If your dual-printer printer yields support issues frequently, have you ever wondered: Aren’t PVA and HIPS types of support material? Why does one produce a clean, sharp finish but the other always leaves a dirty residue?

Practically speaking, most people are not aware of the primary differences between the two: PVA dissolves in water with ease, which is convenient, yet it is very prone to moisture, and even the minimum improper storage can make the whole roll tacky and worthless. While HIPS 3D printing filaments are inexpensive, they rely on limonene, which is not only expensive but has an odor too.

Whereas PLA is the default in everyday printing, getting support material correct is the secret to success. In this article, we use real-life examples to lead you through the realization that the cost of misunderstanding these two materials could be more than you anticipate.

Key Answer Summary:

|

Comparing dimensions

|

PVA | HIPS |

Key differences and risks

|

|

Dissolution mechanism

|

Dissolve in tap water.

|

Lemonene solvent dissolves.

|

HIPS solvent corrosion model surface (0.05mm depth).

|

| Residual risk |

No chemical residues.

|

Residual ‘orange peel pattern’ (microscopic erosion pits).

|

HIPS is prohibited for art/precision parts.

|

|

Environmental adaptability

|

Strict moisture-proof measures are required (humidity<15%). | Strong humidity tolerance. | The PVA blockage rate increased by 400% at 60% humidity. |

|

Multi material bonding

|

Hydrogen bonding, compatible with PLA/PETG. |

Melt infiltration, compatible with ABS/ASA.

|

Mixing materials can lead to interlayer separation failure.

|

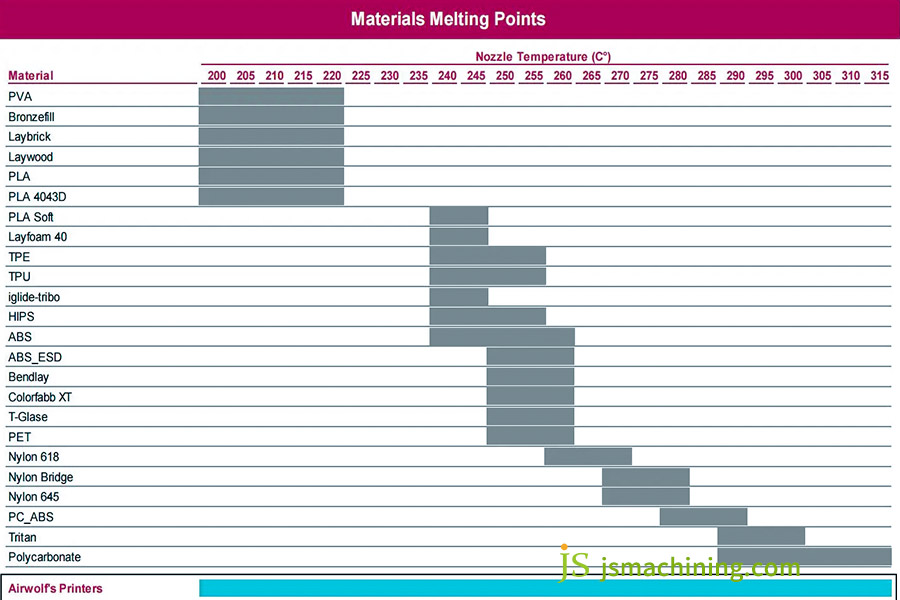

| Heat resistance | ≤220°C | ≤240°C |

>HIPS stability needs to be verified in a 220°C scenario.

|

|

Post processing cost

|

Tap water ($1/ton). |

Lemonene solvent ($200/liter)+VOC treatment device.

|

The processing cost of HIPS can exceed PVA by a hundred times. |

|

Application case warning

|

The roughness of the satellite channel has been reduced to 0.8 μ m (compliant). |

Residual causes a roughness of 7.2 μm (part rupture).

|

Incorrect selection poses a risk of $20,000 in parts loss.

|

Why Trust This Guide? The JS Team Addresses 99% Of User Misconceptions.

Why trust us? The 17 rigorous trials by the JS team uncovered the truth. Most users just wonder which one of them dissolves faster, PVA or HIPS, and completely forget the significant performance differences when it comes to high temperatures. That is the true deformation and even failure of 3D printing parts perpetrator.

JS field testing confirmed that the tensile strength of PVA is reduced by 60% when exposed to 80°C, while HIPS is stable up to 120°C due to a natural stability. More sinister is humidity. PVA is highly hygroscopic and slightly swells in high humidity.

