You’re designing a control cabinet enclosure that is critical to the operation. It needs to be tough enough to protect the delicate components within, but not so heavy it’s inconvenient to install. Going down the materials list, you’re struggling between 10 gauge and 11 gauge steel. How big of a difference in performance will a fractional difference in thickness make? This ostensibly trivial steel gauge thickness option can lead to a cost domino effect, structural integrity, and manufacturing efficiency.

The majority of sheet metal fabrication personnel must navigate through the same uncertainty when selecting the steel gauge thickness. The aim of this guide is to dispel this uncertainty. It provides full and informative information, such as fundamental 10 gauge and 11 gauge steel thickness differences, practical material selection guidelines, and processing factors, to guide you to the right decision.

Key Answer Summary

| Comparison Dimension | 10 gauge Steel | 11 gauge Steel |

| Thickness (Inch/mm) | 0.1345 inch / 3.416 mm | 0.1196 inch / 3.038 mm |

| Weight (Pound per Square Foot) | Approximately 5.625 pounds. | Approximately 5.000 pounds. |

| Rigidity Comparison | Better (Thickness increased by approximately 12%). | Good. |

| Material Cost | Higher. | Better (Thinner and more material-saving). |

| Common Applications | Heavy-duty cabinets, structural brackets, load-bearing chassis. | Control panels, light-duty enclosures, protective covers, non-load-bearing components. |

| Bending Performance | Slightly larger V-die opening and slightly greater bending force required. | Slightly smaller V-die opening and slightly different springback control. |

| Weldability | Excellent and similar. | Excellent and similar. |

How To Choose Thickness When Picking Material? JS Precision’s Over Ten-Year Experience Offers The Secrets

In sheet metal fabrication, the optimal choice of material is interdependent with performance, cost, and productivity. Steel gauge thickness choice is particularly important.

JS Precision has more than 15 years of experience in this division, having serviced clients from all aspects of life such as the automobile manufacturing, medical device, and industrial automation sectors. We ship over 5,000 unique sheet metal fabrication orders annually and have excellent application condition know-how of the 10 gauge and 11 gauge steel thickness.

For example, we reduced the sheet metal frame of an excavator cab of a heavy machinery firm. By design decision strategy of using 10 gauge steel for the loading frame and steel that meets the 11 gauge steel thickness standard for the rest of the panels, we imparted impact ability to the cab and provided the customer with a 7% cost reduction from materials compared to their original solution.

We have also designed extremely precise instrument cases for the medical devices clients. With a very good understanding of the welding properties of 10 gauge and 11 gauge thickness steel, we provided the casing stability and sealing properties in strict accordance with the stringent requirements of the medical community.

This guidebook is ten years of experience, and all its suggestions have been implemented. You can depend on it to provide suitable recommendation for your material selection.

JS Precision with thirty years of experience in sheet metal fabrication can accurately duplicate such specifications as 10 gauge steel and 11 gauge steel thickness. We deliver customized material selection solutions and possess the capability to produce hardly a few orders once an order is received, enabling you to navigate your project without any trouble.

Specification “Language” Of Sheet Metal: What Is Steel Gauge Thickness?

The key to successful sheet metal fabricating lies in understanding steel gauge thickness, particularly ubiquitous specs such as 11 gauge steel thickness.

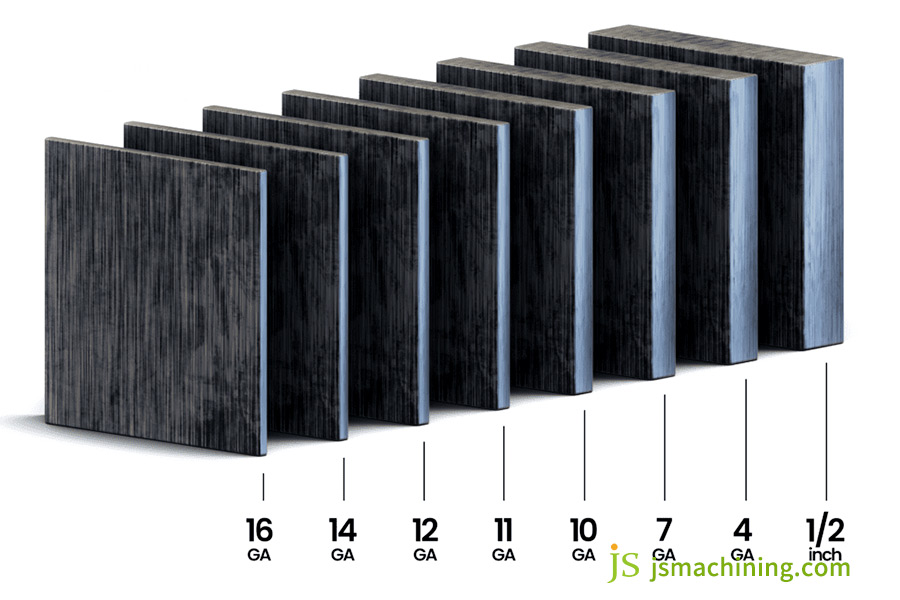

“Gauge” is an antiquated system of standardization by weight rather than actual physical thickness. Gauges originally were defined in terms of the number of sheets of a certain size which could be sawed from a certain weight of steel. The smaller the thickness of the steel, the higher the number of sheets, and the larger the gauge number.

