In the process of injection molding, we all know that it is a highly effective process for the production of plastic components. However, the best process can be made useless if the wrong materials are chosen in the first step.

Entire production lots of medical devices have had to be recalled because the casings were not resistant to disinfectant corrosion. Or, with expensive electronics, the plastic parts shatter into fragments if handled in cold weather. The problem typically is the incorrect material. The cost isn’t even replacing the material at additional expense, but your reputation and market share as well.

There is plenty of material to choose from: ABS, PC, PA, PE, and PP—the first suspects that readily come to mind and lots of fiberglass-enhanced, niche grades. The characteristics of each material vary considerably from the others, including strength, heat resistance, chemical resistance, appearance, cost, and even machinability.Choose the wrong one? The ramifications are enormous: the parts could not survive, the appearance could be compromised, and more importantly, production costs would rise by 30% to 50%! Mold rework and production downtime—these are both expensive.

Plastic resin is the lifeblood of an injection molded component. It determines directly its strength, whether it will last in its operating environment, and for how long. The selection of materials, to be completely blunt, is tightrope-walking between performance requirements, cost of manufacture, and potential dangers.

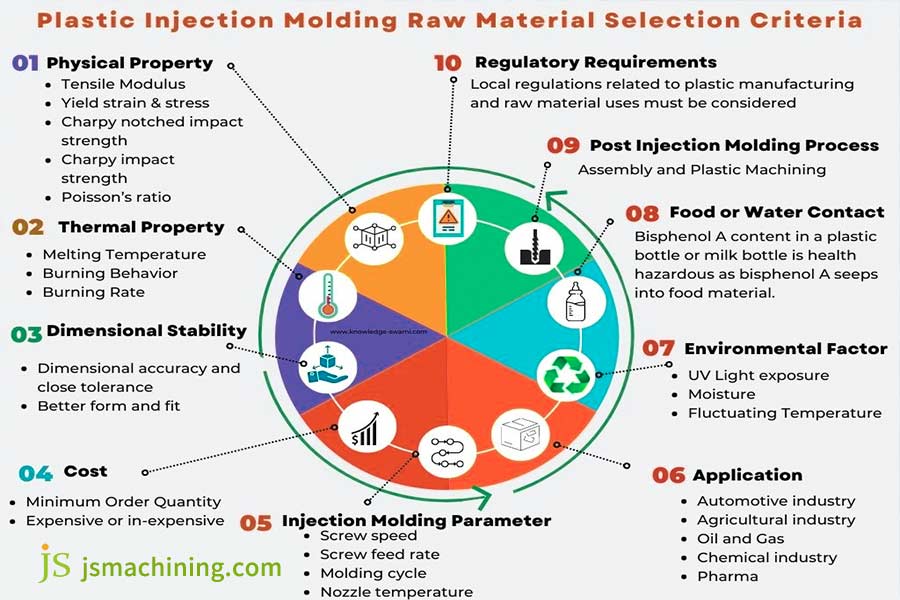

My experience over the years: Don’t blindly screen materials first. Define the requirements initially, Where is the part going to be installed? How much stress is it going to see? What chemicals and temperatures is it going to be exposed to? What appearance level is required? What is the cost cap? Once you have these factors laid out clearly, you’ll have a firm base for selecting materials.

Core answer summary:

|

Core requirements

|

Resin type | Typical Representative | Key risk warning |

| Ultimate cost control | General purpose plastics | PP, HDPE | Insufficient temperature resistance, prone to brittle cracking at low temperatures. |

| High rigidity & dimensional stability | Engineering plastic | ABS, POM | Moisture absorption deformation, long-term creep risk. |

| Corrosion resistance & high temperature stability | High performance plastics | PEEK, PPS | The exponential growth of raw material and processing costs. |

| Biocompatibility certification | Medical grade special resin | USP Class VI PC | The certification cost accounts for 30% -100% of the material price. |

What you’ll gain from reading this article:

- The four building blocks of plastic resins give you a materials foundation.

- Material selection will be informed by studies on the performance attributes of eight common materials.

- Using real-world failure histories on medical device cases, we’ll show how we identify and mitigate risk in custom plastic injection molding manufacturing.

Why Is This Guide Trustworthy? JS’s Materials Science Practice

At JS, we don’t simply perform injection molding, we act as materials scientists. For example, when we select nylon PA66, we don’t simply consider strength. We are more concerned with water absorption. For every 0.3% of water absorbed, the part increases by approximately 0.15%. This has a disproportionate impact on the precision of the end plastic injection molding parts, so these small differences matter when we create the drying cycle.

