Our JS engineers are regularly asked by customers: CNC machining is better on stainless steel or alloy steel. First of all, let’s define: stainless steel is actually a specific type of alloy steel! The key to the choice depends on the specific function your part will perform.

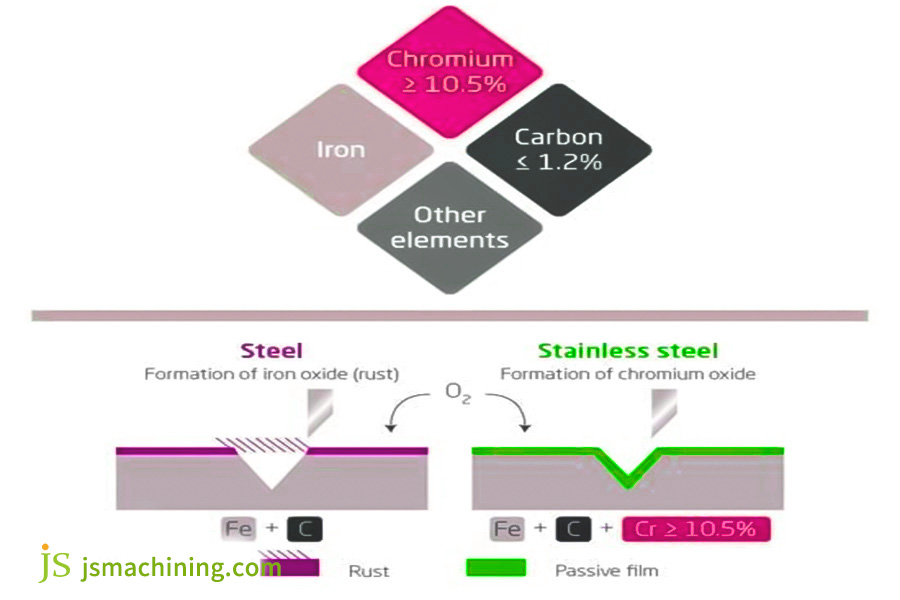

Put simply, “alloy steel” is base steel with some elements (e.g., manganese, molybdenum, and nickel) added to it, primarily for strength, hardening, or wear resistance. The mainstay of “stainless steel” is high chromium (at least 10.5%). Such chromium functions as an armor against rusting and becomes highly corrosion-resistant, which explains its success with JS customers.

But don’t decide based on the name! Especially in CNC machining, choosing the incorrect one can cause monumental problems: wasteful tool wear, difficult and slow cutting, sky-high cost, and even premature failure of parts. Why? Because different materials vary widely when it comes to machinability difficulty, heat transfer, and whether they have a tendency to over-harden once they are machined.

This article will outline the chief distinctions in machining behavior between stainless steel and various alloy steels. When you’ve read this, you won’t have to base your material selection on guesses anymore, you’ll have a better, truer answer!

Core answer summary:

|

Comparing dimensions

|

Stainless Steel

|

Alloy steel

|

|

Core components

|

≥ 10.5% chromium (often added with elements such as nickel/molybdenum/titanium to enhance corrosion resistance or processability). | Based on carbon and reinforced with elements such as chromium/molybdenum/vanadium, it mainly enhances strength, hardness, etc. |

| Core performance | Absolute anti-corrosion advantage: Chromium forms a self-healing passivation film, which is resistant to corrosion such as water, acid, salt, etc. | Absolute strength advantage: ultra-high hardness, excellent wear resistance, high pressure bearing capacity. |

|

Fatal weakness

|

The strength/hardness is generally lower than that of alloy steel (except for martensitic stainless steel). | Poor corrosion resistance and easy rusting, requiring additional rust prevention treatment (such as electroplating and painting). |

|

CNC machining characteristics

|

Austenitic stainless steel (such as 304/316) is prone to sticking to cutting tools and wears them out quickly → CNC machining is more expensive. | Good rigidity, stable cutting, high surface accuracy, and can be further strengthened through heat treatment to enhance performance. |

|

Cost Truth

|

The raw material prices are high (including precious metals such as nickel/molybdenum), but due to maintenance free and anti-corrosion measures, the long-term usage costs may be lower. | The raw material prices are relatively low, but rust prevention treatment increases costs; High wear resistance can extend the lifespan of parts → it has cost advantages in specific scenarios. |

|

Iron law for material selection

|

Preferred for highly corrosive environments: food processing, medical equipment, chemical equipment, marine engineering, etc. | Preferred for high load scenarios: tool molds, bearing gears, automotive structural components, high-strength fasteners, etc. |

