In 3D printing, option tends to trump hard work. A single option can make your prototype look like a cheap hobbyist thing to your customers, or transform it into a strong, beautiful, market-ready professional part. At the forefront of this struggle are two widely used but distinct technologies: the home name FDM and industrial printing’s dark horse, MJF.

Have you ever stressed about the fragility of your FDM printing parts? Or tortured yourself over MJF cost? This article is your ultimate decision-making guide, slicing through the sales jargon and simplifying FDM vs. MJF printing contrasts in speed, cost, and quality, and revealing which is the perfect match for your project.

Key Answer Summary

| Comparison Dimensions | FDM (Fused Deposition Modeling) | MJF (Multi-Jet Fusion) |

| Core Principle | Thermal extrusion: Filaments are heated and melted, then deposited layer by layer. | Powder sintering: Fusing agent is jetted on the powder bed, and the entire layer is melted at once with infrared. |

| Materials | Wide range (Polylactic Acid, Acrylonitrile-Butadiene-Styrene Copolymer, Polyamide, etc.). | Mainly Polyamide 12 / Polyamide 11, with excellent performance. |

| Speed | Slow for single parts | Extremely fast for batch production (entire layer melted simultaneously). |

| Cost | Low unit cost | Low cost for batches, high initial cost for single parts. |

| Surface Quality | Has layer lines, post-processing required. | Smooth without layer lines, high precision. |

| Strength | Anisotropic, weak Z-axis strength. | Isotropic, strength close to injection-molded parts. |

| Application Scenarios | Concept verification, functional prototypes, low-cost small-batch production. | Functional prototypes, small-batch end-part production, complex structural parts. |

Why Should You Trust This Guide? Real-World Project Comparisons From JS

When you are choosing 3D printing technology for precision parts of medical equipment, JS has provided services from design optimization to bulk delivery to over 500 medical enterprises worldwide; When you are struggling with the temperature resistance of automotive parts, our engineers have conducted over 100 material tests to determine the performance of FDM and MJF at different temperatures.

We possess over 10 years of custom 3D printing manufacturing experience in industries such as electronics, automotive, medical, and aerospace. We have completed over 10,000 3D printing parts projects and are knowledgeable in filament selection and post-processing optimization for FDM printing, along with powder bed control and batch scheduling for MJF printing.

This book is not a mere compilation of theory, but the lessons learned and pitfalls our group has faced in actual projects. Every item is supported by actual project data from the real world, which offers credible direction for your technology decisions.

Over 10 years of custom 3D printing manufacturing experience and over 10,000 3D printing parts projects allow JS to closely match your technical needs and provide end-to-end control from concept design through to bulk delivery. Engage us for greater reliability in your 3D printing project.

More Than Just “Stacking Plastic”: Uncovering The Working Principles Of The Two Technologies

In order to know which one is better, FDM printing or MJF printing, let’s first learn how they “create” parts.

How FDM Printing Works

FDM printing, also known as fused deposition modeling, works in the same way as squeezing toothpaste—a thermoplastic filament is heated and melted, and then deposited layer by layer along a predetermined path through a nozzle. The part is formed when cooled. The nozzle moves throughout the process, and the layers are fused together by the heat.

