A large car dashboard assembly is formed in 60 seconds within a thudding machine, awaiting assembly. Meanwhile, a high-accuracy plastic connector employed in minimally invasive surgical procedures requires nearly 120 seconds of highly accurate injection molding and cooling within an extremely cleanroom in order for it to function flawlessly.

This seemingly conflicting timing seems not so much about the ineffectiveness of the machines, but the precise control of the plastic injection molding process based on product requirements.

This guide will break down the time structure of plastic mold injection molding into stages to allow you to effectively plan your project schedule and avoid delays resulting from poor planning.

Core Answer Summary

| Core Dimensions | Key Information | Time/Efficiency Data | Key Influencing Factors |

| Mold Manufacturing | Includes design & programming, precision machining, polishing. | Total Cycle: 4-8 Weeks | Product structural complexity |

| Injection Cycle | Comprises injection time, hold time, cooling time, mold opening/closing time. | Cooling Time: ≥70% of total cycle | Cooling efficiency |

| Cycle Reduction Tech | Conformal cooling, injection parameter optimization. | Case: 40% efficiency improvement | Tech selection & adaptation |

| Hidden Time | Includes material preparation, mold testing & adjustment, quality inspection. | Additional 3-7 Days Required | Production volume & product requirements |

Why Trust JS’s Plastic Mold Injection Guide?

When searching for custom plastic injection mold manufacturing service for industrial industries like automotive and electronics, you may wonder which company’s guide is most worth considering.

JS has over 15 years of practical experience in producing plastic injection molds. We not only produce molds for products made from various kinds of materials (such as nylon, ABS, and PC), but also produce prototypes, middle- to small-scale production molds, and large, complex molds.

We have offered solutions to customers in various industries, including automotive components, consumer products, and medical devices, solving a variety of issues, ranging from cooling issues for products with non-uniform wall thicknesses and poor accuracy in complex mold production.

This guidebook is not theoretical research, it’s an accumulation of the JS team’s hands-on expertise in thousands of custom plastic injection molds manufacturing projects. All the timelines and approaches have been tried and tested in real projects, so you can depend on it for professionalism and ease of use.

If you are seeking trustworthy custom plastic injection mold manufacturing advice and services, JS’s expertise can prevent time constraints. From communicating requirements to implementing solutions, we offer expert support through the whole process, preventing detours.

Mold Manufacturing: Where To Invest Time?

Now that we understand why our guide is credible, let us take a look at the most significant phases in the process of creating plastic molds—they’re the core of the entire plastic injection molds parts project process.

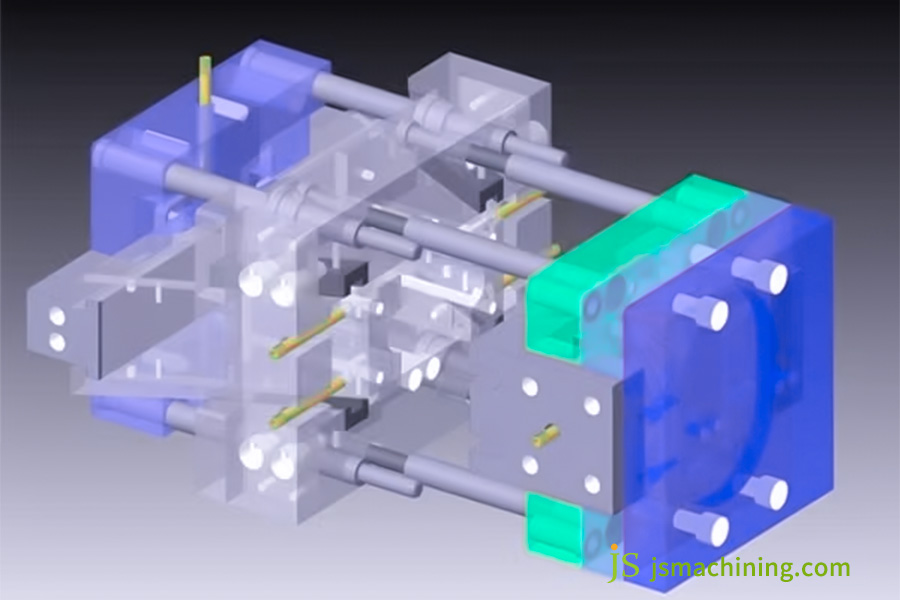

The production of the mold is divided into three basic phases, and each has a determined time investment, as is visible in the table below:

