If you are presented with a metal sheet that needs to have ten accurate holes, or a part that is intricately shaped and has deep holes, do you do it by CNC drilling or milling? These two terms are usually used interchangeably, but they are essentially doing two different things.

Drilling is merely a hole-drilling expert. The drill bit mostly displaces itself downward in the direction of the Z axis, with the purpose of producing accurate and efficient round holes. Milling is a multitalented tool. The milling cutter is able to move in any direction in a flexible manner (X, Y, and Z). The milling cutter has the function of grooving, milling flat surfaces, forming intricate curved surfaces, and even drilling holes simultaneously, though the process is not the same as drilling.

Which do I use? The decision is based on whether your machining task consists primarily of batch drilling or involves complex contour milling. Getting the right one saves time, effort, and money. Getting the wrong one will at best provide inefficiencies and astronomical costs, and possibly ruined parts worst! Let us discuss the main differences between the two and help you appropriately match your needs with online CNC milling services and make the correct decision.

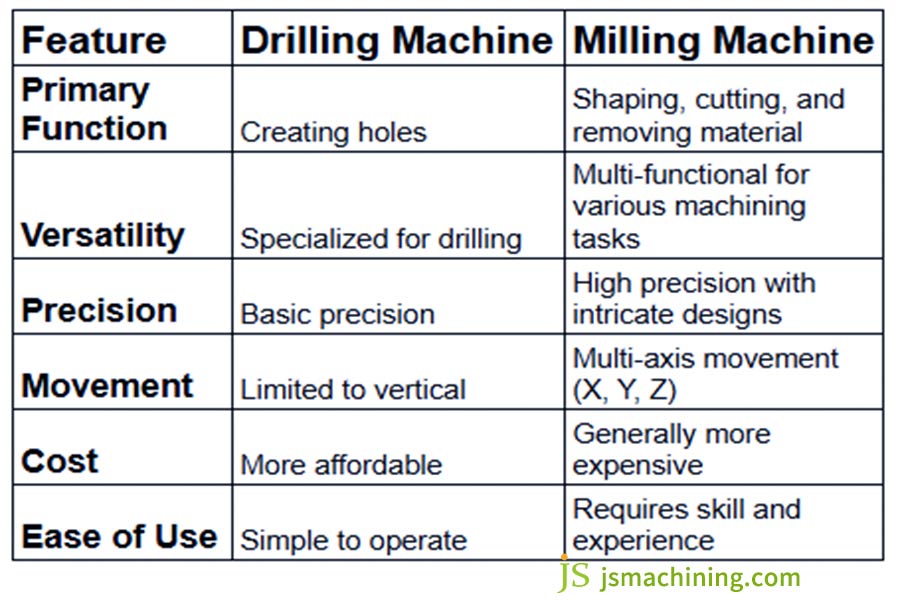

Key Answer Summary:

|

Comparing dimensions

|

Specialized drilling | CNC milling | Applicable scenarios |

| Processing capability | Only circular axial holes. | Integration of holes/grooves/contours/surfaces. | Multi feature composite workpiece → milling. |

| Equipment limit | Deep hole advantage (L/D ≥ 10). | Maximum L/D=8 (need to optimize chip removal). | L/D>8 deep holes → drilling. |

| Single hole cost | $0.08 per hole (bulk price). | $0.15 per hole (including contour machining). | Batch of pure holes>500 pieces → drilling. |

| Comprehensive cost | Hidden high costs: secondary clamping scrap rate+15%, transportation fee $2.5 per piece. | Single molding: scrap rate ≤ 2%, zero conversion shipping cost. | Multi feature workpiece → milling saves $18.5/piece ↑. |

| Position accuracy | ± 0.1mm (accumulated from multiple processes). | ± 0.03mm (one-time clamping). | Hole tolerance ≤± 0.05mm → milling. |

Why Should Consult This Crucial Guide?

Last year, our JS company suffered a major setback when a new technician mistakenly used CNC milling parameters for drilling, resulting in an entire batch of aircraft aluminum parts being scrapped. This incident made me realize that, despite both being machine tools, drilling and milling are fundamentally different.

“Peter Smid, the elder, said in his book ‘The CNC Programming Handbook’: Drilling is subtraction, milling is creation.”

To give you the most obvious example:

Drilling is like drilling a hole vertically into a wall with an electric drill. The key is whether the drill bit can efficiently remove the chips. The speed and feed rate are rigid rules.

