A satellite joint traveling in space will require a bearing which has to be perfectly sealed to take care of the harsh temperature gradients. An artificial knee joint replacing one in the human body must offer a mirror finish surface in order to avoid tissue wear.

Or, a microscopic fuel nozzle which determines the efficiency of an internal combustion engine must offer an internal diameter tolerance of not more than one-fifth of the thickness of a human hair.

Underlying all these applications is a common, unyielding requirement: Zero-Tolerance Precision Machining. This is not just ‘precision’, it’s commitment to ‘perfection.’

This article will help you determine whether a project requires zero tolerance precision machining from definitions, methods, challenges, implementation paths, costs, to practical cases, while also understanding how to efficiently implement it.

Core Answer Summary

| Core Dimensions | Key Information | JS Service Advantages |

| Zero-Tolerance Definition | Not absolute zero error, tolerance ≤ 0.005mm and stable. | Accurately define standards and control long-term stability. |

| Cost Characteristics | Cost of basic parts is 2-3.4 times that of general machining, up to 50 times for complex parts. | Transparent quotation, optimize non-critical tolerances to control costs. |

| Core Challenge Solutions | Professional solutions required for thermal expansion, vibration, etc. | Comprehensive coverage of solutions such as constant temperature workshops and shock absorption designs. |

| Application Scenario Judgment | Only critical functional parts require zero tolerance. | Accurate demand analysis to avoid excessive precision investment. |

Why Trust The JS Team’s Zero-Tolerance Additive Manufacturing Guide?

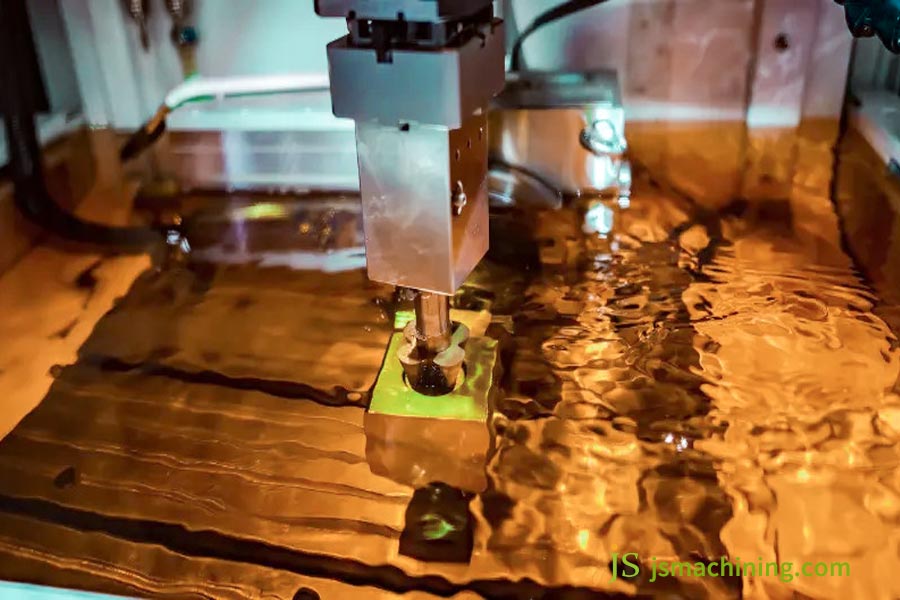

The JS team has over 15 years of experience in the field of CNC machining parts. We specialize in machining difficult-to-machine materials such as copper, aluminum, and specialty stainless steel. We’ve worked with precision-sensitive industries such as aerospace, quantum research, and high-end medical.

For example, we have machined satellite attitude control components for aerospace customers to tolerances of 0.002mm. We’ve also manufactured artificial joint contact surfaces for high-end medical customers, with a mirror surface of Ra0.02μm.

To overcome machining challenges with materials like specialty stainless steel, we have also developed a dedicated cutting parameter library to solve problems like material sticking and work hardening in an effective manner.

This Zero Tolerance Additive Manufacturing Guide is the culmination of our hands-on expertise as a team, complemented by case studies ranging from material selection to measurement verification. You can trust it to be your practical guide for your project.

If you require high-precision CNC machining parts for your project, the JS team with collective 15+ years of on-shop experience and in-depth process know-how can reliably meet your requirements. Simply send over your design drawings, and we will review them forthwith and devise a solution, saving you time and effort.

Beyond ‘Precision’: Establishing True ‘Zero Tolerance’Machining

How is ‘real’ ‘zero tolerance’ machining different from normal ‘precision’ machining? Zero-tolerance machining does not mean completely error-free, but merely that the tolerance range is very small (usually ≤0.005mm) and constant.The effect of the material properties and the environment of the machine tool on long-term accuracy must be considered as well.