Why Refer To This Guide? Based On JS’s Material Matching Logic

At JS, with more than a decade of experience working in industrial material choice, we can tell you firsthand: employing the proper materials saves worry and dollars, making the improper selection creates endless downstream issues and even greater expense.

As Harry Brearley, one of the inventors of stainless steel, said, “The value of a material lies in its performance in the environment in which it is placed.” This statement hits the nail on the head.

For an example in the real world: For medical equipment components that need to be spotlessly clean and rust-free, we always employ 316L stainless steel. Why are we so sure? Because we have proven that such crucial components have been in service for over ten years without even a suggestion of corrosion.

But in the case of a huge hydraulic press plunger, things are just different. The part is exposed to tremendous, daily repeated impacts. Here, 42CrMo alloy steel is our ace up the sleeve. Once processed correctly, its hardness has no problem crossing HRC 55, rendering it highly impact-resistant.

We never choose our materials intuitively. It simply depends on the type of environment and use a component will be subjected to. We have a strict adherence to rigorous standards GB/T 20878 and GB/T 3077. The principle is a simple one: For extremely corrosive environments, stainless steel is the way to go. For components that must endure severe impact and recurrent heavy loads, alloy steel is unbeatable. The goal is simply this: to maximize the value of a material in its best possible application, safely, reliably, and long term.

Essential Differences: Why Does Composition Determine Fate?

I deal frequently with clients to select materials, and I’d like to speak to the “composition-determined” nature of stainless steel and alloy steel. Simply put, there is no purely absolute “one is better”; the issue lies in the particular application your CNC machining parts will serve.

Stainless steel = Your “Rust Guardian”

Key Skill: Antigalling Rust and Corrosion! Chromium (Cr) is the secret (must be ≥10.5%). It automatically forms an ultra-thin but ultra-dense “invisible armor” (a technically referred to as a passivation film) on the steel surface. This film offers excellent corrosion resistance to moisture, sweat, and a wide range of acids, bases, and salts. In JS’s past cases, the 316L stainless steel that we use in medical devices enjoys an 18-year corrosion-free track record, attesting to its proven strength.

A golden duo, both with their own unique strengths:

(1) Nickel (Ni): Contributes stainless steel resistance to cracking, eases forming, and creates an even more lustrous, beautiful finish. Offers improved low-temperature stability too.

(2) Molybdenum (Mo): This “corrosion-resistant enhancer” (utilized, for example, in 316 stainless steel). Molybdenum is particularly resistant to highly concentrated acids and saltwater and forms a key ingredient for chemical plants and seashore hardware.

(3) Titanium (Ti)/Niobium (Nb): They are stabilizers. They primarily inhibit the formation of harmful substances within the material when welding or hot-working, preserving the precious anti-rust covering.

Alloy steel = Your “powerhouse”

(1) Signature Strengths: Hard! Strong!

Wear-Resistant! Carbon (C) is the core, supplemented by a carefully combined mixture of alloying components such as chromium (Cr), molybdenum (Mo), vanadium (V), nickel (Ni), and manganese (Mn). They do not simply get combined; instead, they drastically alter the inner crystal structure of steel, significantly improving its strength, hardness, and wear resistance.

(2) Price and Processing Note: Rust resistance is a weakness.

To achieve these higher mechanical properties, alloy steels compromise on rust resistance. When wet or corroding conditions exist, they rust more quickly than stainless steel and generally require some type of protection such as chrome plating, blackening, or painting.