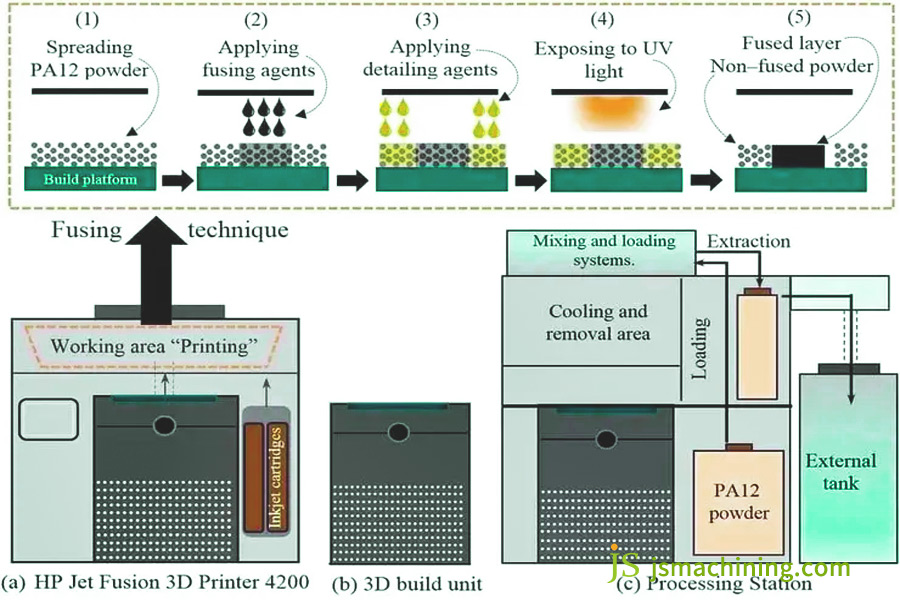

Working Principles of MJF Printing

MJF printing, or Multi-Jet Fusion, operates on a powder bed: a layer of nylon powder is applied first, and then flux and binder are sprayed through the nozzle. Infrared lamps heat the powder, sintering it into a single cross-section. The process of powder application, spraying, and heating is repeated in sequence to build the final part. The entire cross-section is formed simultaneously without the need for nozzle movement.

Comparison of Working Principles of the Two Technologies

| Comparison Dimension | FDM Printing | MJF Printing |

| Technology Type | Fused Deposition Modeling | Multi-Jet Fusion |

| Core Material Form | Thermoplastic Filaments | Nylon Powder (e.g., PA12, PA11) |

| Key Molding Steps | Filament heating & melting → Nozzle deposition → Cooling. | Powder spreading → Fusing agent jetting → Infrared sintering → Repetition. |

| Interlayer Bonding Method | Thermal fusion of adjacent layers. | Overall sintering of powder. |

Even from the principle alone, it is evident that FDM printing would be more appropriate for parts that have simple structures, whereas MJF printing, since it creates cross-sections simultaneously, has a natural advantage for complicated structures and for mass production.

Whether you must know the intricacies of filament melting in FDM printing or the physics of powder sintering in MJF printing, JS can provide technical explanations by experts to help you demystify the manufacturing technology path for 3D printing parts.

Speed Battle: Single-Part Faster Vs. Whole-Piece Faster

Now that we’ve addressed the principles, let’s discuss everybody’s most burning issue of speed—which is faster, FDM printing or MJF printing? Well, it’s not black and white, based on your print volume.

FDM “Speed”

For printing just one small part, FDM printing can be faster. That’s due to the fact that it does not require complex heating of the powder bed or powder preparation. Printing can commence within minutes of powering up the machine, and a small part can typically be completed in 2-3 hours. As the number of prints increases, however, FDM’s speed goes out the window since it must print parts one at a time or in small groups simultaneously. The more parts, the longer the total print time.

MJF “Industry”

Conversely, when printing an entire tray of parts, MJF printing is far more efficient than FDM. Because MJF sinters the complete build section at once, as long as the parts are within the powder bed, printing multiple parts takes almost the same time as printing a single part. For example, 50 small parts FDM printing would take 50-75 hours (approx. 2-3 days) while MJF would take only 8-10 hours. Including post-processing, 50 parts can be delivered in 3 days.

Comparison of Two Technologies’ Speed

FDM Printing vs. MJF Printing Speed Comparison (Based on 50 Small Plastic Brackets Example):

| Comparison Dimension | FDM Printing | MJF Printing |

| Preparation Time | 10-15 Minutes | 1-2 Hours (Powder Bed Preheating & Spreading) |

| Printing Time | 50-75 Hours | 8-10 Hours |

| Post-Processing Time | 15-20 Hours (Sanding & Support Removal) | 5-8 Hours (Powder Removal & Surface Treatment) |

| Total Delivery Time | 3-4 Days | 1-2 Days |

Obviously,MJF printing has a significant speed advantage in mass production.