These abilities are acquired through experience in the real world. From PPS connectors with a 150°C heat rating for a car engine compartment to PEEK orthopedic devices for human implantation, we’ve machined at least 5,000 distinct parts. This has educated us firsthand about how to select materials to actually save money without jeopardizing the expensive disasters of batch failure. These skills were actually acquired through the cost of millions of dollars.

“As Doug Smock, Technical Director of the Injection Molding Association of America, often emphasizes, In plastics applications, the cost of failure far exceeds the material itself.”

We combine this rigorous approach to materials science, a deep understanding of process, and practical experience. This way, our advice stands up to scrutiny and truly helps you solve problems and avoid detours.

Dissecting Plastic Resin: How The Four Components Affect Performance

Let me share the “secret formula” of plastic resin. It’s not just a simple raw material, but a carefully crafted performance formula of multiple ingredients. Much like mixing a good medicine, the amount and combination of each ingredient directly impacts the performance of the final part. Let’s break down these four components:

(1) Base Polymer (Majority: 60%-99%):

This is the “backbone” of plastic resin. It determines the material’s fundamental properties. For example, polypropylene (PP) has a comparatively soft molecular chain and hence is very resistant to repeated fracturing and bending. In contrast, polycarbonate (PC) has a rigid benzene ring structure within its molecular chain and hence is naturally strong and resistant to deformation. Choosing the right main material is the beginning of making certain that a part will be strong enough to withstand the stresses of its proposed application.

(2) Reinforcement fibers (glass fiber and carbon fiber):

When we desire a part to be stronger and less deformed, we have to call for these “strongmen.” The incorporation of 30% glass fiber in nylon can make it resistant to bending and deformation twice or thrice as much!

But nothing comes free. These rigid fibers act like sandpaper, accelerating mold wear and increasing costs. They also create varying strengths in the material in different directions. Not accounting for this partially and mold design can lead to warping or distortion.

(3) Plasticizers, flame retardants, and other additives:

These are the “hidden tuners” of material properties. For example, to make ABS plastic flame retard (achieve a UL94 V-0 flame rating), flame retardants must be added. But don’t forget that excessive flame retardant will induce brittleness in the material.

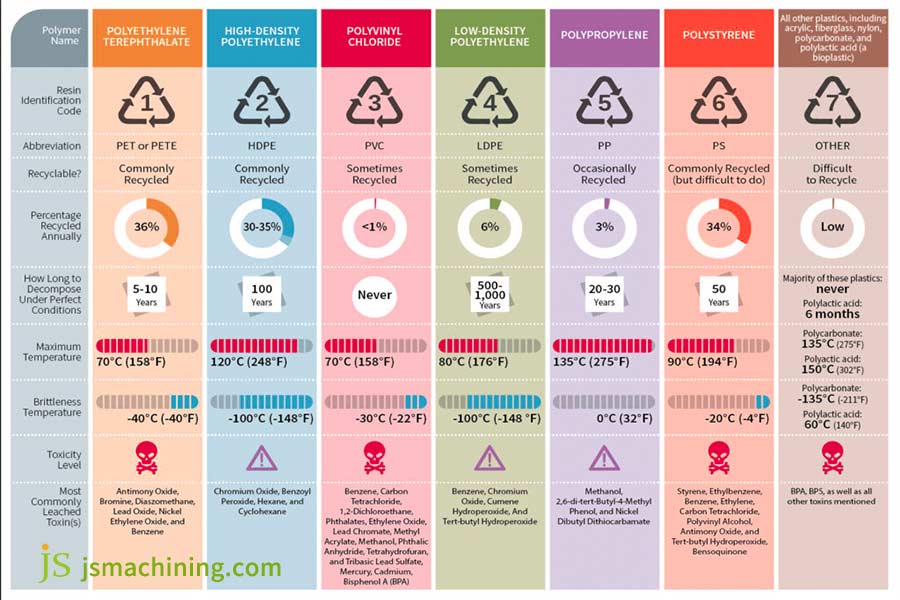

Plasticizers help materials like PVC flow more easily in molds. However, there’s a significant risk: if the additives are not chosen correctly or added in the wrong amounts, they can gradually leach out of the product. This is particularly dangerous in medical products, where these leachates can be toxic and harmful to human cells. This risk cannot be taken lightly.

