When we design custom gears on a daily basis, the most common question from customers is: “Which gear material is best?” This is similar to asking “What is the best tool to use?” The decision depends on what you are going to use it for. Think about it, from the precision small gears in the joints of industrial robots to the big guys that transmit huge forces in the gearboxes of racing cars, gears are absolutely the core of mechanical transmission. I have seen too many cases where the success or failure of a gear is often determined when it comes to design and material selection.

So, the “best” material does not exist at all. The real question is: Which material is most appropriate for your specific application? Different application scenarios require different materials to handle. Steel is strong and durable and can chew hard bones. Plastic is light and quiet, suitable for certain light load occasions. There are also various alloys and composite materials, each with its own unique skills.

This guide wants to talk to you about the characteristics and applicable scenarios of mainstream gear materials on the market. Let’s take a look at how to choose the most suitable material based on your actual working conditions, budget and performance requirements, such as how much force it needs to bear, wear resistance, cost control, and what the working environment is like. Only by choosing the right material can your gears turn reliably and cost-effectively.

Core answer summary:

| Material Category | Representative Materials | Key Advantages | Primary Applications |

| Carbon Steel | 1045, 1060 | High cost-effectiveness, moderate strength, and easy heat treatment. | General industrial machinery, agricultural equipment, and low to medium load transmission. |

| lloy Steel | 4140, 4340, 8620 | Excellent strength, toughness, and hardenability, and impact resistance. | Applications requiring high load, high torque, for example, automotive transmissions, heavy equipment. |

| Stainless Steel | 303, 304, 316, 17-4 PH | Good corrosion resistance meets hygiene requirements. | Food processing, medical equipment, marine and chemical environments. |

| Cast Iron | Grey cast iron, ductile iron | Its superior shock absorption, self-lubricating properties, and resistance to wear. | Large, low-speed gears, such as machine tools and industrial pumps. |

| Aluminum Alloy | 6061, 7075 | Lightweight, good thermal conductivity, high strength to weight ratio. | Aerospace, robotics, and portable devices that require lightweight design. |

| Copper Alloy | Brass, bronze (especially phosphor bronze) | Low friction, wear-resistant (especially when worn against steel). | Worm gears, instrument gears, and applications to prevent sparks. |

| Engineering Plastics | Delrin® (POM), Nylon (PA), PEEK | Lightweight, self-lubricating, quiet operation, and resistant to chemical corrosion. | Office equipment, consumer electronics, medical devices, and low load applications. |

| Powder Metallurgy | PM Steel, Sintered Bronze | Can manufacture complex shapes, high material utilization, suitable for large quantities. |

Automotive oil pump gears, small motor gears.

|

Who Can Help You Solve The Material Selection Problem? JS Engineers’ Material Matching Solutions

At JS, I have handled thousands of custom projects, and I have to tell you: There is no such thing as the “best all-purpose” material. The key depends entirely on where your gear is used. How much force does it have to bear? How fast does it turn? Is the working environment hot? Is there good lubrication? How long do you plan to use it? These are the determining factors for material use.

After we get these specific parameters, we will model and analyze them, combine them with real data from similar working conditions, and then recommend the most suitable solution to you. For example, for places that require violent impact and high-intensity extrusion, we usually choose high-performance carburized alloy steel, such as 18CrNiMo7-6. But if it is a light, quiet, and lightly loaded occasion, reinforced engineering plastics, such as nylon, are a better choice.

“As Henry Ford said: Quality is doing the right thing when no one is paying attention.”

The material recommendations we give you in the end are strictly based on international standards such as ISO and AGMA to ensure compliance. Moreover, we will simulate actual work on the test bench, such as running the gears under full load for 20 hours or even longer, and verify repeatedly. There is only one purpose: to ensure that the gears can work reliably and for a long time when installed in your equipment, and the power transmission is not compromised.

