A medical device implanted in the human body, with a hard titanium alloy structure at its core, providing support for life. The surface in contact with human tissue is covered with a layer of skin friendly and soft medical silicone, which minimizes rejection reactions to the greatest extent possible.

This is more than a combination of two processes, it is an engineering and ergonomic marvel made possible by two groundbreaking injection molding processes: insert molding and overmolding. These unite materials that are different at the molecular level and create products that are greater than what is possible from any single material.

This article concludes with five major factors according to substrate properties and, based on JS Precision’s practice, will guide you to choose the right process and avoid selection errors.

Key Answer Summary

| Comparison Dimension | Overmolding | Insert Molding |

| Core Concept | Layered fusion: Inject a second layer of plastic onto a substrate (which can be plastic, metal, or other materials) to form a permanent chemical/mechanical bond. | Skeleton implantation: Place prefabricated inserts (usually metal, such as threaded sleeves, shaft sleeves) into the mold, then inject plastic to fix and encapsulate them. |

| Essence of Bonding | Fusion between materials, aiming to create new functional characteristics (such as soft touch, sealing, multi-color). | Mechanical interlocking between materials, aiming to enhance structural strength or functions at specific points (such as load-bearing, electrical conductivity, threaded connection). |

| Main Materials | Thermoplastic elastomers/soft rubber + rigid plastic (e.g., TPE+ABS, Silicone+PC), or the same type of plastic in different colors. | Metal (copper, steel, aluminum) + engineering plastic (e.g., nylon, PBT, POM). |

| Key Advantages | Excellent hand feel, shock absorption and anti-slip properties, waterproof sealing, attractive multi-color appearance, and reduced assembly steps. | Extremely high local strength, reliable threaded connection, embedded conductive paths, and simplified final product assembly. |

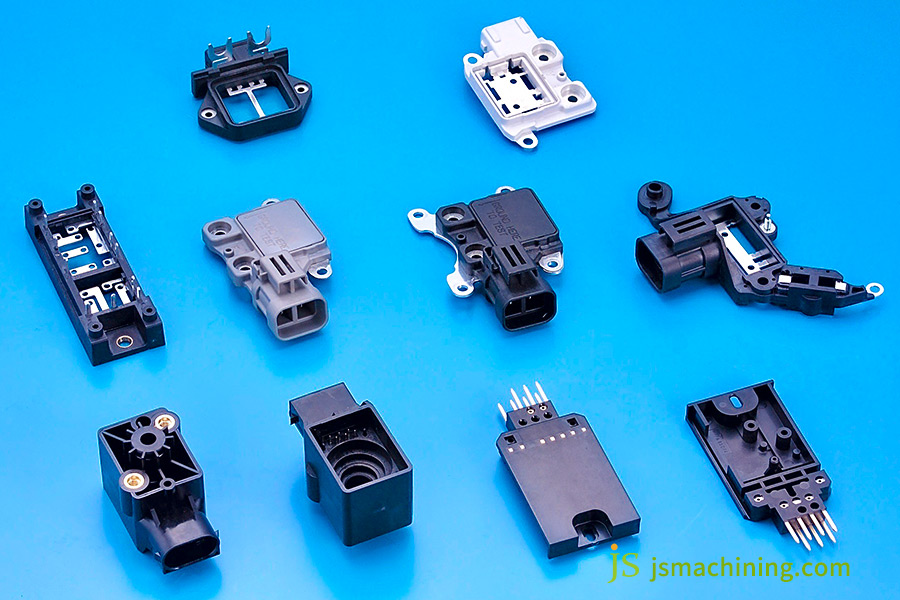

| Typical Applications | Tool handles, toothbrush grips, electronic device seals, multi-color buttons, and consumer products with combined hard and soft parts. | Threaded inserts, bearing housings, circuit board brackets, connectors, and metal fixing points in automotive interior parts. |

JS Precision Team Practice: Five Factors Decide The Best Optimum

JS Precision has over 15 years of insert molding and overmolding experience and is a purchaser to four big industries,e.g., industrial equipment, medical, automotive, and consumer electronics. We have been able to accomplish in excess of 800 of our own unique projects in the past three years, from insert molding parts for transmission sensors to composite structure parts for industrial smart intelligent valves of 50 MPa strength.

