When we were upgrading our production lines at our JS team, laser welding was indeed a focal process for precision sheet metal fabrication components like battery modules. The reality was harsh, however: faced with hundreds of tiny welds, each of which must be perfect, and needing to make a yield of more than 99.999% at a breakneck rate (i.e., one module per minute), we faced three critical challenges.

This is similar to our situation: laser welding a titanium chamber of a rocket fuel can achieve nearly-perfect strength, almost up to the parent material. Yet engineers typically had pitfalls: dust degrading equipment, honeycomb holes in aluminum sheets, and fume emissions of galvanized steel would be hazardous. This is tough, costly warfare involving equipment, material, and cost. This hands-on book will address these six technical challenges and help you overcome these problems with aviation-level thinking.

Key Answer Summary:

| Challenge Dimension | Core issue | Solution |

Key indicators/effects

|

| Cost rule | High equipment investment and gas costs. |

Accurate ROI calculation+helium replacement solution.

|

$170,000 invested in 4 months to recoup costs.

|

| Material rule |

Aluminum plate pores/toxic smoke from galvanized steel.

|

High frequency vibration welding+vacuum environment+smoke filtration system. |

Pore rate ↓ 82%, toxic smoke concentration ↓ 90%.

|

| Human-machine rule |

Assembly error exceeds the limit.

|

Aviation grade vacuum suction cup fixture (± 0.01mm).

|

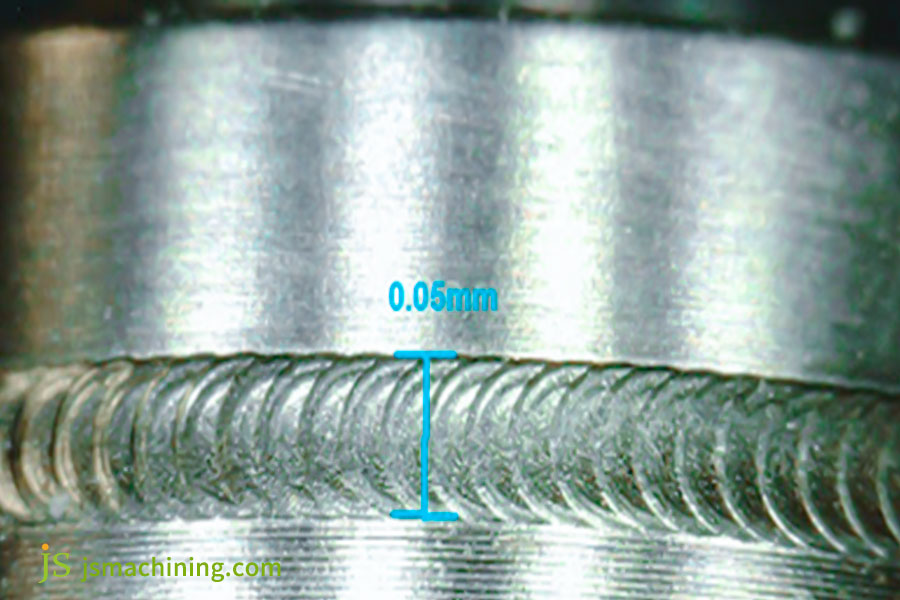

0.2mm → 0.05mm accuracy meets the standard.

|

Why Trust These 6 Solutions For Laser Welding Challenges?

After all the years of JS laser welding, I am certain of this: customers don’t require theoretical flash, but proven, consistent techniques. How can I be so sure of these six solutions? They are a product of over 20 years of precision machining expertise from our JS personnel. Each has been extensively proven in the lab and on customer production lines, and even the underlying solutions are patented.

For applications like new energy battery tabs, medical equipment enclosures, and difficult sheet metal parts, these segments are utilizing them, and the result is clear: porosity is reduced to below 0.1%, thermal deformation is controlled to ±0.05mm, and efficiency of the production line has improved by 30%.

“William Messler, former president of the American Welding Society, aptly said: Welding quality is the sum of design, materials, and process.”