The Cost Enigma: The Visible Unit Price Vs. The Invisible Total Cost Of Ownership

Next after speed is the most important issue of cost. It is a general view that FDM printing is cheaper because of the low unit cost of material and equipment. However, the reality is that 3D printing prices should be considered on the “total cost of ownership” basis, not just the visible unit cost.

Cost Structure of FDM

FDM printers cost between $1,000 and $5,000 per unit, making them accessible to small businesses or laboratories. Materials cost between $20 and $50 per kilogram, making them a low unit cost.

FDM does, however, have two indirect costs: first, support material waste (10%-30%, and much of it is not reusable).Second, post-processing labor ($5-15 per part). For example, the material cost to print a small part is $5 and the post-processing labor cost is $10, for a total of $15 per part.

Cost Structure of MJF

MJF printers are in the range of $100,000-$500,000 per unit and hence are not affordable for small businesses. Material is $80-120 per kilogram and hence more costly than FDM.

Nevertheless, MJF has lower hidden costs: powder usage is over 90%, and labor for post-processing is merely $2-5 per part, which leads to reduced overall costs when it comes to mass production.

Comparison of the Two Technologies with Respect to Cost

Comparison of the Costs of FDM and MJF Printing (on the example of 50 small plastic supports):

| Cost Component | FDM Printing | MJF Printing |

| Equipment Depreciation (5-Year Calculation) | $20 | $100 |

| Material Cost | $750 (Including Support Material Waste) | $400 (Reusable Powder) |

| Post-Processing Labor Cost | $500 | $200 |

| Total Ownership Cost | $1,270 | $700 |

| Unit Cost | $25.4 | $14 |

So, to determine whether the 3D printing price is cost-effective, we cannot just look at the unit price, but also consider the batch size and total cost of ownership.

To consider 3D printing prices, JS will break down FDM’s and MJF’s material, labor, and equipment depreciation costs, giving you a clear understanding of the cost of ownership and presenting you with cost-effective 3D printing parts production solutions.

Revealing FDM And MJF’s Hidden Talents And Extreme Challenges

Beyond speed and cost, both FDM and MJF printing have their own “hidden talents” and “extreme challenges.” Understanding them enables you to more accurately match project requirements.

FDM’s “Special Operations” Capability

- Multi-material and Soluble Support: Print two materials simultaneously, like ABS for the part and soluble material for supports. Dissolve supports, and there is no manual removal required, with less part damage.

- Composite Filament: Carbon fiber and glass fiber-infused filaments have the potential to give part strength close to that of metal, and they are suited for lightweight structural parts.

- Large Size Limits: Industrial-grade FDM equipment can produce parts over one meter in length, exceeding the 50 cm powder bed size limit of MJF.

FDM’s Ultimate Challenges:

- Z-axis strength is only 40%-60% of XY-axis strength, prone to interlayer cracking.

- High surface roughness requires a lot of post-processing.

- Low batch production efficiency, not ideal for orders over 100 parts.

MJF’s “Lean Manufacturing” Philosophy

- Nesting and Batch: Powder bed can nest parts of different shapes and finish them within a single print, significantly improving batch efficiency. For example, 50 electronic components of different specifications can be printed together.

