Have you ever had this dilemma: after carefully designing a model, you hesitated when choosing the material. Should you use the economical standard PLA, or spend more money to try the PLA Plus with the “+” sign? Don’t underestimate this choice, it is directly related to whether your print is just for display or can be really used.

Indeed, PLA (polylactic acid) is the most familiar material for our 3D printing, but it also has recognized shortcomings: it is afraid of heat, relatively brittle, easy to break, and the overall strength is not high. In order to fill the gap between ordinary PLA and high-end engineering materials, PLA+ (or PLA Plus) came into being, and manufacturers all claim that it has stronger performance.

- So, how much substantial improvement does this extra “+” sign in the name bring?

- Can it really surpass basic PLA in all aspects?

- Is the extra money worth it?

Although their basic materials are similar and the names are only slightly different, the actual use is very different. The key is that PLA+ usually works hard on indicators such as strength and toughness to make the printing parts more durable. Of course, changes in performance may also lead to some small adjustments in printing settings.

This guide combines our large amount of proofing and actual test data at JS Company to help you explain the core differences between PLA and PLA+ from material properties, printing experience to actual application scenarios, so that you can choose the right material according to the needs of the project at hand.

Core answer:

PLA+ is an enhanced version of PLA, which improves toughness and interlayer adhesion by adding modifiers. In order to let you grasp the core differences in 3 seconds, please see the table below:

| Comparing dimensions | Standard PLA | PLA+ (PLA Pro / Tough PLA) |

| Mechanical performance | Hard & Brittle. | Tough & Impact-Resistant. |

| Interlayer adhesion | Good. | Excellent, the finished product is more sturdy. |

| Printing temperature | ~190-210°C. | Slightly higher:~205-225 °C. |

| Flexibility | Low, easy to break when bent. | Higher, with some bending before fracture. |

| Surface smoothness | Usually more glossy. | Usually semi matte or matte. |

| Main purpose | Visual prototype, static model, low-cost iteration. | Functional parts, mechanical prototypes, clamps that need to withstand pressure. |

This article will answer your questions:

- We will carefully compare the actual performance of PLA and PLA+ in various performances, and clearly tell you which one to choose in which scenario.

- Through a real case, you will see the specific impact of choosing the wrong material.

- Finally, we will help you judge whether your project requirements have already touched the performance boundary of 3D printing materials, and you need to consider more efficient manufacturing methods.

Why Trust Our Material Advice? We Bridge Prototypes And Production

At JS, we provide online injection molding services, but our engineering team also prototypes and tests in the 3D printing room every day. It is precisely because we have personally turned countless PLA+ functional prototypes into injection molding parts for mass production step by step, we know too well how many technical hurdles there are in the middle. How to control material shrinkage? How to ensure structural strength? How to meet appearance requirements? These real problems cannot be solved by theory alone.

Our cognition is repeatedly tossed and verified in thousands of actual projects. This allows us to accurately judge when 3D printing is fully sufficient, saving time and money, and when its performance can no longer hold up and we must turn to efficient solutions such as custom injection molding manufacturing.

“As product design master James Dyson often emphasizes: real innovation is often hidden in the process of repeatedly tossing prototypes.”

The experience and boundaries shared in this guide are the core experience accumulated bit by bit when we help customers with manufacturing consultation and choose the best path on a daily basis.

What Is Standard PLA? The King Of Prototyping

In 3D printing, PLA is as easy to use as a universal language. Anyway, I will definitely use it first when I adjust the machine, and basically everyone starts like this.

What is Standard PLA? The “Uncrowned King” in the Field of Prototyping

Polylactic acid (PLA) can be called the “universal language” in the 3D printing industry. The first roll of material that most users enter this field is often it. It can be so popular, and the core advantages are very clear:

(1) Super low threshold, easy to get started:

For the easiest material to start with, PLA is second, and few materials dare to come top. It has low printing temperature requirements, very low heat shrinking (e.g, almost no warping), and is not particularly fussy about the printer, making it easy for new people to achieve successful prints.