In-Depth Analysis: The Kingdom Of Stainless Steel

I work with all kinds of materials on a daily basis. Stainless steel is definitely one of our “star players.” From my experience as a JS, I’ll dissect its intricacies and most vital processing techniques:

Why won’t stainless steel rust?

The key is in the surface! The chromium level of stainless steel. When exposed to oxygen in air or water, it instantly “works magic” on the steel surface, forming an ultra-thin, ultra-dense, clear shield film (technically known as a passivation film). This film armor protects the interior iron from additional rust. This forms the foundation for all corrosion resistance of stainless steel.

The stainless steel family is quite diverse, so it’s all about choosing the right material!

Stainless steel is not one particular form of steel, but rather a large family, consisting of a number of groups based on composition (primarily chromium and nickel content) and internal structure:

|

Stainless steel type

|

Core features

|

Common application areas

|

Key points of custom CNC machining manufacturing

|

| Austenite (304, 316) | All rounder! Excellent toughness, excellent corrosion resistance, easy to form, non-magnetic. | Kitchen equipment, plumbing, building decoration, medical equipment, chemical containers. | Relatively easy to process. But the key is to control the cutting speed and feed rate, and ensure sufficient cooling! Avoid local overheating that may cause material hardening. |

|

Ferrite (430)

|

Economical and practical. Containing less chromium and nickel (or no nickel), it has magnetism, moderate corrosion resistance, and low cost. | Automotive exhaust pipes, home appliance casings, interior decorative parts. | Slightly harder than austenite. The tool wear will be faster during processing, and suitable tool materials and parameters need to be selected. |

|

Martensite (420, 440)

|

The tough guy takes responsibility. High carbon content, with extremely high hardness, strength, and wear resistance. But it has weak corrosion resistance and poor toughness. | Cutting tools, bearings, wear-resistant parts, turbine blades. | The most difficult to process, very labor-intensive! High hardness cutting tools must be used, and strong cooling is essential. |

Choosing the right stainless steel is half the battle! No matter what properties your part requires, JS is an expert in custom CNC machining manufacturing of all types of stainless steel. Bring us your needs and challenges, and we’ll ensure they’re realized efficiently and precisely! Contact us today for a solution!

In-Depth Analysis: The Power Of Alloy Steel

Then there’s alloy steel, which is the true workhorse of our engineering field. Its most significant feature is that it has ultra-high strength, hardness, and wear resistance, so it’s a perfect material for dealing with heavy loads, abrasion, and impacts.

(1) High-Strength Low-Alloy Steel (HSLA):

- Its low level of alloying elements (typically below 5%) means that it’s relatively cheap compared to others but offers much higher strength than plain carbon steel.

- Most importantly, it is easily welded and processed.

- It is widely utilized in uses such as car chassis, bridge construction, building frames, gas tanks, and excavator booms where lightweight yet resilient parts are required.

(2) Medium- and High-Alloy Steels:

They possess more specific alloying elements (such as chromium (Cr), molybdenum (Mo), and vanadium (V)) with their own advantages.

| Type |

Core performance

|

Typical applications

|

Industry value

|

|

Cold die steel

|

Maintain ultra-high hardness at room temperature, resist tremendous pressure and wear. | Stamping molds, punches, and shearing blades. | Ensuring the accuracy, efficiency, and mold lifespan of the cold forming process is a key support for mass production. |

| Hot work die steel | After repeated heating and cooling, the hardness decreases and resists thermal cracking. |

Die casting molds, forging molds, and hot extrusion molds.

|

Capable of high-temperature metal forming (such as aluminum/magnesium alloy die casting and forging), ensuring mold stability and product consistency under complex high-temperature conditions. |

|

High-speed steel

|

Extremely high hardness and wear resistance, maintaining cutting ability even at high temperatures. |

Drill bits, milling cutters, turning tools, gear cutting tools.

|

It is the core tool for achieving efficient and precise online CNC machining services! High speed cutting and processing of difficult to machine materials cannot do without it. |

|

Bearing steel

|

High hardness and wear resistance, extremely low impurities ensure material uniformity and stability. |

Ball bearings, rollers, and inner and outer rings of bearings.

|

Ensure smooth operation of bearings under high-speed rotation and heavy loads. |

Choosing the best medium- and high-alloy steel provides a strong safeguard for mission-critical parts. JS will guide you in making accurate material selections and providing efficient online CNC machining services. Do you want severe wear resistance, heat resistance, or accuracy? Contact us at any time and we’ll help you obtain them!

