Imagine: your key customer’s core equipment suddenly malfunctioned,shattering a core aluminum alloy component and completely halting the production line. Each minute resulted in heavy losses. The client demanded repairing within three hours, requesting express shipping of all things.

Aluminum TIG welding is a finicky, time-consuming process, which seems to sacrifice quality in the pursuit of efficiency. The real challenge is getting rid of this image, essentially a quantum leap in efficiency by a very methodical procedure, not sloppy work.

This guide, derived from JS’s extensive amount of welding experience, provides the best way to efficiently complete aluminum TIG welding in under three hours to achieve great sheet metal parts. This guide will help you efficiently shorten welding time without sacrificing quality so that you can meet both emergency and routine TIG welding of aluminum requirements.

Key Answer Summary

| Comparison Dimension | Traditional Approach | 3-Hour Efficient Approach |

| Core Strategy | Proceed step by step and solve problems only when they occur. | Systematic planning: Complete all preparations (materials, equipment, process cards) before welding. |

| Pre-Welding Preparation | Conduct temporary cleaning and on-site assembly. | Precisely clean and clamp all workpieces in advance, and preset equipment parameters. |

| Welding Sequence | Usually follow an intuitive sequence. | Adopt scientific sequences such as “skip welding” and “backstepping” to minimize deformation. |

| Heat Input Control | Rely on welder experience, with large fluctuations. | Use pulsed TIG to precisely control peak current, background current, and frequency, and reduce the heat-affected zone. |

| Equipment Selection | Basic TIG welding machine. | High-performance AC pulsed TIG welding machine: Equipped with high-frequency arc starting, automatic voltage stabilization, and preset functions. |

| Quality Assurance | Conduct post-welding inspection and rework only if problems exist. | In-process monitoring: Conduct quick self-inspection after each weld to eliminate batch defects. |

Why Can We Rely On This Guide? JS’s Extreme Welding Experience

In acquiring a proven aluminum TIG welding method, it is important to choose a guide who has ample hands-on experience. JS possesses ample practical experience in welding with experience in aluminum TIG welding in different sectors like aerospace, automotive, and medical devices.

Whether to process ultra-thin aluminum alloy sheets of 0.5mm or thicker plates of over 20mm, whether to customize intricate sheet metal welding parts or mass-produce common components, JS has solutions for all.

This handbook is a distillation of the JS company’s welding experience derived from these real projects. Every step and recommendation has been field-tested, so you know it will help you get the job done effectively in completing TIG welding of aluminium and successfully producing qualified sheet metal welding parts.

JS offers professional online sheet metal welding services. On the basis of years of field experience, we can provide you with correct aluminum TIG welding solutions. You may get in touch with us for more information on our services.

Why Is Aluminum TIG welding Referred To As A”Time-Consuming Process”?

Now that we have knowledge about the reliability of this guide, let us talk about why aluminum TIG welding is a “time-consuming process” to help you with managing time constraints. There are three main challenges with welding aluminum, and they directly affect welding time.

- A heavy oxide coating easily develops on the surface of aluminum, which requires cleaning thoroughly before welding. Otherwise, porosity occurs, and rework is required, which consumes extra time.

- Aluminum has a high thermal conductivity. Poor control of heat input will add to welding time and may be a factor in part deformation, which must be corrected.

- Aluminum’s low melting point makes it difficult to control the weld pool. Welders have to adjust constantly the angle of the torch and the wire feed speed, thus indirectly adding to operation time.

It is not a tutorial on how to “weld fast,” but how to “weld efficiently” through an organized approach. You can make great quality sheet metal welding parts in 3 hours, defying the “slow work, fine work” myth and ensuring TIG welding of aluminum no longer turns out to be the project bottleneck.

Five Hidden Factors That Impact Welding Time

After the acknowledgment of the challenge of aluminum TIG welding, attention must be called on five subtle factors that can silently increase welding time, which in turn can directly impact the achievement of the 3-hour milestone.

1.Joint Design and Material Thickness

Thickness increase requires greater heat input and weld time. At the same time, the choice of welding material can also affect efficiency, for example, high thermal conductivity welding materials require more precise heat input control, otherwise it is easy to prolong welding time.Complex joint designs (such as multi-pass welds) are longer than simple butt joints because they require more welding processes and changeover time.

2.Cleanliness

Not removing completely the oxide film and oil spots on the surface of aluminum will lead to welding defects, which will require rework. This rework time can typically be more than twice that of normal welding, having a severe impact on overall efficiency.