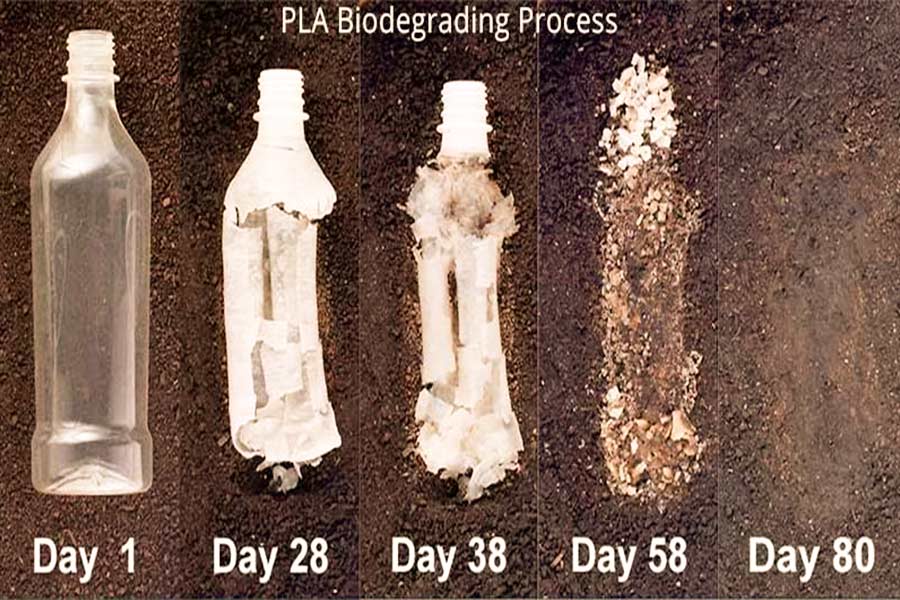

(2) Originated in nature and environmentally friendly:

The main raw materials are renewable bio-based materials like corn starch, which are biodegradable under some industrial composting conditions. In contrast to petroleum plastics, it is a rather environmentally friendly alternative.

(3) Good stiffness and delicate details:

The printed product has high hardness and can ideally keep the design shape and delicate details. It is particularly good at creating display models, appearance prototypes or elements with high dimensional accuracy.

The weakness of this “king” is also evident:

(1) Not tough and can easily break:

The major disadvantage is brittleness! Not tough enough, when struck or flexed, it can be readily broken off suddenly, which is not appropriate for functional parts that need to be endured with respect to load or shocks.

(2) Thermal phobia and poor thermal resistance:

Never use it in a region where heat is emitted! Its glass transition temperature (Tg) is usually between 55-65°C. This means that in situations above this temperature (such as in a car during summer, or near a heat source), PLA will soften and bend, losing its original shape and form.

“PLA is an ideal starting point for rapid design verification and high-precision display models. It is user-friendly and more sustainable. If your prototype needs to withstand mechanical impact or is in a warm environment, PLA may not be able to do it. Welcome to contact JS engineers to help you evaluate material selection or provide free sample verification!”

What Is PLA+? The “Plus” Stands For Performance

PLA+ (also called PLA Pro or Tough PLA) is essentially the familiar polylactic acid (PLA), but it is not a simple packaging change. It is an enhanced version that manufacturers carefully “add” to the basic PLA resin.

The secret of the “+” sign is hidden in the formula:

The “secret recipe” adds modifiers: The core is to mix specific polymer additives (such as TPU or other toughening agents that can improve elasticity) into pure PLA. These “secret recipes” vary from company to company, so different brands of PLA+ (like Bambu Lab’s PLA Plus) will also perform a little differently. The proportion of additives and processes are trade secrets, which is also the source of performance fluctuations of different brands of PLA+.

What are the core improvements brought by PLA+?

(1) Improved toughness:

This is the biggest highlight! PLA+ with added materials is significantly more “fall-resistant”, with an elongation at break increased by 300%+, and can absorb 9-12 kJ/m² impact energy (close to ABS level), making parts more durable.

(2) Enhanced interlayer adhesion:

Chemical adjustments allow each layer of plastic to fuse more tightly during printing. The interlayer bonding strength is increased by 40%, and it is not easy to crack from the printed layer lines.