(4) Colorants and Specialty Additives:

It is not an easy task to color plastics, it is a complex process. Some metallic pigments (such as aluminum powder) will interfere with the rhythmic structure of crystalline plastic resins such as nylon, causing dimensional irregularities. Some organic pigments will decompose spontaneously at high injection molding temperatures to yield various shades of color in the same run of parts, causing extreme color variation. Choosing the color is also dependent on the material properties and processing conditions.

The collective attributes of plastic resin result from the combined effect of the base polymer, reinforcement fibers, additives, and pigments. It’s only through having a balanced “recipe” in adjusting them properly that we can balance strength, precision, safety, and price.

At JS, we dig deep into the operation of these components daily, helping customers select right materials correctly, process streamlining, and produce stable and cost-effective plastic injection mold parts. Do you desire your parts to have stable performance and smooth manufacturing? Call JS anytime!

Performance Overview Of Eight Injection Molding Resins

Customers often ask us which plastic to choose, and this is truly a technical task. I’ve shared the core characteristics and selection criteria for the eight most common injection molding resins we encounter, drawing on our experience. I hope this will be helpful:

| Resin name | Core advantages | Key Weaknesses&Application Risks | Typical application scenarios | Be careful when selecting |

| Polypropylene (PP) | The most affordable price (about 1.2 USD/kg), good resilience, and maximum production capacity. | At low temperatures, it may become brittle (with a sharp decrease in performance at around minus 10 degrees), and packaging boxes in cold storage environments may suddenly crack. | Daily containers and regular packaging. | Be absolutely cautious in cold chain logistics scenarios! |

| ABS resin | The surface can be made very beautiful and smooth, especially easy to electroplate. | Sunbathing can easily cause yellowing, and outdoor equipment’s appearance drops sharply after prolonged use. | Electronic product casings and toys. | Long term outdoor components need to consider other materials. |

| Polycarbonate (PC) | Strong impact resistance, as sturdy as metal. | I am particularly afraid of internal stress and contact with chemical solvents, which may cause cracking if exposed to gasoline or alcohol. | Safety helmets, goggles, and components that require transparency. | After injection molding, the stress should be handled properly and kept away from solvents! |

| Nylon PA6 | Durable and durable, it is very suitable for making gears. | Especially fond of absorbing water (1.5%), the gear size may increase in humid environments, which may cause the machine to jam. | Ordinary gears and wear-resistant parts. | Do not use it for gears in precision or humid environments (such as underwater robots)! |

| Polyoxymethylene (POM) | The size is as stable as Mount Tai, and the precision gear pitch error is very small. | Formaldehyde gas will be released at high temperatures, and the concentration in small spaces inside the car may exceed the standard. | High precision gears, automotive small parts. | Ventilation and concentration are key factors when using in car interiors and enclosed high-temperature spaces! |

| PBT resin | It hardly absorbs water and can maintain good insulation even with heavy moisture. | I am particularly afraid of strong alkali, as it can easily crack and break when exposed to alkaline cleaning agents. | Electrical switch and relay casing. | Used in industrial cleaning equipment? Quickly switch to a more alkali resistant material! |

| Polyphenylene sulfide (PPS) | Champion of high temperature resistance (260 ℃ without deformation), suitable for engines. | Born brittle, sudden strong impact (such as sudden braking) may cause fracture. | High temperature components such as turbocharger housing. | Components that need to withstand impact (such as brackets) must be reinforced with fibers (but it is difficult to make thin-walled parts). |

| Polyether ether ketone (PEEK) | The performance remains strong at high temperatures (260 ℃ is no problem), and the overall performance is top-notch. | expensive! (Over 100 USD/kg). | Extreme environments such as aerospace components and human bone implants. | Unless extreme high temperature, high strength, and biocompatibility requirements are met, wallets cannot withstand it. |

Practical replacement solutions for common problems:

|

Problem scenario

|

Raw materials for the original plan | Risks/Issues | Better solution | Effect | cost |

| Underwater precision gear | PA6 nylon | Water absorption expansion, transmission stuck. |

Replace with PPA high-temperature nylon.

|

Water absorption rate drops sharply (only 0.3%). | Significant increase in cost. |

| Strong alkali resistant clean environment shell | PBT | Corrosion and fragmentation by alkali. | Switch to PPS. |

Excellent chemical resistance (especially alkali resistance).

|

Cost increase, brittleness needs attention. |

| Supports requiring high impact toughness | Pure PPS | Easily brittle under impact load. | PPS+30% carbon fiber. | Significant improvement in resilience. | More difficult to inject thin-walled parts, resulting in increased costs. |

Choosing plastics is an exercise in balancing advantages against disadvantages, there isn’t one material that suits all. Understanding the problems your piece will have can avoid future issues. If you’re uncertain, call us JS. With our internet plastic injection mold technology, quick development of a pilot sample is considerably cheaper and simpler than later finding problems.