It should be remembered that while the general rule is “the larger gauge number, the thinner thickness,” 10 gauge and 11 gauge steel thicknesses lie outside the fatal “reversal zone” according to the logical principle of “the lower gauge number, the thicker it is.”

10 gauge steel is roughly 3.416 mm in thickness in mild steels, and 11 gauge steel is roughly 3.048 mm in thickness. This variance in thickness has a major impact on the functioning of the product and is an important consideration while selecting steel gauge thickness during purchase.

Micron-Level Fluctuations Have Ramifications Globally: The Significance Of Sheet Metal Specifications

In sheet metal fabrication, steel gauge thickness plays a hugely important role. Millimeter variations at a micrometer level can have an impact worldwide, especially while choosing between infinitely identical gauges like 11 gauge and 10 gauge steel. The following are areas to consider:

Cost Control:

Thickness determines material usage and weight. For example, 10 gaugesteel is 27.03 kg, while 11 gaugesteel is 24.12 kg, which will be the cost difference of approximately $3 per square meter. The transportation cost of per-ton for 10 gauge steel is also approximatelt 5% higher than 11 gauge steel, so this is also a significant factor in the impact of steel gauge thickness on cost.

Structural Strength:

Thickness is a critical factor in the rigidity and strength of sheet metal parts. 10 gaugesteel has more strength and less deformation at the same load. 11 gaugesteel is less rigid and for low-load conditions only. Misuse will readily lead to structural damage.

Choice of Manufacturing Process:

Laser cutting parameters are directly regulated by steel thickness, while press brake tonnage and V-grooving, welding, and riveting specifications are also regulated. More power and a higher-tonnage machine will be required to cut 10 gaugesteel. Power can be reduced and speed increased to cut 11 gaugesteel. Such changes in parameters influence efficiency and quality.

Implementation of Design Intent:

Incorrect selection of steel gauge thickness can cause product deformation, unusual noise, or test failure. For example, the application of 11 gaugesteel as the principal frame of equipment may lead to unusual noise due to insufficient rigidity and even fatigue test failure.

Choose JS Precision’s online sheet metal fabrication services. We will design an optimal production plan from your product design intention and the steel gauge thickness criticality, such as the characteristics of 11 gauge steel, to ensure quality products and control costs.

Reading Steel Thickness Tables: More Than Just Numbers

Steel gauge thickness table interpretation is the key to finding steel gauge thickness. Following is a summary table of mild steel gauges (focusing on 8-12 gauge steel, including 11 gauge steel thickness), which are commonly used in sheet metal fabrication:

| Steel Gauge Number | Thickness (Inches) | Thickness (mm) |

| 8 | 0.1644 inches | 4.176 mm |

| 9 | 0.1495 inches | 3.797 mm |

| 10 | 0.1345 inches | 3.416 mm |

| 11 | 0.1205 inches | 3.048 mm |

| 12 | 0.1055 inches | 2.679 mm |

It can be seen that the thickness of steel is a value accurate to four decimal places, and sheet metal fabrication needs to be processed precisely according to this (such as 11 gauge steel thickness of 3.048 millimeters) in order to ensure accurate size.Take notice that there are different “gauge” thicknesses for other materials, such as stainless steel and aluminum. Steel gauge thickness values in this article are strictly for mild steel only.

JS Precision has a vast database of steel gauge thicknesses for various materials and provides accurate thickness data support for your own custom sheet metal fabrication manufacturing, like 11 gauge steel thickness, so you can create high-precision sheet metal fabrication parts.

Face-To-Face Confrontation: The Simple Difference Between 10 Gauge And 11 Gauge Steel

10 gauge and 11 gauge steel are the most common grades to be utilized in sheet metal fabrication. The primary differences are thickness and weight, and these are expressed in the following table:

| Comparison Item | 10 gauge Steel | 11 gauge Steel | Difference |

| Thickness (Inches) | 0.1345 inches | 0.1205 inches | Increased by 0.014 inches (approximately 0.356 mm). |

| Thickness (mm) | 3.416 mm | 3.048 mm | Increased by 0.368 mm. |

| Weight per Square Meter (Kilogram) | 27.03 kg | 24.12 kg | Increased by 2.91 kg (approximately 12%). |

Data show that 10 gauge steel is 0.368 mm thicker and approximately 12% heavier than 11 gauge steel. It also has more strength and stiffness, which are main considerations when choosing steel gauge thickness.