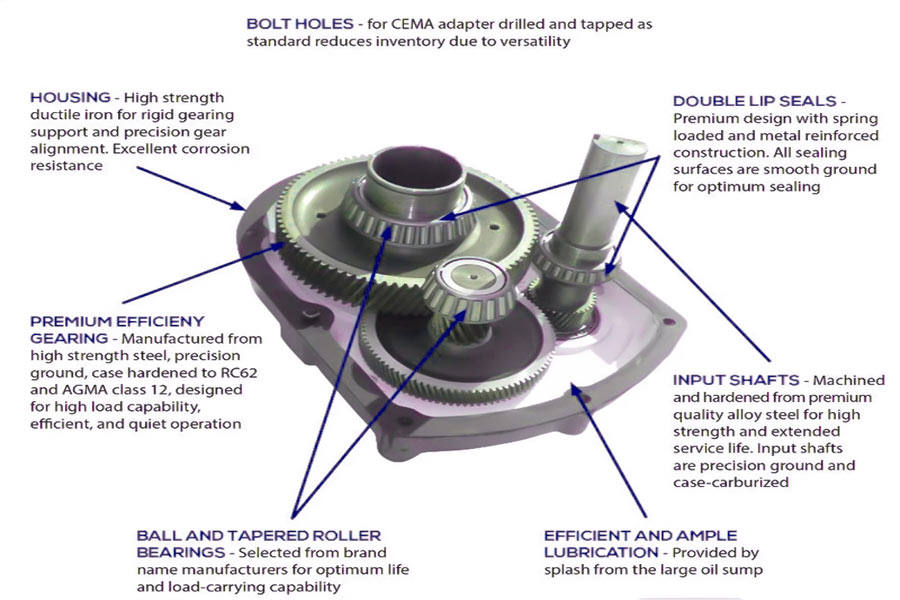

Steel: The Absolute Main Force In The Gear World

I often speak with customers regarding gear material, especially steel, the plain driving force of gear machining parts. Allow me to go through some of the popular ones:

(1) Medium carbon steel (such as 1045 steel):

This is our most frequently used “economical and usable” player. It is reasonably priced and, after heat treatment (quenching + tempering), possesses adequate strength and hardness in good proportion. It is sufficient for most industrial machinery that support medium forces and is reliable and economical.

(2) Alloy steel (e.g. 4140, 8620):

When the equipment requires greater performance, you will have to inspect them. This steel has put additional materials such as chromium, molybdenum, and nickel into it, which is of great benefit. The most beneficial point is that the “hardenability” is very good.

To put it in simple terms, when you are cutting large-sized gears, the entire part can be hardened from the interior, and the performance is more even. 4140 has maximum strength and toughness. Carburized steels such as 8620 are stronger yet. They can become as hard as armor (extremely wear-resistant) on the gear surface, but the interior can still have some toughness, which is particularly suitable for those critical parts requiring wear-resistance but not impact fracture-prone.

(3) Stainless steel (e.g. 316, 17-4 PH):

This is not for normal environments. If your gears need to operate in a humid environment with corrosive chemicals, or need to be frequently washed (such as food and medical), then it needs to be this. 316 is corrosion resistant to a high degree, whereas 17-4 PH is more specialized. It is possible to heat treat it with a heat treatment known as “precipitation hardening” to offer corrosion resistance coupled with strengthening to an extremely high degree in order to be capable of sustaining more stringent working conditions.