| Manufacturing Stages | Time Range | Key Work Content |

| Design & Programming | 1-2 Weeks | Design mold structure (e.g., cavity, water channel, gate) based on product drawings, and write CNC machining program codes to ensure machining accuracy. |

| Precision Machining | 2-4 Weeks | Use CNC milling machines, EDM machines and other equipment to cut and carve mold steel, and process core mold components such as cavities and cores. |

| Polishing & Surface Treatment | 1-2 Weeks | Polish the mold cavity surface to reduce demolding resistance of plastic parts, and perform anti-rust treatment or surface coating as required. |

It should be noted that if you need structurally complex plastic injection molds parts, such as several clips or cutouts, mold design and precision machining will take an additional one or two weeks because more time will be consumed to detail the structure and make corresponding processing parameters adjustments.

If you need a trustworthy partner for plastic injection molds parts manufacturing, reach out to JS. Just provide your product specifications, and we’ll rapidly assess and offer a timeline to enable you to process your project efficiently.

Injection Molding Cycle—The “Harvest” Cycle Where Every Second Counts

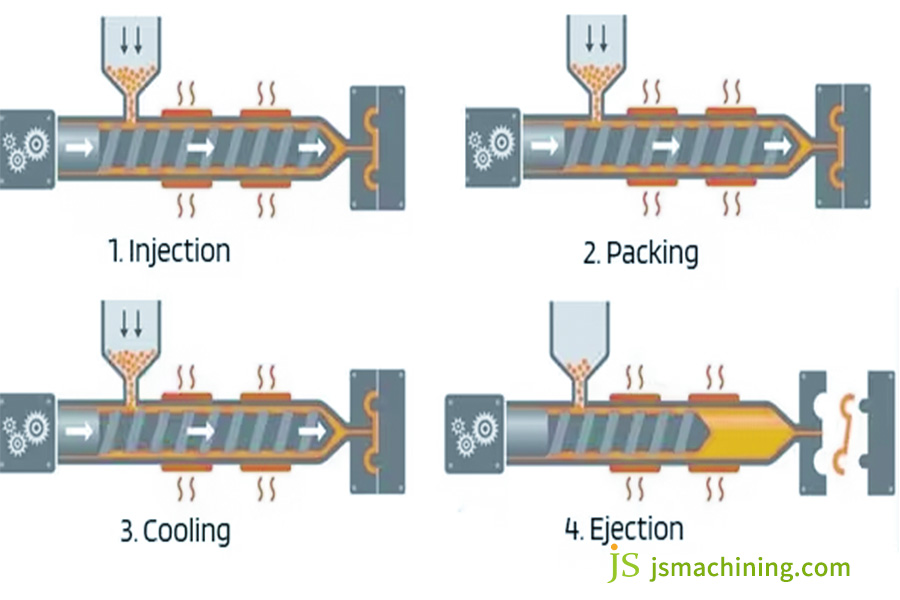

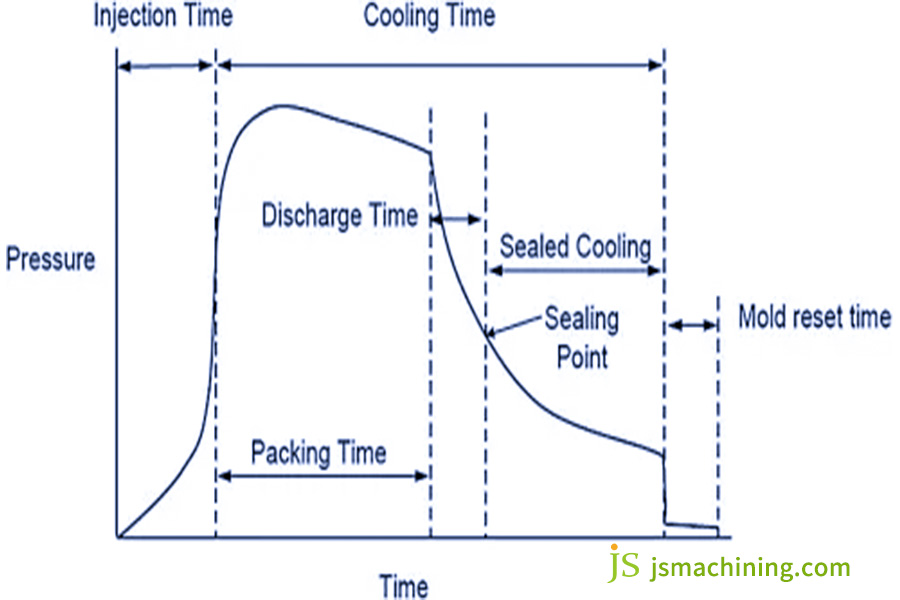

After the mold production is complete, the injection molding begins, and the injection molding cycle is significant to the productivity of plastic mold injection manufacturing. The injection molding cycle is the time between the completion of one injection and preparation for the next. The calculation is applied as: Cycle = Injection time + Holding time + Cooling time + Mold opening and closing time.

You may wonder why time percentages of every process are not identical. That is closely linked to rules of plastic molding. The aim of every process is directly associated with product quality and productivity.

Specified time percentages and duties of every process are shown in the table below:

| Injection Cycle Stages | Time Proportion | Main Functions |

