As Tesla adopts 3D printing technology to alleviate supply chain crises, and the world’s first 3D-printed car, Urbee, makes a debut, the question on one’s mind is: Is 3D printing an addition or alternative for traditional automotive manufacturing in the Industry 4.0 era?

You may be the R&D manager of an automaker, suffocating in the pace of part iteration, or perhaps a component maker seeking new manufacturing opportunities?

This handbook, based on JS Precision’s decade of real-world experience with additive manufacturing, will give you a lucid appreciation of 3D printing automotive parts as it exists today, how it works, its benefits, and the challenges. This will assist you in being able to properly ascertain whether or not this technology is suitable for your manufacturing requirements and how it can deliver value to your company.

Key Answer Summary

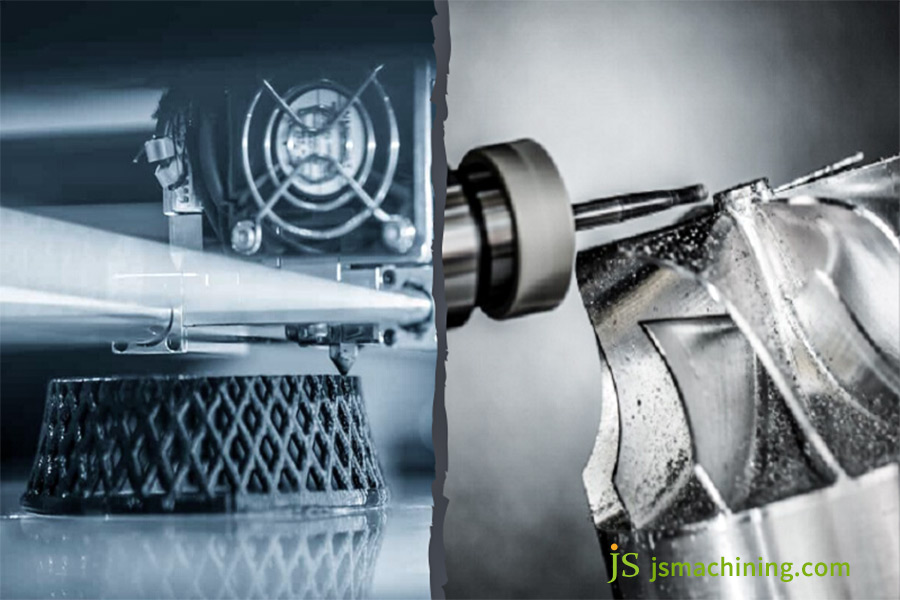

| Comparison Dimension | 3D Printing (Additive Manufacturing) | Traditional Manufacturing (Subtractive/Formative Manufacturing) |

| Core Philosophy | Build layer by layer from scratch. | Remove materials or form parts via molds. |

| Design Freedom | Extremely high, capable of manufacturing complex lightweight structures (lattices, topology optimization). | Limited by tool angles, mold opening and closing, etc. |

| Economic Threshold | Low (no mold cost), suitable for small-batch production and customization. | High (high mold cost), suitable for large-scale production. |

| Production Cycle | Extremely short (direct manufacturing from digital files). | Relatively long (requires manufacturing of fixtures and molds). |

| Material Utilization | High (only uses required materials). | Relatively low (produces cutting waste). |

| Typical Applications | Prototype verification, customized tools, lightweight structural parts, spare parts inventory. | Engine blocks, body panels, standard fasteners, etc. |

Why Trust? JS Precision’s Ten Years Of Additive Manufacturing Experience

In 3D printing of auto components, a decade of unflinching hard work is sufficient to establish customer-faithed expertise, and JS Precision is the best example of it. Within the last decade, we have serviced more than 200 automotive manufacturers and supporting organizations, and produced more than 500,000 3D printing parts, from nylon functional components to titanium alloy structural parts.

For instance, we once tailored a 3D-printed seat bracket for an automobile manufacturer. With topology optimization, we reduced weight by 40% and improved strength by 20%, completely satisfying vehicle safety requirements. Additionally, we constantly optimize certain core processes like metal SLM and SLS process, cutting part printing cycle time from 72 hours to 19 hours on one project.