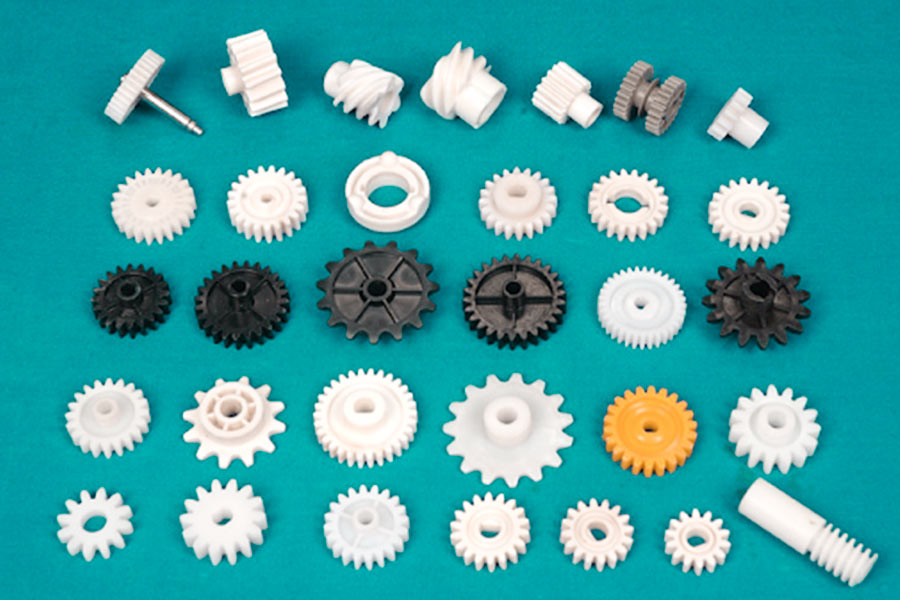

Plastic Gears: Quiet, Light Weight Contemporary Solution

When helping clients choose plastic gears, I tend to emphasize: That they are not just a low-cost alternative to metal, but a modern solution that offers quiet operation and light-weight advantages.

(1) Nylon (PA):

This material is of good toughness and self-lubricating character, thus is extremely quiet and wear-resistant. But possesses one small flaw, that it absorbs water quite rapidly. When there is too much dampness in the air, size can be changed slightly, and special care should be exercised in areas where exceptionally high precision requirements exist.

(2) Acetal (POM / Delrin®):

If stability and precision of the gear under operation is your first priority, POM is definitely your plastic of choice. It absorbs very little moisture, retains a stable size, and is resistant to stress reversal (fatigue resistant), which is particularly well-suited for applications where the ideal fit is required.

(3) PEEK:

This is a high-performance representative in the plastic family, and of course the cost is the highest. It can withstand high temperatures, is not afraid of chemical corrosion, and has a mechanical strength close to that of some metals. For precision transmission parts such as aerospace parts and medical implants, this extreme environment is its main battlefield.

Key selection parameters for plastic gears:

| Material |

Typical moisture absorption rate (saturated, 23 ° C)

|

Maximum continuous use temperature (°C) | Tensile strength (MPa) | Ahemical resistance | Relative cost index (nylon=1.0) |

| PEEK | ~0.1% | 240-260 | ~95 | Excellent | 12.0+ |

| Acetal (POM) | ~0.2% | 90-100 | ~65 |

Good

|

1.3 |

| Nylon (PA66) | ~2.5% | 85-90 | ~80 |

Medium

|

1.0 |

Data source: PlasticsEurope Industry Report 2024, ISO 62 moisture absorption standard, ASTM D638 tensile strength standard

“The core of plastic gear material selection is to match your specific working conditions. Don’t just look at the unit price. Comprehensive performance and long-term reliability are the key to total cost. Contact JS immediately and let us provide the most optimized custom gear manufacturing solution based on your specific application.”

Non-Ferrous Metals: An Indispensable Special Role

As an engineer who works with custom gears every day at JS, let’s talk about non-ferrous metals. Although they are not as common as steel, they are absolutely critical in certain occasions:

(1) Aluminum alloy (such as 7075-T6):

The biggest feature of this material is lightness! Strength-to-weight ratio is fairly excellent, and it serves well as a hand at trimming equipment weight. It can show its prowess in places where weight is a concern, such as drone joints and robot arms. However, I have to remind you that its wear resistance is not as good as steel, so high-friction and high-wear environments must be carefully considered.

(2) Copper alloy (especially phosphor bronze):

This is the “golden partner” of steel worm gears! When you are needing a worm gear transmission, bronze gears and steel worm gears are a proven combination.