| Injection Time | 10%-15% | Inject molten plastic into the mold cavity at a certain pressure to ensure the plastic fills every corner of the cavity. |

| Hold Time | 5%-10% | Maintain pressure after injection to make up for the gap caused by plastic shrinkage during cooling, avoiding product depression. |

| Cooling Time | Over 70% | Allow the plastic in the cavity to solidify gradually until it has sufficient strength for demolding, preventing product deformation or cracking. |

| Mold Opening/Closing Time | 5%-10% | Open the mold to take out the finished product, then close the mold for the next injection, mainly depending on the mechanical speed of the injection machine. |

As the table shows quite clearly, cooling time typically accounts for the largest percentage, and so, cooling efficiency is the most critical aspect of the injection molding cycle. The lower the cooling efficiency, the longer it takes for the total cycle time, and it can even cause product warping and increased rates of defects.

If that which you are looking for is optimizing your plastic injection molding cycle, JS can help with professional cooling system design and process optimization services. After you specify your project details, we will help you reduce cooling time, boost production efficiency, as well as save money.

Racing Against Time: Cutting-Edge Techniques For Shortening Molding Cycles

Since cooling performance contributes so much to the injection molding process, can anything be done to speed it up? Yes. Drawing on experience from a number of online plastic injection molds services projects, JS has found three proven leading-edge ways to actually improve plastic mold injection efficiency:

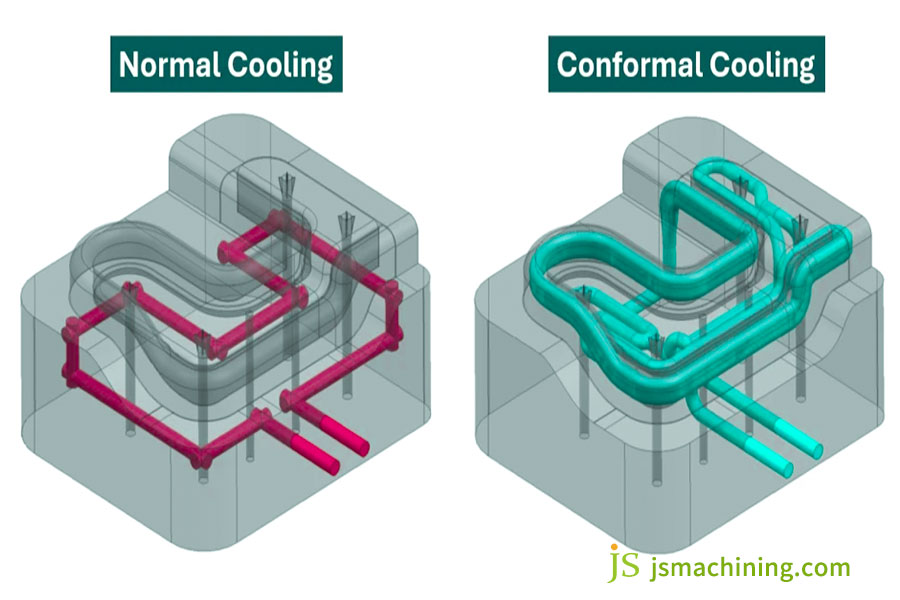

Improving Cooling System Design

Ignoring traditional linear cooling channel design, conformal cooling technology is adopted. Specially designed curved cooling channels are designed to follow the product shape and enhance more uniform contact between the mold cavity surface and the cooling water.

