Imagine: the phone case you are holding in your hand feels soft and elastic, which can effectively cushion the impact force when it falls. Your sports shoes bottoms are tough and hard and provide a firm support.And your handles of daily tools are non-slip, soft, and easy to grasp.

The majority of these items use thermoplastic polyurethane (TPU), but they are anything from very hard to very soft. This raises doubts: is thermoplastic polyurethane hard or soft? The answer is: it’s hard and soft, or rather, it can be formulated to any hardness between.

This seemingly “flexible” attribute is the underlying key to TPU’s success for anything from mass consumer goods to premium industrial goods. Here in this article, we will outline the secrets of TPU hardness to enable you to use TPU materials on injection molding parts more effectively.

Key Answer Summary

| Comparison Dimension | Soft TPU | Rigid TPU |

| Hand Feel & Characteristics | Soft, highly elastic, similar to rubber. | Tough, high rigidity, impact-resistant, similar to nylon. |

| Typical Shore Hardness Range | 60A – 95A | 50D – 80D |

| Key Application Examples | Phone cases, shoe soles, hoses, wristbands. | Gears, casters, sports equipment housings, automotive parts. |

| Processing Characteristics | Slightly poor flowability, and attention should be paid to sticking to the mold. | Good flowability, similar to engineering plastics. |

How Do I Choose The Proper Tpu Hardness For My Product? JS’s Material Selection Experience

Within the thermoplastic polyurethane (TPU) industry, the choice of hardness is absolutely central to the success of a product, and JS has great real-world expertise in this regard. During the last decade, JS offered TPU material selection and injection molding services to more than 500 customers in a broad range of industries such as electronics, automotive, and sports equipment.

For example, when creating a protective case for a best-selling mobile phone brand, JS team, after strictly testing it, eventually utilized Shore 85A TPU material. The material met both softness and drop resistance and was also easy to disassemble.

In the automotive industry, when selecting materials for automobile weather strips, Shore 70A TPU was utilized, focusing on sealing performance and also resistance to weather. This weather strip maintains outstanding performance under temperatures ranging from -40°C to 80°C.

JS not only possesses information regarding the hardness requirements of the TPU for various industries, but also possesses vast amounts of material information, enabling precise matching of product requirements with TPU hardness. This handbook is an encapsulation of our experience, bringing out the key points of the entire process, from needs analysis to material testing. You can trust this handbook as a true guide for selecting TPU materials for your products.

JS has extensive experience in TPU material selection and injection molding, allowing us to match your product needs to perfection. If you have injection molding manufacturing needs, please contact us and we will provide quality service.

The Emergence Of TPU: From Chemical Raw Material To “Moldable Material”

After understanding the TPU hardness scale, let’s talk about how TPU is transformed from a chemical raw material to a “moldable material.” This will come in handy in how we interpret its hardness properties.

Basic Process

TPU production primarily relies on the process of reactive extrusion. Polyol, isocyanate, and chain extender are loaded to the reactive extruder in suitable ratio. After heating, mixing, and chemical reaction, a TPU melt is obtained. After extrusion, the melt is cooled and pelletized to obtain TPU pellets, which can be used for subsequent injection molding and other processes like manufacturing of injection molding parts.