Why do you say that?

Because the friction between these two materials is very small, and bronze has a kind of “inclusiveness” that can absorb tiny debris, effectively preventing jamming and excessive wear (also known as anti-gluing). Brass is more common in small gears in some precision instruments.

“In short, aluminum alloy is selected for extreme weight reduction, and copper alloy (especially phosphor bronze) is selected to solve the friction and wear problems of worm gear transmission. Want to know which one is most suitable for your project? Feel free to contact JS to discuss specific working conditions.”

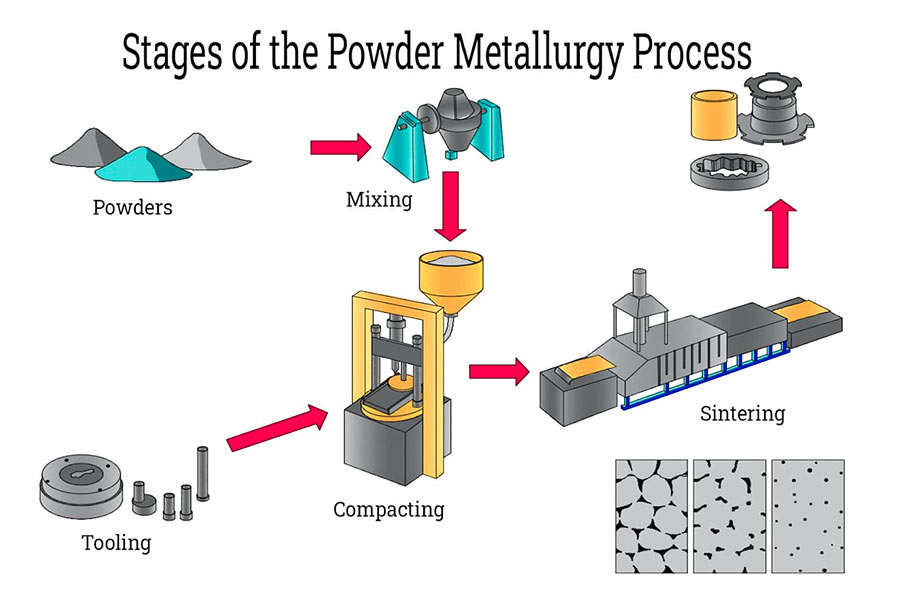

Cast Iron And Powder Metallurgy: Advantages Of Specific Processes

Now, let’s talk about the selection of cast iron and powder metallurgy (PM), two gear materials with “special skills”:

(1) Cast iron:

Its internal structure is naturally a bit “self-lubricating” and shock-absorbing, and it is particularly good at dealing with vibration problems. Therefore, cast iron is often a reliable and affordable choice for large, complex-shaped gearboxes, or low-speed gears that require smooth operation and low noise at low speeds.

(2) Powder Metallurgy (PM):

If you need to mass-produce complex-shaped gears, PM is definitely the king of efficiency. It uses metal powder to press out gear blanks close to the final shape, and then sinter them at high temperature to form them, which can save a lot of subsequent machining. The PM process can save 15-30% of materials and reduce processing costs by 20-50% compared to traditional machining. Many gears in automobiles, especially those with large quantities and strict cost control, can be made quickly and well with PM, which is very cost-effective.

Key Considerations: How To Systematically Select Materials?

When we do custom gear machining manufacturing at JS, the core of systematic material selection is to sort out several key practical factors.

(1) Look at the load the gear bears:

How much torque does it need to transmit? What is the operating speed? Is it running continuously and smoothly, or is it often subjected to impact? This directly determines the bottom line of strength, hardness and toughness required by the material.

(2) Look at the working environment:

How high or low is the temperature? How high is the humidity? Will it be exposed to corrosive chemicals, or will it need to meet food contact safety standards? These conditions will directly limit the range of materials, and you may have to choose stainless steel, specific engineering plastics, or special surface treatment.