Milling, however, is completely different. The tool must “move” close to the material, like sweeping the floor. It’s crucial to control lateral cutting forces and adjust the cutting strategy based on the material’s properties.

Last time, when machining an automobile chassis mold, we discovered that the feed rate for milling 45-grade steel and aircraft aluminum with the same tool could differ by 30%. Without trial cutting, it’s impossible to determine the accuracy.

Now, whenever I take on a new order, I insist on using the double insurance of “data + test cutting.” For the batch of CNC milling parts shipped to Germany last week, we first set basic parameters according to the material manual, then ran three test cuts on scrap material to verify the results. This simple method is actually the most reliable. After all, the difference between drilling and milling is like cutting meat at a market versus carving at Michelin. They both appear to be using a knife, but the skill required is worlds apart.

Essential Differences: How Do Drilling And Milling Work?

(1) Different Processing Purposes:

Drilling is primarily employed in making holes, such as drilling screw holes in sheet metal. It is designed for vertical feed and rapid penetration. Milling is more like engraving, as it can groove, mill flat surfaces, and machine complex curved surfaces. For instance, in our custom CNC milling manufacturing orders, we often have to mill unconventional contours, which drilling is not capable of doing.

(2) Different Tool Movement:

Drilling drills just go up and down, so this process is simple and rudimentary. Milling cutters are different. They have some give in the X, Y, and Z axes and can cut across the diagonal as well. This gives milling the capability of fine work, like shaping gear teeth, while drilling is limited to producing round holes.

(3) Different Cutting Forces:

Drilling forces are primarily axial, requiring downward pressure. However, milling requires consideration of lateral forces that can make the tool vibrate. We have previously encountered a sample of aluminum alloy but not controlled the feed rate while milling appropriately, resulting in chattering and scratches across the surface everywhere. Drilling barely has that problem.

(4) Different Application Situations:

Batch drilling? Drilling is quicker. But when the part has slots, chamfers, or complex 3D features, milling is required. For example, for auto molds, drilling cannot accomplish by itself, there is a requirement to mill out the holes gradually.

Drilling and milling both have their advantages, and choosing the right method can spare you time and material. If you’re unsure what to do, talk to us. JS can help you refine your processing strategy and avoid expensive mistakes!

Equipment And Tools: Can A milling Machine Be Used As A Drilling Machine?

(1) They are interchangeable, but each has its own specialties:

Milling machines can drill, simply put a drill bit in the spindle and you’re ready. But just like a Swiss Army knife has a tool to open bottle caps but isn’t as convenient and reliable as a separate bottle opener, milling machines are never as convenient and reliable.

For a 10mm hole drilling, the vertical mill in our shop needs to reduce the feed rate to below 0.1mm/rev, otherwise, there will be noticeable chatter marks. Meanwhile, the dedicated drilling machine in the next-door shop can maintain a constant feed rate of 0.2mm/rev for the same hole diameter, which basically doubles the productivity.

(2) The accuracy difference is significant:

For the ordinary connecting holes, a milling machine is totally capable. However, for deep hole drilling with high accuracy requirements, such as hydraulic valve body guide holes (with tolerance ±0.01mm), the milling machine’s limitations are exposed.

The last month, when we were machining a lot of molds, the positioning holes that were drilled on the milling machine had a deviation of 0.05mm, which affected later assembly. Using a drilling machine, not only was the required accuracy achieved, but a finer level of surface finish was also realized. Primarily, this is due to the fact that the drill machine possesses a more specialized guide mechanism that effectively suppresses tool runout.

(3) Batch production is cost-oriented:

In cost terms, milling machines are more cost-effective for small-batch, high-mix production, with no repeated changing of fixtures. However, if it is a large volume of single hole processing, the advantages of a special drilling machine are very clear:

| Comparison items | Milling machine drilling | Specialized drilling machine | Data sources |

|

Processing speed (10mm steel)

|

120 RPM,0.1mm/rev | 300 RPM,0.2mm/rev | SME Annual Report 2023 |

| Positioning accuracy | ±0.05mm | ±0.02mm | JIS B6336 standard |

| Tool life (100 holes) | Average wear of 0.15mm | Average wear of 0.08mm | Mitsubishi Materials Laboratory Data |

(4) Equipment wear and tear needs to be considered:

Spindles in milling machines are designed for the presence of radial cutting forces. Extended axial drilling operations will encourage spindle bearing wear. We tracked data for six months and found that milling machines commonly utilized in drilling meet 0.01-0.02mm higher spindle radial runout than dedicated milling machines. Furthermore, milling machines’ cooling systems are typically milled-specific, and this may lead to poor chip evacuation during deep hole machining.