The 5 Dimensional Decision Compass For Plastic Resin Selection

For those struggling with material selection, choosing plastics is like choosing a partner: there’s no “best,” only “most suitable.” Stop asking which resin is the best. Before making a selection, be sure to clarify the following five dimensions:

Dimension 1: Mechanical Load—What forces will your part withstand?

Don’t just look at the “strength” rating on the material data sheet!

For example, a PP shelf will meet the static load-bearing mark by static loads, but loaded with a prolonged length of heavy weights, will creep slowly as in slow motion (a creep phenomenon). Switching to PA66 nylon with 30% glass fiber is almost half the price, but after ten years might creep less than 1 mm, offering stability.

Dimension 2: Thermal Environment—What is the part’s operating temperature?

Materials soften in high temperatures! A car manufacturer lost out while using conventional ABS (heat deflection temperature about 90°C) for a small component near the motor compartment. The component softened and deformed, however, when driven at high speeds in summer months. It was remedied by substituting high-temperature-resistant PPS (heat deflection temperature 260°C), but the mold, especially the hot runner, had to be re-molded and fitted, a considerable expense.

Dimension 3: Chemical Exposure—What media will the part be exposed to?

Chemical corrosion is an “invisible killer” that’s likely to be overlooked.

The housing of a cleaning robot, for example, was fabricated using common PS plastic. Continuous contact with floor cleaners caused blistering and cracking within just three months. Its lifespan was doubled when changed to chemical-resistant PBT plastic.

Dimension 4: Regulatory Certification—What standards does the product have to meet?

This directly determines if your product can be sold and to whom!

Baby bottles are a great example: Standard PC plastic can be tens of yuan per kilogram, but top-of-the-line PC materials with food-grade certification can be 60% or more more expensive. This certificate cost is the cost of market entry and cannot be avoided.

Dimension 5: Total Cost – Is it sufficient to just consider the unit price of the resin?

Don’t just examine plastic pellets’ unit price when it comes to costs! Think about the overall cost.

For instance, top-grade PPSU plastic used in medical fields could be priced at $150 per kilogram, 15 times that of normal ABS (about $10).

It does come with one main advantage: it is naturally resistant to repeated repeated steam sterilization at high temperatures. The use of regular ABS for medical parts entails additional sterilization time and expense. In creating custom plastic injection mold, while PPSU is more expensive, it eliminates the sterilization process, and thus it can be more cost-effective in the long term.

Accurate material selection requires a systematic assessment of load, temperature, chemical, certification, and total cost. Unsure of your needs? Contact our JS engineers directly. Drawing on our experience in custom plastic injection mold manufacturing, we can help you find the optimal solution!

Life And Death Decision: The Rehabilitation Of Resin For Medical Ventilator Housings

That incident, ventilator housings cracked in multiple hospitals, nearly causing a major crisis. As a core materials engineer, I deeply understood that the reliability of plastic resins used in medical devices is directly related to patients’ lives.

The Cause of the Difficulty: Disinfectant “Corrodes” the Plastic

In trying to save costs, a ventilator manufacturer chose standard ABS plastic (at the time costing about $14 a pound). But housings were frequently disinfected at hospitals, cleaned with chlorine-based disinfectant up to six times a day. As a result, in two months, many ventilator housings began to crack, with some developing spiderweb-like cracks across their surfaces, and some actually cracked during shipping.

JS laboratory tests showed that the housing strength decreased over 40% after 100 disinfection cycles. This is as if the plastic was “being eaten away” by the disinfectant. The disinfectant leached out the rubber component in the ABS, and the material fell apart internally. To make matters worse, the internal stress generated during injection molding at the housing clips accelerated the crack growth, so the housing clips became the weakest link.