We have established a strong substrate test program that stringently tests substrate performance like PA66 and carbon steel, TPE and PC/ABS, and process choice for each project is data-driven. This guide summarizes our shop-floor experience, test data, and industry wisdom, generating expert and practical recommendations in your process choice.

JS Precision focuses on custom insert molding manufacturing and can provide full process services from substrate testing, process design to sample production according to your product needs. Producing insert moulding parts with us is as easy as a breeze.

Twin Craftsmanship: Deconstructing The Core Of Overmolding And Insert Molding

Having learned the practical rules of JS Precision, now let’s specifically distinguish the nature of these two “twin processes” of insert molding vs overmolding and basically differentiate them.

What is overmolding?

Overmolding is a two-shot injection process. Pre-molded substrate (usually a hard plastic like PC or ABS) is fed into a special mold. Soft plastic like TPE or TPR is injected, exactly covering the substrate. Its basic purpose is to create a fine bond between the two materials so that the end product will be in position to marry the hardness of the substrate with the soft touch or sealing property of the material to be overmolded.It is applied in tool handles and anti-slip buttons in electronics.

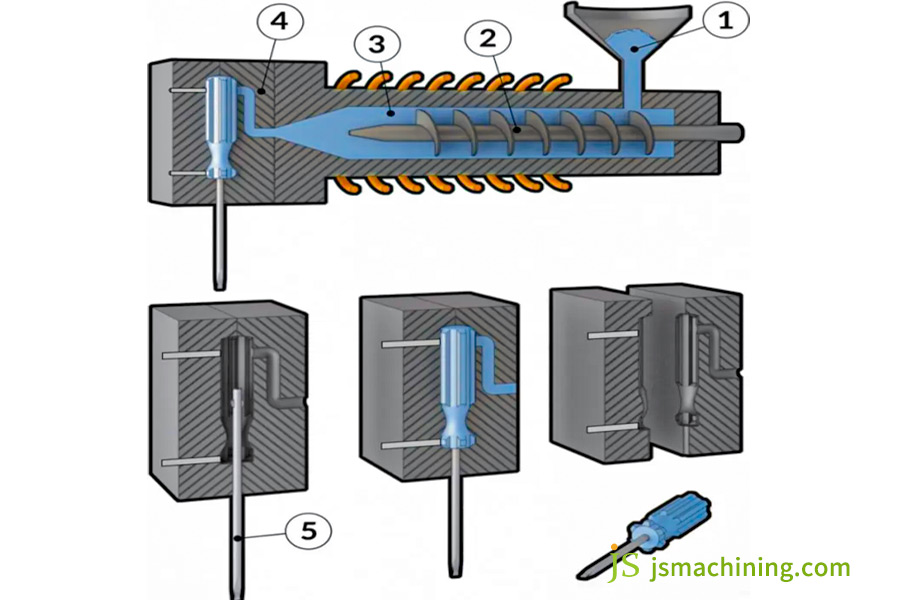

What is insert molding?

Insert molding involves the insertion of an insert (basically a metallic part, e.g., copper nut or carbon steel connector, but sometimes ceramic or glass) into the mold before injection molding. Plastic melt, e.g., PA or PP, is injected subsequently. Plastic adheres with the insert when it cools and becomes a single unit.

The general process is to encapsulate the insert in plastic for added strength, with the expectation that the nature of the insert will compensate for whatever the plastic lacks. Plastic housings and connectors with threaded metal contacts—a process at which JS Precision excels, and where the precision and reliability of our insert molding parts come under extreme test—are some of the common ones.

Mutual Benefits Of Insert And Overmolding

Although insert molding vs overmolding differ in their fundamental principles, being offspring of injection molding, they share a great deal and are widespread across industrial manufacturing.

- Injection molding-based: Both of them rely on high-pressure, high-precision injection molding machine and molds, which deliver the product dimensional accuracy and uniformity and reduce downstream processing operations.

- Functional Integration: Merging two or more components in a single component, i.e., insert molding metal insert and plastic component in a single process, reduces the assembly operations and enhances the manufacturing efficiency.