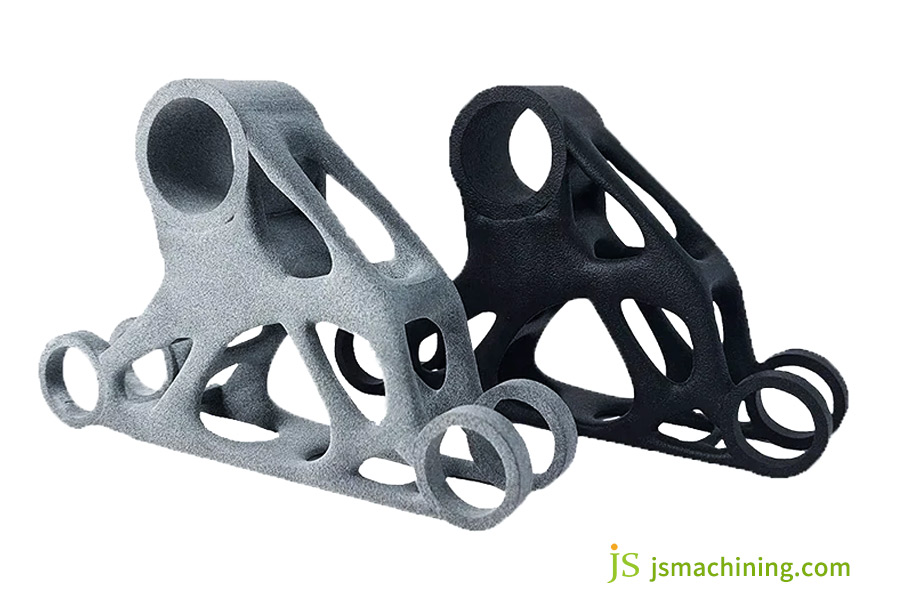

- Consistency: Sintering is a process with consistent part dimensional tolerances of ±0.1 mm and stable mechanical properties, making it suitable for end products with high consistency requirements.

- Light-weighting and Integration: Allows for complex lattice structure designs and possesses the ability to consolidate multiple components into a single component, reducing assembly operations and errors.

MJF’s Ultimate Challenges:

- Costly equipment that is not accessible to small businesses.

- Limited material selection, which is currently dominated by nylon.

- The inability to print parts larger than 50 cm.

Whether multi-material composite parts that require FDM printing or lightweight integrated parts that require MJF printing, JS Precision Manufacturing can leverage its tech strength to meet your custom 3D printing manufacturing requirements and resolve your technical issues in part manufacturing.

Future Prospect: Selecting 3D Printing Is No Longer a Single Option

Everyone wonders if 3D printing’s future will be a one-size-fits-all solution. The fact is that as FDM printing and MJF printing continue to develop, the areas they are applied in will become more and more complementary, and the selection will not be an either-or decision anymore.

Future Development Trends of FDM Printing

The future for FDM printing lies in the realm of material extension and efficiency improvement. Companies have already developed biodegradable FDM materials to allow their use in high ecologically demanding projects. The batch efficiency of FDM has also improved with the introduction of multi-nozzle FDM machines that could potentially position FDM as more competitive in small and medium-scale production.

Future Development Directions of MJF Printing

The future direction of MJF printing is material diversification and cost reduction. Beyond nylon, some companies have already attempted to use MJF to print metal powders, and more kinds of materials may be added in the future. As the equipment becomes more widespread, the unit price of MJF will gradually decrease, allowing more small and medium-sized enterprises to benefit from MJF.

Future 3D Printing Options: A Combination of Technologies

For companies, 3D printing options in the future can be a combination of technologies:

- Using FDM printing for initial prototypes to quickly validate designs.

- Using MJF printing for small-series end production for quality and productivity.

- Considering injection molding when order volumes reach 1,000 or more.

This combination allows for the selection of the most appropriate technology at each stage, balancing cost and productivity.

In anticipation of the future development of 3D printing technology, JS can provide FDM printing and MJF printing solutions in a flexible combination based on your project stage, with ongoing custom 3D printing manufacturing services available to aid your adaptation to your production needs at different stages.

Case Study: Two Iterations Of ADrone Enclosure

Project Background

A startup needed to trial-manufacture 50 sets of weather-resistant, high-strength enclosures for an innovative industrial drone. The enclosures needed to withstand temperatures of -10°C to 50°C and vibrations of 20 to 2000Hz. Trial manufacture was required in three weeks to facilitate market launch.

Why was JS’s solution superior?