For example, for products with different wall thickness, increased density of channels in thicker areas promotes heat transfer. The aforementioned design can shorten 30%-50% of the cooling time.

Precise Regulation of Injection Molding Process Parameters

Adjustment of injection temperature, pressure, and rate based on the properties of the plastic material. For instance, in the case of PP with good fluidity, the injection rate can be increased to reduce injection time. At the same time, maintaining a reasonable holding pressure range prevents the holding time from influencing the overall cycle time.

The injection cycle times are typically shortened by 10%-15% by optimizing parameters.

High-performance machinery and materials are utilized

Choose high heating and cooling speed injection molding machines. They are capable of rapidly changing mold temperature, thereby reducing preheating and cooling waiting time. Also, using modified plastic materials such as glass-fiber reinforced nylon, cures by about 20% faster than ordinary nylon, further reducing cooling time.

If you need to shorten the molding cycle through online plastic injection molds services, JS can integrate and optimize solutions for you. You only need to submit product drawings and production capacity requirements online, and we will help you achieve efficient production.

Exceeding Cycle Time: Those “Hidden Times” You Need To Consider

While making plastic injection mold project plans, most individuals only consider mold production and the injection molding process without regard to the usually neglected “hidden times.” Not planning the hidden times in advance may cause project postponements.

Below is a table of usual hidden time types, durations, and factors that influence them:

| Types of Hidden Time | Duration Range | Key Influencing Factors |

| Material Preparation Time | 4-24 Hours | Different plastics have different drying requirements (e.g., nylon needs drying at 80-100℃ for 4-8 hours, while PC needs 12-24 hours). |

| Mold Testing & Adjustment | 1-3 Days | After the first test, check for flash, material shortage and other issues, and adjust mold structure or process parameters based on the problems. |

| Quality Inspection & Packaging Time | 1-2 Days | Depends on production volume: 1 day for small batches (≤1,000 pieces), 2 days for large batches (≥10,000 pieces). |

In addition, the period used to calculate the of plastic injection molds price is considered hidden time. If your product design is complex and requires multiple communications and accurate confirmations, calculation of the price may take one to two days.

Therefore, when planning a project, it’s better to add an additional 3-7 days of hidden time, besides the mold production and injection molding cycle.

If you are concerned about the impact of “hidden time” on project progress, JS can provide you with a full process service including plastic injection molds price calculation and material preparation.

Case Study: Conformal Cooling Technology – Helping Automotive Connector Production Efficiency Increase By 40%

Project Background and Customer Pain Points

An automaker of car accessories was troubled by poor production efficiency of a nylon connector for a bestseller vehicle.

The product’s complex design and uneven wall thickness resulted in extremely poor cooling effectiveness with traditional molds. Cycle times were as much as 60 seconds long, with over 40 seconds spent on cooling. The lengthy cycle dramatically limited production capacity, keeping the company from being able to keep up with growing order demand. At the same time, unit production at high cost squeezed out profit margins.

The client had previously attempted to optimize the injection molding process with minimal success, hopelessly seeking a breakthrough answer.

JS’s Innovative Solution

- Problem Diagnosis: JS Precision Manufacturing first analyzed the product structure and discovered that uneven wall thickness was the underlying cause of low cooling efficiency. Straight cooling channels could not accommodate thick-walled components.

- Technology Introduction: JS discarded traditional design and utilized conformal cooling technology and custom-made mold inserts to allow the internal cooling channels to deform as the product shape to achieve effective and uniform heat removal.

- Process Optimization: The injection molding parameters were optimized as a whole, lowering the injection temperature from 250°C to 240°C and decreasing the hold time from 5 seconds to 3 seconds to ensure stable molding.

Results

- Production efficiency soared: Total injection molding cycle time was reduced from 60 seconds to 36 seconds, 40% of efficiency improvement.

