When engineers and designers require quality, fast, and affordable custom part machining service, they are left with slow quotes, ineffective communication, obscure pricing, and uncertain quality. Good online CNC service can solve these problems.

JS is aware of the challenges that individuals experience while looking for CNC machining services and therefore we have come up with this guide. It explains our online CNC machining services and enables you to find the ideal custom CNC machining manufacturing solution easily.

We are seeking to make manufacturing as easy and reliable as internet shopping, so basically bridge the gap between “ideas” and “physical objects”. Order today and receive 5% discount on your first purchase, your manufacturing process streamlined and accelerated!

Core Answer Summary

| Core Dimension | Key Information | Advantage Highlights |

| Service Type | One-stop online cnc service, including intelligent quotation, production, and logistics. | Available 24/7, with convenient cloud-based operation. |

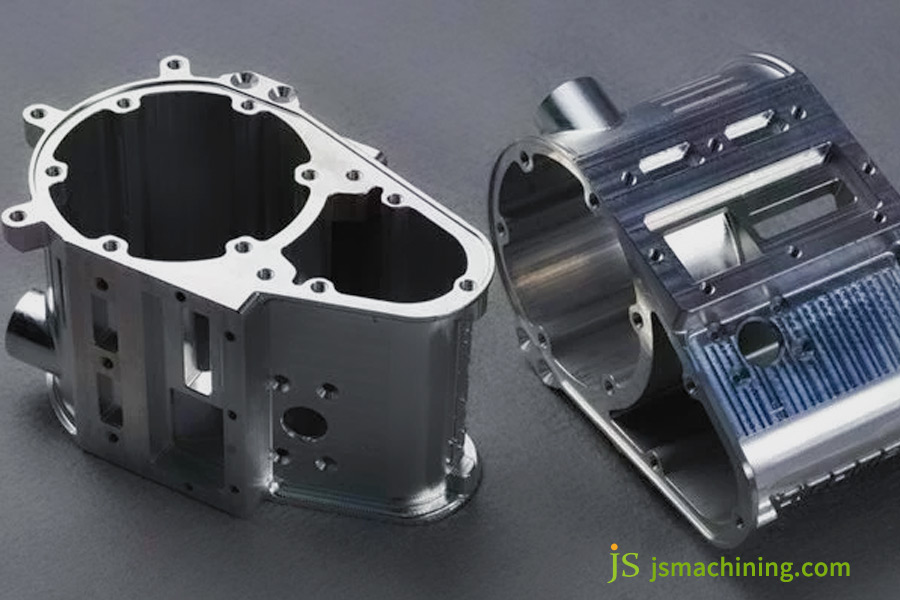

| Process Capability | 3/4/5-axis CNC milling, turn-milling combination, supporting anodizing and mirror polishing (Ra<0.1μm). | Medical/aerospace-grade precision, compatible with multiple materials. |

| Quality Assurance | Compliant with ISO 9001, tolerance up to ±0.013mm, providing FAI and CoC reports. | Full inspection process, clear material traceability. |

| Price Advantage | Transparent costs, cost reduction via AI-optimized paths, 5% discount for first orders, and up to an additional 12% discount for bulk orders. | No hidden fees, better cost-performance than peers. |

| Delivery Efficiency | 4-step ordering process, 7-10 days delivery for regular parts, and 5 days ahead of schedule in medical cases. | 50% improvement in project management efficiency. |

Why Do Top Teams Use JS?

JS has been deeply rooted in the CNC machining industry for many years and has accumulated rich experience.We have provided high-precision CNC machining parts to the aerospace industry, with extremely small tolerance of as low as ±0.005mm. All the products are stringently tested and are now in use. We have also fabricated complex parts in large batches for the auto industry, with more than 5,000 pieces monthly capacity and more than 99.8% pass rate consistently.

We also have sufficient successful examples in medical and electronic devices industries, such as medical device manufacturer surgical instrument components machined that strictly meet medical-grade material specifications and accuracy standards. This manual, a compound of our years of experience, has the key points and choice suggestions for online CNC services, every confidence that it will serve as a sound reference.

If you choose JS’ online CNC service, our extensive industry expertise can fit you perfectly. We provide expert services from consultation to delivery to help you get quality CNC machining parts successfully.

What Is JS Online CNC Service? Your Cloud-Based Manufacturing Workshop

After understanding the reasons why top teams trust us, we will now introduce in detail what JS’s online CNC service is. It is like your cloud based manufacturing workshop, making CNC machining more convenient.