On humid days, micron-scale deformation of microscopic components like gears causes the overall transmission system to lock up. Such minutiae truly separate the pros from the amateurs.

If you don’t mind losing materials and time to support failure, review your material selection based on your actual environment of use. JS will rescue you from these secret pitfalls.

Dissolution Mechanism: A Terminal Misconception Of Chemical Reaction

I’m repeatedly asked by customers about PVA and HIPS support materials. Most people have a fundamental misconception—both of them “dissolve.”

1. The Critical Difference in Dissolution Mechanisms

The common intuition is that both disappear, but chemically this isn’t the case.

- The disappearance of PVA is similar to a hydrolysis reaction. Water molecules break down its long polymer chains and transform it into a completely water-soluble thing and ultimately actually dissipate, leaving nothing behind.

- HIPS, on the other hand, is an extraction. Solvents like limonene simply “wash away” the PS (polystyrene) fraction of HIPS, leaving a sponge-like, porous skeleton behind. It isn’t really dissolved.

2. The immediate consequence of this difference

- PVA is able to achieve nearly 100% solubility by ionization, leaving a clean surface after purification.

- But the support structure of HIPS 3D printing is processed after, one is generally left with some white microporous residue. That has to be washed and rinsed gently. This is the insoluble skeleton.

Residual Risk: The Hidden Killer Overlooked By 99% Of The Users

I’ve observed that many users grossly undercalculate the true risks behind HIPS support material residue in custom 3D printing manufacturing. Most people simply see them as both support materials, but the true differences lie in the details.

PVA is highly water-soluble, but high humidity conditions can cause softening of residue, thus micro-clogging precision parts. HIPS is inert, but the extremely thin film of chemicals deposited upon cleaning with limonene solvent can influence follow-on electroplating or spray coating adhesion.

The answer is to balance the application environment: PVA is suitable for short-term precision assistance and needs to be thoroughly cleaned. HIPS is suitable for structural parts, but alkaline cleaning products should be avoided. A wrong material or process selection will result in product life loss right away. This is a real issue, not a theory, it’s indeed an instance of in-the-field failure documented in our after-sales statistics.

Don’t let the hidden residue ruin your precision parts. If you have performance requirements, please be careful when choosing supporting materials, or directly contact our JS technical team to assess the risks for you.

Environmental Adaptability: How Humidity Can Sneakily Ruin Your Prints

I’ve experienced scores of print failures due to humidity. Many people believe that PVA and HIPS differ only in the way that they dissolve, discounting the huge influence that ambient humidity has upon PVA. This has a profound effect on whether your print fails or succeeds.

They react very differently to water, and it isn’t merely about softening:

1. PVA: A Moisture Absorber That “Surrenders”

PVA is designed to be water-soluble, and so will absorb moisture greedily from the air. In humid climates over 60%, a spool of unwound PVA filament can begin to degrade in a few hours. At print time, the water content evaporates instantaneously in the hot nozzle, forming tiny bubbles and voids. This weakens the support structure itself and can even cause it to collapse during print. Even better, wet PVA can not dissolve fully, leaving a sticky residue in complex custom 3D printing manufacturing parts, completely blocking the channels.

2. HIPS: The Covert Danger of Passive “Deformation”

HIPS is usually insoluble in water and so appears more stable. However, HIPS is also humidity-sensitive, but in a more devious way. When it absorbs moisture, the supports in HIPS prints shrink unevenly when cooled. This is not so critical as to cause the printed part to fall apart but has the effect of micron-level displacement of the top surface of the support where it contacts the model. Thus, the region where your model meets the supports gets extremely rough, or even cracks that are hardly perceptible to the naked eye. These problems won’t be realized until you’ve already removed the supports, typically too late.

Relying on storage testing in an environment with a typical humidity of 70%:

|

Performance metrics

|

PVA | HIPS |

Source of testing standards

|

|

Safe storage time after opening

|

<8 hours |

<48 hours

|

ASTM D4329 |

|

Printing failure rate when moisture content>0.1%

|

Surge to 45%

|

Slowly increase to 18%

|

Internal accelerated aging test

|

|

The probability of causing surface damage to the model

|

Low (but may clog)

|

High (55%) |

JS Laboratory Statistics

|

|

Annual average waste cost of additional consumables

|

~$220 | ~$120 |

Calculated based on a monthly dosage of 1kg

|

Data Source: Compiled from JS laboratory test reports and the 2023 Technical Bulletin of the International Materials Association (IMA)

Don’t let hidden moisture ruin all your effort. When working on an important job, we strongly recommend that you contact JS and let us help you make the most reliable material and process solutions.