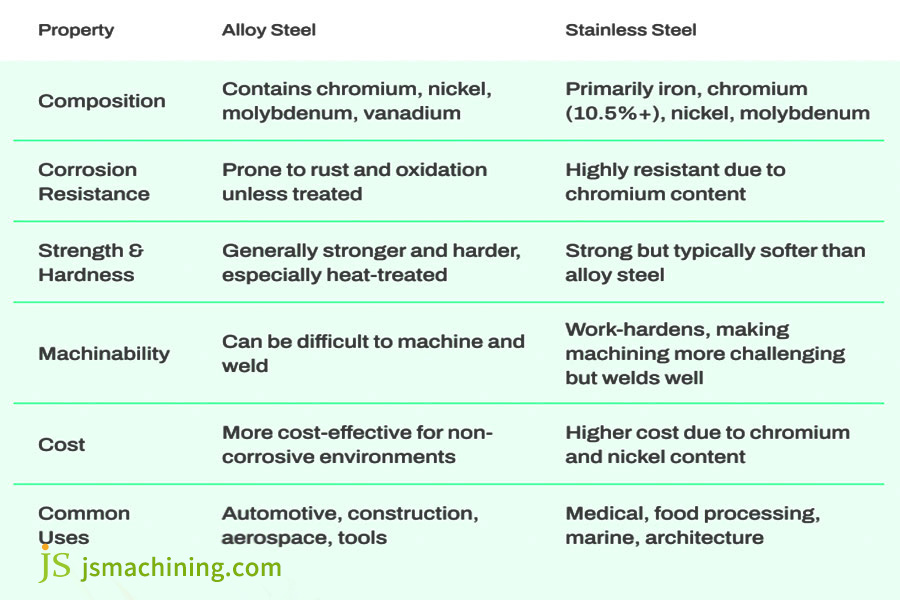

Alloy Steel vs. Stainless Steel: The Ultimate Showdown

When it comes to stainless steel vs alloy steel (which is generally structural alloy steels that need extra rust protection), there’s no clear winner; it simply depends on your application. Based on our experience machining CNC machined parts, let me break down their fundamental differences:

(1) Rust Resistance: Stainless Steel Has a Clear Advantage

The corrosion resistance of stainless steel is because it has a minimum 10.5% chromium content. This protective layer of chromium oxide shields well against corrosion from moisture, salt, and most chemicals. This is one of the primary reasons we employ it for corrosive and humid environments.

Regular alloy steels lack this natural protective layer. Using them normally requires additional surface protection, like electroplating, paint, or blackening, and this adds both to the process and expense.

(2) Strength and Durability to Wear: Alloy Steel Excellent

By introducing elements like chromium, molybdenum, and vanadium into the smelt process and then going through a rigorous “quenching and tempering” heat treatment, alloy steel achieves excellent hardness, strength, and advanced wear resistance. It’s an ideal material for heavily loaded, high-wear applications.

Stainless steel is also available in high-strength grades, although as a general guideline the upper levels of wear resistance and strength for regular grades are not typically as high as those of well-designed and heat-treated alloy steel.

(3) Cost Factors: A Balanced Perspective

Simply to equal material cost of purchase, plain old alloy steel is generally less expensive than stainless steel, especially when stainless steel contains high percentages of precious metals like nickel. The cost difference is even greater.

However, cost shouldn’t be solely based on the purchase price of the material. If the environment is prone to rust, alloy steel must be treated with rust-proofing, and ongoing maintenance may be more frequent and expensive. Stainless steel is virtually maintenance-free in corrosive environments and tends to last longer. Therefore, using stainless steel in corrosive environments may actually result in lower total cost of ownership and less worry in the long run.

(4) Machinability: Each has its own advantages.