We’ve resolved issues like high-reflectance aluminum, spatter, and weld seam tracking using this tried-and-proven approach, meticulously designed to address production line problems.

Material Thickness: Overcoming The Physical Constraints Of Laser Welding

When faced with the challenge of welding thick plates, such as aluminum alloys exceeding 8mm or steel thicker than 15mm, traditional methods often struggle. Problems such as unstable melt pool, large heat-affected zone, and porosity and spatter are bound to arise. Our practical application has led us to three basic methods:

1. Stepped Preheating:

Don’t jump right in with a laser! We first use an auxiliary heat source (e.g., induction heating) to bring the material temperature up slowly from around 200°C to around 350°C. This eliminates internal stresses, with smoother heat transfer and less distortion during the actual weld.

2. Dual-Beam Synergy (Primary Beam + Auxiliary Heat Beam):

The primary beam provides deep penetration welding, and a second lower-energy auxiliary beam is overlaid with it. The auxiliary beam acts as a “thermal umbrella,” covering the primary melt pool and maintaining a more stable high-temperature zone. This prevents the excess heat from being lost and allows the melt pool to penetrate the weld continuously.

3. Ultra-high frequency pulse (≥500 Hz):

The most annoying issue with thick plate welding is spatter. Our secret is to use an ultra-high frequency pulse laser, which has the ability to provide 500 or more “bursts” of energy per second. This ultra-fast energy switching precisely regulates the weld pool dynamics, preventing the spatter of metal vapor and droplets, resulting in a much smoother weld surface.

This solution has been rigorously proven at JS. As an example, in a military project a year ago, this solution successfully reduced weld porosity from 11% to below 1.9% in welding 12mm thickness aluminum alloy plates. The success of achieving this goal with thick plates lies in this integrated solution that stringently controls preheating, heat field maintaining, and weld pool stability.

Safety Hazards: A Defense System Against Invisible Killers

While receiving orders for online sheet metal fabrication services, we understand that safety is the priority. We address the three greatest risks of the welding process by:

1. Dust Explosion Risk: Addressed with an Effective Dust Suppression System!

Metal welding dust is also explosive when it encounters sparks. Our powerful explosion-proof dust extraction system, which is a giant vacuum cleaner running 24/7, generates negative pressure and extracts dust continuously before reaching dangerous levels, eliminating these hazards.

2. Toxic Zinc Sheet Fumes: Source Capture + Real-Time Monitoring!

Zinc fumes from welding galvanized sheet are extremely hazardous. We first use a removable dust hood positioned close to the welding point to remove most of the toxic fumes, which are then extensively filtered by a high-efficiency multi-stage filter. Most importantly, the system also continuously monitors the fume concentrations and gives an immediate alarm if they are approaching dangerous levels, thereby ensuring a safe working environment. Concentrations can be successively reduced from over tenfold of the permissible amount to within national standards.

3. Laser Reflection: Absorption and Monitoring for Double Protection!

Unintended reflections of high-power lasers are extremely dangerous. We’ve installed honeycomb absorbers with unique inner walls in the work chamber to effectively absorb scattered laser energy. Furthermore, coupled with infrared detection “electronic eyes,” when there is an extremely intense reflected light path, the system can respond in real time (e.g., machine shutdown), completely eliminating the danger.

Why Are The Costs Of Laser Welding So High?

I understand that people have a love-hate relationship with our technology. They love its efficiency and precision, but they hate the cost pressure. Especially when accepting large orders, the competitiveness of sheet metal fabrication price is crucial:

1. Is shielding gas too expensive? Switching to a “formula” can save you money!

We previously used pure argon to shield the weld, which cost a lot of money. We altered our procedure to a mixture of helium and argon in a specific ratio (e.g., 3:7), and we achieved the same or superior result by lowering gas expenses by nearly 70%! The math is quite staggering.