Basic Definition

JS online CNC service is a one-stop web-based service that combines smart quotation, process planning, production management, and logistics. It is easy to use custom CNC machining manufacturing services where you can complete the entire process from parts design to delivery online.

Workflow

Only four steps required to use our online CNC machining services:

- Upload Drawing: Post your part’s 2D or 3D drawing on the website, and the platform automatically recognizes the drawing data.

- Smart Quotation/Process Selection: The platform immediately creates a smart quote with material, size, and precision specifications in the drawing and offers different process options.

- Locked-in process and order: After confirming the quotation and process plan, confirm the order online and complete the payment, with a transparent and efficient process.

- High-quality parts: We produce to your order and ship them your way through professional logistics on completion.

Core Experience

Our internet-based CNC service relies on a dream of “automated, digital, worry-free.”

- Automation is embodied in intelligent quoting and incorporated automatic process tracking with minimal human intervention.

- Digitalization offers real-time clarity into the order status and the manufacturing process.

- Worry-free manufacturing is what our highly experienced team offers, from checking of drawings to shipping and logistics, thereby transforming the manufacturing into no longer an old-school “project” but merely an “order.”

Find JS’s Process Capabilities: Start-To-Finish Solutions Milling To Turning

Having read this short intro of JS’ CNC services on the Internet, you may be curious about our capability of process. The following is a complete explanation of the professional custom CNC machining manufacturing services we offer.

CNC Milling (3/4/5-Axis)

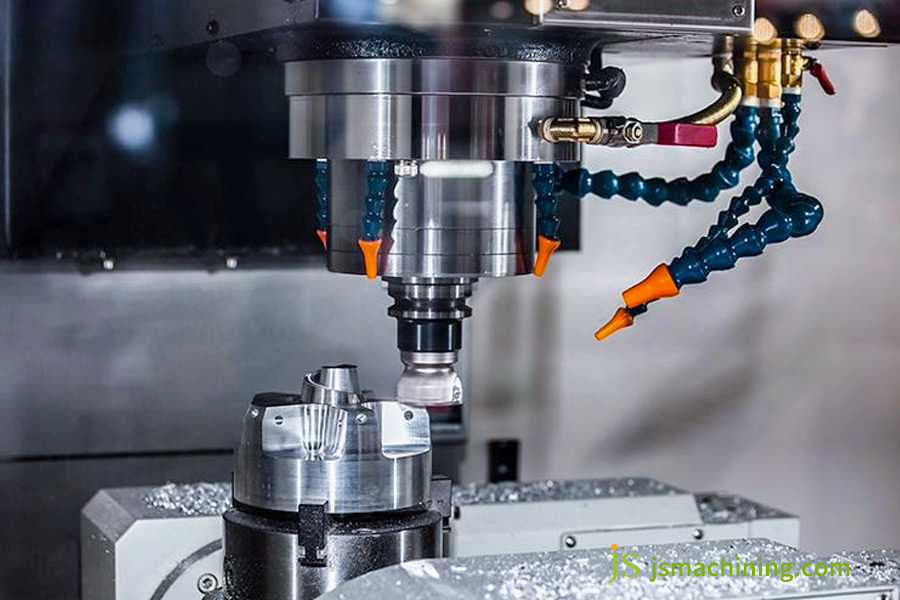

3-Axis milling can mill simple features with high accuracy ±0.01mm, 4-Axis can mill parts with circularly distributed features, 5-Axis can process in multi-angles, fit for complicated parts, with over 30% efficiency than general machines.

CNC Turning

General turning supplies rotary parts of 500mm diameter and 3000mm length. Mill-Turn machines are multi-purpose machines that machine parts with slots and odd holes, and are 50% faster than traditional tapping.