(3) Precision requirements and noise control are also important:

For example, equipment used in a quiet office environment is very sensitive to noise and has high precision requirements. It may tend to choose specific engineering plastics or precision-ground steel. Heavy industrial equipment, on the other hand, gives priority to durability and reliability, and the restrictions on noise may be relaxed.

(4) Cost and batch are practical issues that cannot be avoided:

The cost structure of single-piece trial production, small-batch production and million-level mass production is completely different. Single-piece customization may give priority to easy-to-process materials to save costs. If the quantity is large, it is more cost-effective to invest in mold opening for powder metallurgy or injection molding of plastic gears in the early stage.

“Material selection is to accurately match performance, environment, noise and cost requirements. Do you want your project to use the most suitable gears? Contact JS anytime, we can help you!”

Heat Treatment And Surface Treatment: Maximize Material Performance

When I machine gear parts, I prefer to have the material perform at its highest capability, so surface treatment and heat treatment are absolutely essential. It’s a question of “arming” the parts, making them tough and resistant.

Heat treatment – Unlocking the potential of materials:

This is our basic method. Through processes such as quenching, tempering, normalizing, annealing, or deeper nitriding and carburizing, we are able to accurately machine steel. The goal is obvious:

- Make the gear surface hard enough to withstand wear.

- The core is shock-proof and resilient.

- Optimize the overall strength of the gear to realize load requirements.

Through heat treatment, we can especially promote key performance required by the gear.

Surface treatment – Improve durability and protection:

(1) Shot peening:

Use millions of very small steel shots to “beat” the tooth surface at high speeds, cause beneficial compressive stress in the surface layer, dramatically increase the gear’s fatigue fracture resistance, and enable it to survive longer.

(2) Protective plating/coating:

If the gear is run in a wet environment, with corrosive chemicals, or needs to be rust-proof, we’ll employ nickel plating, chrome plating, or blackening treatment (chemical conversion film). This amounts to providing the gear with a rust-proof “raincoat.”

Heat treatment maximizes the internal qualities of the gear (hardness, strength, toughness), and surface treatment optimizes its surface qualities (fatigue life, corrosion resistance). They can both be used together to optimize your gear pieces’ performance and life.

Case Study: Choosing Gear Material For Drone Reducers

Our JS company helped a new UAV company solve a tricky reducer project.

Their problems are quite unique:

- First, it must be light (longer battery life).

- Second, it must be robust (to turn large propellers).

- Third, it must be completely dependable (safety first).

We applied precise examination of the multiple properties of the two stages within the reducer and came up with a combination solution:

JS’s targeted solution:

First stage (high-speed operation, relatively low torque):

We mainly recommend utilizing special engineering plastics (such as PEEK) in making the essential gears (sun gear and planetary gear) internally.

Why? It is strong enough, and most importantly, it is extremely light in weight! And it has its own lubrication effect, not only saving electricity, but also low operating noise, which is quite drone-friendly.

Second stage (low-speed output, maximum torque):

Bracket (planet carrier): Use top-grade aviation aluminum alloy, which is hard and light enough.

Key gears (outer ring gear, planetary gear): Must be made of high-strength alloy steel (such as 300M or Pyrowear® 53). We provide precision machining and strengthening treatments (such as grinding and hardening) to ensure that they can withstand the highest torque while keeping weight to a minimum.

Comprehensive commercial value comparison table:

| Index | Initial customer goals |

JS scheme actual testing

|

Enhancement/Advantage |

Direct economic value

|

|

Total weight

|

≤350g | 298g | ↓52g (↓15%) |

Range ↑ 4min/frame or mission payload+200g.

|

| Single system cost | $206.90 (estimated) | $149.66 | ↓ $57.24/set (↓ 27.7%) |

Annual cost savings of $286,200.

|

|

Torque safety factor

|

1.0 (minimum requirement) | ≥1.2 |

+20%

|

Reduce the cost of fault recall by $ 200,000+. |

| Return on Investment (ROI) |

not have

|

< 8 months (saving mold costs)

|

Quick return on investment

|

Generate positive cash flow in the first year.