The differences between normal precision machining and zero-tolerance machining can be easily seen in the following table:

| Comparison Dimensions | General Precision Machining | Zero-Tolerance Machining |

| Tolerance Range | 0.01-0.1mm | ≤0.005mm |

| Stability Requirement | Batch qualification rate ≥95%. | Batch qualification rate 100%. |

| Environmental Dependence | Regular workshop environment. | Constant temperature (±0.5°C) and constant humidity. |

| Measuring Tools | Calipers, micrometers. | Laser interferometer, coordinate measuring machine (CMM). |

In a nutshell, actual zero-tolerance machining not only pursues high precision during machining but also ensures the part never experiences precision drifts due to stress, environmental factors, and other parameters long term.That’s the gist that separates it from normal ‘precision’ machining.

Various Precision Machining Methods For Measuring Zero Tolerance

With a comprehension of what zero-tolerance machining is, let us discuss some methods for measuring zero tolerance and the different application scenarios for each method.

The characteristics of the mainstream zero tolerance machining methods are compared as follows:

| Comparison Dimensions | 5-Axis CNC Machining | Mirror Grinding | Electrical Discharge Machining (EDM) |

| Applicable Materials | Aluminum, copper, stainless steel, titanium alloy. | Metals, ceramics | Cemented carbide, high-speed steel |

| Accuracy Range | 0.001-0.005mm | 0.0005-0.002mm | 0.001-0.003mm |

| Advantages | High efficiency, capable of processing complex shapes. | Extremely low surface roughness. | No cutting force, suitable for hard-to-cut materials. |

| Disadvantages | Extremely high requirements for equipment accuracy. | Long processing time | Low efficiency |

In actual projects, the choice of a single method isn’t a one-size-fits-all solution. Because different materials have different cutting characteristics, for example, cemented carbide is best suited for EDM.Although titanium alloys are suitable for 5-axis CNC machining, a careful consideration should be made based on the material and precision requirements of the project.

JS offers a variety of custom CNC machining manufacturings, including 5-axis CNC machining and mirror grinding, so that we can select the optimal method based on your material and precision requirements. Submit your project specifications and we will attempt to get you matched up with the optimal machining solution.

Challenges And Conquests: Hardships And Solutions Towards Zero Tolerance

Four common problems occur in the process of obtaining zero tolerance. Unless corrected, the desired accuracy cannot be achieved. Some problems and solutions are as follows:

Thermal Expansion:

Heat generated due to friction between tool and workpiece can cause deformation of the workpiece, especially for materials with high thermal expansion coefficients.

Solution: Maintain a 22±0.5°C temperature constant in the workshop, equipped with an in-real-time cooling system, focus on materials with small thermal expansion coefficients.

Vibration:

Equipment operation or interference can cause vibration that creates tool deflection errors.

Solution: Install equipment on a vibration-damping base to isolate the machining area, monitor vibrations before machining to ensure the amplitude is ≤0.001mm.

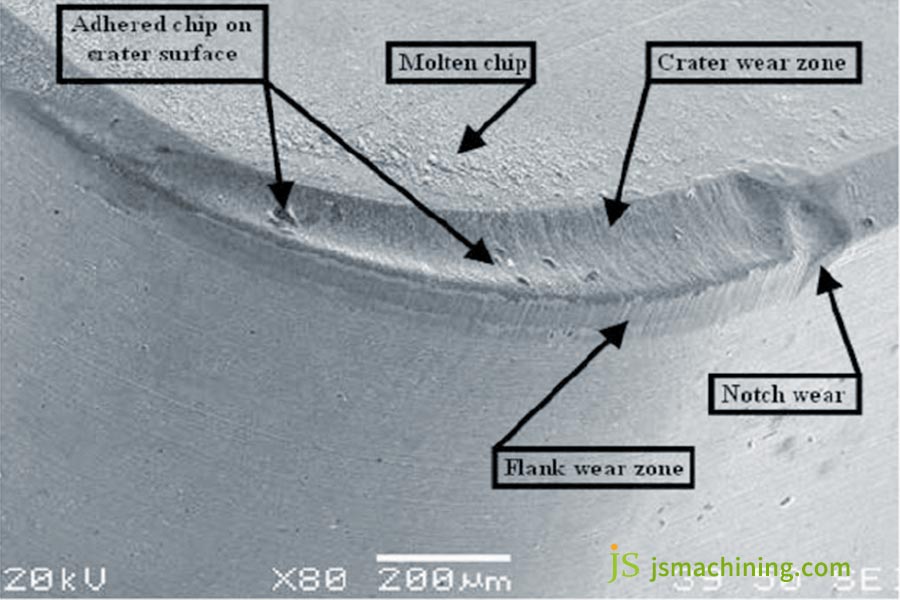

Tool Wear:

Tools wear out over time, resulting in reduced cutting accuracy.