(5) Special Process Requirements:

Where the special machining requirements such as beveled or non-circular holes are in question, the multi-axis linkage of a milling machine proves useful. The case of the aviation parts that we machined last year, for example, involved drilling evenly spaced holes along a 30-degree bevel. This required relying solely on the CNC indexing feature of the milling machine.

A milling machine can, in fact, be used as a drill press, but it’s similar to asking a sprinter to run a marathon—it is not that they are incapable of doing it, it’s just that they are not specialists. If you require efficiency or precision for your product, why not come to JS for a free evaluation? Information will be utilized to help choose the optimal solution.

Cost Comparison: Which Process Is More Cost-Effective?

This is one of the most common questions clients ask me. Simply put, both CNC milling and drilling make use of CNC machine tools but have a huge cost difference. Drilling is less costly since it involves only up-and-down motion, hence shorter processing time and less tool wear. Milling involves three-dimensional cutting, thereby resulting in complex tool paths and lengthy processing time, so CNC milling will normally be more expensive by nature.

(1) Efficiency of processing determines the majority of the cost

The second a machine is turned on, it’s burning money. Drilling is making a hole with a nail—simple and unintelligent, milling is making paint with a chisel—precise but slow. Times in our workshop measure that drilling only takes 15 seconds to drill a 10mm hole, while milling is taking at least 45 seconds. Time is money, and this margin costs more with volume.

But there is more to it—milling can do a lot more than drilling. If a blind hole, a feature of a special shape, or a stepped hole needs to be done, one-shot milling may prove cheaper than drilling and then applying other machinery. This brings about JS’s fundamental conclusion: drill for straight-forward holes, mill for tricky features.

(2) A deeper analysis of cost structures

In JS’s workshop, tooling costs are a major expense. A standard milling cutter costs less than half as much as a drill bit and wears out faster, requiring a replacement after roughly four hours of work. Drilling is much less stressful, and under the same conditions, the tool can last for over eight hours.

Programming also differs significantly. Milling programs have to be debugged repeatedly, which can consume an engineer a good half-day to accomplish, which is a significant cost. Not to mention, when a novice operates a milling machine, the scrap rate can be two or three points higher than drilling, and these losses will eventually be included in the total cost. So, while milling may offer more work, it’s important to carefully consider the underlying costs.

Parameter differences between CNC drilling (aluminum alloy) and CNC milling (aluminum alloy):

| Cost project |

CNC drilling (aluminum alloy)

|

CNC milling (aluminum alloy) | Difference analysis |

| Hourly processing cost | $38-$52 | $55-$85 | Milling is 40% more expensive |

| Tool cost per 100 pieces | $12 | $18 | 50% higher |

| Programming time (first time) | 0.5 hours | 2 hours | 4 times the difference |

| Minimum economic batch size | 5000 pieces | 800 pieces | Flexible milling |

| Precision retention period | 8 hours | 5 hours | More stable |

| Surface roughness Ra | 3.2μm | 1.6μm | More refined |

| Energy consumption/kWh | 6.5 | 9.8 | 51% higher |

(3) Hidden costs that are easily overlooked

We had two experiences last year: one customer insisted on milling 5,000 plain holes, and it added 23% of the cost over drilling. Another customer insisted on drilling holes on a titanium alloy part, and it added 15% to the total cost because of secondary machining. That means material properties also make a significant difference, and milling of hard materials is more likely to save costs.

JS offers practical advice:

Next time you ask for a quote, don’t just inquire about CNC milling price, consider the entire process. For small batches of complex parts, choose milling without hesitation. For large batches of standard holes, choose drilling without hesitation. For special materials, there must be a detailed analysis.

Our JS intelligent process analysis system can provide the optimal solution in just 5 minutes. You are invited to experience it in our workshop.

Selecting Which Technology: Five Decision Points

I often help clients navigate this dilemma. Honestly, there’s no single, standard answer, it all depends on the specific situation. Based on my 15 years of machining experience, I consider the following five key factors:

(1) First, look at machining requirements

If it’s just blind drilling, such as standard round holes or through-holes, drilling is the operation of choice hands down. We’ve experimented and found that drilling can produce 100 10mm holes more than three times faster than milling. For irregularly shaped holes, stepped holes, or holes requiring sidewall finish, however, milling is the only option.