2. Maintenance Downtime: Self-Cleaning Systems Take Care!

Monthly downtime for servicing of the optical system was the norm, taking up a lot of the day and resulting in excruciating loss of production capacity. Now, with smart self-cleaning technology, these machines possess an immaculate optical path, slashing maintenance frequency and downtime by over 80%. The longer the machine runs, the lower the cost per workpiece.

3. Scrap Loss: Online CT Precision Checks!

Welding defect scrap is among the most significant hidden costs. In the past, the annual scrap rate could be as much as 15%. Now, we have online CT inspection systems, which perform “real-time X-ray inspection” of welds, properly identifying faults in manufacture and reducing the scrap rate to below 0.5%.

Comparison of Optimization Results for Key Cost Items in Laser Welding

|

Cost item

|

Traditional methods (USD/year)

|

JS New plan (USD/year) | Savings amount | Save % |

Rare factors

|

| Gas consumption | 50,000 | 16,000 | 34,000 | 68% | The helium argon mixture reduces the rework rate of the oxide layer. |

|

Shutdown loss (based on production capacity)

|

200,000 | 40,000 | 160,000 | 80% | Including the cost of buffering fluctuations in sheet metal processing prices. |

|

Waste disposal

|

300,000 | 10,000 | 290,000 | 97% | CT detection reduces the repair time for microcracks. |

|

Additional treatment of oxide layer

|

30,000 | 5,000 | 25,000 | 83% | The influence of surface cleanliness in sheet metal welding is often overlooked. |

Key data source: International Institute of Welding 2024 report

It is not a prohibitive expense. Through gas optimization, intelligent maintenance, and in-line quality testing, we can significantly reduce bottom-line expenses and make sheet metal fabrication costs cheaper. Curious about learning how these solutions can help you save money precisely? Contact the JS team today for a personalized assessment!

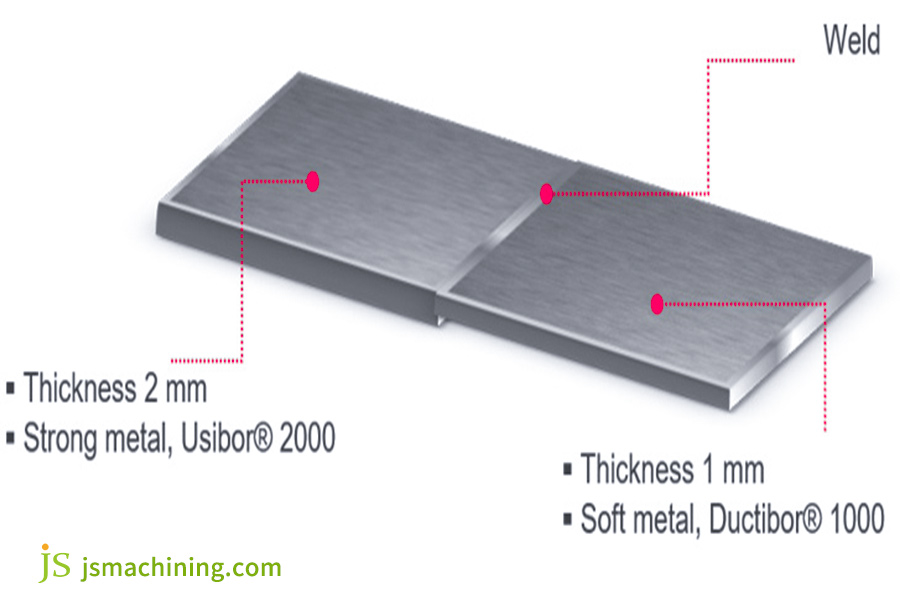

Precision Tooling: Defending The 0.05mm Lifeline

In the laser welding industry, thermal expansion and contraction can cause part deformation, slight misalignment, and inconsistent weld quality—three major challenges constantly threaten the 0.05mm “lifeline.” If this is breached, the part is ruined.

Our JS team relies on a combination of precision tooling to maintain this barrier:

- Adaptive fixtures act like “smart hands,” firmly grasping each part and ensuring an absolutely accurate starting point.