Value-Added Services

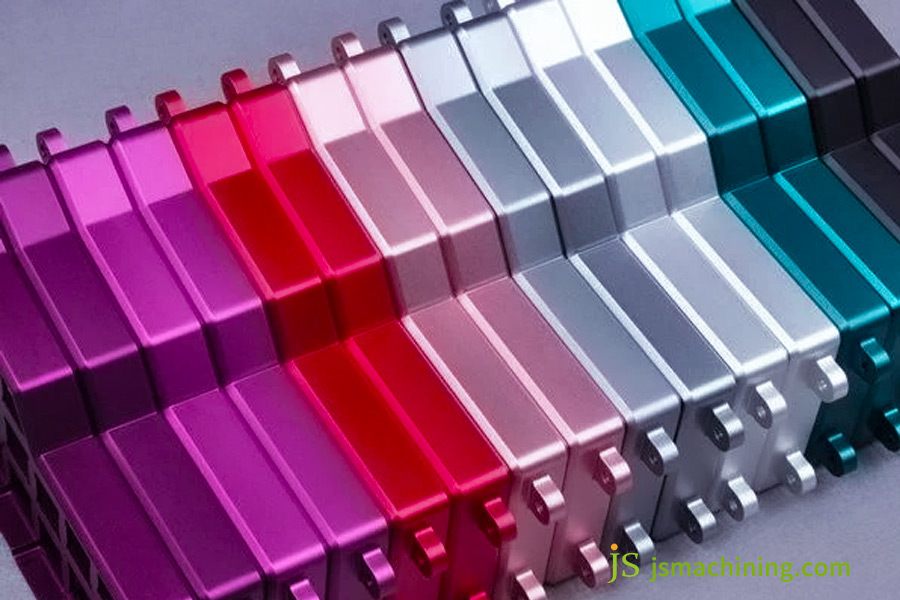

Anodizing: In addition to the usual silver and black, special effects such as gradient and fluorescent colors are also available. The oxide film thickness can be controlled at 5-20μm, which improves part wear resistance and corrosion resistance.

Metal Surface Finishing: In addition to polishing and sandblasting, we also carry out mirror polishing with a surface roughness of Ra <0.1μm, suitable for high finishing requirement components such as optical devices and precision molds.

Rapid, Low-Volume Casting Support: Precision casting services for producing small quantities of complex metallic parts are offered, a powerful supplement to CNC machining. The minimum lot quantities can be 10 pieces.

Choose JS’s custom CNC machining manufacturing services and enjoy a broad range of processes and value-added services to suit your diverse needs. From complex part machining to surface treatment, we offer professional solutions to help you achieve your ideal part.

Our Guarantee Of Precision: JS’s Tight Tolerances

In CNC machining, accuracy is paramount, with a direct impact on part functionality. In this article, we’ll outline JS’ high accuracy standards and why you can trust our CNC machining parts.

Our default machining tolerance standard is ISO 2768-mK, and we can achieve even tighter tolerances depending on the part’s specific features and materials. The precise tolerance ranges are outlined in the following table:

| Part Feature | Material | Typical Achievable Tolerance Range | Testing Equipment | Applicable Industry |

| Simple Plane | Aluminum Alloy | ±0.025mm | Coordinate Measuring Machine | Electronic Equipment |

| Complex Cavity | Stainless Steel | ±0.05mm | Projector | Medical Equipment |

| Slender Shaft | Titanium Alloy | ±0.075mm | Micrometer | Aerospace |

| Large Disc-shaped Part | Cast Iron | ±0.125mm | Dial Gauge | Automotive Manufacturing |

We achieve such precise tolerances through the use of the latest CNC equipment, such as five-axis machine tools, with a positioning accuracy of ±0.003mm. We also maintain a rigorous quality control system, and each process is checked by experienced quality inspectors to ensure that each CNC machining part meets precision requirements.

Value Revealed: Why Are JS Custom Parts Prices So Competitive?

Now that you’ve understood our craft and attention to detail, you may be concerned about CNC machining price. Let us explain to you why JS Custom Parts pricing is so competitive and provide you with a good sense of our pricing advantages.

Cost Transparency

The prices of CNC machining essentially consist of four components:material cost, machine costs, labor costs, and post-processing costs.

- Material costs are calculated based on the type, specification, and weight of the part’s materials.

- Machine costs for each part are calculated based on the part’s machining difficulty, machining time, and equipment depreciation.

- Labor costs are personnel costs for design, programming, operation, and quality inspection.

- Post-processing costs are for processing such as anodizing, polishing, and heat treatment.

We provide a clear description of the calculation basis of each cost to the client for a clear understanding of CNC machining price.

JS Optimization Methods

Intelligent Layout and Process Optimization: As AI algorithms optimize machining paths and material usage automatically, we can enhance material utilization by 15%-20%, reduce machine idle time, and conserve labor costs.

