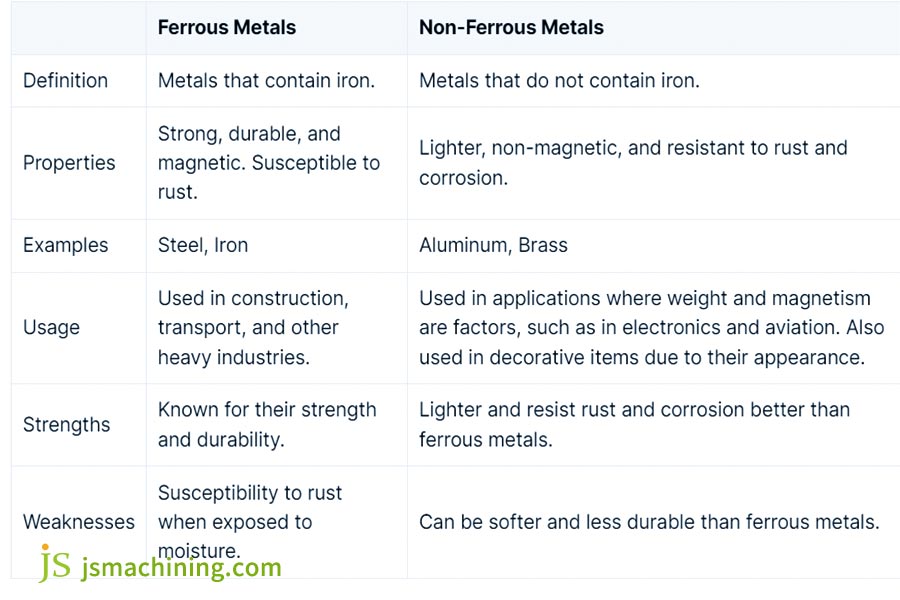

When engineers make material selections on a daily basis, having an accurate identification of ferrous and non ferrous metals can instantly dictate the outcome of a project.

In plain language, ferrous metals (that is, countless various steels and cast iron) are basically iron-based, with high tensile strength, excellent magnetic properties, and fantastic durability, which is why they’re the plug-and-play workhorses of construction and heavy machinery. Non ferrous metals, devoid of iron content, are a whole different ball game. Alloys like aluminum and copper are light, rustproof, and have excellent electrical and thermal conductivity, which is why they find widespread application in precision components for aerospace and electronics uses.

When making and designing, knowing the material type is not sufficient, the application scenario is the key—is absolute strength needed, or does corrosion resistance or weight savings come into play? This guide will assist you in prioritizing and selecting the correct material for your project.

Core Answer Summary:

| Performance dimension | Ferrous metals | Non Ferrous metals |

| Core components | Iron based (Fe>50%), containing carbon and other elements. | Zero iron/trace iron, mainly composed of aluminum, copper, zinc, etc. |

| Strength ceiling |

★★★★★

(Quenched steel exceeding 2000MPa).

|

★★★☆☆

(Titanium alloy is about 1000MPa).

|

| Corrosion resistance |

★★☆☆☆

(Dependent on alloying/coating).

|

★★★★★

(Natural passivation film).

|

| Cost sensitivity | The raw material price is low, but the heat treatment cost is high. | The fluctuation of raw materials is large (such as copper futures), and there is a premium for lightweight. |

What You’ll Get from This Article:

- This article will explore the industrial origin of “ferrous” and take you through the simple contrasts between the two metals in three steps.

- We will give you a real case study of seawater pump corrosion and illustrate how we helped a customer avoid millions of yuan in losses through custom metal casting manufacturing.

Why Trust This Guide? JS’s Metal DNA

At JS, we’ve been working with properties of metals daily for over a decade. For example, the word “ferrous” sounds technical, but it just means “contains iron.” Ferrous metals like steel and cast iron are strong and can support heavy loads. Non-ferrous metals like aluminum and copper are light, more corrosion resistant, or have good conductivity, thus being useful in many fields.

But it’s not just about composition; the key lies in practical application. As metallurgist Harry Bhadeshia said, “Performance lies in the microstructure.”

We draw on extensive failure case studies and data to help you make accurate decisions based on your specific application. For example, choosing the right material for power plant boiler tubes requires considering both high-temperature creep and oxidation risks. We’ve handled everything from metal casting parts for Antarctic temperatures to non-magnetic semiconductor components.

This is precisely why JS’s online metal casting services are so reliable: backed by solid adherence to standards (such as ASME/ISO) and the material selection experience honed through numerous projects, we help you manage risk and maximize performance.