Stainless steel (such as the common 304): It has good ductility, is relatively easy to bend and form, and generally has good weldability.

However, there is a problem when cutting with CNC machines: it is prone to “sticking” of the tool, which causes accelerated tool wear, and requires more precise control of the surface finish.

Alloy steel: It generally has better machinability, is more efficient in CNC machining, and is easier to achieve a good surface finish.

Its disadvantages are also obvious: high-strength alloy steel is difficult to cold-bend and is prone to cracking when forced. It is also prone to cracking during welding, and usually requires complex preheating and post-weld heat treatment processes.

Case Study: Selecting the Optimal CNC Material for an Aerospace Sensor Bracket

Below is a real-world example of a sensor bracket we recently helped an aerospace client select and process. We’d like to share our approach and results:

The client’s challenge was clear:

They needed a sensor bracket suitable for aircraft use, with extremely high requirements: it had to withstand extreme temperature fluctuations and high vibration, while also being extremely strong and stable to ensure accurate sensor readings. It also had to be as lightweight as possible, as reducing weight on an aircraft saves money. Finally, the bracket’s complex shape required precision CNC machining to achieve precise dimensions and a smooth surface.

JS Material Selection and Processing Strategies:

Material selection is crucial. We focused on comparing two mainstream high-performance materials:

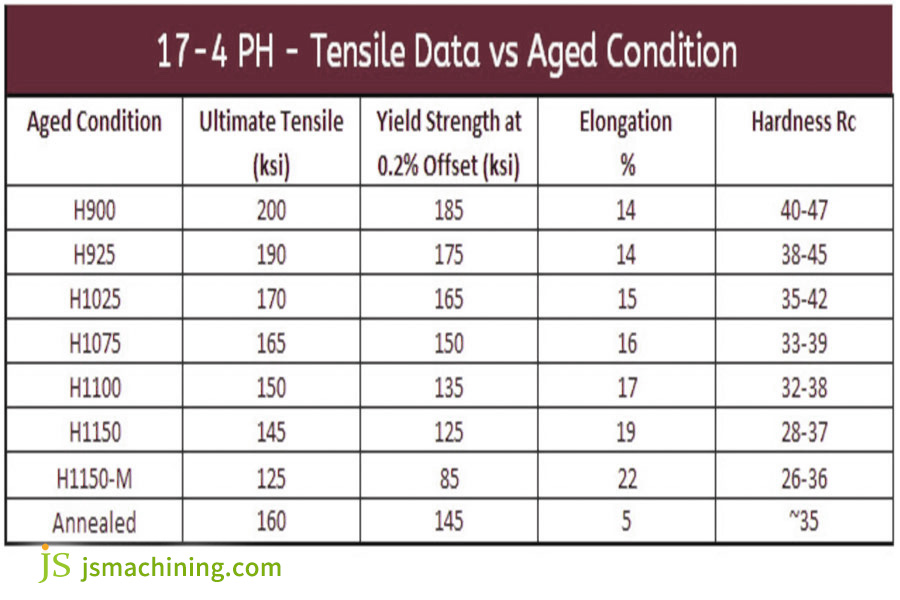

(1) Stainless steel (17-4PH, H1150 temper):

- Advantages: Outstanding strength, corrosion resistance, relatively easy processing, and inexpensive.

- Drawbacks: Strength becomes less significant at high temperatures, and the weight is ever so slightly heavier than optimally wanted lightweight best-of-class materials.

(2) High-temperature alloys (e.g., Inconel 718):

- Advantages: Outstanding high-temperature strength, first-class deformation (creep) and fatigue life, and high-quality thermal stability.

- Weaknesses: Machining is a nightmare in reality! Heavy work hardening leads to rapid tool wear and inferior thermal dissipation, so that machining speeds are brought down to extremely low levels and expenses are extremely escalated.

CNC machining has a crucial role:

For machining of 17-4PH stainless steel, we use normal carbide tools with best parameters, which result in high efficiency and reasonable expenses.