3.Adjustment of Fixture and Tooling

When the fixture is not well designed, components can easily shift in the course of welding, and adjustments are frequently required, taking on average 10-15 minutes per adjustment. Less than optimum tooling preparation could also result in welding stops and wait time.

4.Equipment Quality and Parameters

Poor-quality TIG welders are slow to heat up and experience unstable current, extending the welding time. Poor parameter settings must be repeated multiple times and are wasteful to the extent of 20 minutes of progress on average.

5.Welder Competency and Process Awareness

Incompetent welders take more time handling the weld pool and wire feed speed and take 40%-50% more time compared to competent welders. Process unawareness leads to missed steps, wasting time.

Three-Hour Roadmap: Step-By-Step Learn Aluminum TIG Welding

After knowing the factors which can change time, employ the following phased outline to get aluminum TIG welding within 3 hours. Each phase has clear objectives and requires rigorous execution.

Minutes 0-30: Planning and Preparation (Don’t be cheap!)

- Confirm the aluminum alloy type (e.g., 5052, 6061) and thickness not to make a wrong decision using the wrong welding wire (e.g., 5052 aluminum with ER5356 wire).

- Acetone clean at least 50mm on both sides of the groove. If the oxide film is heavy, clean with a stainless steel wire brush.

- Set the TIG welder parameters provisionally according to material thickness and have the machine in proper working condition.

Minutes 30-45: Precision Assembly and Clamping

- Form the workpiece to the required shape, keeping the joint gap in accordance with the specification (0-1mm) to ensure that it will not compromise the quality and welding speed.

- Hold the workpiece using an aluminum clamp in controlled clamping pressure so as not to move or be deformed.

Minutes 45-150: Effective Welding

- Use pulsed TIG welding with pre-programmed parameters (i.e., 190-200A peak current for 3mm 5052 aluminum).

- Use 15-20-degree workpiece-gun angle, uniform wire feed rate of 50-120mm/min.

- Be in constant monitoring of the weld pool. If wide or sagging, cut the speed or current immediately to minimize defects.

150-180 minutes: Final Inspection and Fast Post-Processing

- Visual examination of weld after welding for surface defects such as pores and cracks.

- Penetrant testing (PT) to inspect for internal defects. Minuscule defects can be removed by cutting with an angle grinder.

- Scrape away slag and dirt using compressed air, followed by post-processing.

JS is an expert in custom sheet metal welding manufacturing services and adheres to this strict game plan in delivering quality TIG welding of aluminum products within the stated timeframe. Just order your things, and we’ll begin the process and efficiently guide your project.

Magic Sequence: Time Saving And Reducing Deformation Welding Sequence

Efficient welding means having a welding sequence that reduces distortion and saves rework and correction time. The following are significant principles and practices.

Fundamental Principle: Stability of heat balance to prevent localized overheating

Aluminum has good thermal conductance, which preferentially leads to workpiece distortion by localized overheating. A structured sequence of welding is essential to provide stability of heat distribution, preclude the risk of distortion, and preserve stability time for correction.