- The weld seam tracking system monitors the weld in real time, automatically following the laser’s path, eliminating micro-deformation.

- Intelligent temperature control combined with precise gas shielding keeps the temperature down and the weld pool well protected, significantly minimizing thermal deformation.

- Closed-loop monitoring keeps a constant eye on the weld pool’s condition, automatically adjusting the welding gun at the slightest sign of error.

With this combined approach, we’ve secured the 0.05mm lifeline! Looking at the neat welds and parts, this is the precision welding JS strives for!

Application Limits: When Do You Need To Say “No” To Laser Welding?

Now, let’s discuss the “forbidden zones” of laser welding in actual processing. Although laser welding is fast and effective in custom sheet metal fabrication manufacturing, the following three situations require a firm change in strategy:

|

Typical welding difficulties we encounter

|

The core reason behind it |

|

The clearance between parts during assembly is too large (>0.1mm)

|

Laser welding is most afraid of large gaps. If the gap slightly exceeds 0.1mm, the laser beam can easily “leak” through the seam and not really act on the joint surfaces on both sides. The result is that the welded area is not fused well and the strength does not meet the requirements at all. |

|

Thick copper alloy parts (thickness>2mm)

|

The surface of copper is like a mirror. When laser is applied, about 99% of the energy is directly reflected and the material cannot absorb enough heat. Not only is it inefficient to weld, but the reflected strong light may also damage the equipment. |

| Ultra thick galvanized steel sheet (zinc layer>20µm) | The zinc layer is too thick, and when the laser heats it up, the zinc underneath instantly vaporizes and expands. This expansion force is very strong, it can directly “break” the just welded area, causing the weld seam to either crack or burn out a hole, making it impossible to weld. |

JS’s Solution: Laser-MIG Hybrid Welding

This technology is specifically designed to address these “difficult problems” mentioned above:

- Working with zinc vapor from galvanized sheet metal: The MIG arc in hybrid welding can first “cover” it to provide excellent stability.

- Working with high reflectivity from heavy copper: The MIG arc is preheated before striking the copper to get it ready for better absorption of the laser energy.

Most impressive is its ability to handle gaps: Laser-MIG hybrid welding can handle gaps as small as 0.8mm, eight times the size of pure laser welding (limited to 0.1mm)! This is a boon for us when working with complex custom parts.

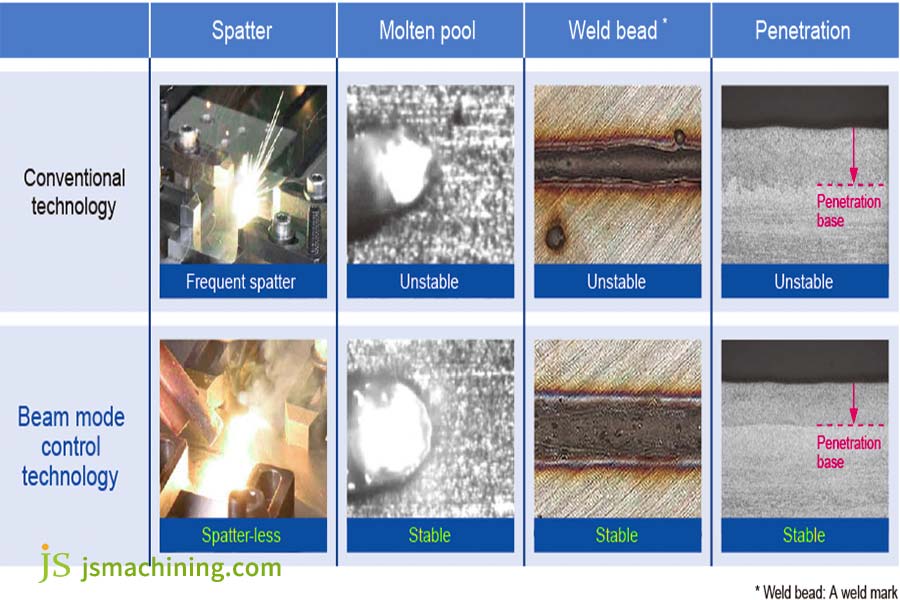

Beam Control: The Microscopic Battlefield Of Welding Quality

As a JS laser welding engineer, I optimize beam control every day in production environments. The key is three critical areas: beam spot tuning, motion control, and real-time feedback. These are the keys to solving our welding problems.