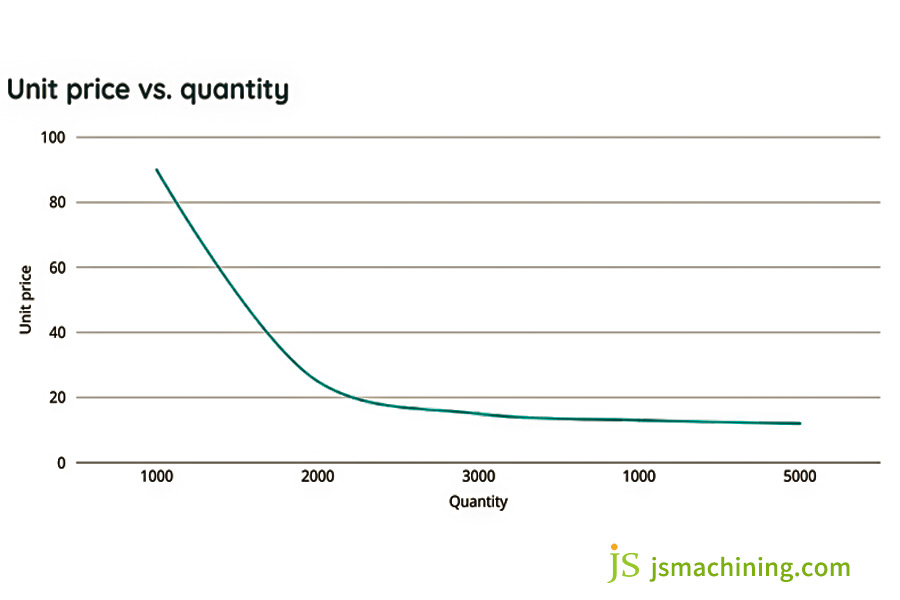

Economies of Scale: By accepting a large number of online CNC service orders monthly, concentrated orders dissipate unit costs, such as equipment depreciation and management costs, which reduce CNC machining prices overall.

Automated Processes: The process from manufacturing is highly automated, from smart quoting and automatic programming to automation of production process monitoring, with very little manual intervention, which reduces labor and management expenses.

Comparison with Peers

To give you a more intuitive understanding of our price advantages, we’ve compared JS with 3erp and RapidDirect on a number of aspects, as shown in the following table:

| Comparison Dimension | JS Precision Manufacturing | 3erp | rapiddirect |

| Price Transparency | ★★★★★ (Clear display of various cost components). | ★★★★ (Some cost components are unclear). | ★★★★ (Some cost components are unclear). |

| Cost-performance | ★★★★★ (Low price with high quality). | ★★★★ (Moderate price with good quality). | ★★★★ (Moderate price with good quality). |

| Hidden Fees | None (No additional hidden fees). | Yes (Additional service fees for some orders). | Yes (Additional service fees for some orders). |

| First-order Discount | 5% discount | 3% discount | 4% discount |

| Minimum Order Quantity for Bulk Discount | 100 pieces | 200 pieces | 150 pieces |

| Quotation Response Time | Within 10 minutes | Within 30 minutes | Within 20 minutes |

Choose JS’s online CNC service. Our transparent cost structure and multiple cost optimization options further render our CNC machining prices more competitive, allowing you to obtain high-quality CNC machining parts at low costs.

First-Order Special + Bulk Discount: JS’s Double Benefit

Now that you’ve learned about our price advantages, here’s even more great news: JS offers customers a first-order discount and volume discount so that you can enjoy the advantages of top-quality online CNC service and save even more.

First-Order Discount

You can receive a 5% discount for your initial purchase of CNC machining parts at JS. It’s simple to obtain the discount: simply register a JS account and place the first order. Then, reach our customer service team and inform them of your order number. They will refund the discount to you. The amount of the discount will be added to your account within three working days and can be utilized for your subsequent order or withdrawn directly.

Extra Discounts for Bulk Purchases

We also offer a graduated price schedule, with additional discounts for bulk orders. Discounts vary slightly by material and part complexity, as shown in the table below:

| Order Quantity (Pieces) | Regular Metal Parts (e.g., Aluminum Alloy, Stainless Steel) | Special Material Parts (e.g., Titanium Alloy, PEEK) |

| 100-500 | Extra 3% discount. | Extra 2% discount. |

| 501-1000 | Extra 5% discount. | Extra 4% discount. |

| 1001-5000 | Extra 8% discount. | Extra 6% discount. |

| Above 5000 | Extra 12% discount. | Extra 10% discount. |

For example, if you order 1,000 standard aluminum alloy CNC machining parts, you’ll receive a 5% discount on the initial order, plus an additional 5% bulk discount, for a total of 10% off, which will save you plenty of CNC machining prices.

Choosing JS’s online CNC machining services offers a 5% discount on your initial order and additional discounts for large orders. This dual benefit enables you to save money and also get high-quality custom CNC machining manufacturing services at a reduced cost.

Case Study: Precision Saves Time – How JS Accelerates Product Market For Medical Device Startups

Client Background

A startup medical technology company was working on an electrosurgical pen with high frequency that was handheld in nature and required functional prototype and small-batch test production parts to be made for clinical trials to enable clinical validation.