Welding methods in detail

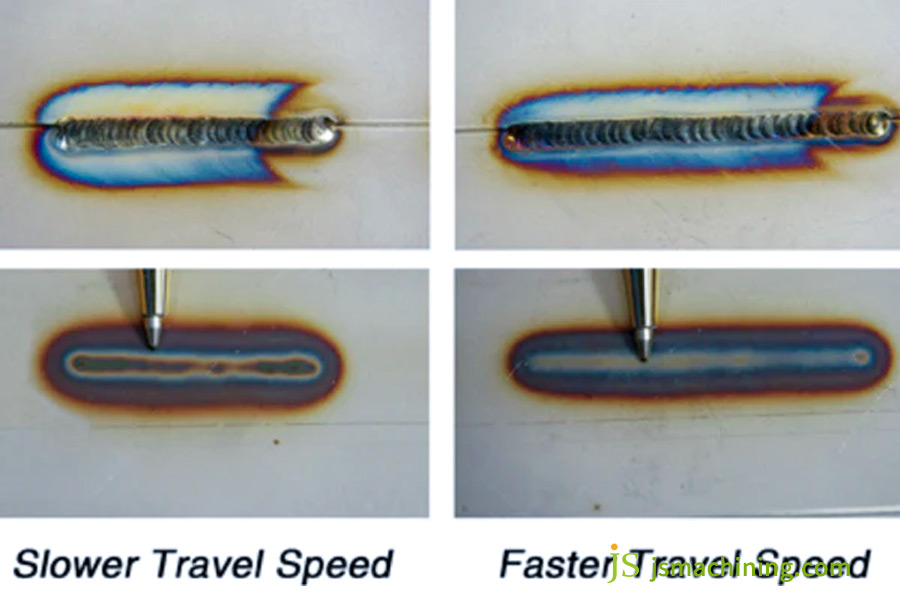

- Skip Welding: Divide the weld into multiple segments (e.g., a 300mm weld into 3 segments) and weld in sequence 1-3-2. Rapidly cool the welded segments and minimize deformation.

- Backstepping: Weld from the end of the weld toward the start, each segment 50-100mm long (e.g., a 200mm weld into 4 segments). It can be used in long welds.

- Symmetrical Welding: Weld symmetrical parts (like a square aluminum box) in opposite positions (front-back-left-right) to divide the heat among them.

Heat Input Control

Continue the welding torch as quickly as possible with deep penetration. Regulate speed by weld pool width (not over double the wire diameter) and the weld sinking condition, balancing quality and efficiency.

Difficult First, Easy Later, Internal First, External Second

Weld high constraint, low deforming areas (such as immovable ends of aluminum frame) first and subsequently weld free ends. This minimizes the impact of the following welding on already welded portions.

For any questions on welding order, JS technical team can help with any questions related to the welding order. Our sheet metal welding service will determine the most appropriate order of welding based on the workpiece structure, to maximize efficiency and quality, to help you successfully complete your TIG welding of aluminum projects.

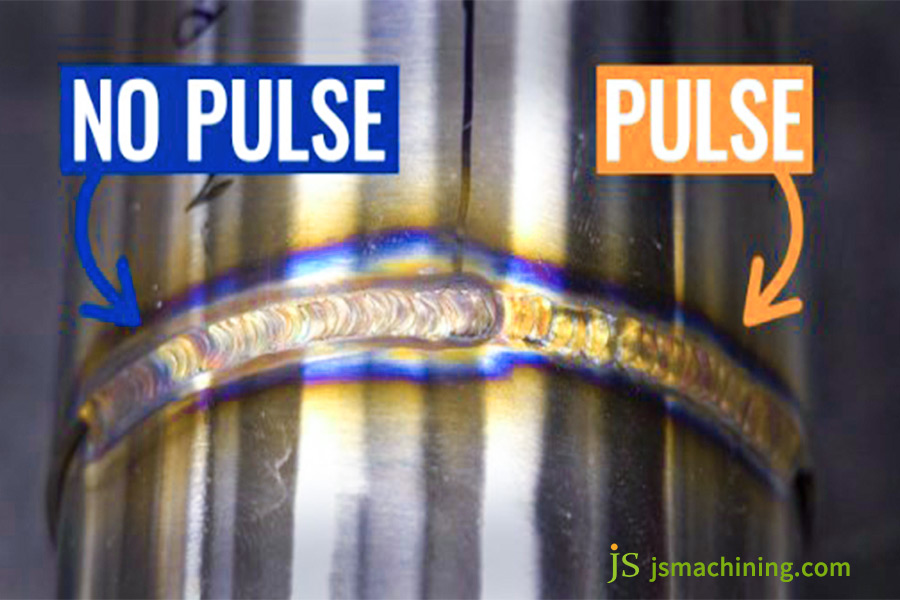

Core Weapon: Precision-Tuned Pulsed TIG Function

To achieve high-quality and efficient TIG welding of aluminum, the pulsed TIG mode must be precisely calibrated. Three basic parameters influence efficiency and quality quite strongly.

Three Basic Parameters of Pulse TIG

Peak Current: Used to melt wire and workpiece. Insufficient peak current produces poor penetration,excessive height will increase the risk of deformation.

Background Current: Maintains arc stable and quenches the workpiece. The value is too low to be susceptible to arc extinguishing, and too high a value prevents effective heat dissipation.

Pulse Frequency: Controls weld pool agitation and welding speed. Low frequency (1-10Hz) gives greater appearance but lower speed, while high frequency (50-100Hz) gives greater efficiency.

