Do you need some metal items personalized, whether it’s a unique piece of home decor or an essential item to help streamline factory performance? As a JS engineer, I consult with customers on a daily basis regarding such needs. What they most frequently inquire about is, “What’s the cost?” Honestly, custom sheet metal work is by no means inexpensive.

We have seen many cases where clients’ prototypes were flawless and production was near, only to be forced into halting production due to a 30% overrun on cost in sheet metal enclosures. The root of the problem is most often due to underestimating how details like material thickness and bending will impact cost. These errors typically stem from design choices and process specification.

We’ve made anything from high-accuracy medical enclosures to factory brackets. What our experience teaches is that materials, design sophistication, bend processes, surface finish, and even batch size all come into play when it affects the final cost. In certain instances, a clever optimization will save you 30% or more without giving up quality.

Key Answer Summary:

The cost of custom sheet metal work depends on four key factors: material, process, quantity, and complexity. The best price comes from precisely aligning your specific goals with the capacity of the supplier.

|

The issue that concerns you the most

|

Cost core influencing factors | Rapid cost reduction strategy |

| Single prototype price |

Start up fee, programming fee, material utilization rate.

|

Select standard materials and simplify the design. |

| Mass production cost | Material usage, labor efficiency, and bulk discounts. | Design nested and strive for tiered pricing. |

| Fast delivery (such as online services) | Order queue status and logistics transportation distance. | Choose local or online laser cutting services. |

| Strict precision/special process | Secondary processing requirements and quality inspection costs. | Clearly define necessary tolerances to avoid excessive machining. |

This article has your answers:

- We’ll divide five primary variables influencing prices, provide an approximate processing fee range for your specific sheet metal work, and address the rules of volume discounts.

- We’ll also present three proven cost-saving methods.

- Finally, we’ll use the example of a medical device enclosure to show you how we helped a customer save 35%.

Why Trust This Guide? JS’s Sheet Metal Fabrication Experience

We don’t just produce your sheet metal parts, we truly want to help you streamline and save money. Having been in this industry for so long, we know the ins and outs. For example, when laser-cutting parts made of 304 stainless steel, the price isn’t simply determined by the thickness of the steel plate, the key lies in how to arrange the steel plate for optimal efficiency! Even a subtle corner in your design could cost you 20% more.

These experiences are all gained through practical experience. From designing a single prototype to handling large cabinet orders exceeding tens of thousands per month, we’ve optimized over 4,000 sheet metal designs.

“As the master of quality management, Deming, said: Quality is designed in, not tested.”

We specialize in helping you identify optimization points (DFM, or Design for Manufacturing) during the design phase of your custom metal fabrication near me, clarifying your cost structure. This ensures a truly reliable price, without hidden unexpected costs.

5 Core Factors: Dissecting The Cost Structure Of Custom Sheet Metal

Let me break down the cost structure of custom sheet metal. But a quote is more than just “material + labor”! The following five core factors truly impact your final cost:

Material Cost: Choose wisely, and save money!

Material: Cold-rolled steel, stainless steel, and aluminum vary significantly in price. Which one to choose depends on your specific needs, don’t blindly pursue the most expensive option.

Thickness and Size: The thicker and larger the sheet, the higher the material cost. More importantly, this directly impacts the difficulty and efficiency of laser cutting. Cutting thicker sheets is slower and more expensive, and excess scrap is also wasteful.

Surface Treatment: Post-processing steps like painting, electroplating, and anodizing each incur additional costs. Choose a process that’s sufficient, but be careful not to overdo it.

Process Complexity: The more steps, the higher the cost!