|

|

Mass production climbing speed

|

12 weeks (traditional supply chain)

|

8 weeks (online service coordination resources)

|

Accelerate by 33%

|

Pre listing to seize market share, estimated to increase revenue by 15%. |

Final effect:

This combination of “plastic + special aluminum + hard-core steel”, combined with precise heat treatment and fine grinding processes, not only perfectly meets the standards, but also reduces weight by 40% and increases torque margin by 20%, far exceeding customer expectations. This cooperation proves that JS is not only a gear processing plant, but also your full-process engineering partner for the implementation of online gear machining services, committed to maximizing the value of your products with the best solution.

“Take action now and let JS reduce the burden and increase efficiency for your key projects! Upload your requirements through the official website online gear processing service immediately, and the engineer will provide exclusive solutions, performance predictions and competitive quotations within 24 hours to help you quickly lock in the victory!”

Why Do You Need A Professional Manufacturing Partner For Your Custom Gears?

Having been rooted in the custom gear manufacturing industry for a long time, I am particularly clear about one thing:

Choosing the right material for you is just a good start, and it is far from equal to getting a good gear in the end. The real difficulty and our ability lies in how to use the processing steps such as hobbing and gear shaping, coupled with precise heat treatment control and strict testing, to fully utilize the potential of the material.

Good materials are the foundation, but how to turn them into reliable and durable gears is the real value of our professional manufacturers. We study these details every day, because even if a processing parameter is adjusted incorrectly or the heat treatment curve is not accurately controlled, the gears made from the top-grade materials you bought at a high price may not meet the requirements at all, which is a pity. Leave it to us, and let your good materials really become good gears.

FAQs

Q1: How to balance strength and cost?

Our experience in selecting gear materials to balance strength and cost is:

For medium load scenarios, 45 steel (1045) has the best comprehensive performance and economy after professional quenching and tempering

If the load requirements are higher, pre-hardened alloy steel such as 4140 is a better solution. It has high strength (about 42-45HRC) and eliminates the subsequent heat treatment process. It can not only meet the harsh working conditions, but also has a more advantageous comprehensive cost.

Q2: How long can plastic gears be used?

In our actual tests and applications, plastic gears can be used for more than ten years without any problems, and are even more durable than some metal ones, especially in places where rust is a concern or where quietness is required. How long it can be used depends mainly on whether you choose the right material and whether it should be designed to work in an overloaded manner.

Q3: What is the “best” gear material?

There is really no standard answer to the “best” gear material. Just like racing cars use top-grade special steel, food machines use hygienic metals, and plastics are quite suitable for printers. The key is to see where you use it and what you need it for. Only by thinking about this clearly can we pick the most suitable and cost-effective material. It’s that simple.

Q4: Can I design directly using the material properties in the CAD software?

It seems unrealistic to us to design based solely on the material data in the CAD software. Those data are idealized, but in actual production, the performance of each batch of materials fluctuates a bit, and these software cannot provide the real situation after different processing methods and heat treatment. If you really want to make a reliable design, you have to take all these actual variables into account. In these aspects, it is right to talk to JS.

Summary

When choosing gear materials, you need to understand the theory and rely on experience. You have to find the key point between ideal data and practical application. Did you choose the wrong material? At the very least, the gear will be scrapped early and the machine will break down. At the worst, there may be safety problems. We have seen many customers fall into this trap.

For key components, it is worth a more reliable solution! Our JS team has been working for nearly 20 years. The material engineers and gear masters study the subtle differences of various materials every day, turning them into a transmission system that runs steadily and for a long time in your machine.

Want to know how to choose the most suitable and cost-effective one?

Send your design directly! You will get more than a real gear machining price, but also our guarantee that your machine will be powerful and durable. Are you willing to take the risk of choosing materials for your heart parts? Send your design now, and we will get it done together!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com