Solution: Use hard cutting tools such as diamond and cubic boron nitride, monitor wear in real time and change them automatically when the wear threshold reaches 0.002mm.

Measurement Uncertainty:

Different measuring devices and conditions can introduce errors in readings, which can render the judgment of accuracy useless.

Solution: Use laser interferometers and coordinate measuring machines, machine and measure under the same constant temperature environment.Calibrate tools before measurement so that error is ≤0.0005mm.

JS easily addresses zero-tolerance issues in machining with professional solutions such as constant temperature control and vibration-dampening designs. Using our online CNC machining services, you will not have to worry about machining issues, we will provide you with end-to-end full support.

How Is It Done? Engineering With Zero-Tolerance Precision

After solving the processing problem, it is necessary to achieve zero tolerance accuracy through full process engineering control.The process as follows:

Step 1: Requirements Analysis

Consideration of the project’s precision requirements, material characteristics, and working conditions will determine core requirements, allowing for creation of a targeted solution.

Step 2: Process Planning

Employ a multi-phase process of ‘rough machining – stress relief – semi-finishing – natural aging – super-finishing,’ with accuracy checkpoints at each phase.Progress only once the requirements are met for the subsequent phase.

Step 3: Preparation of Tool and Equipment

Select high-precision machines, e.g., 5-axis CNC machine with positioning capability of ≤0.001mm, readied tooling suitable for the material.Also, calibrate measuring instruments to provide accuracy achieved.

Step 4: Control of the Environment

Machining and measurement are performed in a workshop that has a stable temperature (22±0.5°C), stable humidity (45%-55% RH), and dust-free (Class 1000) environment.This precludes environmental influences on quality.

Step 5: Monitoring of the Whole Process

During machining, real-time monitoring parameters such as temperature, vibration, and tool wear are monitored, and immediate adjustments are made if abnormalities are noted, multiple calibrations are performed during the measurement process.This ensures reliable data.

Pricing For Perfection: A Cost Approach To Precision Machining

Zero-tolerance precision is achieved with additional equipment, materials, and time, rationally at a higher price than standard machining.The majority of customers are concerned about the cost difference between zero-tolerance machining and standard machining prior to making a decision.

Let’s examine the cost difference through some numbers:

| Cost Type | General Machining (per unit) | Zero-Tolerance Machining (per unit) | Cost Multiple |

| Equipment Depreciation | $50 | 150-250 | 3-5 times |

| Material Cost | $100 | 200-300 | 2-3 times |

| Processing Time Cost | $80 | 160-320 | 2-4 times |

| Labor Cost | $60 | 90-120 | 1.5-2 times |

| Total Cost | $290 | 600-990 (for basic parts) | 2-3.4 times, up to 50 times for complex parts. |

As seen from the table, the cost of a straightforward zero-tolerance part is 2-3.4 times the cost of standard machining.Complex parts like quantum device shields, in light of the extra special processes and monitoring steps required, can cost up to 50 times as much.

Therefore, before choosing zero-tolerance machining, one should be extremely sure if the project essentially requires such accuracy or not in order to avoid unwanted cost incurrence.

JS will provide sharp-line CNC machining price quotes according to your project requirements so you know exactly what each fee is for. Forward your design, and we’ll provide a complete quote so you can make an objective assessment of whether zero-tolerance machining is necessary.

JS’s Wisdom: The Key To Providing You With The Most Economical Precision Machining Solutions

The cost of zero tolerance machining is relatively high. JS mainly helps you reduce costs while ensuring accuracy through the following four aspects, and obtain a cost-effective solution:

Precise Requirements Analysis

Cut up project requirements and separate ‘must-zero-tolerance’ and ‘relaxable-tolerance’ areas and reduce unnecessary investment in precision and costs.

Technical Combination

Combining strengths of different processes, such as the application of 5-axis CNC machining to the body (low cost and high efficiency) and mirror grinding to key areas (precision kept), a balance between precision and cost.

Scaling Benefits

If there is a bulk demand for the project, reduce the cost of individual items and improve cost-effectiveness by purchasing materials in bulk and optimizing the processing flow.

Transparent Quotations

List each link’s costs and provide quote comparisons for different precision solutions so you can pick the optimal solution within your budget and requirements.