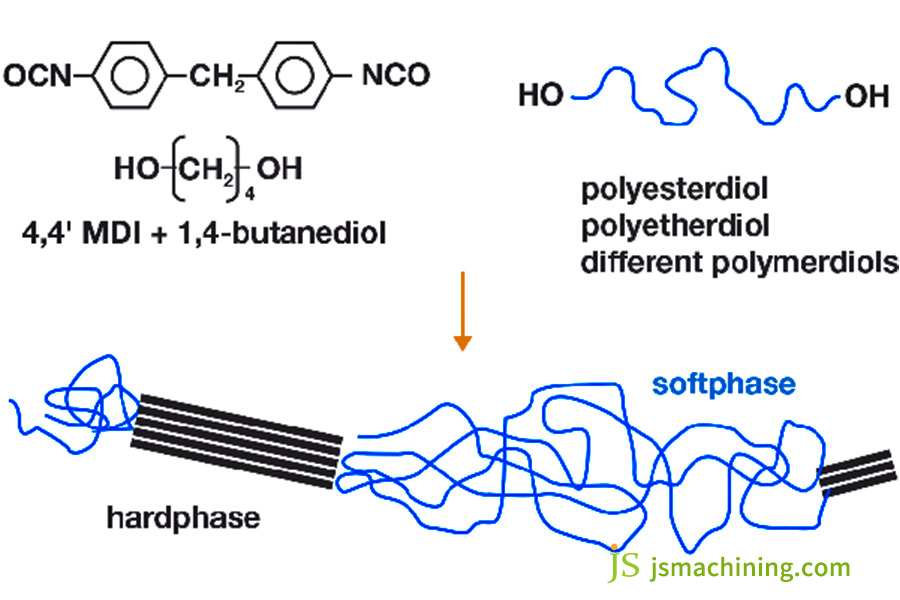

The Significance of “Segment” Structure

TPU has a microphase structure of separation, including soft segments and hard segments. The soft segments (essentially consisting of polyols) make TPU soft and elastic, while the hard segments (formed by the reaction of isocyanates and chain extenders) determine its hardness, strength, and heat resistance. The structure allows TPU to have a wide range of adjustable hardness to meet different needs.

JS is familiar with the process of manufacturing TPU and its material properties and can use its innovative injection molding technology to convert TPU pellets into high-quality products. When you want online injection molding services, choose JS, we can meet your demands efficiently.

Hardness Scale: Familiar With Shore A And Shore D In TPU

Now that we already understand the process of TPU creation, let us go to the scales used in determining TPU hardness—Shore A and Shore D—to better recognize TPU hardness.

Hardness Unit: Shore Durometer

Shore Durometer is a widely used instrument in measuring hardness of TPU. It is essentially composed of two kinds of scales, each one being used for materials with different hardness properties.

- The A scale is used primarily for soft and elastomeric materials, such as standard phone cases and sneaker insoles. It measures the softness and the elasticity of these kinds of products precisely.

- The D scale is suited best for testing hard products, such as tool casings and auto parts. The D scale easily shows the hardness and firmness of products with greater hardness.

Full Hardness Range

TPU’s overall hardness range is very wide, from soft products of Shore 60A to hard products of Shore 85D. With such wide hardness coverage, TPU can meet products’ needs in multiple fields and applications. Products may require higher softness and elasticity or components with great demands for hardness and toughness, and suitable thermoplastic polyurethane materials will be within TPU’s hardness range.

In order to more intuitively explain the characteristics and applications of TPUs with various Shore hardnesses, the following table provides some specific examples:

| Shore Hardness | Material Properties | Common Applications |

| Shore 70A | Soft and has good elasticity. | Grips of hand grippers. |

| Shore 95A | Slightly higher hardness and good elasticity. | Rollers of luggage cases. |

| Shore 55D | Higher hardness and good strength. | Casings of small tools. |

| Shore 75D | High hardness and strong rigidity. | Structural parts of automobiles. |

JS precisely controls the processing of TPUs with various Shore hardnesses and is also capable of customizing injection molding parts of various hardnesses. Our injection molding prices are reasonable and affordable, and we look forward to cooperating with you.

The Magic Formula: Four Core Factors Determining TPU Softness And Hardness

Now that we have information on the hardness scale of TPU, let’s discuss the four primary parameters on which its hardness and softness rely. The modification of these parameters can alter TPU hardness.

Soft/Hard Segment Ratio (Most Important):An increased soft segment ratio will result in softer and more elastic TPU,an increased hard segment ratio will result in harder and stronger TPU. For example, a 70% soft segment and 30% hard segment TPU would be Shore 70A, while a 60% hard segment and 40% soft segment TPU would be Shore 60D.

Polyol Type: Polyether TPU is a little softer compared to polyester TPU at the same ratio, but has greater elasticity and cold-weather stability and therefore it’s suitable for being used in outdoor goods in cold climates. Polyester TPU has excellent wear resistance, and is best suited to components subjected to high friction.