Practical Parameter Reference (Flat welding position using 3mm 5052 aluminum alloy)

| Parameter Type | Low-Frequency Scheme (Pursuing Quality and Temperature Control) | High-Frequency Scheme (Pursuing Production Efficiency) |

| Tungsten Electrode | Ø2.4mm cerium-tungsten/lanthanum-tungsten, tip ground to a 30-degree taper. | Ø2.4mm cerium-tungsten/lanthanum-tungsten, tip ground to a 30-degree taper. |

| Welding Wire | ER5356 Ø2.0mm | ER5356 Ø2.0mm |

| Peak Current | 190A | 200A |

| Background Current | 70A | 60A |

| Pulse Frequency | 2 Hz | 80 Hz |

| Welding Speed | Approximately 50-70 mm/min. | Approximately 100-120 mm/min. |

| Application Scenario | High-precision sheet metal welding parts with high appearance requirements. | Sheet metal welding parts for emergency orders and mass production. |

For different common aluminum alloy types, see the following table for initial pulse TIG welding parameter selection. This will effectively match the desired material to the correct shielding gas and optimize parameter setting efficiency:

| Aluminum Alloy Type | Recommended Welding Wire Type | Applicable Pulse Frequency Range | Peak Current Range (Flat Position, 3mm Thickness) | Shielding Gas Flow Rate (Pure Argon ≥99.99%) |

| 5052 | ER5356 | 2-80 Hz | 180-200A | 14-16 L/min |

| 6061 | ER4043 | 5-90 Hz | 170-190A | 14-16 L/min |

| 7075 | ER5183 | 10-100 Hz | 190-210A | 15-17 L/min |

| 3003 | ER3103 | 3-70 Hz | 160-180A | 14-16 L/min |

Shielding Gas Requirements and Selection Recommendations:

Utilize pure argon (≥99.99%) at a flow rate of 14-16 L/min. Use a gas lens for improving shielding performance. If cosmetic issues are of concern, choose a low-frequency solution.If time-sensitive deadlines are a concern, choose a high-frequency solution. Both deliver high-quality TIG welding of aluminum.

JS precisely corrects pulse TIG parameters according to customer part specifications in TIG welding of aluminum. Our online sheet metal welding services can act with a quick response to your requirement and provide customized parameter solutions to help you operate your welding activity smoothly.

Case Study: 180-Minute Countdown – Emergency Repair Of ARacing Car’s Aluminum Fuel Tank

Background

On the eve of a large rally, a racing team’s specially made aluminum alloy fuel tank suffered a longitudinal crack around 80mm in length on its bottom while being transported. Due to the customized nature of the fuel tank, the size and interface are exclusively designed,a replacement was not available. A TIG welding repair was necessary in order for the car to race.

Additionally, even though the tank had been drained, leftover fuel vapor still existed within. Sparks produced during welding could quickly lead to an explosion or fire, and thus incredibly high safety standards were needed. Additionally, the subsequent installation of the tank imposed stringent size requirements, and there could be no deformation after welding, or else the installation precision would be affected.

Challenge

The time limit was set to three hours, and all from preparation to inspection needed to be done within this interval. The welds had to be 100% sealed, with no leak, or else there would be a possibility of fuel leakage during driving. The tank should not be deformed after welding in order to avoid any issues regarding installation. Safety was the main priority, and the fuel vapor should not lead to any safety concerns.

JS’s 3-Hour Action Plan

- Minutes 0-30 (Safety and Preparation): Use three 99.99% argon three times, each 10 minutes, to flush the fuel tank, create a 60-degree V-groove (2/3 tank deep, 4mm) and clean the groove with wire brush and acetone.

- 30-45 minutes (Equipment Setup): Select pulsed TIG welder, Ø2.4mm cerium-tungsten (30-degree cone), high-frequency parameters (200A peak, 60A base, 80Hz frequency), ER4043 welding wire preparation, and support fixture installation.

- 45-150 minutes (Welding Execution): De-weld in four 20mm increments, two operators (one welding torch, one feeding the wire and observing). Cool with compressed air between increments.

- Minutes 150-180 Minutes (Inspection and Finishing): The welds were inspected with a PT, were pressure tested at 0.5 MPa for 30 minutes, and were sanded to smoothness.

Results

JS was successful in performing the TIG welding repair of the fuel tank within the three-hour timeframe. After installing the fuel tank, the car participated in the rally as per schedule and finished the race successfully. There were no leakages observed during the race, and the tank installation was precise to all specifications.

This case demonstrates the perfect functioning of four main elements: preparation, parameters, sequence, and inspection in a limited time frame. It also demonstrates the ability of our TIG welding of aluminum technology to respond to emergent conditions and resolve emergent issues for our clients.