“PLA+ has greatly enhanced the toughness and overall strength of the basic PLA in terms of ease of use, making the printed parts closer to the final use requirements. Want to experience the actual performance of PLA+? Welcome to contact our JS engineers to get free samples or printing parameter suggestions, and try it out to see if it can handle your project!”

Deep Dive: PLA vs. PLA+ Performance Metrics

Today, let’s talk about the two most commonly used materials in 3D printing: standard PLA and its upgraded version PLA+ (also known as PLA Plus), focusing on their performance differences, especially the comparison of key performance of PLA-vs-PLA-plus.

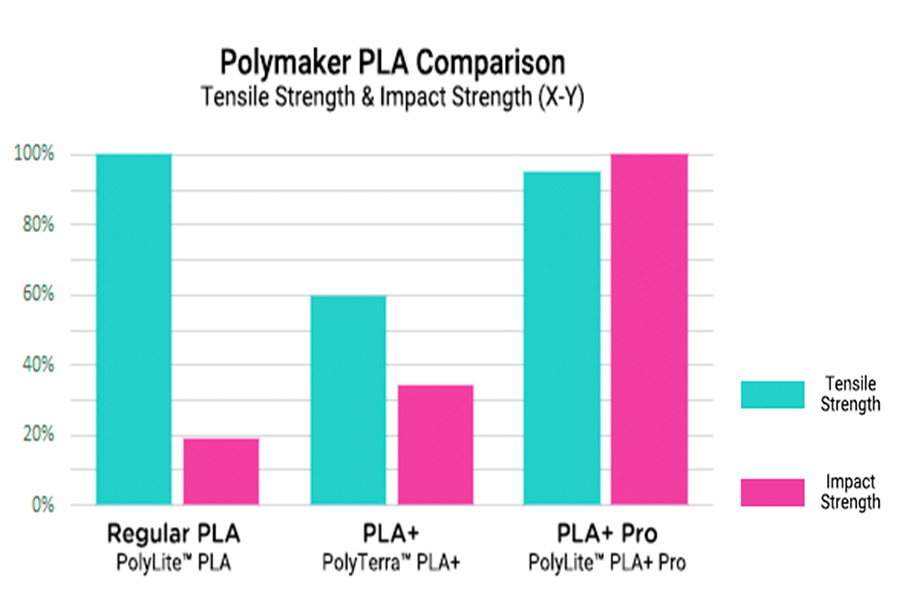

Trade-off between strength and toughness

Standard PLA: This material is characterized by “hard but not tough”. It is quite hard in itself, and it is not easy to break if you pull it hard (tensile strength is usually 60-70 MPa), but it is very brittle! A slight bump or impact may cause it to crack or break (impact strength is usually < 4 kJ/m²).

PLA+: Toughening agents and copolymers are added to special harden regular PLA. As a result, the tensile strength may be comparable to or slightly lower than that of regular PLA (e.g., 55-65 MPa). But the most important benefit is that it toughened! Its notched impact strength is typically twice or higher than regular PLA (> 8 kJ/m²), meaning that it is more capable of absorbing impact energy and is hard to crack immediately after bending. That makes it much more suited for components that need to be capable of withstanding some pressure or can be impacted.

Key printing parameter settings

(1) Temperature (pla plus temperature key point):

This is the most critical setting when printing PLA+. The additives in PLA+ usually need to be warmer in order to melt completely and mix well. Therefore, in printing PLA+, the nozzle temperature usually needs to be 5°C to 15°C higher than that of normal PLA. Don’t underestimate this temperature difference, it has a direct bearing on whether the layers will bond well. It will be simple to delaminate if the temperature is inadequate. When the temperature is right, strength will be improved.

(2) Cooling fan:

Regular PLA likes to be blown with cool air quickly so that it can solidify quickly and retain the transparent form. But for PLA+, to make its layers bond more (which also is part of the source of its strength), sometimes you need to slightly slow down the fan speed so it has more time to “bond”. The adjustment will vary depending on what specific brand and setting you have.

Warping and durability:

Likelihood of warping: PLA and PLA+ both require less likelihood of shrinking, and are less likely to curl up as ABS does, which is extremely beginner-friendly.