The 3D Decision Compass: Understanding The Essential Differences Between Ferrous And Nonferrous Metals

Are ferrous metals inherently stronger? Are nonferrous metals inherently more expensive? Don’t be trapped by these outdated notions. Material selection is actually much more complex. The key lies in understanding three core dimensions:

The First Dimension: Composition and Performance — The Dual Side of Iron

1. Core Differences:

Ferrous (iron-based) metals typically contain high iron content (typically > 50%), and their strength is their hallmark. For example, the tensile strength of 4340 alloy steel after quenching and tempering easily exceeds 1500 MPa, more than three times that of structural steel! However, this comes at the cost of high density (~7.8 g/cm³) and susceptibility to oxidation and rust. Ordinary carbon steel can rust within a few days of exposure to humid air.

Nonferrous (non-ferrous) metals, on the other hand, contain little or no iron. Their natural advantage is lightness and corrosion resistance. Aluminum, for example, will leave a protective coating, copper will develop a patina, and titanium is very inert and nonreactive, which earned it the nickname “ocean metal.”

2. Practical application: how to make the choice?

For wear-intensive components like excavator teeth, we definitely use reinforced special alloy steels like hardened alloy steel (e.g., AR400 wear-resistant steel). Its surface hardness as much as over 400 HB, and many times greater wear resistance than regular steel. Though costly, replacement frequency is significantly reduced, hence the overall cost savings.

But what then of satellite brackets? Every kilogram of weight reduction saves tens of thousands of dollars of launch expense. The best option are titanium alloys (e.g., Ti-6Al-4V). They possess a tensile strength in excess of 900 MPa, yet merely 57% the density of steel, and resist the harsh conditions of space.

The Second Dimension: Cost and Processing – From Melting Point to the Real Account on the Shop Floor

1. The Unpalatable Truth: Unseen Costs Cannot Be Disregarded

Castings (for example, HT250) are economical, but high energy consumption (melting temperature >1500°C) is required to melt and cast them into metal castings at two to three times the amount of that required for aluminum alloys. They are not easy to machine and tool wear rate is high.

Aluminum alloy castings are lightweight, cost-effective, and simple to work. Aluminum ingots are expensive (approximately $2,500/ton, more than four times that of cast iron). Low volumes or prototypes are best handled with our online metal casting services, which offer rapid turnaround times and circumvent the expense of mold making (a complex die-casting mold can cost in excess of $100,000), making them extremely versatile and efficient.

Copper alloys are advantageous in terms of having high electrical and thermal conductivity, but their budget is a rollercoaster ride to account for, fluctuating at $7,000 to $9,000/ton in recent times. They are highly associated with the international futures market, making it hard to budget for them. Machining is also difficult, resulting in low efficiency.

2. Key Points for Practical Decision-Making:

That’s the bottom line. Specialty materials like Inconel 718 are over $15,000/ton, but can you afford it? If the quantities are large enough, it might be worth designing a special mold, and that would amortize the cost per piece. If you’re only making a few parts, you’ll have to purchase pre-existing profiles or off-the-shelf components, sacrificing best design for cost control.

The Third Dimension: Environment and Lifespan—Invisible Killers Determine Success or Failure

1. Environmental Adaptability: the number one killer of corrosion

Corrosion is the most common trap. Ferrous metals rely on surface passivation (e.g., stainless steel’s oxide film) to resist corrosion, but the covering layer is very vulnerable in chloride ion or acid environments. Non ferrous metals (e.g., aluminum, copper, and titanium) naturally resist corrosion because of thick surface oxides, so they are more adaptable.

For example, in a salty and humid environment, cast iron may become perforated after only 3-5 years, while aluminum-bronze parts can last over 15 years.

2. Lifespan depends not only on the material but also on the environment.

Many people assume that “stainless steel” means it will never rust, but in fact, it depends entirely on the environment.

|

Material type

|

High temperature deep-sea seawater (50°C, 5MPa) |

Concentrated sulfuric acid (90%, 60°C)

|

High temperature sulfurization environment (H₂S, 250°C)

|

Acetic acid vapor (100°C)

|

|

Low carbon steel (A36)

|

1.50 mm/year | >25 mm/year | >20 mm/year | 0.80 mm/year |

|

316L stainless steel

|

0.15 mm/year | 0.60 mm/year |

Stress Corrosion Cracking (SCC) occurs

|

0.10 mm/year |

|

Aluminum Bronze Alloy (C61400)

|

0.04 mm/year |

complete failure

|

0.55 mm/year | 0.02 mm/year |

|

Hastelloy C-276

|

0.01 mm/year | <0.01 mm/year | 0.03 mm/year | <0.01 mm/year |

Data Source: NACE International, Corrosion Data Survey (Metals Section), 6th Edition

This table tells us several key insights:

- There is no “universal material”: For example, aluminum bronze is excellent in seawater and acetic acid but fails instantaneously in concentrated sulfuric acid.