This handbook is a condensation of our decade of real-world experience, and all of our observations are drawn from actual project data, so you can have faith in its contents.

If you need a specialized automotive parts solution, JS Precision’s internal custom 3D printing manufacturing capability is in place to provide. Simply forward us your design files and we’ll process an assessment and quotation back to you as soon as possible. We can begin production within 72 hours of order receipt, practically solving your manufacturing problem.

Market Outlook: The Size And Growth Path Of Automotive 3D Printing

Market facts is the best natural foundation to measure the potential for development of 3D printing automotive parts. The following table provides some key statistics regarding the world and regional markets:

| Indicator | Data / Situation |

| 2024 Global Market Size | 3.36 billion US dollars. |

| 2025 Projected Global Market Size | Over 4.00 billion US dollars. |

| CAGR (2024-2030) | 15.94%. |

| Region with Highest Penetration | North America (driven by manufacturers like Ford, General Motors, and Tesla). |

| Region with Greatest Future Growth Potential | Asia-Pacific (especially China, driven by the booming new energy vehicle industry). |

Three key drivers of market growth are:

- Supply chain flexibility. For example, during the epidemic period,3D printing allowed car producers to quickly replenish critical parts and avoid production line downtime.

- The trend towards personalization. Consumers’ demand for personalized exterior and interior styles is forcing car manufacturers to employ 3D printing for low-volume personalization.

- The urgent need for weight reduction, especially for electric vehicles. Reducing weight directly affects range, and 3D printing’s topological optimization design perfectly addresses this need.

JS Precision, with its extensive industry experience, can provide you with 3D printing automotive parts that meet global market demands. Our online 3D printing services support global orders. You can submit your requirements online at any time, and we will optimize solutions based on regional market characteristics to ensure product competitiveness.

How Do You “Print” An Automotive Part? Decoding The Additive Manufacturing Process

After being aware of the market situation, you might be interested in how a car component actually gets manufactured using 3D printing. The entire process is comprised of three elementary steps along with their major points.

Step 1: Digital Blueprint – Full Design Freedom

Computer design of the blueprint is completed first, releasing design completely. 3D printing is not founded on generative design and topology optimization technologies like conventional design.

Designers merely set parameters such as part load requirements and weight constraints, and the software creates the ideal, most material-efficient shape automatically. Shapes are typically irregular and complex and would be impossible without 3D printing, such as light-weight brackets with complex lattice structures.

Step 2: Technology Selection – Matching the Material to the Application

Step two is technology selection. The working rule here is matching the application to the material. Different technologies are suitable for different materials and application environments:

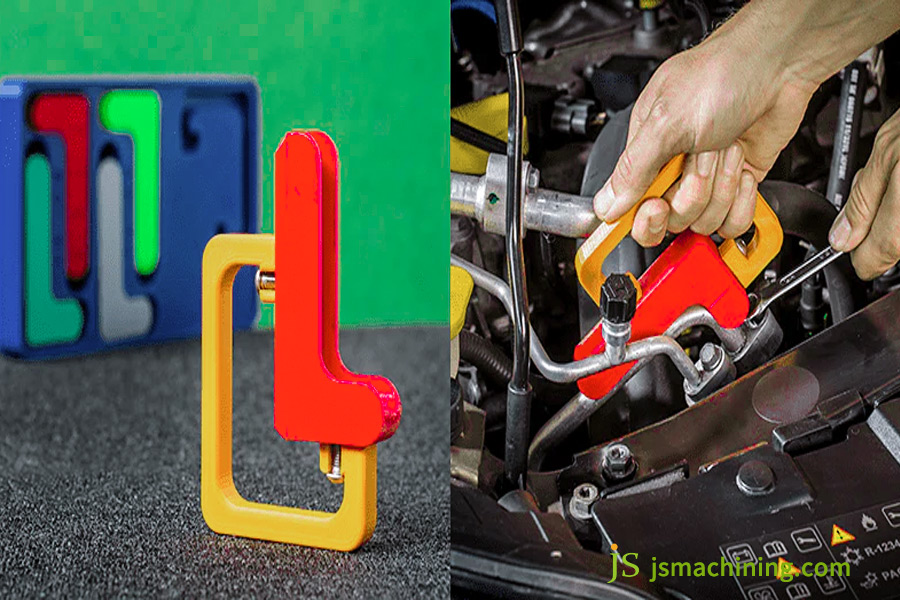

- SLS (Selective Laser Sintering): Well-suited for producing strong nylon functional parts, such as automotive interior use application clips and brackets.

- SLA/DLP: Perfect for making high-precision, smooth-surfaced transparent or display parts, such as car headlight models.

- FDM: Cost-effective, primarily used for proof of concept and rapid tooling manufacturing, allowing automobile companies to make prototypes during the R&D phase.

- Metal SLM/DMLS: The technology crown jewel, able to directly produce high-strength final-use metal parts, such as high-heat-resistant parts near engines.

Step 3: Post-Processing – From “Rough” to “Fine”

The third is post-processing, which transforms parts from “rough” to “fine.” Some of the typical post-processing processes are:support removal (eliminating immobilization support structures employed in printing), sandblasting (to improve surface roughness), polishing (to yield a smoother surface), heat treatment (to eliminate inner stress and increase strength), and hot isostatic pressing (to seal internal micropores and increase durability).

All of these processes make sure part performance and appearance are entirely at automotive manufacturing standards.

Strength Showdown: Can 3D Printing Parts Match Traditionally Made Parts?

Many people are worried about whether the strength of 3D printed car parts is sufficient?Are they comparable to conventionally manufactured parts? In fact, there are some genuine examples that have justified it. Let us observe the overall performance in the table:

| Application Case | Manufacturing Method | Weight Change | Strength Change | Special Performance |

| Honda Crankshaft | 3D Printing | 30% weight reduction | Maintains original strength. | – |

| GM Stainless Steel Seat Bracket | 3D Printing | 40% weight reduction | 20% strength increase. | – |

| Volkswagen A-Pillar Reinforcement System | 3D Printing | 74% weight reduction | No impact on strength. | Meets durability requirements. |

| Bugatti Titanium Brake Caliper | 3D Printing (Titanium Alloy) | – | – | Withstands high temperatures of nearly 1000°C. |

| Traditionally Manufactured Seat Bracket | Casting + Machining | Baseline value | Baseline value | Difficult to reduce weight. |

Breakthrough performance achievements: 30% weight reduction of Honda crankshaft, 20% strength gain and 40% weight saving of universal seat bracket, 74% weight saving of Volkswagen A-pillar reinforcement system, Bugatti brake calipers endure temperatures of almost 1000°C.

Technical Advantage Principle: Through the use of topology optimization and lattice structure engineering, the material is at stress positions where it is most required, balancing strength against lightweighting.

To achieve 3D-printed parts that are equal to or better than the performance of traditional materials, three aspects must be tackled:

- Materials science: Develop sophisticated metal powders (e.g., high-strength aluminum and titanium alloys) and advanced polymers.

- Process control: Accurately control laser power, scanning trajectory, and shielding gas in order to obtain complete material fusion.

- Post-processing strengthening: Internal stresses are eliminated by heat treatment, and grain structure is optimized, while hot isostatic pressing fills internal micropores.

Realistic Constraints: Challenges Facing 3D Printing Technology In The Automotive Industry

While 3D printing of automotive parts has significant advantages, it yet has several practical limitations that prevent it from completely displacing traditional production.

1.Material bottleneck: The current materials available for 3D printing are still far fewer than those that are actually used in the automotive industry. Moreover, they have specific parameters of particle fineness and sticking power required. Most specialty materials are also very expensive, increasing the manufacturing expenses.

2.Efficiency and cost concerns: Industrial-grade 3D printer and peripheral designs are expensive. While 3D printing is economically competitive for single-unit or small-batch production, its cost and print speed is still inferior to traditional manufacturing for high-volume mass production applications. For example, the initial print of an electric Strati vehicle took 44 hours.