Structural integrity and robustness:

With higher printing temperatures and enhanced interlayer bonding capacity, PLA+ is more likely to be dependable when printing large or complex models, with layers sticking together better, and the overall structural robustness of the parts generally feels stronger.

“When it comes to specific performance data, Professor Janne Jokinen said: The value of material modification is ultimately reflected in the improvement of printability and final part reliability.”

This is extremely clear in PLA+. Consider the following data comparison from independent testing to get a more intuitive sense of the difference:

| Performance index | Standard PLA (typical value) | PLA+(typical value) | Performance change trend | Testing standards |

| Bending modulus (MPa) | 3500 – 3800 | 3200 – 3500 | ↓ About 5-10% | ISO 178 |

| Gap impact strength (kJ/m ²) | 2.0 – 3.5 | 5.5 – 8.0 | ↑ >100% | ISO 179/1eA |

| Hot deformation temperature (0.45MPa, ° C) | 55 – 60 | 60 – 65 | ↑ 5-10% | ISO 75 |

Data source: Summary of comprehensive evaluation reports of materials of multiple international brands published in the journal Polymer Engineering and Science in 2024.

PLA+ has been tweaked to greatly enhance toughness and bonding between layers without sacrificing the ease of printing and lack of warping of PLA. While the hardness slightly decreases, the overall strength is increased, particularly ideal for uses that need some strength and impact resistance. Don’t be finicky over hardness, try PLA+ and experience the better toughness and reliability it offers, you will find that in more realistic conditions, it is a better choice!

When Standard PLA Is Your Best Choice

As an engineer at JS, I enjoy reminding customers: More expensive does not necessarily mean better! Sometimes, standard PLA is the budget-friendly champion. It’s your best friend in the following applications:

(1) Look at the appearance and idea model: If your most important consideration is whether the product is good-looking and whether the design concept is right, the model printed by regular PLA is perfectly sufficient.

(2) Teaching and design creation: Extremely popular among schools or studios, safe and easy to use, low cost, and no teacher and student burden.

(3) Clean decoration or display parts: Parts like stands, decor, and protective casing for display don’t load and don’t need the strength requirement of injection molded parts. Regular PLA is most affordable.

(4) Rapid trial and error prototyping: If you need to test a new concept rapidly and would want to use the lowest possible cost to make several copies to see the effect, regular PLA’s low cost and rapid prototyping are the best advantages.

“And the next time you need such a solution, contact the JS team directly! We allow you to enjoy the most benefits of the cheapest regular PLA – the amount saved can also stretch further!”

When You Need To Upgrade To PLA+

I typically point out to customers: When your parts need to withstand actual work rather than simple static display, it’s a worthwhile investment to print with PLA+. It’s stronger, more durable, and longer-lasting than regular PLA and is particularly well-suited for the following more heavy-duty uses:

(1) Prototyping parts that need movement: For example, parts such as gears and connecting rods for testing, PLA+ can better simulate the real force conditions so that you can see whether the design is feasible.

(2) Parts that need snapping or tight assembly: Parts should be a little challenging when assembled and disassembled, and should not break effortlessly. The flexibility of PLA+ can hardly support this assembling pressure. It is cheaper than injection molding parts but sufficient.

(3) Robot and drone components: In the situation of ongoing vibration and potential impact, PLA+ has greater impact resistance and fatigue resistance, and the components last longer.

(4) Workshop simple fixtures and tooling: For example, positioning blocks and light clips, PLA+ strength and rigidity can endure day-to-day light work, handy and cost-saving.

“If your project requires part strength, toughness and durability specialization, the step-up to PLA+ is a necessary step to ensure performance. Contact JS and let us recommend the correct PLA+ solution for your application to make sure your functional parts will perform consistently!”