- Improved Reliability: Avoidance of traditional connection components like screws and snaps eliminates possible failure due to loose fits, increasing product structural integrity and life and service life.

- Improvement in the User Experience: Soft touch, non-slip finish, and multi-color finish can be achieved in products, and hence they become more appropriate to fulfill the needs of the user.

- Cost-Effectiveness: While initial mold cost is expensive, in the long term, the labor savings of assembly, part buying, and inventory control drastically lower overall production expenses.

Core Decision Framework: Five Key Factors For Selecting Between Them

Having gained knowledge regarding the advantages for each other of both the processes, we’ve outlined five factors determining the choice based on substrate properties to help you use insert molding or overmolding to maximum effect.

Factor 1: Core Purpose – Enhanced Functionality or Better Quality?

If the core purpose is to enhance functionality, e.g., if a product must be conductive, magnetic, tough, or threaded, insert molding is the way to go. For example, incorporating metal contacts in electrical connectors imparts conductivity.

If the objective is to impart value addition, for example, a soft touch to the substrate, anti-slip performance, seal performance, or bright appearance, overmolding is apt. For example, overmolding an anti-slip water bottle handle with TPE material.

Factor 2: Material Combination – Chemical Compatibility

Insert molding requires proper handling of plastic and insert (usually metal) thermal expansion coefficient difference. Materials shrink or expand at different ratios with temperature changes. Excessive differences can lead to plastic cracking and affect reliability.

Overmolding, apart from thermal expansion coefficient, requires proper handling of chemical compatibility and adhesion between the two plastics. In the event of incompatibility, they will easily separate upon cooling. Compatibility of some plastics combinations is as follows:

| Substrate Material | Overmolding Material | Compatibility | Applicable Scenarios |

| PC/ABS | TPE | Excellent | Electronic device casings, handles. |

| PA66 | TPR | Good | Automotive interior parts. |

| PP | TPE | Average | Simple daily necessities. |

Factor 3: Part Geometry – Form Determines Feasibility

Inserts used for insert molding must be seated and retained in the mold. Inserts of complex shape (e.g., irregular protrusions or deep bores) elevate mold design complexity and cost, and even cause the insert to shift during injection molding.

In overmolding, the substrate has to be conceived with mechanical interlocking features like holes, grooves, and bosses to achieve stronger adhesion with the overmolding compound. The presence of a smooth surface of the substrate with no interlocking features can quite simply lead to the flaking off of the overmolding material.

Factor 4: Production Volume and Automation – Economies of Scale

For insert molding, such hand insertions are feasible for small- and medium-volume production, saving the upfront equipment cost. However, for the extremely high production volumes (over 100,000 pieces a month), expensive automation insert placement systems become inevitable for improved efficiency.

Overmolding is more amenable to high-volume, full-automatic production, particularly on rotary molds or multi-color injection molding machines. It has the benefit of perpetual production and is highly efficient with no utilization of complex insert position equipment.

Factor 5: Cost and Cycle Time – The Tradeoff Between Mold Complexity

Both methods differ significantly in cost and cycle time, as will be explained below:

| Cost/Cycle Item | Insert Molding | Overmolding |

| Mold Investment | Medium (requires design of insert positioning structure), usually 5,000-20,000 US dollars. | High (mostly multi-shot molds), usually 8,000-30,000 US dollars. |

| Unit Cost | Low (high material utilization rate, no additional assembly), approximately 0.5-5 US dollars per piece. | Medium (multi-material injection, slightly higher material cost), approximately 1-8 US dollars per piece. |

| Production Cycle | Long (requires insert placement, even longer for manual operation), with a batch production cycle of approximately 1-2 weeks. | Short (fully automated), with a batch production cycle of within approximately 1 week. |

JS Precision provides online insert molding service effectively. Regardless of small batch, medium batch, or mass production, we can provide corresponding automation solutions, shorten the production cycle, and supply qualified products according to schedule.