Chain Extender Type: Short-chain chain extenders close hard segments of TPU and increase hardness,long-chain chain extenders open hard segments and reduce hardness.

Additives and Reinforcement Materials: Plasticizers lower hardness, glass fiber, calcium carbonate, and other additives harden and increase strength. However, a high proportion of reinforcing materials can affect elasticity.

JS has widely researched TPU formulation and hardness. We can select an appropriate thermoplastic polyurethane formulation based on your product requirement and provide professional custom injection molding manufacturing to create satisfactory products for you.

Liquid To Solid: How Does The Hardness Of TPU Influence Its Processing Methods

TPU hardness not only determines its properties but also affects processing. TPU with varying hardness requires varying injection molding, extrusion, and blow molding needs.

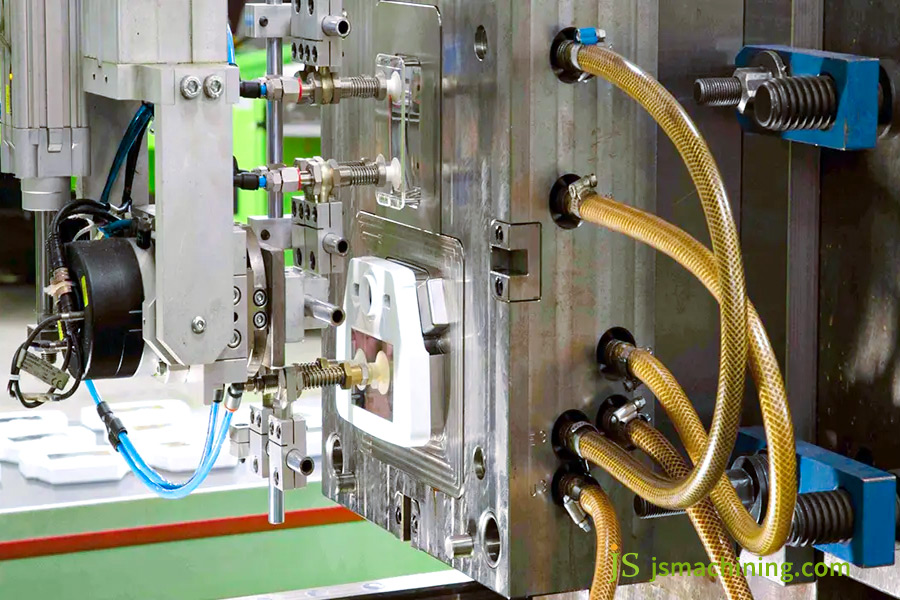

1.Injection Molding (Key Process)

Injection molding is the key process for the production of injection molding parts, and TPU hardness significantly influences it:

Soft TPU: The liquidity of the soft TPU is poor. In the injection molding process, molten TPU is difficult to fill in the mold cavity in a short time and is prone to adhering to the mold, making demolding product difficult. While processing the soft TPU, one needs to respectively increase the injection temperature, extend the hold time, and apply special mold surface treatment to prevent sticking.

Hard TPU: The processing behavior of hard TPU is more similar to that of engineering plastics such as nylon. It has excellent fluidity and fills the mold cavity in a short time. However, hard TPU is very hygroscopic and has to be dried intensively before processing. Otherwise, bubbles and silver streak defects will be caused in the injection molding process, leading to a decrease in product quality.

2.Extrusion Molding

Soft TPU requires the selection of suitable pitch screws, smooth mouth molds, and slow cooling.The compression ratio of the hard TPU screw can be slightly larger, the precision of the mouth mold is high, and the cooling is fast.

3.Blow Molding

Low hardness or medium hardness TPU is usually used to impart sufficient melt strength to the parison. TPU of extremely high hardness will have bad melt strength and will readily break the parison upon stretching.

TPU Hardness-Temperature Relationship: Investigation Of The Main Evolutionary Trends

Apart from processing methods, temperature also affects TPU hardness, and understanding such a relationship is crucial to the design of the product.

Basic Principles

TPU is a thermoplastic polymer, and hardness changes significantly with temperature.