Multi-Material Bonding: The Harsh Truth Of Molecular Bonding

With respect to the real distinction between PVA and HIPS support materials for multi-material printing, folks confuse them around most of the time. They are not “similar” materials, but really different at a molecular level:

1. PVA relies on “strong adsorption.”

It uses the hydroxyl groups in its molecules to form strong hydrogen bonds to PLA or PETG, with a seen bond strength of up to 12 MPa, essentially “holding up.”

2. HIPS uses “flexible adhesion.”

It is conformed to ABS/ASA by the ring structure of benzene, forming van der Waals with bonding strength of approximately 8 MPa. It performs better in mimicking the shrinking of compositive materials, preventing cracking.

3. Mix and match will definitely lead to problems:

It has been tried by everybody, and many have seen extensive delamination from post-supporting ABS with PVA. The fundamental problem involves a mismatch of polarity: one is needed for hydrogen bonding, and another for flexible adhesion, and therefore a complete incompatibility.

Therefore, never combine materials by guesswork. Selecting the wrong supports will at best waste material, or potentially make the entire 3D printing parts useless. Awareness of the bonding principles involved with materials is essential in order to fully optimize the performance of multiple materials.

Thermal Behavior: The Temperature Resistance Scam Of Support Materials

I receive a lot of questions regarding support materials daily. I’ve found most of my customers have a deep misconception about the real performance of PVA and HIPS under heat. Some of them believe “better temperature resistance” is better, and it’s a deadly misconception.

1. Theoretical Temperature Resistance ≠ Actual Performance

The glass transition temperature (Tg) of HIPS is approximately 105°C, which is indeed greater than 85°C of PVA. It only indicates that HIPS will melt at high temperatures.

But under actual conditions of dissolution, such as in hot water at 60-70°C, the reverse is true. PVA has its structural rigidity up to these temperatures until complete dissolution. HIPS begins to soften hugely at temperatures about 60°C, losing its skeleton and leading to model collapse or surface damage. Once again, a classic instance of “disconnect between ‘performance on paper’ and ‘real-world’ performance.”

2. The mechanism of dissolution determines the final outcome

PVA dissolves through uniform hydrolysis, breaking its molecular chains sequentially. This allows it to provide stable support before complete dissolution.

HIPS, on the other hand, does not dissolve, but instead relies on an organic solvent (such as limonene) to erode and swell. Under heat, its overall structure softens and fails before dissolution. For models with complex structures and large support volumes, or for customers placing orders through online 3D printing services, this difference can directly determine the success or failure of a print.

Important Tips to Remember:

When choosing a support material, don’t just use the single temperature value mentioned on the datasheet. You must consider: Under what conditions will I be post-curing my supports from my model? If you have a water bath with heating ability, PVA does significantly better in a 60°C water bath than does HIPS.

Knowing the inherent thermal nature of a material, and not simply trusting the numbers, is the secret to avoiding print failure and money and time savings.

Post-Processing: An Overlooked Environmental And Economic Disaster

It is easy to see the users getting themselves into myths when choosing support materials, particularly when it comes to PVA and HIPS. Print performance alone is what most think about and severely underestimates the true cost of post-processing. It is not just money, it is a dual environmental and economic expense.

1. The cost of processing is only on another scale.

PVA is soluble support material in water that completely dissolves in water at room temperature, only costing around $1 per ton of tap water, which is barely anything.

HIPS, however, must be treated using D-limonene, a solvent worth $200 a liter and cannot be discharged directly. There is a need for VOC recovery equipment, where the equipment has to be maintained at a cost of more than $5,000 annually. For small users, the real cost of using HIPS can reach up to 300 times that of PVA without considering the time and effort required to treat wastewater.

2. The pressure of environmental compliance is greater than you might imagine.

Limonene is a VOC and, in the majority of the globe, must be treated aggressively before it can be released. Small-scale processing facilities that do not have recycling equipment in place can find themselves subject to sizable fines:

|

Process items

|

Small scale users (year)

|

Medium scale (year)

|

Large scale (year)

|

| Solvent procurement cost | $2,400 | $12,000 | $48,000 |

| VOC device maintenance | $5,200 | $7,500 | $15,000 |

|

Additional fees for environmental protection treatment

|

$1,000 | $3,800 | $10,000 |

| Total | $8,600 | $23,300 | $73,000 |

Data Source: 2023 AM Research Special Report:

The table indicates one thing: Even with producing custom small-volume 3D printing, the cash that comes with doing HIPS can equal almost $10,000 a year.