- Version 1(Incorrect Choice): FDM Printing (ABS Material)

The company initially used its own high-end FDM printer, with the expectation that the low unit cost of FDM materials would maintain the cost within budget. The team labored 16 hours a day and completed the 50 sets in a fortnight.

The following problems repeatedly occurred: the housing surface had an Ra value of 10μm and had to be manually polished, with over 100 hours of labor. Z-axis wall cracks during the assembly of 15 housings, and interlayer cracking during one flight test. Final yield was a mere 60%, which delayed the project by one week and missed the initial launch date.

- Version 2 (JS’s Solution): MJF Printing (PA12 Material)

After the company contacted JS, our engineers analyzed the requirements and recommended MJF printing using PA12 material—which possesses excellent weather resistance, stable performance within -10°C to 50°C, and improved vibration resistance over ABS. Optimized the design files within 24 hours of receiving them from the customer and printed 50 sets in 8 hours and delivered them in 3 days.

The results were ideal: the housing had a Ra value of only 2μm, ready for direct use, tensile strength was as much as 50 MPa in all directions, with no issue of chipping or cracking, and the yield rate was 100%. Although MJF’s $25 per part cost was higher than FDM’s $18, the elimination of polishing labor (approximately $1,500) and delay costs (approximately $5,000) lowered the total cost effectively, getting the product to market successfully.

Key Lessons

One of the most expensive R&D errors is underestimating a prototype’s functional requirements. The choice between MJF and FDM does not depend on which plastic costs less, but rather on which final product will be able to do its final job correctly the first time.

FAQs

Q1: Are MJF parts as strong as injection molding parts?

Very close! MJF nylon (PA12) part strength, rigidity, and impact resistance are up to 80%-90% of their injection molded part counterparts, which meet most end-users’ needs. For example, MJF PA12 tensile strength is about 50 MPa, while for injection molded parts it is about 55 MPa, a minor difference. For electronics parts and automotive interior use, MJF can replace injection molded parts, with high cost and efficiency benefit for small batches (10-500 parts).

Q2: Do FDM-printed parts have less strength compared to MJF parts?

Yes, especially in the Z-axis direction. FDM has weak interlayer bonding, with Z-axis strength only 40% -60% of XY axis, and parts are prone to cracking. And MJF parts are sintered as a whole, with a performance difference of less than 5% in all directions. PA12 has a tensile strength of about 50MPa in all directions, which is more durable and suitable for complex parts under stress.

Q3: Does MJF print in only black?

Much commercial PA12 used today is gray or black because it contains carbon powder to sinter in the infrared. MJF parts created in white PA11, however, may also be red, blue, or some other color through dyeing. Dyeing involves immersing the part into a unique dye that diffuses at a specific temperature. The resulting color is uniform, has good adhesion, and does not affect mechanical properties, meeting most aesthetic requirements.

Q4: Do I buy an FDM or outsource my MJF project?

Cost savings are achieved with FDM when you print fewer than 10 parts per month and need low accuracy (±0.5 mm) and low strength. In case you need to print end-use parts or parts of high accuracy (±0.1 mm) and high strength, outsourcing to JS is more economical. We have a professional team to ensure quality, and our online 3D printing services have a simple ordering process.Send us your files and we’ll quote you back within 24 hours. 3-5 day turnaround from acceptance, no equipment charges.

Summary

FDM vs. MJF is not “who’s better”, but “who’s more appropriate.” FDM democratizes innovation and brings manufacturing capability to everyone. MJF, on the other hand, equates industrial production efficiency to bringing 3D printing within the realm of end-use direct production.

When you make a choice between FDM printing and MJF printing, JS can give you a professional technical comparison and match you with the optimum technical solution. We provide fully transparent online 3D printing service from quotation to delivery, so you achieve excellent quality 3D printing parts at reasonable 3d printing price and your project runs smoothly.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Resource

Pingback: Nylon Is Just The Beginning: 5 High-Strength 3D Printing Materials Revealed - JUSHENG

Pingback: What Are The Core Challenges Facing PVC Materials In 3D Printing Technology? - JUSHENG