- Increasing temperature increases molecular movement, weakening interaction, and softens and reduces the material’s hardness.

- Decreasing temperature slows molecular movement, tightens interaction, and hardens and increases the material’s hardness.

Glass Transition Temperature

Tg is the temperature at which TPU undergoes phase shift from the glassy state to the highly elastic state. At temperatures below Tg, TPU becomes hard and brittle and does not exhibit good elasticity. At temperatures above Tg, mobility of the soft segments takes place, the material becomes elastic, and the hardness decreases. The Tg varies with different TPUs, typically in the range of -70°C to 20°C.

Application Implications

It is critical to product design. A Shore 95A shoe sole, for example, will harden and lose grip at very cold temperatures, and become soft and lose support at very hot temperatures. Therefore, when selecting thermoplastic polyurethane, ambient operating temperature must be considered.

| Initial TPU Hardness | Temperature Change (℃) | Hardness Change Trend | Example of Application Impact |

| Shore 95A | 25 → -20 | Increases (becomes harder). | The sole loses grip and is easy to slip. |

| Shore 95A | 25 → 60 | Decreases (becomes softer). | The sole loses support and affects comfort. |

| Shore 70A | 25 → -30 | Increases (becomes harder and brittle). | The seal loses elasticity and fails to seal. |

| Shore 70A | 25 → 50 | Decreases (becomes softer). | The grip deforms too much and is unstable to hold. |

JS company will fully consider the impact of temperature on TPU hardness during the product design phase.By using custom injection molding manufacturing services, we are able to provide products with stable performance. If you would like to inquire about injection molding price, please feel free to contact us.

Exterior Static Hardness: TPU Creep And Stress Relaxation

In real-world applications, mere consideration of TPU’s static hardness is not sufficient. It’s essential to know its creep and stress relaxation characteristics as well. Even the same hardness materials can perform differently in long-term stress.

Under prolonged stress, TPU will creeps slowly (creep). When maintaining deformation, internal stress gradually decays (stress relaxation).To illustrate, for TPU seals of identical hardness, the ones with lower creep will retain their sealing performance over time, whereas the ones with higher creep will deform and lose seal.

This is important for seals and long-term tensile components. Creep-resistant seals that are poor leak gas and liquids, and parts in long-term tension experience large stress relaxation and fail. Polyether TPUs are likely to exhibit better creep resistance than polyester TPUs due to a more stable molecular arrangement.

When selecting TPU, apart from initial hardness, dynamic mechanical properties such as creep and stress relaxation also need to be considered in order to select the most suitable thermoplastic polyurethane in order to ensure long-term product stability and life.

Case Study: Overcoming the Injection Molding Challenges Of AHigh-Performance Multi-Purpose Tool Pliers

Customer Requirements

One sports outdoor company needed to develop a multi-tool pliers: the handle had to be Shore 75A (non-slip, soft and comfortable), while the inner gears and lock had to be Shore 75D (hard, functional and durable). The goal is to produce high-quality injection molding parts through one shot dual color injection molding.

Challenges:

The two TPUs have significant differences in hardness and processing windows. The soft TPU has low flowability and is prone to mold sticking, while hard TPU has a different shrinkage rate from the soft TPU and hence is prone to poor bonding or internal stress cracking.

JS’s Solution

We selected two TPU special grades with excellent chemical compatibility and compatible processing fluidity to avoid bonding issues at the origin.

Mold Design: Adopting precision two-color injection molds. The parting surface is specifically polished to reduce sticking of the soft TPU. Positioning pins are built into the mold cavity for high-precision placement of the two injections. Hard TPU is injected first to form the tool skeleton. The mold is turned and moved over for applying soft TPU on the skeleton in the second cavity.

Process Optimization: The TPU mold hardness is tightly regulated at 80-90°C in order to obtain a hard skeleton. The hard TPU is injected at high pressure of 80-100 MPa and high injection speed of 50-60 mm/s. The holding time is extended to attain product density.