|

The solution adopted by JS

|

How does it work |

Effect description

|

| Change to rectangular dot (0.4 × 3mm) | Replace outdated small circular dots with thin rectangles. | The energy dispersion is more uniform, and the ratio of weld seam depth to width has been optimized from the hazardous 10:1 to the safe 3:1, thereby eliminating the cracking risk. |

| Utilize high-speed spiral scanning (3,000 revolutions per second) | Get the beam of light to rotate and stir up the molten pool at high speed like an electric drill. | Remove porosity defects in small areas (such as 0.2mm points) in order to give a more secure welding. |

|

Real-time monitor using a spectral analyzer

|

Like a welding electrocardiogram, constantly monitor the light signals from the molten pool. | This tool is like a radar, triggering power adjustment within 8 milliseconds of plasma anomalies, 30 times quicker than a blink, and provides welding stability. |

At JS, we use intelligent beam control to address welding pain points, improving efficiency and quality. If you’re facing similar challenges, please contact us to test these solutions and build a more reliable welding process together!

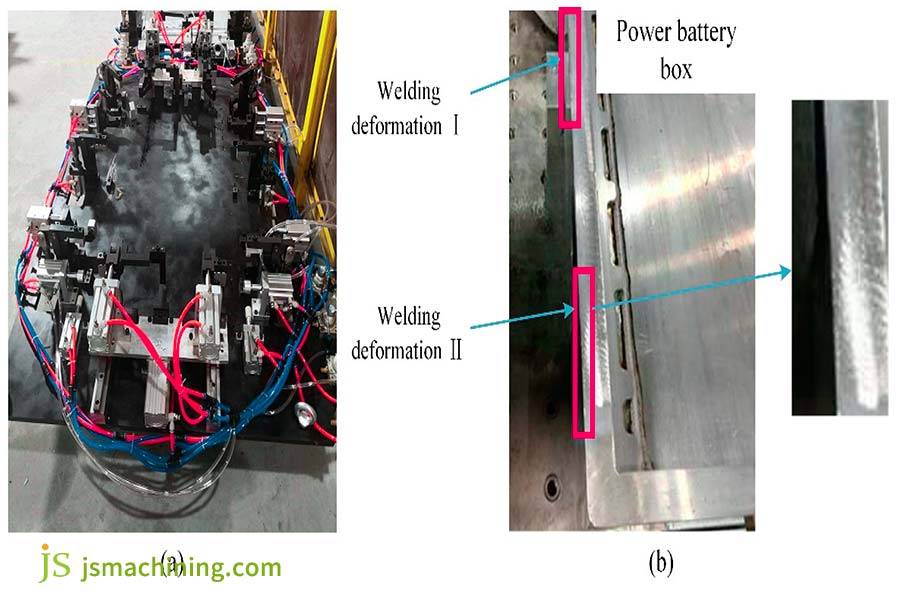

Field Review: 120 Days Of Welding A New Energy Battery Tray

Customer Pain Point: Three Major Challenges Crushing the Production Line

When we stepped in on an emergency basis, the customer’s aluminum alloy battery tray production line was on the verge of breakdown. Its weld porosity had escalated to 8.7%, far above the 1.5% tolerance of the industry. This had led to six out of ten products failing, resulting in a staggering fine of approximately $428,000 and a complete product recall by the new energy vehicle maker.

To add insult to injury, manual assembly deviations reached up to 0.2mm (four times that of laser welding), resulting in 12,000 units being scrapped annually and direct losses amounting to approximately $400,000. Worse still, the concentration of smoke generated when welding galvanized steel was 13 times higher than the standard, causing the shutdown of the entire workshop. These three major problems ground the production line to a halt.