Machining Inconel 718, however, requires aggressive techniques: ultra-hard ceramic or CBN tools, extremely low rotational speeds, specialized high-feed strategies, high-pressure coolant, and top-tier rigidity machine tools. The result is significantly longer machining times and skyrocketing tool costs.

JS’s final choice: 17-4PH stainless steel (H1150 grade)

While Inconel 718’s optimal performance is preferred, the difficulty to machine and prohibitively high prices many times over the client’s budget are insignificant. After close examination of the actual working conditions, we established that 17-4PH with reinforcement of H1150 fully satisfied the main requirements in terms of strength, precision, and heat resistance.

To enable successful first-cutting of this complex bracket, we made full use of the CNC machining approach, tool path planning, cutting parameter adjustment, and cooling with specific attention paid to controlling deformation and stress during machining.

Comparison of key engineering data supporting decision-making

|

Key considerations dimensions

|

17-4PH (H1150) | Inconel 718 |

|

200 °C yield strength (MPa)

|

1030 | 1100 |

|

Room temperature damping ratio (%)

|

0.8 – 1.2 | 0.2 – 0.4 |

| Typical thin-walled (1mm) flatness deviation after milling (µm) | < 40 | 80 – 150 |

| Relative unit volume processing cost coefficient | 1.0 | 4.5 – 6.0 |

| Material cost (USD/kg) | ~ 25 – 35 | ~ 80 – 100 |

Results and Value:

The customer was provided with a bracket that met all performance requirements timely. More importantly, the manufacturing cost was approximately 30% of what the Inconel 718 solution would have required and the delivery cycle decreased by 55%.

Material selection should not be based solely on peak performance. Consider a balanced assessment under actual operating conditions, manufacturability, and cost. If you require precision components, contact JS. We can help determine the optimal solution with our skilled online CNC machining services!

Material Advantages and Precision Manufacturing: Your Needs, Our Achievements

Stainless steel possesses excellent corrosion resistance, whereas alloy steel is strong in bearing heavy loads. Do our customers have complex operating conditions and challenging machining requirements? No concern. We utilize accurate CNC machining, together with appropriate heat treatment, to leverage the maximum possible of each material’s true strengths—ranging from strength and wear resistance to corrosion resistance. We provide strength where needed, as well as corrosion resistance where needed.

FAQs

Q1: Can stainless steel replace alloy steel for high-load parts?

We generally do not recommend it.

While high-strength stainless steel like 440C can be used as a replacement, the cost is significantly higher. When it comes to material selection, alloy steel is more cost-effective and reliable for critical areas, especially those bearing significant stress, offering a better price-performance ratio.

Q2: How can alloy steel parts be rust-proofed?

We generally recommend several methods:

Zinc plating or nickel plating are the most cost-effective and hassle-free. For wear resistance, opt for a black finish. For particularly harsh environments and the highest level of protection, DLC coating is a better choice. The specific choice depends on your specific needs and budget.

Q3: Which material is easier to achieve precise tolerances in CNC machining?

In our workshop, alloy steel offers better control. Stainless steel is more prone to deformation and requires multiple processing steps and aging treatments to achieve high precision, so this should be considered when selecting a material.

Summary

Simply put, whether stainless steel or alloy is “better” depends entirely on the intended application. Stainless steel is particularly strong in corrosion resistance and durability. Alloys, on the other hand, offer the greatest advantage of being lightweight and having a high strength-to-weight ratio. Choosing the right material depends on your priorities: corrosion resistance, part weight, material cost, or machining convenience.

Don’t hesitate! Contact an engineer from our JS team today to discuss your decision.

Simply share your part’s specific application, the forces it will withstand, and your budget. We’ll recommend the most suitable material and provide transparent CNC machining price. Contact us now for a free material proposal and quote, helping you get the most out of your money!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: What Is The Difference Between Ferrous Metal And Non-Ferrous Metal? - JUSHENG

Pingback: How Can You Tell If Aluminum Is Anodized? - JUSHENG

Pingback: 304 Vs 316 Stainless Steel: Who Is More Expensive? - JUSHENG

Pingback: What Is Stronger, 10 Or 11 Gauge Steel Thickness? - JS Precision