficient cutting. This is a recognized and mature solution for plastic cutting in the industry.

Fiber laser (wavelength of about 1 micron): Not so suitable for cutting

This light wave is mainly designed for efficient cutting of metal, which absorbs it very well.

But here comes the problem: For most transparent or light-colored plastics, the 1-micron light wave almost passes through directly, and the plastic has a hard time absorbing its energy. The result is: it is difficult to cut plastic.

Although it can be used to mark things on some plastic surfaces, such as leaving text or patterns, want to cut through plastic sheets cleanly? Basically impossible. So, the direct answer is that fiber lasers usually can’t cut plastic.

“For cutting plastic, CO₂ lasers are a reliable choice. Fiber lasers are mainly good at metal processing and can’t do anything with most plastics. Not sure about your specific needs? Contact JS at any time, we will help you choose the right tool and solve the problem of plastic cutting!”

FAQ – All your questions about laser cutting plastic

How can I tell if an unknown piece of plastic can be laser cut?

Safety is the most important thing!

The safest way is: never try to cut when you can’t confirm the composition of the plastic. Some plastics (such as PVC) release toxic gases (such as chlorine) when exposed to lasers, which is very dangerous.

A preliminary test that is sometimes used in the industry is for reference only and must be performed carefully in an extremely well-ventilated environment: light a small sample with a lighter. For example, when PVC burns, the base of the flame will be green and there will be a pungent chlorine smell. But this is only a rough clue and does not guarantee safety or effectiveness.

It is strongly recommended that you: provide samples to professional service providers such as us. We have safe analysis methods and experience databases to accurately judge the material and provide safe online Laser cutting services. Don’t take risks, please feel free to ask us!

Why cannot I laser cut PVC, yet I notice a person engraving it with CNC?

The key is that the processing principles are different:

(1) CNC engraving: Just like engraving with a sharp knife, it physically cuts the material. This will not cause the PVC material to decompose at high temperatures, and it will not produce highly toxic chlorine gas.

(2) Laser cutting: The essence is to “burn” the material with a high-energy beam. PVC will chemically decompose under the high temperature of the laser, which will inevitably release toxic chlorine-containing gases, which are extremely dangerous to operators and equipment.

Therefore, laser cutting is absolutely prohibited for PVC! CNC is a safe mechanical processing method.

How is the cost of laser cutting plastic calculated?

The price of laser cutting plastic is mainly determined by three aspects:

(1) The cost of the material itself: The cost of different plastic sheets significantly varies.

(2) The actual cutting time: This depends on the type of plastic you use, the thickness, and the total path length that needs to be cut. The thicker and longer the path, the more time it takes.

(3) The complexity of the pattern: Cutting complex curves requires more delicate operations and longer processing time than simple straight lines.

In short, the material cost + processing time cost (affected by the material, thickness, cutting length and complexity) jointly determine the final laser cutting price.

Summary

Laser cut plastic has significant advantages in accuracy and efficiency, but the performance advantages and the guarantee of safe operation depend deeply on the precise grasp of material properties and the strict implementation of safety regulations in the process. Without these core supports, the cutting process potential cannot be released safely and stably.

Now, let your project advance efficiently and safely:

(1) Eliminate the trouble of materials and parameters:

Upload your CAD design file directly to our platform. Our team of engineers will intervene at the first time, strictly review the cutting safety and applicability of the material, and accurately configure the laser processing parameters.

(2) Get transparent quotes instantly:

After uploading the file, you will immediately receive a highly competitive laser cutting price, and the process is transparent and efficient.

(3) Enjoy professional customized services:

Confirm the cooperation and start the full process of custom laser cutting manufacturing. From material safety review to process optimization to finished product delivery, we ensure that every link meets professional standards.

We undertake the complex technical links, and you will get safe, reliable and high-precision plastic laser cutting parts. Upload the drawings now and get started easily!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It’s the buyer’s responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Laser Cutting: From Steel Plate To Paper Lace - JUSHENG

Pingback: 6 Solutions To Address The Three Major Challenges Of Laser Welding - JUSHENG