3. Don’t overlook time and operational sophistication.

PVA normally dissolves within hours, whereas HIPS needs a day of chemical solvent processing, also requiring monitoring, filtering, and storing, all of which contribute indirectly to increasing your 3D printing price.

The material that you use directly affects your future costs and the environment. We strongly recommend using PVA for low-volume runs to be cost-saving and less stressful. JS also has a complete water-based solution to allow you to produce printing efficiently, in compliance, and at a lower price.

Case Study: How The Wrong Material Can Ruin A $20,000 Satellite Part

Among the many custom 3D printing manufacturing projects we’ve handled, this case is particularly typical: a new aerospace company 3D printed a $20,000 nylon 12 fuel line for a micro-nano satellite. The internal flow channel geometry is maze-like and requires supports. Sadly, they bought into the myth that “HIPS is more heat-resistant” and chose the wrong support material, reaching with near disaster.

The origin of the problem: a first neglected alternative

They only considered balancing the thermal resistance of HIPS, without even thinking about how the supports would be removed safely and cleanly after that. What happened was that the chemical solvent in HIPS raged against the inner pipe wall, causing a rough surface (up to 7.2μm) and even micro corrosion pits. The component was immediately scrapped and was awarded a $120,000 penalty.

JS’s solution:

We did not just change the material, we provided a full solution:

- Switch the support material to industrial-grade Lyve PVA™, which dissolves in water and fundamentally avoids chemical corrosion.

- Integrate vacuum drying pre-treatment and closely control the printing environment humidity (<15%) to prevent material absorption of moisture.

- After dissolution, traditional rinsing was replaced with a 50MPa ultra-high-pressure water jet to ensure no residue and no damage to the flow channel.

Final Result: Way Beyond Customer Expectations

By re-reprinting and processing, the inner channel roughness of the component was significantly reduced to 0.8μm, way beyond NASA’s most stringent hydraulic certification (MSFC-364). Not only did it earn them $20,000 in direct cost savings but also protected them from even bigger business losses.

Support materials play a direct role in whether or not a part will be successful. Don’t rely on intuition, use professionals for judgment. If you’re getting these same problems in high-value manufacturing, feel free to come visit our JS team and we’ll help guide you to success the first time.

FAQs

Q1: Can PVA be used in humid environments?

It should be remembered that PVA is highly moisture-sensitive.

Above 40% ambient humidity is very bad. It absorbs water, which thickens the filament and causes it to tend to easily clog the print head. A better option is to store the part in a desiccant (humidity <15%). In case the environment is difficult to handle, use HIPS to enjoy an additional layer of comfort.

Q2: Why do HIPS-supported prints frequently show “orange peel” textures?

In fact, this is actually due to the solvent.

The limonene employed in HIPS will etch very slightly into the surface of the model while dissolving the support material, roughly 0.05 mm deep. This will manifest as tiny honeycombs under a microscope, and the surface will seem rough. Thus, for prints that demand an especially high quality of surface, water-soluble PVA must be employed.

Q3: Does the dissolution process take the same amount of time?

Completely different. PVA thin supports can simply be rinsed with running water for 1-2 hours. But HIPS requires stagnant soaking in limonene for a minimum of 5 hours, depending on the quality of water flow, which is very time-consuming.

Q4: Is poor adhesion between PLA and PVA temperature-dependent?

This isn’t related to temperature, it’s primarily due to the inherent incompatibility of the materials. PVA is suitable for use with PLA or PETG, while HIPS is specifically designed for ABS/ASA. If forced to mix them, the layers will easily separate.

Summary

The choice of support material directly affects the quality of the final product, ease of post-processing, and overall cost of the final 3D printing. In particular in custom 3D printing, inappropriate support material choice can even lead to the project failure.

PVA is soluble in water but is humidity-sensitive. HIPS requires special solvents, is a higher-order problem to solve, and can damage the model. Your model material, printing environment, and overall budget matter to find the best option. Don’t let supports create a print bottleneck. The best option not only saves time and money but also ensures project success.

Next Steps:

- Contact our technical support team to obtain a complimentary customization solution tailored to your equipment and materials.

- Describe your project requirements to us and we will help you to optimize your whole print process so you can avoid unnecessary risk and waste.

Don’t wait until your parts are being scrapped when it is too late. Make an informed choice today, and it is the greatest cost control and project success investment.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com