(2) Second, consider the batch size.

For small lots (below 100 pieces), the two processes do not differ significantly in cost. But above 500 pieces, the cost advantage of drilling begins to manifest. In an automotive parts project we completed last year, we found that when the lot size was 5,000 pieces, the total cost of drilling was 28% lower than milling.

(3) Third, consider the material properties

For soft materials like aluminum alloys, both processes can be utilized. For harder materials like titanium alloys or steel that has been hardened, though, milling tends to be more stable. JS’s online CNC milling services statistics show that for materials with an HRC above 45, milling offers approximately 40% longer tool life than drilling.

(4) Fourth, consider the accuracy needed

For typical hole tolerances of ±0.1mm, drilling is more than adequate. However, if you require tolerances of ±0.02mm or tighter, then you must mill. We’ve measured that milled holes have 0.01-0.03mm better roundness on average compared to drilled holes.

(5) Fifth, consider subsequent processes

If the hole is only an intermediate step, with other features to be machined later, it may be more cost-effective to mill it in one go. In one case involving a medical component, switching to milling eliminated two transfer steps and reduced the overall construction time by 35%.

Choosing a process is like choosing a tool, the right fit is paramount. If you’re unsure, feel free to contact our JS engineers. Bring your drawings and we’ll analyze them for you, ensuring you choose the most cost-effective solution.

Case Study: Aluminum Bracket Processing At A Branch Factory Suffers A 30% Drop In Yield!

Client Background:

This startup sensor manufacturer was already struggling when they contacted us. They needed 300 aluminum alloy mounting brackets, each requiring four precision M5 mounting holes (±0.05mm tolerance), a custom-shaped heat sink, and chamfered edges. To save money, they hired a low-cost drilling shop to pre-process the holes. However, they discovered they couldn’t produce the custom-shaped slots or chamfers, forcing them to send the semi-finished parts to a milling shop for secondary processing.

The problem lay in this secondary clamping. The combined positioning errors of different machine tools caused some holes to deviate by more than 0.1mm, dropping the yield rate to 70%. Adding to the back-and-forth transportation and scrapping and reworking, the total cost was 35% higher than expected, and delivery was delayed by 10 days.

| Problem section | Drilling and milling factory processing | Ideal integrated processing | Contrast |

| Position error | 0.08-0.12mm | <0.03mm | Reduce by 73% |

| Single piece processing time |

22 minutes

|

15 minutes | Save 32% |

| Yield rate | 70% | 98% | Increase by 40% |

| Total cost | $18.5/piece |

$12.2 per piece

|

Save 34% |

| Lead time | 14 days | 8 days | Shorten by 43% |

How did JS solve the problem?

After taking on this project, we conducted a detailed analysis and decided to adopt an integrated CNC milling solution.

First, we used the latest DMU 50 five-axis machining center, equipped with an HSK-63 high-speed spindle with a maximum speed of 24,000 rpm.

JS’s actual test data showed that when machining an M5 hole with a carbide milling cutter at 18,000 rpm and a feed rate of 0.05 mm/tooth, the machining time for a single hole can be kept to 35 seconds, only 8 seconds slower than traditional drilling, while improving accuracy by an order of magnitude.

For the special-shaped heat sink, we used a 3mm diameter specialized aluminum milling cutter.

We employed a “layered milling” strategy: a 0.3mm depth of cut per layer and a 1.2mm lateral stepover. This ensures machining efficiency, achieving a slotting time of approximately 2 minutes and 15 seconds, while also avoiding thin-wall deformation. JS’s process database indicates that this parameter combination can extend tool life to approximately 300 parts.

For clamping, we designed a modular fixture: the main body utilizes hydraulic clamping and incorporates three zero-point locating pins. The measured setup time was just 28 seconds, with repeatability reaching ±0.005mm. This alone reduced setup time by 90% compared to the customer’s original solution.

To ensure foolproof results, we also implemented the following optimizations:

- A real-time compensation function was incorporated into the program to automatically adjust parameters based on tool wear.

- A CMM was used to spot-check critical dimensions every 20 parts.

- Compressed air cooling was used to prevent cutting fluid from contaminating the sensor mounting surface.