Result

This multi-function tool pliers was successfully molded by a one-shot, two-shot injection molding process. The finished handle is flexible and conforms to the hand, offering better anti-slip properties. It has been proven to provide 30% more grip friction than regular handles in wet conditions. The internal mechanism and locking system are durable and long lasting, with full operation without damage or loosening after 5,000 opening and closing fatigue tests.

Since its launch, the product has been a sales sensation with its excellent feel and durability, achieving phenomenal sales volume for the customer and displaying JS Precision Manufacturing technical competence in thermoplastic polyurethane processing to its utmost.

How Do I Choose The Most Appropriate TPU Hardness For My Project?

After the understanding of TPU hardness and case studies, proceed with these four steps to select the most appropriate TPU hardness for your project.

1.Clarify Application Requirements

Specify the inherent product requirement: flexibility (e.g., grippers), support (e.g., tool housings), or wear resistance (e.g., rollers). Also, consider ambient operating temperature. For example, use TPU with low Tg for cold regions in order to obtain proper hardness and elasticity at low temperatures.

2.Consider Processing Feasibility

Understand the TPU hardness your supplier or factory is expert in. Various TPU hardnesses demand different equipment and processes. JS, an expert in both hard and soft TPU injection molding, can deal with processing issues and be the go-to support for your project.

3.Perform Prototype Testing

Before hardness is determined, it’s strongly recommended to make TPU samples with different hardness, and tested under real-world conditions to sense the variations and avoid problems in mass production due to improper hardness.

4.Consult an Expert

You can discuss with your material supplier, or, like JS, provide project specifications for specific recommendations. Experts might even provide injection molding price references to help you control costs and deliver quality.

FAQs

Q1: Is the hardness of TPU equivalent to that of rubber?

Though both TPU and rubber are usually measured with the Shore A scale for hardness, and show superficially alike, they are very different. TPU varies from Shore 60A to Shore 85D, whereas rubber is generally in the softer end. Furthermore,TPU can achieve more precise hardness control by adjusting the proportion of soft and hard segments, polyol types, etc. in the formula, which can meet the needs of more segmented scenarios. It cannot easily be accomplished in rubber.

Q2: Can the hardness of post-processed TPU products be changed?

The hardness of TPU products cannot be altered permanently through post-processing. The hardness of TPU is essentially determined in the raw material formulation stage in manufacturing, and the basic hardness characteristics are set as soon as the product is molded. Although post-processes such as heat treatment can soften and reduce its hardness for the time being, the hardness will revert to normal once the temperature returns to normal, and no permanent alteration can be achieved.

Q3: When choosing TPU, will higher hardness mean higher wear resistance?

Not entirely.TPU wear resistance is a complex property, not simply one of hardness, but molecular structure, the type and amount of additives in formulation, and other factors. Within a limiting range, higher hardness will increase wear resistance. But hardness limit overpass may cause the TPU to be brittle, less wear-resistant, and prone to cracking or quick wear. Therefore, selection should be made overall based on the situation of application.

Q4: My soft TPU component is difficult to demold when being injection molded. Why?

It is a common problem with soft TPU injection molding, and there are plenty of reasons why it occurs:Too high a mold temperature slows down the cooling of soft TPU, which will not set up well and will adhere to the mold. Incomplete cooling time makes the part unfixed and creates snagging during demolding. Incomplete draft angles or incomplete polish of the mold surface creates friction, so demolding is hard. Process and mold design must be optimized selectively.

Summary

TPU hardness is never an absolute term, it is a spectrum of highly customized properties. Understanding and leveraging this characteristic can unlock paradigm-bending innovations for your products—be it maximum comfort, incredible strength, and toughness. Whatever your innovative concept demands, our technical material know-how and manufacturing capacity can bring it to life.

JS has extensive TPU application and processing experience, offering complete services from material specification to injection molding. From simple injection molding parts to highly complex custom injection molding manufacturing, we are able to meet your needs effectively.

If you are experiencing an issue with TPU material selection or processing for your project, you may choose our online injection molding services. We are happy to assist you in creating high-quality TPU products and accelerate your business success.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Insert Molding Vs Overmolding Selection Guide: 5 Key Factors Based On Substrate Characteristics - JS Precision