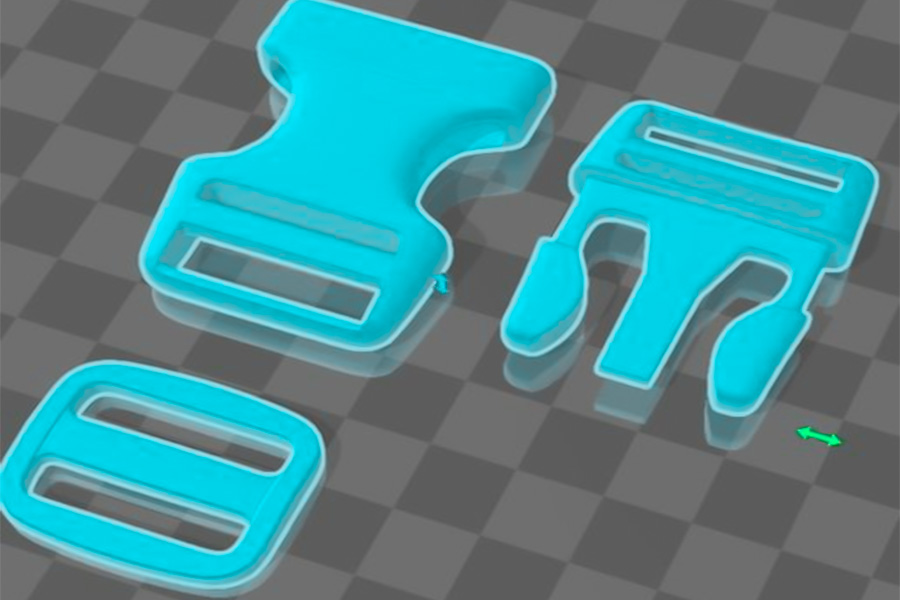

Case Study: The Difference Is Illustrated By A Simple Latch Failure

Problem description: Real-world challenges experienced by customers

A customer approached me the other day regarding the toolbox latch that he designed. The prototype was printed with regular PLA, but the movable hinge broke when he opened and closed it for the second time.

This is not unexpected: PLA material alone is too brittle, and it will break after being bent several times, just like we break a dry twig. The customer was panicked at the time because the latch needs to be opened and closed repeatedly, not just once.

Cause analysis: Why will not ordinary PLA work?

I caught it at a glance: PLA toughness is too low to sustain repeated stress. In engineering, such bending stress will cause material fatigue accumulation and ultimate failure. PLA impact toughness is only about 3J/m, far below the requirement. For comparison, PLA+ has improved toughness with additives and is more suited for dynamic applications.

Here is a critical point: material selection cannot be random, it has to be in accordance with the real load, just like the selection of a tire cannot just consider the pattern, but also the road conditions.

JS’s solution: Simple material change, immediate effect

I suggested the customer reprinting with PLA+. PLA+ has advantages over bending strength and toughness (as the following table shows), and can distribute stress. After trying out by the customer, the new buckle was still in good condition after dozens of opening and closing. This saved him time for repeated remaking, and the cost was low, printing a buckle only cost a few dollars.

But I also reminded him: 3D printing is very efficient if you only make a few prototypes, but when it comes to mass production, you have to make a trade-off.

Longer thinking: The compromise between materials and production

This case highlights the core of materials science:

Different scenarios require different solutions. For example, PLA is fine for small batches, but when it exceeds 100 pieces, 3D printing is inefficient, and manual post-processing and consistency are difficult. At this time, custom Injection molding manufacturing is more cost-effective, it can use high-toughness materials such as ABS, ensure durability, and is suitable for complex geometries.

“Wrong material selection can ruin a good design, but don’t worry, we JS company can help you optimize it. Contact us when you have a project to quickly get a prototype or custom injection molding to ensure durability and save money. Take action!”