Complete Analysis Of The Key Distinctions Between Insert Molding And Overmolding

From the above analysis, you must be aware of the main differences between the two processes in the main determining factors. Let’s now look into their intrinsic differences to make you identify them more naturally from the core.

| Difference Dimension | Insert Molding | Overmolding |

| Essence of Bonded Objects | “Body-to-body” encapsulation (plastic encapsulates the insert, and the insert is a three-dimensional structure). | “Surface-to-surface” bonding (the overmolding material bonds with the surface of the substrate to form a coating layer). |

| Treatment of Substrate/Insert | The insert surface is required to be clean, and some inserts need pre-treatment (such as polishing, coating) to enhance bonding with plastic, the insert must withstand the high temperature and pressure of injection molding. | The substrate is required to withstand the heat and pressure of secondary injection molding to avoid deformation or damage, the substrate surface may need pre-treatment to improve bonding with the overmolding material. |

| Mold Complexity | Requires the design of a precise insert positioning and clamping system, the structure is relatively simple, but the positioning accuracy requirement is extremely high. | Usually complex multi-shot molds , which require the design of multiple cavities and gating systems, resulting in higher manufacturing difficulty and cost. |

| Automation Challenge | Highly dependent on the accuracy and reliability of the automatic insert feeding and placement system, the automation difficulty increases if the insert shape is complex. | Automation is mainly reflected in the injection molding machine itself, no complex insert processing equipment is needed, so automation is relatively easy to achieve. |

JS Precision has experienced mold design engineers who can optimize mold structures based on the nature of insert molding parts for precise insert positioning with lower mold complexity and affordable on your mold investment.

JS Precision Case Study: The Ultimate Solution To “Zero Leakage” In Hydraulic Connectors

Project Background and Challenges

One of the manufacturers of heavy industry needed to design high-pressure connectors for the hydraulic system of excavators. The connectors were installed on hydraulic hoses and had to withstand permanent vibration, temperatures over 80°C, and oil contamination.

First of all, the connectors must withstand permanent operating pressure of over 300 bar and strong pressure shocks at the same time. At the same time, metallic joints must ensure well-predictable O-ring seals to avoid oil leaks—time-wasting leaks and even accidents.

Pain points of the traditional solution: The traditional solution’s 45-gauge steel metal joints are machined first by CNC machines and then assembled manually with rubber O-rings. Manual assembly can easily lead to O-ring deformation and misalignment with a leakage rate of up to 5%. Besides, O-rings deteriorate and wear under harsh environments and require replacement every three months on average with a maintenance cost of $200 a set a year.

JS’s Solution: Synergistic Use of Insert Molding and Overmolding

We take a combined strategy of “insert molding for priming, overmolding for sealing”:

Step one, insert molding: A high-strength phosphated carbon steel connector core is inserted into a unique mold and charged with PA66-GF30 (tensile strength 120 MPa, temperature range -40°C to 120°C). The plastic, upon cooling, clings to the carbon steel core to form a composite skeleton that combines metal strength and plastic corrosion resistance.

Step two, encapsulation molding: The combined skeleton acts as the base material and is placed in a multi-shot mold. HNBR special oil-resistant rubber (oil resistance meets ASTM D471 standards, volume change <10% after 70 hours soaking in 40°C engine oil) is injected. A seal lip is integrally molded in one stroke, replacing the traditional O-ring.

Why choose this combined process?

Insert molding alone cannot ensure consistent sealing, and overmolding alone cannot meet the structural strength requirement at high pressure. This combined process takes advantage of insert molding’s strength advantage and the sealing advantage of overmolding to precisely meet project requirements.

Achievements and Value

- From the performance viewpoint, the connector has run 5 million ultra-high-pressure pulse tests (0-350 bar pressure cycles) without deformation or leakage on the sealing lip, “zero leakage.”

- From the cost perspective, it avoids O-ring purchasing ($80 per set per year saving), storing, and hand assembly (sparing two workers per production line), reducing the failure ratio by 5 to 1.5%, and reducing general maintenance by 70% per set per year.

- In terms of value , we provide clients with a “zero leakage” hydraulic connection solution in order to make their excavator products more reliable than others and receive more orders.

JS Precision can combine insert molding vs overmolding processes based on your project requirement. We also provide transparent insert molding price quotations so you know every cost and make a well-informed decision to use our services.