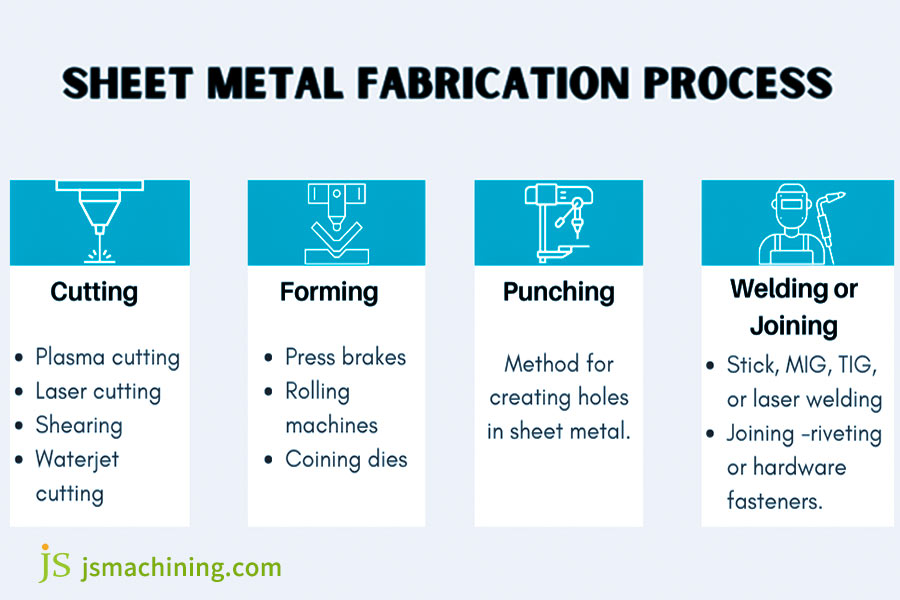

Cutting Method: Laser, water jet, or stamping? Each has its own strengths and price tags. Laser cutting is fast and versatile, suitable for complex shapes. Water jet cutting can cut very thick or exotic materials, but it’s slow and expensive. Stamping is suitable for high-volume production of simple shapes. Mold-making is expensive, but cost per part is low. The magic is in your part features and batch size!

Bending: The greater the number of bends, the tighter the angles, and the higher the precision requirements, the longer the machine setup time and complication, the longer the work hours and the higher the cost.

Welding/Assembly: This is a very manual process and takes time. Considering assembly during design and minimizing weld length and complexity can readily control work hours.

Special Processing: Additional steps like embossing, riveting, and tapping are charged separately and may require specialized tools.

Design Details: Small changes on the drawing can make a big difference in your wallet!

Hole Cutting: Small and dense holes are very expensive when laser cutting. Try to make the holes larger (>Ø3mm), fewer, and more spaced apart.

Bend radius and tolerance: An overly small bend radius will require special tooling or multi-step bending. Close tolerances (e.g., ±0.05mm) translate to slow, painstaking work or re-machining after cutting, which means mounting costs. Relax tolerances if function allows.

Material Nesting: Well-designed components can be densely packed in a puzzle-piece arrangement on a large panel, with material utilization levels of 80% or higher, minimizing waste and conserving cost. A design that is broken up may finish at a 50-60% utilization level, and you’ll be paying for any surplus material.

Order Quantity: Quantity naturally involves more competitive unit cost!

The unit cost can vary exponentially when making one prototype, 100 beingness, and 1,000! Fixed costs like mold opening fees and machine setup time can be diluted with higher volumes. Yet more is not necessarily better, the optimum quantity is key.

| Process combination | Prototype (1-5 pieces) |

Small batch (50 pieces)

|

Medium batch (200 pieces)

|

Large batch (1000+pieces) | Urgent fee (24-48 hours) | Local Logistics (Asia) | Overseas logistics (Asia ->East Coast) |

| Stamping (including simple molds) |

$450 er piece

|

$15 per piece |

$9.5 per piece

|

$5.2 per piece

|

Usually not feasible | $30-80 per order | $400-750+customs duties |

|

Laser cutting+simple bending

|

$85 per piece

|

$22 per piece |

$14 per piece

|

$8.5/piece

|

+35% – 50% | $25-75 per order |

$350-700+customs duties

|

| Laser cutting+multi pass bending/welding |

$220 per piece

|

$65 per piece | $38 per piece |

$21 per piece

|

+40% – 60% | $40-100 per order |

$450-900+customs duties

|

| Water jet cutting (thick/special) |

$150 per piece

|

$50 per piece |

$35 per piece

|

$25 per piece

|

+50% – 80% | $35-90 per order |

$500-1000+customs duties

|

Data Source: JS Internal Q2 2024 Typical Order Analysis

Supply Chain Efficiency: Being Close Saves Money!

Find a local custom metal fabrication project (like ours) for fast communication and sample inspection, less shipping cost, prompt response, and rapid problem solving, which will cost you less time and money.