Beyond The Norm: Three Unconventional But Highly Time-Saving Professional Techniques

In addition to the basics, the following three professional skills can make aluminum TIG welding more efficient and help you complete sheet metal welding tasks within a short time.

“Hot Start” Technology

Old arc initiation includes preheating (5-8 minutes of wastage). “Hot Start” includes ramping the current to 1.2 times its peak (of 1-2 seconds) at the arcing moment. This instantly melts the oxide film and wire directly forming a weld pool. This is most appropriate for emergency TIG welding of aluminum projects.

Two-Person Collaboration

Single-operator operation is characterized by a lot of switching of the welding gun, wire, and cleaning (lost time). With two-person team mode, one operates the welding gun (speed and angle) and the other operates wire feeding, observation of the weld pool, and cooling. It has the ability to boost efficiency by 30%-40%, thus saving time on sheet metal welding.

“Cold Welding” Technology

For thin aluminum sheets ≤1mm thick, traditional welding requires constant current adjustment to prevent burn-through (time-consuming). “Cold welding” uses low heat input (peak current ≤80A, pulse frequency ≥100Hz) with copper heat sink to achieve one-time molding, saving 10-15 minutes adjustment time. It suits the welding of thin aluminum sheet metal components.

JS employs these techniques in adaptable manners in custom sheet metal welding manufacturing, as per the needs of the workpiece. Our sheet metal welding price is reasonable, and can help you save money and improve efficiency without sacrificing quality. We invite you to contact us and let us provide expert support for your sheet metal welding project.

FAQs

Q1: Is the 3-hour welding time including workpiece cooling time?

Yes. That is because of active cooling methods such as pulsed TIG welding, segmented de-welding, and forced cooling (for example, compressed air cooling) where the workpiece is cooled rapidly between welding gaps and after welding,rather than sitting idly by and waiting for the cooling process. Each step incorporates cooling time. A 3-hour cooling cycle incorporates all cooling necessary, so usable sheet metal welding components are shipped on time.

Q2: Short of time, can the standards of cleanliness be reduced?

Absolutely not. Cleanliness is essential for successful aluminum welding. If the oxide film and oil marks on the aluminum surface are not entirely removed, they will be sucked into the weld pool upon welding and form weld defects such as porosity and slag inclusions in the weld. Redoing follow-up will increase the weld time and can also affect the sheet metal welding parts’ hardness. Therefore, no matter what the urgency of the condition is, cleaning is a must to ensure the quality of TIG welding of aluminum.

Q3: Is MIG welding suitable in a rush?

For urgent conditions with thicker plates with less concern about appearance, MIG welding is feasible, it is 20%-30% faster than TIG welding. But for precision sheet metal welding parts that have exacting quality and appearance requirements, there are special strengths of TIG welding that cannot be substituted. It avoids rework subsequently initiated by defects in quality and is more suitable to the 3-hour deadline goal. It is also one of the core choices for JS’s TIG welding of aluminum.

Q4: How can I ensure that my heat input is too large?

This can be determined by looking at the weld seam on the back and front of the weld pool. If the back is collapsed or severely oxidized, or the front weld is blackened, sunken, or coarse-grained, this indicates there is excessive heat input. In this case, raise the welding speed or reduce the peak current (e.g., from 200A to 180A). By adjusting, the heat input returns to a reasonable range to avoid affecting the size and strength of the sheet metal welding parts.

Summary

TIG welding aluminum is a skill and strategy challenge. Conquering the 3-hour extreme test does not rely on brute force, but an advanced system including preparation, planning, sequencing, and parameter control. Mastery of this process will allow you to break the myth of “slow and steady wins the race” and give quality sheet metal welding parts.

JS offers a one-stop custom sheet metal welding manufacturing service, from custom design to production delivery.Our sheet metal welding prices are transparent and reasonable, and it is simple to place an order. Just provide your part drawings and specs, and we will instantly develop a solution and get into production. Use JS and transform your sheet metal welding project into a smooth and hassle-free process.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Nylon Is Just The Beginning: 5 High-Strength 3D Printing Materials Revealed - JUSHENG

Pingback: Reduce Costs By 20%! JS Accurately Identifies The Brass Sheet Metal Grade - JUSHENG

Pingback: What Are The Core Challenges Facing PVC Materials In 3D Printing Technology? - JUSHENG

Pingback: What Is Stronger, 10 Or 11 Gauge Steel Thickness? - JS Precision