Cost Optimization Strategies: How To Maximize Your Mold Investment Value?

Once you have selected the correct process, how do you maximize your mold investment value and minimize production cost further? JS Precision, with years of expertise, has concluded four effective strategies.

1.Simplify Design: Work together with engineers in order to maximize part geometry to prevent unnecessary undercuts and thin-wall regions less than 0.8mm. Undercuts add mold slides or core pulls, and thin walls quickly result in inadequate injection molding, both of which drive up the cost of the mold. Redesigning parts to reduce undercuts cut a customer’s mold expense by 30%.

2.Modularity and Standardization: Use standard inserts (e.g., M3 and M4 standard threaded sleeves) wherever possible. Standard inserts eliminate customizing, reduce procurement costs, and lower the production lead times. Design modular inserts to serve multiple products, e.g., using a common metal contact insert within a series of connectors, to reduce the number of inserts and lower inventory outlays.

3.Early Supplier Involvement: Involve manufacturers (such as JS Precision) in the design of the product. Our Design, Function, and Function (DFM) analysis can identify cost traps early on. A medical device customer failed to consider the difficulty of insert positioning in the early design. By adjusting the insert geometry, we avoided mold rework and a $2,000 change cost.

4.Automation and Labor Balance: For small- to medium-volume production (1,000-5,000 units/month), the economic feasibility of fully automated insert placement must be taken into account. For certain situations, an in-mold robot (approximately $3,000) is more economical than a fully automated feeding system (approximately $15,000) because a fully automated system has a longer payback time and can manage small- to medium-volume requirements.

JS Precision provides full Design for Modification (DFM) analysis service in custom insert molding manufacturing to achieve optimum design and lowest insert molding price, with professional support from pre-design to post production.

FAQs

Q1: Can metal inserts be mixed with overmolding?

Yes, definitely! This is an advanced and common application, and JS Precision frequently provides this type of solution to customers. Insert molding is utilized first to insert a metal threaded sleeve into a hard plastic part (e.g., a PC housing) for reinforcement. This hard plastic part is subsequently overmolded with TPE to obtain a soft-touch feel. This can be seen frequently in medical device handles and home appliance control panels.

Q2: How is the bond strength of overmolded parts tested?

There are a variety of tests, depending on the product application. Some of the standard tests are 90° or 180° peel tests (peel force testing with a tensile testing machine), shear tests (separation force testing), and thermal cycling tests (-40°C to 80°C for 100-500 cycles). JS Precision will employ the correct method, based on customer specifications, to ensure bond reliability.

Q3: Is overmolding the same as overmolding (two different injection molding processes)?

Not exactly.The key differences are in mold and bonding quality: Overmolding is one multi-shot or rotary mold, which runs both injections within the same injection molding machine. The substrate and overmolding material bond together within the mold, with good bonding and high efficiency. Secondary injection molding is two different molds, possibly on different machines, which results in poor bonding and easily compromised precision due to substrate positioning variations.

Q4: Are both of these processes economical for small-batch prototypes?

The most important cost driver for small-batch prototypes (tens to hundreds of pieces) is the mold, but the right choice of the mold can reduce costs. For example, the utilization of aluminum molds ($2,000-5,000, over 50% less than steel molds) or 3D-printed injection molds ($1,000-3,000) with a production cycle of 1-2 weeks significantly reduces initial costs and lead time. JS Precision provides small-batch prototyping services and can recommend suitable mold choices.

Summary

Insert molding and overmolding represent extremely useful mechanisms for delivering functionality and value in product design today. To speak their language not only rescues you from pitfalls in design but also unlocks boundless possibilities. Whether your goal is to create a wow user experience or build a rock-solid internal structure, the right decision begins with a professional conversation.

JS Precision, supported by abundant practical experience and technical expertise, can help you accurately assess process needs, design for optimal efficiency, and control costs for seamless project execution. Choose our online insert molding services and we’ll lead you through the production of high-quality insert molding parts, from process determination to product delivery.

If you have project requirements, please don’t hesitate to contact us at any time. We’ll provide you with detailed proposals and quotations that are easy to understand to make your cooperation easier.

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com