(1) Transparent Online Service Quotes!

JS offers a strong online platform to provide you with real-time quotations for simple processes like laser cutting with transparency and peace of mind. More importantly, if you require complex processes (e.g., multiple bends, welding, and special surface treatments) or technical in-depth consultation, you can conveniently connect online with our offline specialist team. This overcomes the “online price, offline price markup” bottleneck.

(2) Expedited Orders:

We understand the imperatives of close project deadlines. JS’s rush service (24-48 hours) carries a premium, but it is reasonable and upfront (typically 30%-50% additional, depending on complexity and factory capacity). And, because of our multi-factory partnership and intelligent scheduling system, our rush service success rate far exceeds the industry standard. We’re not just charging for service.

See how JS’s supply chain efficiency translates directly into your cost advantage (compared to a typical scenario):

| Supply chain scenario | JS Company (Localization+Efficient Collaboration) | Domestic ordinary suppliers in the United States | Typical overseas suppliers (Asia ->East Coast) | JS saves/benefits for you |

| Standard part logistics cost (e.g. medium-sized chassis) | $25- $75 (regional delivery). | $50 – $150. | $400- $800+customs duties (7-15%)+customs clearance. | Save $375+&avoid tariff/customs clearance risks. |

| Standard delivery cycle (including production and logistics) | 7-10 days. | 2-3 weeks. | 4-6 weeks (minimum). | Speed up by 2-3 weeks, the project will land faster. |

| Urgent delivery (24-48 hours production completion) | Urgent fee of 30% -50%, success rate>95%. | Urgent fee of 50% -80%+. | Basically not feasible/sky high air freight price ($1000+). | Reasonable expedited cost with high certainty. |

| Production exception handling time | Local team, on-site fix and response within 24 hours. | Coordination of response time of 1-3 days is required. | Communication cost is high and the cycle length is long (weekly). | Maximize production uptime and ship. |

| Design problem communication and change response | Direct engineers’ link with less than 2 hours’ average response time. |

Email/phone, with 4-8 hours’ average response time per iteration.

|

Email time gap, reply within 24-48 hours on average per round. | Problem not overnight, reducing the risk of delay. |

Data Source: JS Company 2024 Customer Order Data Analysis & Industry Benchmark Survey

Sheet metal cost management is as crucial as choosing the proper process! Choosing the proper partner is equally crucial. JS allows you to exclude hidden costs from your supply chain with local manufacturing, same-day response, open book expedited shipping, and actual expert advice. Let delays and distance burn through your profits. Contact JS today for streamlined design and accurate quote, and start production in 48 hours or less!

Practical Cost Cutting Tips: 3 Steps To Halve Your Sheet Metal Manufacturing Costs

Working with the JS team, I deal with sheet metal costs on a regular basis. In reality, we have applied these methods in our effort to reduce costs significantly, and we’d like to share them with you:

Tip 1: Reduce costs at the design origin

We use a consistent bend radius, for example, R2mm on all bends. This reduces mold changes and reduces bending costs by 25%.

We also have strict hole design rules: minimum diameter of holes should be 1.2 times plate thickness (at least 2.4mm for a 2mm plate). This reduces time and labor in laser cutting since there is no necessity to continue drilling those pesky little holes.

Efficiency in sheet material is even more crucial. With effective utilization of auto-nesting software, obtaining more than 80% utilization rates becomes common practice, reducing scrap from 30% to a mere 12%.

Tip 2: Matching Suppliers

Local firms offer the convenience of communication and are most appropriate to handle high-priority parts as well as timely welding and assembly. Although 8%-15% more expensive, they offer assurance, rapid first-part approval, and minimal logistics risk.

If the project is price-sensitive and parts are reasonably standard, online laser cutting services are very budget-friendly. The website offers transparent pricing along with real-time price comparison.

Tip 3: Leverage Volume Discounts

For all processes like laser cutting, bending, and welding, the more the volume, the lower the unit cost. A $2.40 per-minute laser cut of 500 pieces is 25% lower than a $3.20 per-minute cut of 50 pieces.

How does JS work?

Our common practice is to congregate orders for prototypes, trial production, and production in numbers to become immediately eligible for the highest discount. Further, in the event of cutting parts for several projects onto one standard plate (e.g., 2400 x 1200mm), if size allows, additional 15% of scrap can be avoided.