‘Silent Guardian’: The Birth Of High-Precision Electromagnetic Shielding

Client Background:

A prominent research institution needed to create an electromagnetic shield for the central component of a quantum computer to prevent electromagnetic leakage from interfering with quantum computing, imposing extremely high demands on precision and sealing.

Core Challenges:

- Absolute Sealing: Various materials must be sealed, with seam tolerances of <0.003mm to prevent electromagnetic leakage.

- Material Diversity: Different materials have varying cutting properties, again adding to the complexity of machining.

- Stress-Free Machining: Internal stresses must be eliminated to prevent deformation and seal damage during prolonged use.

JS Solution:

- Process Planning:

Uses a ‘rough machining – 24-hour constant temperature stress release – semi-finishing – 72-hour natural aging – super finishing’process. Stress testing is conducted after each process stage to reach over 99% internal stress removal rate to prevent deformation.

- Hybrid Technology:

The main body is machined by 5-axis CNC machining, and the main mating flanges are mirror-polished in a way to be extremely level (≤ 0.001mm). Laser welding is utilized at joints for minimizing deformation, striking a balance between efficiency and accuracy.

- Environmental Control:

Machining and measurement are performed within a dust-free environment at a temperature of 22±0.5°C and humidity level of 45%±5% RH. The equipment is placed on an anti-vibration base, vibration being controlled to ±0.001mm to preclude environmental interference with accuracy.

- Final Measurement:

A flatness of the shield cover is measured by a laser interferometer 360° and a data point every 1mm² (totaling 100,000 data points) is taken. Secondary calibration is also done with a coordinate measuring machine (CMM) in order to verify joints have a tolerance less than 0.003mm.

Project Results

The shipped shield had a theoretical electromagnetic shielding effectiveness of 99.99%, much higher than the client’s expectation of 99.9%. The client saved time, effort, and resources dealing with suppliers of materials, fabrication houses, and agencies of measurement, and JS solved all these problems independently. The project duration was also shortened by 10 days.

JS Precision Manufacturing again demonstrated its expertise in zero-tolerance machining through this project.

JS has rich experience in CNC machining parts such as high-precision electromagnetic shielding shells and has the ability to process complex issues such as multi-material and stress-free machining. If your company also has such requirements for high-precision components, please send your design drawings and we will customize a solution for you.

FAQs

Q1: Does zero-tolerance machining guarantee 100% absolute zero error?

From the scientific point of view, absolute zero error is not possible. However, on the basis of real industrial applications, ‘zero tolerance’ signifies that the error ought to be maintained within an extremely small range (usually micrometers). This error can be completely ignored for the expected functions such as assembly and operational stability of the parts, far less than the functional tolerance requirements of the parts themselves.

Q2: Do I need to apply zero tolerance to the entire part?

No, that’s a cost trap. Use the tightest tolerances for only critical dimensions and features having a direct impact on product function, part fit, or service life, and non critical areas can be appropriately relaxed.This not only meets the core requirements but also avoids the cost doubling caused by high precision of the entire piece, making it the most effective way to control costs.

Q3: How do you ensure zero tolerances are achieved?

We apply measurement tools of an order of magnitude higher accuracy than the part we are working on. For example, for a tolerance of ±0.005mm, we make use of a Zeiss CMM with ±0.001mm repeatability. Following strict procedures to generate FAI reports, presenting clear comparisons between measured values and tolerances of critical dimensions, ensuring intuitive verification of compliance.

Q4: Can I still avail of your precision machining service for small orders?

Yes. We prototype and mass produce single items or large quantities. We understand that the prototype precision is often more critical, and our flexible manufacturing system enables us to accommodate these varying needs of order quantities.We will not lower the processing quality or increase the unit price due to a small order quantity, fully meeting your precision machining needs at different stages of the project.

Summary

Zero-tolerance precision machining is the gemstone of modern industry, representing the quest for all-around ultimate performance and reliability. However, the wise thing to do is to avoid having to pay for ‘excessive precision.’The secret is to collaborate with a partner who has both world-class technical know-how and lengthy engineering experience to achieve the best balance between accuracy, performance, and cost.

Whether your project demands the zero-tolerance precision of precision machining or traditional CNC machining of components, JS can offer expert services.We offer online CNC machining services for simple, 24/7 communication and advance support in CNC machining prices. Simply provide your project details, and we’ll be there at the start to the finish to ensure that the completion is a success.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Is 5 Axis CNC Machining Difficult? - JUSHENG

Pingback: Is A Milling Machine The Same As A CNC Machine? - JUSHENG

Pingback: JS Precision Vs. Xometry: Which CNC Shops Near Me Offer The Most Transparent Quote? - JS Precision