JS’s three-step solution:

Step 1 – Deep testing and verification:

Disinfectants are the culprit of degrading critical ABS components, and residual stress is the culprit of prolonging crack growth. Merely repairing the ABS solution is not effective, material replacement is necessary.

Step 2 – Selecting PC/ABS alloy:

We abandoned the traditional ABS repair approach and turned to a PC/ABS alloy solution.

Why use it?

PC is a corrosion shield, highly resistant to disinfectant corrosion. ABS is a shock absorber, which provides impact protection. The two combined are 1+1 more than 2.

Even as its cost increased to approximately $36 a pound, a 1.8-fold increase in unit price, we redesigned, reducing the casing thickness to 2.8mm from 3.2mm. Most significant, we maintained the original plastic injection molds for the same amount of money, letting valuable mold costs wither away. The ultimate cost of the device, ultimately, increased by only 17%, a far cry from recall losses.

Step 3 – Rapid certification!

We quickly sent the new formula out for testing and were amazed at the results: cell survival rates in the soaking solution were 99.1% (well over the national standard of 90%). We received key international certification in just 72 hours, overcoming the market entry barrier.

Achievement: Turning a crisis into a commercial opportunity

(1) Leap in performance:

The new case passed 2,000 tests for sterilization (equivalent to five years of use) without experiencing any damage. Its impact strength at -30°C was four times higher than the old case, and shipping damage was completely eliminated.

(2) Business Turnaround:

The most immediate impact was the cancellation of the recall of 100,000 units at a cost to customers of approximately 210 million yuan! Furthermore, the lifespan of the units was tremendously extended from two to eight years, generating approximately 30 million yuan yearly revenue from charging for service alone. The solution further became the industry standard for corrosion-resistant casings.

This life-or-death decision made us realize that the selection of materials for medical devices carries a heavy burden on human life and reputation. Don’t let short-sighted cost-conscious choices create significant risks! When selecting materials, always prioritize rigorous, real-world testing. I’m a JS engineer, and we specialize in solving tough material problems.

FAQs

Q1: Are engineering plastics always better than ordinary plastics?

The choice between engineering plastics and normal plastics is based on use. For shampoo? Normal PP plastic is cheap and good enough. But for gears, you need an engineering plastic like nylon to endure wear and tear. The biggest problem is to use the wrong material just to save money, and this could lead to frequent parts failure and higher repair bills—that is the real cost!

Q2: Why is PA66 nylon more expensive than PA6?

PA66 nylon is more expensive than PA6 mainly because it is heat resistant and can withstand temperatures in the range of 260°C for short periods.

For parts like those in the engine area close to heat sources, PA66 is safer. For everyday gears, PA6, which does not require as much heat resistance, is sufficient and less expensive. The key is the application; going cheap with the wrong material can cost more.

Q3: How do I avoid material traps when shopping online?

When buying materials online, do not merely look at the price. Ensure that you request the supplier for these three:Official reports of material testing and certification, specific injection molding production parameter settings, and real-case studies of problems with the same material.

If these three are not available, do not sign hastily. This will minimize the chances of poor material performance or operational issues, saving your time and effort.

Q4: What should I be looking for when choosing a medical part resin?

The first thing to do when choosing a medical part resin is to find out how it is sterilized!

If it’s constantly wiped with alcohol, materials such as PPSU will hold up better. If it’s being sterilized with ethylene oxide gas, PC will generally pass the test. Don’t omit verification to cut costs on testing fees, only to have the component fail during sterilization and then endure a recall and financial loss. That’s an actual loss!

Summary

We’ve seen many problems that arose from the incorrect choice of resins. Choosing the incorrect plastic resin is to plant a time bomb in your product—the ultimate cost is not only in the wasted part, but in the significant cost of redesigning the plastic injection mold, and even the loss of customer trust. In custom injection molding business, cost control is dependent on scientific material selection, not targeting unit prices.

Avoid making part material selection a headache! Upload your part specifications to the JS platform today. Our engineers will provide the following within 24 hours:

- Comparison of three optimized resin options.

- Cost-performance simulation curves.

- Feasibility assessment for real production.

Want to know prices upfront? Use our online plastic injection molding services. Simply fill out your parameters and get a comprehensive, open breakdown of plastic injection molding price and part quotes in real-time. Have expert material selection be the launching point for your product’s success.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: TPE vs. Silicone: What Is The Difference Between Them? - JUSHENG