However, observe that they typically only cut, requiring separate staff to bend and weld, the latter of which is often difficult to coordinate. Therefore, JS uses a combination of approaches: online cutting for general components saves 30%, with complicated bending and assembly left to local manufacturers, with delivery and price being maintained in check.

These three strategies have proven effective in significantly reducing sheet metal costs. In particular, leveraging the flexible combination of custom laser cutting manufacturing and local processing can achieve a win-win situation in both cost and efficiency. Want fast results? Contact JS now!

Avoid Unclear Quotes! Sheet Metal Process Cost Range Reference

Customers often complain about unclear sheet metal quotes, saying they can’t make sense of the cost structure. Let me clarify the cost ranges and the principal factors to decide on ordinary processes:

(1) Bending Processing Cost:

The basis for the price is at the foundation with bends, one bend equalling one cut, for $0.50-$3 per cut.

What makes a difference in price?

Sharp Angles: Bends that are non-standard 90-degree bends, i.e., ones requiring acute or obtuse angles, typically command a 20%-50% premium price due to greater complexity of adjustments and tool changes to the machine.

High Precision Requirements: Require a tolerance of ±0.1mm? That is significantly tighter than the typical ±0.5mm tolerance, and the price could be 40% higher due to more precise operation and inspection required.

(2) Laser Cutting Costs:

Charging is on the basis of machine time or cutting length. Machine time is from $0.80 to $80 per minute, and cutting length is from $1.20 to $12 per meter.

What affects the price?

Material Thickness: Thicker plates take longer and need more tooling and thus are more expensive. Cutting 12mm stainless steel, for example, would be roughly three times more expensive than cutting 3mm carbon steel. The more small holes (e.g., 2mm diameter), the longer it takes, and each small hole takes roughly $0.10.

(3) Welding Process Cost:

The price is charged by the labor hour or by the weld length. The hourly labor rate is $18 to $60+, and welds range from $12 to $50+ per meter.

What can change the price?

- Material difficulty: Aluminum or stainless steel welding? These are far more difficult than doing carbon steel work, and the cost is generally over 30% higher.

- Rigorous inspection: Demand non-destructive testing like X-rays to ensure there are no internal defects? Then add a separate inspection fee of at least $60 per unit.

(4) Surface treatment costs:

- Powder coating: $3 to $12/sq m. If special ones like medical grade are required, the price can almost double.

- Anodizing: $6 to $24/sq m. For harder anodizing for extra wear resistance, twice the regular anodizing price is typically charged.

Just saying the price range by itself may be a little unclear, so let’s compare:

| workmanship |

Typical 3ERP quotation

|

Typical quotation for Xometry | Typical quotation of JS company |

JS Advantage Explanation

|

| Laser cutting | ~$1.2 per minute |

~$1.5 per minute

|

$0.8/minute (3mm carbon steel) |

High efficiency and good cost control of equipment.

|

|

Bending (90 °)

|

~$0.75 per cut |

~$0.90/cut

|

$0.55 per cut (≤ 2mm, ± 0.5) | The mold library is complete, and the single cost is low. |

| Welding (carbon steel) | ~$25/hour or~$18/meter | ~$30/hour or~$22/meter |

$20/hour or $15/meter

|

The skilled welding team is stable and the utilization rate of working hours is high. |

| Powder coating | ~$5.8/㎡ |

~$6.5/㎡

|

$4.5/㎡ (standard color) | We have our own spray coating line, with obvious advantages in batch production. |

Data Source: Based on JS’s standard pricing as of August 2025

While many factors influence sheet metal costs, JS, with its efficient equipment, economies of scale, and mature processes, offers core costs for laser cutting, bending, welding, and painting that are significantly lower than those of Xometry and 3ERP. Looking for transparent, cost-effective sheet metal processing? Contact JS directly; our engineering team is ready to provide you with an accurate quote and solution!

Case Study: Saving 35% On Production Cost For Medical Monitor Enclosures

We worked with a startup company some time back on a cost problem for a medical monitor enclosure. When they were getting ready to mass-produce the aluminum case, they discovered that the quote was 40% more than the budget, nearly killing the project. Today, I am going to show how we helped them save this 35% cost step-by-step.