3.Lack of quality and standards: The sector at the current moment lacks a universal safety and quality standard framework for 3D printing automotive parts, and regulatory bodies’ mandate is not clearly established. This has left automakers in dread of applying 3D printing for security-critical components such as brake systems.

4.Protection of intellectual property: 3D printing makes use of digital files, and copying and utilization of the files can easily lead to infringement of intellectual property rights. While emerging technologies such as blockchain can be used to protect intellectual property rights, their use is not widespread currently.

5.Industry chain and professional pool: 3D printing remains underdeveloped in China. There remain gaps for some of the nodes in the printing industry chain. For example, the high-quality equipment, core components (such as laser heads), and specialty materials are still imported. Moreover, there lack professionals with expertise in automobile manufacturing and 3D printing technology.

JS Precision efficiently manages 3D printing prices by streamlining its supply chain and processes. For small-batch production requirements for customers, our solutions strike the right balance between cost and efficiency and enable you to get high-quality 3D-printed auto components at a reasonable price.

3D Printing In Action: A Dual Revolution From “Mass Production” To “Agile Manufacturing”

You might wonder how 3D printing would perform in actual car production. The following two real-life examples of JS Precision will show its double revolution from “mass production” to “agile manufacturing.”

Case 1: Betatype Metal Printed Heat Sinks, completed

384 units in 19 hours, cost lowered to $3

Background and Challenges

Traditional auto LED headlight heat sinks typically consist of a combination of machining or casting processes. This causes long production cycles, where one batch requires 444 hours. Mold costs are also prohibitively high, and design changes require re-manufacturing, making it difficult to react quickly to custom needs.

A certain car company has faced the problem of radiator supply not keeping up with research and development progress multiple times due to fast design iteration.

How JS Precision Overcomes the Problem with 3D Printing

We first redesigned the heat sink for integration in function, eliminated unneeded assembly structures, and achieved support-free, integrated production, reducing future steps. We next employed multi-laser equipment (such as the RenAM 500Q four-laser machine) and optimized laser exposure methods, enabling effective simultaneous processing of multiple parts.

This enabled printing of 384 stacked parts in a single print job, ultimately reducing build time from 444 hours with traditional processes to less than 19 hours and per-unit cost from $30 to less than $3.

Comparison and Differences with Traditional Manufacturing

In the efficiency area, 3D printing doubled efficiency over 23 times. In the cost area, mold cost was eliminated, and unit cost was reduced by 90% for small lot production. In the design freedom area, integrated design reduced the number of parts and replaced intricate traditional steps like casting and assembly. When it implemented our solution, the car maker tripled its rate of R&D iterations, essentially driving its new headlight project ahead.

Case Study 2: Enabling CATL with printed battery cell fixtures, from 2-4 weeks to 4 iterations in 2 days

Background and Challenges

CATL requires constant tooling and fixture iterations in battery cell assembly. As cell designs are constantly optimized, fixture changes need to be performed. However, normal CNC machining cycles run from 2-4 weeks, and tool limitations hinder the manufacturing of intricate structures such as positioning pieces with internal cavities. This severely delays battery cell innovation.

JS Precision’s Solution

We commissioned a Raise3D ultra-large-scale printing center for CATL, with multi-process machines such as FFF and SLS. Combined with an in-house private cloud management system, we enable digital, on-demand production of fixtures.

For instance, in manufacturing battery cell models, conventional production is 15 days and costs $200 per unit, whereas our 3D printing takes a mere 8 hours and costs $80 per unit, enabling us to accomplish four design optimizations in two days.

In production, a standard pallet weighs 8 kg and takes 40 days of production cycle. Pallets produced by 3D printing weigh 75% less (only 2 kg) with a 10-day short production cycle with considerably less energy used in the supply chain.