FAQ: PLA+, PETG, And Moving To Mass Production

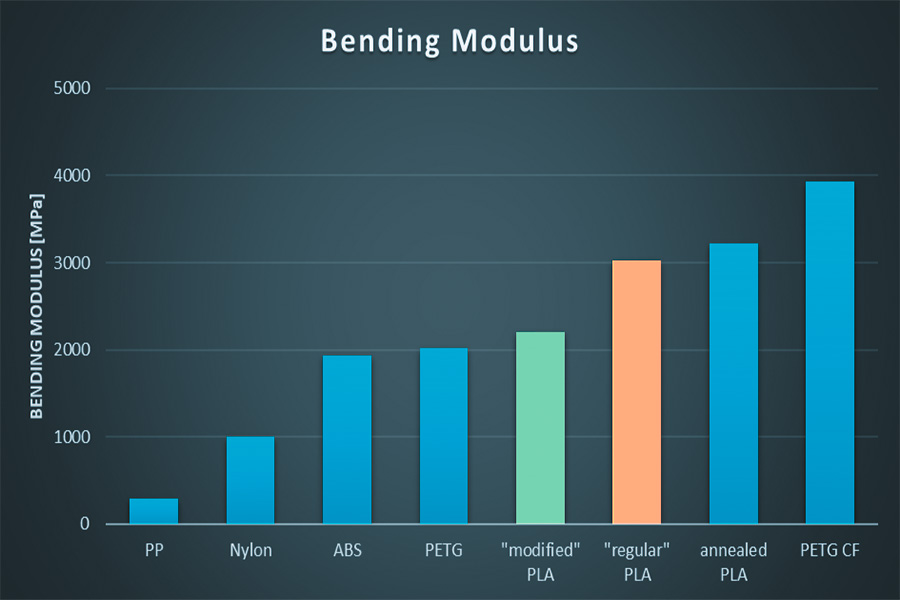

Is PLA+ stronger than PETG?

It’s all relative what you mean by strong.

PLA+ is usually stiffer (high rigidity), while PETG performs better in durability (toughness), chemical corrosion resistance and high temperature resistance.

For example, if the parts you make need to be placed outdoors in the sun or exposed to chemicals and detergents, PETG is definitely a more suitable choice. The key to our engineers choosing materials depends on where the parts are used.

What’s the difference between PLA+ and PLA Pro?

In short, PLA+ and PLA Pro usually refer to the same modified PLA material, just like classmates have different nicknames. They are both more impact-resistant and tougher than standard PLA. Don’t get too hung up on the name, the key is to look at the data sheet of the specific manufacturer. Which brand you choose, just look carefully at its marked impact strength and bending performance data, which is much more real than the name.

When should I switch from 3D printing to Injection Molding?

(1) Mass production scale drives cost advantages:

When your part demand reaches hundreds or thousands of pieces, the unit cost advantage of injection molding will be significantly reflected. Although the initial mold investment is higher, the amortized unit cost is much lower than 3D printing. This is the core economic driver for switching to custom Injection molding manufacturing.

(2) Unlocking high-performance engineering materials:

Injection molding boasts a range of materials to provide much more than 3D printing. For applications that require extreme strength, toughness, high temperature resistance (such as nylon + glass fiber) or special chemical resistance (such as polycarbonate), injection molding is almost the only viable mass production solution.

(3) Striving for ultimate consistency and surface quality:

When your application requires parts with highly consistent precision dimensions (tolerance ±0.1mm or tighter) or excellent surface finish (close to mirror effect), the stability and repeatability of injection molding under mass production is difficult to achieve with 3D printing.

When mass production scale, high-performance material requirements, or strict appearance/dimensional consistency become key factors, it is a mature time to evaluate the transition to injection molding. We can help you accurately calculate the cost inflection point and optimize production plans.

Summary

In short, our view has always been clear: PLA is indeed a good entry material, and PLA+ allows you to make more reliable prototypes to test functions. But we have to know that no matter how good they are, they are just “stepping stones” to the final mass production product, not the end station.

When you get to this step, talk to JS about what to do next?

The positioning of PLA/PLA+ is clear: They help us get started quickly and verify the design, which is a great credit. But when it comes to mass production and the products are put to the test, their performance and the efficiency and cost of 3D printing may become bottlenecks.

Recognize limitations: PLA/PLA+ and 3D printing are indispensable in the rapid iteration and design verification stage. However, when the goal turns to mass production and market delivery, they may encounter bottlenecks in performance, production efficiency and cost-effectiveness.

Let JS help you cross this hurdle: Don’t let 3D printing hold you back! Upload your design files to us, and the JS team will immediately tailor a professional injection molding solution for you, and attach a realistic Injection molding price evaluation. From prototype to excellent product, we will accompany you to take this step steadily.

Ready to scale up? Upload your design and let’s talk about the injection molding solution right away!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Classification Of Filament Used In 3D Printers - JUSHENG

Pingback: Insert Molding Vs Overmolding Selection Guide: 5 Key Factors Based On Substrate Characteristics - JS Precision