Challenges

The customer had very stringent primary specifications:

- Tolerance of the stainless steel connector sleeve bore was ±0.013mm, and the product should also be as per medical-grade 316L stainless steel and ISO 10993 specifications.

- A supplier is required to simultaneously process and anodize aluminum alloy, stainless steel, and PEEK materials.

- There must be complete material traceability and quality inspection records, and very tight deadline for project completion.

JS Solution

JS provides a one-stop solution:

- Aluminum alloy shell (6061-T6) is machined with four axis CNC and anodized.Turning of a 316L sleeve to micron accuracy on a Swiss-type milling center, and high precision CNC milling of PEEK insulation.

- Engineers also suggested rounding of housing grooves, increasing reliability with an additional 15% reduction in machining time. An FAI and CoC report was also provided, thus saving the testing cost.

Termination Results

All the components were passed first-time fit and fit, a great milestone. Project efficiency was improved by 50%, and delivery time was five days earlier than planned, hence creating enough time for clinical evaluation. The client was very complimentary towards JS, referring to it as an invaluable partner in their quest to productization.

Choose other online CNC services from JS. No matter the level of sophistication of your machining challenge, we offer one-stop solutions to assist you in getting through the challenge, saving you time to market, and manufacturing high-quality CNC machining parts.

How Do You Begin Your First (Or Nth) Custom Part Project?

After the case study, the steps below will make it easy to get started on a custom parts project and take advantage of JS’s web-based CNC service.

Getting Ready Preliminarily

Develop 2D or 3D part drawings with dimensions, tolerances, material identification (for example, 6061-T6 aluminum alloy), and surface finish requirements (for example, anodizing). Identify part quantity and delivery date to enable accurate quotation.

Platform Operation

Go to the JS online platform to register (enter minimal information and verify your email). Login to post your designs on the order page. The system will provide a smart quote within 10 minutes and present you with 2-3 process options to select according to your needs.

Confirmation and Delivery

Accept the quote, process, and delivery date. If unsure, contact customer service. After confirming the information, online payment (supports multiple payment methods) and monitoring of real-time production process. After producing, each part will undergo inspection, be transported by professional logistics companies.If there are any quality objections within 7 days after receiving the goods, the after-sales team will handle them promptly.

FAQs

Q1: I just have an idea or a drawing. Will you draw it for me and prepare it?

Of course.We provide internet full-service CNC service from manufacturing to design. If you already possess a pre-existing idea or sketch, inform us and our engineers will get back to you with your requirements and expectations. We then provide professional consulting services in designing. CAD modeling would then translate your idea into a 3D producible model. Finally, strict CNC machining would produce high-quality CNC machined parts.

Q2: My part contains very hard-to-machining thin-walled features. Will JS be able to machine them?

Yes. We have advanced five-axis CNC machining centers and very experienced programming engineers who specialize in handling high difficulty custom CNC machining manufacturing tasks. We will analyze the thin-wall parameters and utilize specific fixtures to hold the part. In the meantime, programming engineers will refine machining operations to make them more efficient, reduce vibration and deformation, and produce thin-wall features to your precise specifications.

Q3: Do you offer assembly?

Yes, we offer simple assembly and press-fit as added value for our online CNC machining services. If you are ordering more than one CNC machining part and these are to be assembled, please select “Assembly Service” during order and let us know about explicit assembly requirements and drawings. We will assemble and press-fit the parts according to your requirement after machining them on professional equipment and tools for accurate fit of parts, thus making them ready to use directly.

Summary

Are you looking for “CNC machining near me“?JS Online CNC Services marries strong manufacturing and military-quality with the ease and transparency of the web. A single prototype or production of components in thousands, we offer the most advantageous solutions.

Order now and enjoy a first-order discount of 5% as well as volume discounts for bulk orders. Enjoy high-quality CNC machining parts at an affordable CNC machining price. Upload your drawings now to start customization!

If you have a design already prepared:Upload your 3D file now and we’ll inspect it in a moment and offer a 5% first-order discount!

If you are still brainstorming: Contact our seasoned team for a free Design, Measure, and Functionability (DFM) consultation so that your design gets off to a flying start!

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: The Composition Of Brass Material:Why It's Not 100% Copper - JUSHENG

Pingback: What Special Designs Do Tools In Cutting Need For Cutting Composite Materials? - JUSHENG

Pingback: JS Precision Vs. Xometry: Which CNC Shops Near Me Offer The Most Transparent Quote? - JS Precision