- Different modes of failure: Ferrous metals (such as 316L stainless steel) do not corrode uniformly in sulfidic environments but instead suffer surface cracking (SCC), a more dangerous and sudden failure.

- The cost-life trade-off: Hastelloy alloy offers the best performance but is much too expensive. For most applications, aluminum bronze or copper-nickel alloys of non-ferrous metal offer tremendous cost-benefit and very long life in specific environments and are excellent alternatives to high-end stainless steel.

3. Hidden costs in post-maintenance

Ferrous metals are less expensive up-front but require additional corrosion protection systems such as coatings and cathodic protection. Non ferrous metals, while more expensive per unit, are virtually maintenance-free in aggressive environments.

We estimated that on offshore platform projects, substituting carbon steel and maintenance with copper-nickel alloy piping reduced total cost 30% by eliminating two major overhauls and replacements.

Selecting metals, and especially metal casting parts, can’t be a random decision, it must be carefully considered. Don’t merely argue the merits of using “ferrous” or “non-ferrous.” The key is to properly identify the material’s properties with your individual needs. At JS, we apply solid data and decades of experience to make the optimal choice for you, and your project gets off to the best start possible!

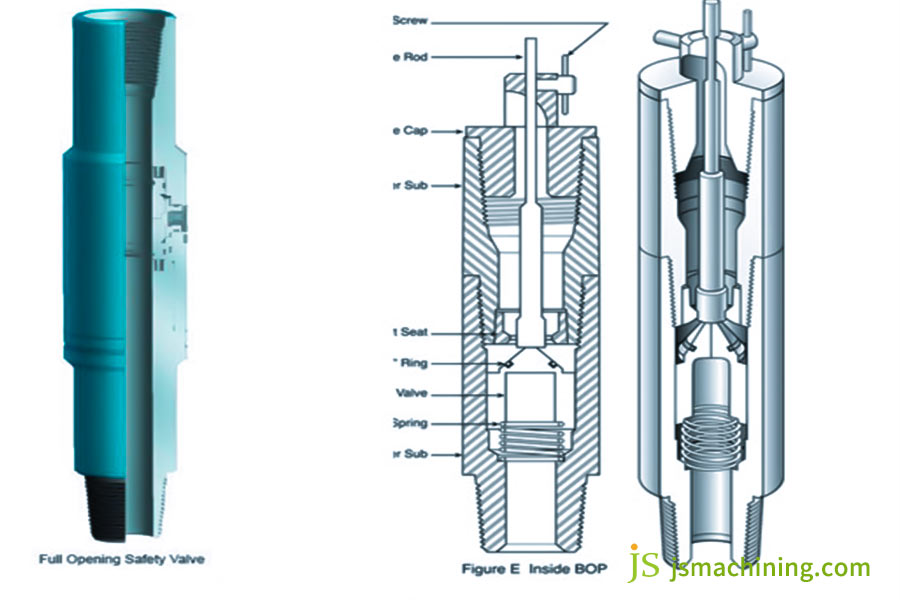

Real-Life Case Study: The Life-Or-Death Decision Of A Deepwater Drilling Platform Valve Body

Project Background:

A 1,500-meter-deep Pacific Ocean energy giant was confronted with serious challenges. The blowout preventer (BOP) valve body, an essential wellhead safety-critical component, was experiencing recurrent problems.

The first design utilized ZG270-500 cast steel (a conventional ferrous alloy). Under the high-pressure (1,500-atmosphere equivalent) and high-sulfur (up to 5,000 ppm sulfur level) acidic environment, corrosion would not take more than three months, resulting in leaks. A daily maintenance downtime costs $1.8 million, and more threatening is the high likelihood of an uncontrolled blowout.

The root explanation of the failure: Why don’t cast steel valve bodies have much lifespan in the deep sea?

We thoroughly analyzed the scrapped valve bodies in the laboratory and determined three main “killers”:

1. Sulfur’s deadly attack (SSC): Hydrogen sulfide (H₂S) is like a poison, invading tiny pores and grain boundaries in cast steel, quietly initiating cracks. Ferrous metals are inherently vulnerable in sulfur-containing environments.

2. Accelerated electrochemical corrosion: In deep water, tiny “corrosion cells” form on the steel surface, which consume the steel at high rates. The corrosion rate can strip 2.3 millimeters of material within one year! That is not viable in the high-pressure environment of the deep ocean.

3. Brittle fracture at low temperature: 4°C cold seawater isn’t something to laugh at. It reduces the toughness of this carbon steel by nearly 40%, and tiny flaws in the material soon become enormous flaws.