Client Background:

This new company, making portable medical monitors, needed an initial order of 200 cases. The first material they used, 6061 aluminum, was too expensive, and the bid was 40% too high.

Upon checking JS, three major issues were discovered: excessive use of high-grade aluminum, wasting money, 11 unnecessary complex bends on the casing, making processing more difficult, and small batch purchases leading to high prices.

JS’s Solution

(1) Material Change: We switched to 5052 aluminum alloy, which is stronger and easier to work with. This saved us 18% in the cost of laser cutting parts alone.

(2) Design Streamlining: Seven of the ornamental bends were eliminated, simplifying the U-shaped body and by 25% minimizing bending steps. Furthermore, the various hole diameters on the housing (originally ranging from 1.5mm to 5mm) were standardized to 3mm. This streamlines laser drilling in terms of cost and time, reducing processing by 15%.

(3) Supply Chain Optimization: We opted for the quarterly buy of 500 pieces to initiate volume discounts (reducing the laser unit price by 22% and bending unit price by 18%). We split the process and leveraged the low power cost of electricity in the Yangtze River Delta zone and internet-based laser cutting services to complete the plate cutting. The remainder of the painting and the assembly were completed on-site at the customer’s location, minimizing overall expense and yet providing swiftly.

The results?

Ultimately, the cost of each enclosure was reduced from $187 to $122, a 35% reduction! Overall production time was also reduced by two weeks, allowing the customer to finally start mass production on schedule. They particularly appreciated our approach: we did not rely on pressuring suppliers for payment but instead used an engineering approach to solve and optimize the problems at hand.

This case demonstrates that from material selection and design optimization to supply chain restructuring, every step can be streamlined. If you’re also struggling with product enclosure costs, don’t hesitate to talk to JS! We bring engineering thinking to help you discover the optimal pathway to cost savings and efficiency improvement.

FAQs

Q1: Are prices on online quotation sites reliable?

I’m an engineer at JS, and I deal with price issues on online quotation sites every day. The initial quotes on websites are typically generated from simplified models and don’t take into consideration real-world costs like complex bends, specialty material handling, or high-precision quality inspection. So I’d recommend you review your quote manually after uploading your drawings to avoid cost surprises.

Q2: Must small-volume orders lose money?

I often meet with customers who worry about the expense of small orders.

In fact, there is no reason to lose money. My advice is to use standard-size sheet metal to prevent cutting expenses, share costs with batch production, and relax tolerances in processing to reduce commissioning time. Mastering these tricks will allow you to profitably produce small batches—what you save is what you gain!

Q3: How much more expensive is stainless steel compared to cold-rolled steel?

Simply put, raw material cost for stainless steel is two to three times more than cold-rolled steel.

It takes more effort to work with, 15%-20% lower laser cutting speeds, and requires higher-tonnage machines to bend. The cost of stainless steel parts is typically 2.5 to 4 times that of cold-rolled steel, depending on the process complexity. Therefore, in material choosing, you need to determine whether the difference in price is worth it.

Summary

The cost issue with custom sheet metal production. Simply put, many projects go over budget, either because of overly complex designs that drive up costs or because of inefficient supply chains that waste money. Our experience in helping medical clients save 35% speaks volumes. The key isn’t relentless price reduction, but rather systematic adjustments to the entire process, from material selection and design optimization (DFM) to production strategy.

Want to truly get a handle on costs? Send us your design drawings today:

- Within 24 hours, receive a free “Money Savings Guide” report: Our software will flag areas on your drawings to optimize and potential savings, backed by data.

- Competitive pricing for different quantities: We offer quotes for 50, 100, and 500 pieces. The bigger orders have more competitive piece prices, with savings on cost up to 30%. The laser cutting price you require will also be clearly given based on quantity.

- Online tracing + local manufacturing, fast and convenient: JS has integrated high-quality local custom metal fabrication near me resources, sparring you from the hassle of finding nearby factories and monitoring manufacturing updates. Production can be tracked online, ensuring timeliness.

Don’t let hidden costs erode your profit. Looking for a truly reliable solution to reduce costs for you? Send us your drawings now and let’s give it a try!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Titanium Vs Tungsten: Who Is The Ultimate King? - JUSHENG