How did JS solve the problem? Core Solution:

1. Precise Positioning + Stable Support:

To address the issue of assembly deviation, we used a “vacuum suction cup + laser eye” system. The laser eye scans the weld seam in real time, and the vacuum suction cup tightly clamps the workpiece. This ensures constant positioning error within 0.05mm, especially for components with complex shapes that require custom sheet metal fabrication, fully meeting the high requirements of laser welding.

2. Gas Shield + Process Innovation:

To combat the two entrenched enemies of porosity and smoke, we pursued a two-pronged strategy:

- First, we used the addition of helium, employing high-purity helium to effectively shield the molten pool and expel the gases that cause porosity.

- Second, we employed “high-frequency dithering” (or beam oscillation). This high-velocity, micro-oscillation of the laser beam disturbs and agitates the molten pool, allowing bubbles to escape while also suppressing the zinc vapor concentration.

Results: A remarkable turnaround in four months

- Scrap rate plummeted 97%, saving 11,640 pallets annually and recovering approximately $383,000 in losses.

- Orders Tripled: With a 98.5% pass rate for pallet waterproofing tests, we helped our client secure an order from a leading new energy giant.

- Fast Payback: The total technical upgrade expense of approximately $171,000 was recovered in just four months!

Regardless of how difficult laser welding is, finding the pain points and applying the correct solution can yield breakthroughs. If your production line has the same problems, feel free to reach out to our JS engineering team to tailor your welding solution!

FAQs

Q1: Is the exorbitant price of helium worth the investment?

Worth every cent! An investment in helium for laser welding is well worth it!

Having reduced porosity in welding aluminum by 8.7% to 1.5%, the customer avoided 11,640 units of scrap (approximately $383,000) annually. Even considering the expense of the helium, along with the high-frequency vibrating welding technique, the payback time was four months, with the scrap loss far exceeding the expense of the gases.

Q2: What is the advantage of laser welding over argon arc welding?

Laser welding is significant with regard to welding thin plates. For example, in 1mm titanium alloy welding, weld strength can be up to 95% of parent metal, much more than 82% of TIG welding.

However, when welding plates thicker than 15mm, TIG welding offers more reliable penetration. The key lies in the heat action: precise laser focus, a narrow heat-affected zone, and minimal deformation in thin plates. TIG welding also offers a wide heat distribution, making it more suitable for deep penetration.

Q3: Is thick plate welding a sure win?

Of course, there is a solution to thick plate welding!

During welding 8mm aluminum alloy, we used 200°C preheating and dual-beam laser welding, which reduced weld porosity by 82%. The key is that preheating slows down solidification of the molten pool, allowing gases to escape, and dual-beam laser welding enhances penetration stability. Aluminum alloy possesses excellent heat conduction, and this is a remedy for the classic porosity problem with thick plates, and laser welding can do it as well!

Q4: Is a 0.1mm gap fillable with laser welding?

It’s relatively simple to fill a 0.1mm gap using laser welding, the actual limiting factor being 0.05mm—any more and you’ll have a weld leak!

JS uses two viable solutions to avoid this problem:

- Firstly, the vacuum gripper offers delicate control of accuracy to ±0.01mm (something impossible with standard tooling).

- Second, precisely adding 0.08mm of weld wire to fill the gap. If assembly tolerances are minimal, thin sheets can be welded flawlessly too.

Summary

We are aware of the challenges of laser welding: cost, materials, and operator control. Fear not! Our six solutions will destroy these challenges. In on-site sheet metal fabrication, these solutions are not empty words, they are practical tools for less waste, safety, and lower costs. Is it not worth a shot?

Now it’s your turn! Still struggling with weld leaks, dust, or sky-high expenses? Contact our JS crew today and we’ll customize your production line with aviation-grade solutions. Let worrying no longer reduce your profits—contact us and a payback in four months is an option. With us, we’ll control welding from a bloody game into a guaranteed win battlefield!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Which Is Better, A CNC Or Laser Engraver? - JUSHENG