- Cost savings and productivity: The production capacity of the customer’s per day increased to 4,800 units with ease to fulfill monthly orders.After the increase in production capacity, the unit production cost decreased to $1.1, significantly improving profitability.

- Quality Improvement: Uniform cooling reduces product warpage from 0.3mm to less than 0.1mm, increasing yield to over 99.5%.

When you’re facing efficiency problems on complex plastic injection molds parts, JS can help. Just forward your product details, and we will arrange a one-to-one meeting with our engineers, providing end-to-end services to help you improve efficiency as well as reduce costs.

How To Plan a Realistic Timeline For Your Project?

Now that you are aware of the timelines for all the steps involved in the plastic injection molding process, you may wonder how to bring all of this data into a plausible timeline for your project.

Through experience working online with plastic injection mold services, JS has identified four major steps to allow you to properly plan your timeline:

| Planning Steps | Key Actions | Recommended Duration |

| Clarify Project Requirements | Confirm product specifications (size, wall thickness), material type, production volume, and clarify quality requirements (e.g., yield rate). | 1-2 Days |

| Select Mold Type | Choose molds based on volume: prototype molds (suitable for 100-1,000 pieces), mass-production molds (suitable for ≥1,000 pieces). | 1 Day |

| Reserve Mold Testing & Adjustment Time | Reserve 1-3 days for mold testing regardless of mold type, and prepare 1-2 days for adjustment. | 2-5 Days |

| Connect Production Process | Confirm delivery time with material suppliers, and communicate production schedule with injection molding factories to avoid no production plan after materials arrive. | 3-5 Days |

For example, if you need 1,000 ABS electronic housings (prototype molds), the whole schedule can be as follows:

1-2 days for setting requirements → 1 day for selecting mold type → 4-8 weeks to produce the mold → 2-5 days to make adjustments to the mold trial → injection molding (2 days for a daily rate of 500 pieces) → 1-2 days for quality inspection and packaging, for a total period of around 5-9 weeks.

FAQs

Q1: Can the cooling time be reduced to any degree?

No. Proper cooling time ensures that the plastic component is within stable limits at ejection time. Inadequate cooling time can lead to part deformation and ejection instability. It can also leave excessive residual stress in the part, causing it to crack under later use. For precision components like automotive connectors, this can lead to assembly inaccuracy, which in turn negates the benefits.

Q2: Why are so many mold trials required (T1, T2, T3……)?

Each mold trial is a particular step designed to solve for different problems. T1 is with ensuring part dimensions are up to design requirements and the mold structure is functional. T2, which corrects any flaws that may exist in T1, once again guarantees that the look of the part is to specifications and dimensional accuracy never fluctuates. T3 would be the final inspection before mass production, guaranteeing that the mold can produce qualified items consistently during mass production.

Q3: How much is a simple mold?

Price of a typical mold can vary significantly, anywhere from several thousand to several hundred thousand dollars, depending on several key factors: size of the mold, material, number of cavities, mold life requirements, and surface treatment requirements. As mentioned earlier, price of plastic injection molds will vary with product details. We can estimate structural complexity only accurately after you provide a 3D model, enabling us to provide a proper quotation.

Q4: Why is the mold cooling system so critical?

The mold cooling system is far more important than you know. Not only does it directly impact plastic injection mold production efficiency but also product quality and production costs. An outstanding cooling system can decrease cooling time dramatically. Moreover, balanced cooling decreases part warping and distortion, improving yield. Furthermore, higher efficiency can decrease the production cost per unit, saving firms a lot of money.

Summary

Time is money in production, and information is the best lever to save time. Having knowledge of the entire injection molding cycle time and utilizing it, rather than resisting it, is the secret to success of your product. Mature partner selection is responsible for achieving both efficiency and stability in your project.

JS offers start-to-finish services from custom plastic injection molds manufacturing to plastic injection mold production. Our skilled staff helps you with everything from the schedule of mold production to injection molding cycle improvement.

Just give us your product requirements, and we’ll offer transparent pricing and timelines on plastic injection molds. From order.placement through delivery, we will provide special support to help you.successfully complete your project.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Why Is My Resin Not Curing In My Silicone Mold? - JUSHENG