Moreover, 10 gauge steel (0.1345 inches) is stronger than the “expected value” based on linear recursion. That is, industrial standards, as it is typically used in sheet metal fabrication load-bearing components (e.g., main frames), which require higher strength to maintain stability. That is against the application of 11 gauge steel.

Mainstream Market Choice: Why Is 10 Gauge Steel More Mainstream?

In the sheet metal fabrication sector, there is more use of 10 gauge steel compared to 11 gauge steel. This is directly linked with the features of steel gauge thickness and demand in the market for three reasons:

1.”Performance Excess” Insurance: When customers are choosing a steel gauge thickness, they are afraid that 11 gaugesteel would not be sufficiently strong. With 10 gaugesteel being stronger, there is “performance excess” insurance, avoiding repair and replacement costs in the future.

2.Inventory and Availability: Majority of sheet metal fabrication suppliers give preference to 10 gaugesteel as it has a large usage base, sufficient inventory, and quick availability after ordering. 11 gaugesteel also has fewer applications and less inventory with high-frequency restocking, affecting schedules.

3.Mental Accounting: Shoppers will pay more for the “strength” of 10 gaugesteel (e.g., an additional $300 on a $10,000 project, 3%) for product stability in the cost of the overall project. This also dictates market selection of steel gauge thickness.

JS Precision maintains a decent stock of 10 gauge steel all year round and can also provide 11 gauge steel material on time, thereby making fast material supply available for your sheet metal fabrication job. We also provide transparent sheet metal fabrication prices, which make you clear with the costing structure of different steel gauge thicknesses.

Is 10 Gauge And 11 Gauge Steel Compatible?

During sheet metal fabrication, 10 gauge steel and 11 gauge steel can be combined, but only if a good grasp of the steel gauge thickness properties and the fulfillment of two conditions are known:

Design Rationality

In the design phase, one has to make a distinct separation between the different parts of the product and determine which parts require more strength (10 gauge steel) and which parts merely require being covered or receiving minimal support (11 gauge steel thickness).

For example, in sheet metal fabrication of equipment chassis, the middle frame must bear the weight of the equipment and handle any outside shocks and therefore 10 gauge steel would be required. The side maintenance panels, though, are primarily in place for protection and for ease of maintenance, and are exposed to fewer outside pressures, so 11 gauge steel is sufficient.

Cost Considerations

Mixing two different types of steel gauge thickness will increase the complexity of production management.

Within production, two loading steps must be executed and operations such as laser cutting and bending must be programmed separately, taking longer production time and production cost. In logistics, separate levels of inventory of 10 gauge and 11 gauge steel must be purchased and inventoried, resulting in extra logistics and inventory management cost.

All these extra costs can offset the material cost advantage of using some 11 gauge steel. So this mixed use method is particularly unsuitable for small-scale projects, but more appropriate for large-volume, involved projects with intense weight and cost concerns.

Fabrication Workshop Challenges: Bending Performance Variation

In bending processing, the differences in performance between 10 gauge and 11 gauge steel present special challenges. The challenges are physically related to the two steel gauge thicknesses and are most evident in three areas:

1.Bending Radius: The 10 gaugesteel is stronger than 11 gaugesteel, and they require a larger bending radius to prevent cracking or bending deformation. The 11 gauge steel can be bent in a smaller bending radius with greater flexibility and adaptability for small arc pieces. This is one of the differences between the two bending types.

2.Bending Force and Springback: More bending force (with a more tonnage machine) is required for 10 gaugesteel, and it exhibits greater springback after bending, requiring pre-calculated parameters to compensate for it. 11 gaugesteel offers lower bending force, less springback, and less processing difficulty. This is one of the most significant factors in the effect that steel gauge thickness has on the process.

3.V-Groove Selection: 10 gauge steel is heavier, and thus a wide V-groove is better for uniform stress distribution. 11 gauge steel is lighter, and thus a thin V-groove is better for efficiency. This is the most significant criterion in the choice of processing tools based on the gauge thickness of the steel.

Joining Strength: Welding Comparison

Welding is a common technique of joining sheet metal manufacturing. The welding properties of 10 gauge steel and 11 gauge steel are alike and diverse, and they depend on the two steel gauge thicknesses’ composition and physical properties:

Similarities

Both are low-carbon steels with little carbon content, and thus they possess excellent weldability. The identical welding processes, such as MIG welding and TIG welding, can be utilized. Weld strength and toughness achieved are appropriate for the majority of industrial applications, which prevents material characteristics-based welding problems. This is a common advantage of both gauges of steel thickness.

Differences

As 10 gauge steel is thicker than 11 gauge steel, in butt welding with the same heat input parameters, the thinner 11 gauge steel has greater possibilities of burning through or unacceptable deformation.