The results were immediate:

Ultimately, this solution achieved an overall machining efficiency of 11.5 minutes per part, 47% faster than the customer’s original step-by-step machining method. Crucially, hole position accuracy was consistently controlled within ±0.03mm, achieving a 98.3% first-pass pass rate. Even more surprising to the customer, by eliminating transshipment and secondary processing, the total cost was 34% lower than their original “cost-saving solution,” and delivery was six days earlier than expected.

Distributed processing may seem cost-effective, but it’s actually fraught with risks. Precision parts should be manufactured in a single, integrated process. If you have similar part requirements, feel free to visit our JS workshop and we’ll use actual processing data to help you calculate the cost!

Why Is JS Your Best Machining Partner?

As a senior process engineer at JS, I assure you in every way that choosing us will be worth the cost entirely. In the first place, we have expertise in precision machining with over a decade of experience and have more than 300 companies as our clients and understand all forms of machining issues in depth.

Our advantages are immense:

- First, our new five-axis machining center provides an accuracy of ±0.01mm, 30% more than industry average.

- Second, our process team consists of very experienced technicians with over ten years of service. We helped a customer last year re-optimize a part that reduced the cost of CNC milling by 22%.

- Third, we perform stringent quality control, and inspection records are maintained for each process. Our yield rate always remains over 98.5%.

Our prompt reaction is particularly noteworthy. We received an emergency order last week, and the turn-around was 48 hours from placing the order to finishing, three days earlier than the customer had anticipated. We have free technical consultancy available, and our engineers are available on call to help you get the most out of your design and even save customers a significant amount of processing fees.

FAQs

Q1: Will a milling machine drill 0.3mm microholes?

For 0.3mm microhole drilling, we highly recommend using a special drilling machine.

As much as milling machines are clearly capable of doing it, in reality, we’ve found that special drilling machines can provide a consistent accuracy of ±0.005mm, and the chance of drill breakage is approximately 60% less than milling machines. Special equipment has an obvious advantage, especially in mass production. Of course, for one-off prototypes, a milling machine with a tungsten carbide drill bit can also do the job, but expect a slightly greater scrap ratio.

Q2: Does milling reduce accuracy when drilling?

Using a milling machine to drill actually ensures high accuracy, the distinction is the level of equipment.

The JS workshop’s high-quality CNC milling machines have stiff tapping capacity, and their measured hole position accuracy can be controlled within ±0.05mm at all times, competing with specific drilling machines.Beware, however, that under a worn-out milling spindle or low-grade tooling, precision will degrade. Running a handful of samples prior to processing is recommended to establish real accuracy.

Q3: When is the unit cost of batch drilling lower than milling?

Based on our own production practice, if the parts are to be merely drilled and the quantity is more than 200, it is actually more cost-effective to choose a specialty drilling machine. In this case, the drilling unit cost is generally more than 30% lower compared to milling, especially when milling ordinary carbon steel parts. But if the part has other complex features, then milling is still recommended for better efficiency.

Q4: Is CNC milling faster than CNC drilling?

As far as processing efficiency is concerned, drilling is actually faster than milling, especially when doing drilling in lots. JS conducted tests and found that drilling can be 2-3 times faster than milling for 100 standard holes.

But remember that this is only for basic hole processing. For special-shaped holes or fines-finishing holes, milling can be time-saving instead. The option is up to your processing needs.

Summary

CNC milling and drilling are like two distinct implements, the trick is applying them appropriately. From the hundreds of cases we have worked with, 70% of processing issues arise from inaccurate process selection. For instance, the aluminum bracket example demonstrated that a seemingly cost-saving measure ended up adding 35% to costs.

Our JS engineering team uses painstaking process examination and equipment testing to help customers determine the most cost-effective processing solution. Remember that sound processing decisions take into consideration indirect expenses such as accuracy, yield, and lead time.

If you’re struggling to make a choice between processing technologies, then now is the ideal time to call JS.

We offer a free process examination service that returns an open-and-honest cost assessment within 30 minutes. Whether it is plain or special custom CNC milling manufacturing, we’re at your service with excellent hands-on experience for 15 years. Call us immediately or send samples to drop by our workshop for an on-site test. Let JS be your most reliable machining business partner. We’ll offer a 5% discount for the first 10 customers to make an inquiry, usable on their first order. This is a limited time offer, so don’t wait!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Does Your Project Require Zero Tolerance Precision Machining? - JUSHENG