Comparison and Differences with Traditional Manufacturing

We have transitioned from being “inventory-driven” to being digital inventory-driven with zero-inventory production and response enhanced by 300%. On intricate parts, we can form internal flow channels and light lattices in one piece that cannot be produced by traditional CNC machining.

We have completed 100,000 of CATL’s orders for printing by the end of 2023 with just a 2.1% failure rate, thus fully testing the 3D printing high-density industrial reliability.

JS Precision’s online 3D printing services can provide you with agile manufacturing support. After you’ve ordered, we will send a solution to you in 24 hours so that your project can go on as usual.

Future Vision: Complementary Integration, Not Simple Replacement

From the case, we can see the potential of 3D printing. So, what is its future development direction?The entire industry believes that 3D printing will never replace conventional large-scale manufacturing technologies like casting and forging entirely in the near future, but would have deep integration and complementarity.

Development Route Projections: It will never replace traditional manufacturing but will be tightly coupled, a hybrid trend where “large-scale manufacturing relies on traditional methods, whereas complex/customized/R&D parts rely on 3D printing.”

- Technical Upgrade: Greater material heterogeneity (high strength, high thermal resistance),better performance, larger and intelligent equipment,and with artificial intelligence and Internet of Things on board in an endeavor to achieve smart manufacturing.

- New Business Models and New Forms: Distributed manufacturing and virtual inventories will go main stream, minimizing cost of inventory and supply chain risk.

- Macro Trends: It complements intelligent production, and clean production (minimum material wastage), and is strategically invested nationally.

In car manufacturing long-term planning, JS Precision’s 3D printing parts can provide class-leading support. We monitor technology advancements in the background continuously and can provide customized, long-term collaborative solutions to your long-term plan so that we can experience industry trends together.

FAQs

Q1: What is the number of parts that can be 3D printed in an automobile

Theoretically, with the exception of very uniform and lower-priority components (such as ubiquitous screws), most car parts can be printed through 3D printing. In practice, due to present economic and efficiency levels, 3D printing focuses on non-body parts, personalized parts, and lightweight structural parts. The number of actual used parts ranges from dozens to hundreds per car model and production requirement.

Q2: Besides metal and plastic, some of the other substances that can be 3D printed and potentially used in car manufacture?

Apart from plastic and metal, automotive 3D printing has other promising materials such as carbon fiber composites (strong and lightweight and appropriate for body frames), high-heat-resistant specialty polymers (appropriate for engine compartment parts), and multifunctional materials (appropriate for the co-printing of hard structures and soft structures). 3D printing embedded circuits and battery electrodes will also be leading sectors in the future.

Q3: Is the 3D-printed part less costly than traditional manufacturing?

Whether 3D-printed parts are less costly than traditional manufacturing depends solely on production quantity and complexity. Its cost benefit is now in “high-performance, small batches” and “tool-free, rapid response” uses. Specifically, 100 customized intricate parts have 30% lower cost. But if it is 10,000 volume-standardized mass-produced items, traditional manufacturing has higher speed and cost benefits.

Q4: Will 3D-printed car parts pass safety certification?

Yes, but this is still an application to which the industry needs to assign greater priority. Certain auto parts already produced with 3D printing have gained proper automotive industry certification, such as TS16949 quality management system certification. To use 3D printing for safety-critical functions like brakes and steering systems, however, the industry needs to formulate more accurate, industry-specific requirements for certification, and regulators need to become more open in describing their regulatory procedures.

Summary

3D printing is not going to displace traditional manufacture, it’s creating a brand new dimension of possibility within the world of automobiles. It’s breaking the limits of design, transforming economics in the supply chain, and enabling levels of performance and personalization previously unheard of.

This transformation is not a ‘replacement’, but a profound ‘integration’ that will redefine the way we manufacture, own, and experience cars.

JS Precision, an industry partner over a decade, offers end-to-end 3D printing services ranging from design optimization to shipping of production. Whether you require custom 3D printing manufacturing or wish to manage 3D printing prices, we can provide you with professional solutions.

Choose us and let 3D printing technology inject new vitality into your automotive manufacturing projects, working together towards a more efficient and flexible manufacturing future.

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com