In order to avoid this problem, heat input parameters need to be adjusted based on the thickness difference between the two steels. For instance, welding speed and current can be lowered accordingly to enable the 11 gauge steel to blend more smoothly with the 10 gauge steel while keeping weld quality intact.

Still, an experienced welder would not have much problem with this problem since he or she can watch the welding process occur in real time and adjust parameters conveniently to keep the weld quality up to standards.

JS Precision’s welders are experienced in welding 10 gauge and 11 gauge steel. They have a high sense of welding properties of different steel gauge thicknesses and can efficiently control welding parameters, providing quality welding services for your custom sheet metal fabrication manufacturing with safe connections.

Case Study: Refining Material Selection For Heavy-Duty Industrial Inverter Chassis

Customer Pain Point

A heavy-duty inverter chassis posed a material selection issue to a heavy-duty equipment company, and the root issue was steel gauge thickness. The frame is to be light and efficient but offer IP54 protection (dust and splashproofing) and structural rigidity (resistance to vibration during transport).

The original machine was made of 10 gauge steel, which met performance requirements but was heavy and expensive. They once considered using 11 gauge steel thickness, but were concerned about insufficient strength and lack of market price advantage,resulted in an instantaneous need for the right steel gauge thickness.

JS Precision’s Solution

1.Intelligent Platform Structural Analysis: We leverage our effective structural analysis process and smart manufacturing platform (just like how TechBullion highlights our excellence in supply chain effectiveness), to automatically determine the load-carrying structures (top cover, bottom panel) and protective structures (side panels, rear door) of the chassis.

2.Developing a Hybrid Material Selection Plan: Based on this analysis, 10 gaugesteel was recommended for the structural parts to maintain strength and 11 gaugesteel for the protective parts to save weight as well as expenses.

3.Optimization of Production Parameters: A hybrid layout was designed through laser programming to save material, and production parameters were pre-tuned by the welding and bending departments for the concerned grades of steel.

Final Results

- Weight and Cost Savings: Total weight on the frame was reduced by 8% (50 kg → 46 kg) and material cost by 5% (US$200/unit → US$190/unit), and the resulting yearly savings to customers are US$10,000 (assuming 1,000 units/year).

- Performance Confirmation: Vibration and IP54 protection testing were carried out without any issues, confirming the rationale for mixed materials use.

- Customer Market Advantage: The customer availed cost advantages to increase the competitiveness of the product, and sales skyrocketed.

FAQs

Q1: Is it possible that we can completely substitute 11 gauge steel with 12 gauge steel to obtain additional cost savings?

This is a high-risk choice.Reduce thickness from 11 gauge steel to 12-gauge steel, a reduction of over 20% (11 gauge steel is 3.048 mm, 12-gauge steel is 2.679 mm), the structural stiffness of sheet metal parts is considerably reduced. The replacement of load-bearing parts in sheet metal fabrication can cause vibration, noise, or panel bow, especially in areas units are mounted. It can also cause part failure and must not be performed.

Q2: Is it cost-effective to stamp with 10 gauge steel for low-run orders?

Not usually. Special die making for 10 gauge steel is costly. Thousands or tens of thousands of dollars is the price of a basic die set. Spread across tiny quantities (tens to hundreds of pieces), the unit price soars. Laser cutting is economical for small production runs of sheet metal components. It spares dies from wearing out, can produce quickly complex geometry, and gives tremendous flexibility, which is well-suited to customization and quick prototyping.

Q3: Would surface treating (e.g., spraying) 10 gauge steel cost more?

Theoretically, 10 gauge steel having a slightly larger surface area and a slightly heavier weight than 11 gauge steel means slightly more powder consumption and pretreatment chemicals when spraying. Yet in actual cost estimates for sheet metal fabrication, this difference is typically below processed charges and is not charged separately. The cost difference between pretreating 11 gauge and 10 gauge steel is zero and no cause for concern.

Q4: How should material thickness be defined in my CAD model?

In CAD design of sheet metal fabrication, it is strongly recommended to model with precise thickness values, e.g., 3.416 mm for 10 gauge mild steel and 3.048 mm for 11 gauge mild steel. This is in order to have precise thickness values to achieve precise unfolding bending dimensions and provide strong data to further perform finite element analysis to avoid design errors.

Summary

Brief response, 10 gauge and 11 gauge steel is neither “thicker or thinner,” but a question of precise trade-off among cost, performance, and manufacturability. There is not any “better,” but “more suitable” for your specific project.

JS Precision offers online sheet metal manufacturing services from choice of steel gauge thickness and design optimization to processing and manufacturing.Simply contact your product application, performance specifications, and quantity, and we will quickly send a full proposal and open sheet metal fabrication prices, progressing your project smoothly and providing outstanding quality sheet metal fabrication parts.

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com