At the time, the client was engaged in a heated internal debate:

- One was to use super duplex stainless steel 2507, which would triple the cost.

- The other was to use Hastelloy C276 entirely, which would increase the cost by 12 times.

JS’s innovation: Accurate strike + material “blending”

1. Load and Media Analysis

CFD simulation indicated that 90% corrosion occurred within the channel transition zone, where it was subjected to erosion by a sand-carrying fluid at a velocity of 30 m/s. The corrosion in the rest of the zones was negligible.

2. Hybrid Material Structural Design

- Core channel region: The hollow inserts are made of Hastelloy C276 with an inner wall polished to Ra 0.4μm to eliminate crack initiation locations.

- Major composition: Duplex stainless steel 2507 is sand-cast and solution-treated, and laser strengthening in high-usage areas.

3. Vacuum Casting Process

Hastelloy alloy inserts are pre-positioned under vacuum conditions, and duplex steel is poured over them. A controlled temperature gradient is used to deliver metallurgical bonding, forming a performance transition layer.

The result: a remarkable turnaround in performance and cost

This tailor-made hybrid metal casting parts solution delivered immediate results:

- The cost is only 28% of the all-Hastelloy solution.

- The valve body life is extended from 3 months to 5 years.

- The overall weight is reduced by 40%, reducing system energy consumption.

There’s no silver bullet for engineering challenges in extreme deepwater operating conditions. The key to our successful valve body project was breaking away from the “black or white” material mindset. Utilizing cutting-edge custom metal casting manufacturing techniques, we achieved a leap in performance and cost optimization.

Facing extreme working conditions, we leverage our deep understanding of materials and processes to achieve breakthroughs through hybrid materials and innovative casting designs. If you face similar challenges, please contact JS and we can help you customize a solution.

FAQs

Q1: Is stainless steel considered a “ferrous metal” or a “non-ferrous metal”?

I concur that stainless steel is a ferrous metal.

Although it contains additives like chromium and nickel to improve it, it is still iron-based, with an underlying composition of over half. Rust resistance comes from a naturally forming covering layer on the surface that blocks oxidative corrosion.

Q2: Why is aluminum known as a “non-ferrous metal” but appear silvery-white?

“Non-ferrous metals” are not typically non-ferrous metals, but are instead metals that are not iron-based metals. They bear no connection to their true color. Aluminum is silvery white, copper is reddish, and gold is yellow. These hues are a product of energy transformations as a result of electrons in the metals when light is absorbed.

Q3: Titanium alloys surpass steel in performance, making them a complete replacement?

We understand that while titanium alloys offer strength and lightness, they are 60 times more expensive than carbon steel and more difficult to process. They are not yet used to replace steel in industries with extremely high performance demands except in aerospace and medicine.

Q4: How can I avoid material errors when placing orders through online metal casting services?

We’ve found that consumers are likely to overlook application information when selecting materials online. We strongly recommend that you clearly state these four important factors when you’re uploading drawings:

The forces the part will withstand, the liquids or gases it will come into contact with, the operating temperature range, and the expected service life.

A customer previously wanted to replace steel with aluminum alloy, but failed to specify operating temperatures as high as 800°C—at which point aluminum alloys would soften and fail. By providing complete information, we can help you avoid these risks.

Summary

In the end, no single metal is inherently “best”, what matters is whether it fits your system as a whole. The question of whether to go with ferrous or nonferrous metals is essentially just a question of finding the best set of factors for each consideration: strength, corrosion resistance, price, and processing complexity.

A brief overview of the two characteristics:

- Ferrous metals: They have good load-carrying capacity and excellent high-temperature capability, but are relatively more susceptible to rusting and corrosion.

- Nonferrous metals: They are lightweight and will have good corrosion resistance, but their performance is limited on applications that subject them to heavy loads or high temperatures.

Don’t let material selection compromise your part performance!

Send your part drawings and exacting requirements to the JS online metal casting service platform today. Our engineers will study your application situation carefully and accurately pair you up with the best material:

(1) Long-term service simulation: We analyze material composition and predict likely alterations (e.g., corrosion) in your working conditions (e.g., media exposure and temperature variation) for a long period (e.g., 20 years).

(2) Avoid known hazards: We cross-reference our extensive global database of material failure occurrences with yours to identify and help you steer clear of potential material failure risks.

(3) Providing custom solutions and transparent quotes: Based on our assessment, we will recommend at least three customized metal casting solutions, along with the corresponding metal casting price transparently, for making an effortless decision-free selection.

Choosing the appropriate metals forms an authentic solid foundation for your project. Connect with JS to share your specific needs!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com