On a highly mechanized, cutting-edge production line, every second wasted is expensive. When a valuable injection molding part is destined for the scrap heap because of some imperfection, or when standard adhesive bonding cannot achieve the stringent automotive vibration standards, a very low-tech but highly efficacious solution is performing miracles on the factory floor: plastic welding.

Unlike conventional metal welding, plastic welding creates a join of the materials through controlled heat fusion and provides an engineering plastic joint with the same strength as the original material and which is not affected by aging or corrosion.

According to the real experience of the JS team, this article completely answers several possible questions about plastic welding, from elementary knowledge to real processes and industrial application examples, and helps you become a master of reliable plastic welding methods.

Key Answer Summary

| Comparison Dimension | Plastic Welding | Metal Welding | Key Significance |

| Core Principle | Thermal fusion bonding: Heat the plastic itself to melt, then cool and solidify. | Metallurgical bonding / Filler material filling: Melt solder or base metal at high temperature. | No external metal, high bonding strength. |

| “Solder” | Same-material / compatible plastic welding rod. | Tin-lead-silver alloy solder. | Rod compatibility determines bonding firmness. |

| Temperature Requirement | 200-400°C (depending on plastic type). | ≥300°C (for soldering irons) / Higher (for arc welding). | Prevent plastic combustion and toxic gas emission. |

| Key Preparation | Clean to remove oil / oxide layer. | Use flux to remove oxide layer. | Plastic is more sensitive to contamination. |

| Main Advantages | Body bonding, weather resistance, polishable. | Conductive, suitable for load-bearing structures. | Suitable for repairing structural / appearance parts. |

Why Is The JS Team’s Welding Experience Valuable?

When you have a plastic part that’s broken in your facility and are unsure what to weld it to, or are attempting to choose which welding process to use, the JS team’s everyday experience can provide you with the most relevant guidance for your manufacturing needs.

JS team has been deeply rooted in the welding sector. Not only have we accumulated a great deal of experience in welding metals in the custom sheet metal fabrication manufacturing, but also have been involved in hundreds of practical projects with plastic welding, such as repairing PP pallets for automotive parts to fixing plastic tank cracks with multiple types of thermoplastics like PP, PE, and ABS.

We also provide welding support in our online sheet metal fabrication services as per customer specifications. This guide is not just academic research, it’s the result of the JS team’s hands-on experience acquired through hundreds of welds. All the recommendations are field-tested, so you can rest assured it will correct actual plastic welding problems.

When you need professional plastic welding solutions or custom sheet metal fabrication manufacturing help, the JS team can provide solutions based on their long-term experience. Simply phone us to discuss your needs and we will start an efficient cooperation.

What Is Plastic Welding? When Thermoplastics Meet The Soldering Iron

Prior to talking about whether soldering irons could be employed for plastic welding, let us first define the basic definition of plastic welding and how it contrasts with adhesive bonding.

Basic Definition

Plastic welding is a joining process for thermoplastic materials. The plastic to be welded is melted by thermal energy, followed by pressure and cooling to bond the two together. A soldering iron, used as a heat tool, can precisely apply heat to a spot of plastic that is useful for low-scale, high-precision welding (like repair of plastic part cracks).

Differences from Gluing

The core principles and performance differences between the two are significant,as outlined in the table below:

| Comparison Dimension | Plastic Welding | Adhesive Bonding |

| Connection Principle | Thermal fusion and solidification of thermoplastics themselves after melting. | Fix plastics by the adhesion of adhesives. |

| Bonding Strength | High, close to the strength of the plastic itself, can withstand large external forces. | Low, dependent on adhesive performance, easy to fall off under external forces. |

| Temperature Resistance | Good, suitable for common industrial environments (-40°C to 120°C). | Poor, adhesives tend to soften and fail at high temperatures. |

| Durability | Strong, not easily affected by humidity and chemicals. | Weak, adhesives tend to age after long-term use. |

| Application Scenarios | Load-bearing components, industrial plastic parts, automotive plastic parts. | Non-load-bearing components, decorative plastic parts, temporary fixation. |

JS has years of experience in plastic welding and has no difficulty distinguishing between the conditions under which welding and gluing can be used. In case you need to join plastic parts, kindly contact us and we will guide you on the best way to do it.

Not All Plastics Are Weldable: Determine Your Welding Material

Only thermoplastic plastics can be melted and welded by heating, while thermosetting plastics will carbonize upon heating and cannot be welded. Before welding, the type of plastic needs to be identified.

Thermoplastics – Weldable

Thermoplastics possess a linear molecular structure, soften and melt when heated, and harden upon cooling, thus suitable for soldering with a soldering iron.

| Plastic Type | Common Applications | Welding Temperature Range (°C) | Suitable for Soldering Iron Welding |

| PP (Polypropylene) | Automotive battery trays, plastic containers. | 300-320 | Yes |

| ABS (Acrylonitrile-Butadiene-Styrene) | Electronic device housings, automotive interior parts. | 250-280 | Yes |

| PE (Polyethylene) | Plastic films, chemical containers. | 280-300 | Yes |

| PVC (Polyvinyl Chloride) | Pipes, door and window profiles. | 200-230 | Yes (ventilation required) |

Thermosets – Non-weldable

On curing, the molecules form a cross-linked network that degrades and carbonizes on heating. Common types: are:

- Epoxy resin: Circuit board encapsulation, adhesives.

- Phenolic resin: Electric switches, heat insulation.

- Unsaturated polyester resin: Fiberglass products, bathtubs.

If unsure of the plastic type, check the material markings on the item. If none are present, perform a burn test in a well-ventilated area (for example, PP smells of paraffin when burned while ABS material smells of rubber when burned).

Do You Require ASpecial Soldering Tip?

In an emergency, any common soldering iron will do, while in professional soldering, there are specific soldering irons and ancillary tools.

Common soldering iron

Strengths: Commonly available for purchase, cheap, can be used in emergency soldering of parts with no load (e.g., soldering toys to seal cracks),

Weaknesses: No temperature control, one-shape head makes it clumsy for fitting for intricate shapes, poor heat transfer rate, not fit for soldering large surfaces.

Special plastic soldering iron

Advantages:

- Stable temperature control (PP 320°C, ABS 260°C).

- Exchangable shaped head (e.g., copper head for pallet reinforcement fitting).

- Pure copper head to accelerate heat transfer.

Additional equipment needed

Hot air gun (in order to pre-heat and prevent internal stress), position fixture (for part holding), solder rod of the same material, cleaning agent (for degreasing and removal of bubbles), micro-grinding wheel/scraper (for beveling and soldering).

JS provides plastic welding equipment and custom sheet metal fabrication manufacturing services. Quote for sheet metal fabrication price and procurement or outsourcing agreements.

Step-By-Step: JS Team Standard Operating Procedure For Plastic Welding

Follow JS team designated procedures to obtain weld quality:

1.Surface Preparation: Detergent clean, dry wipe, prevent welding bubbles.

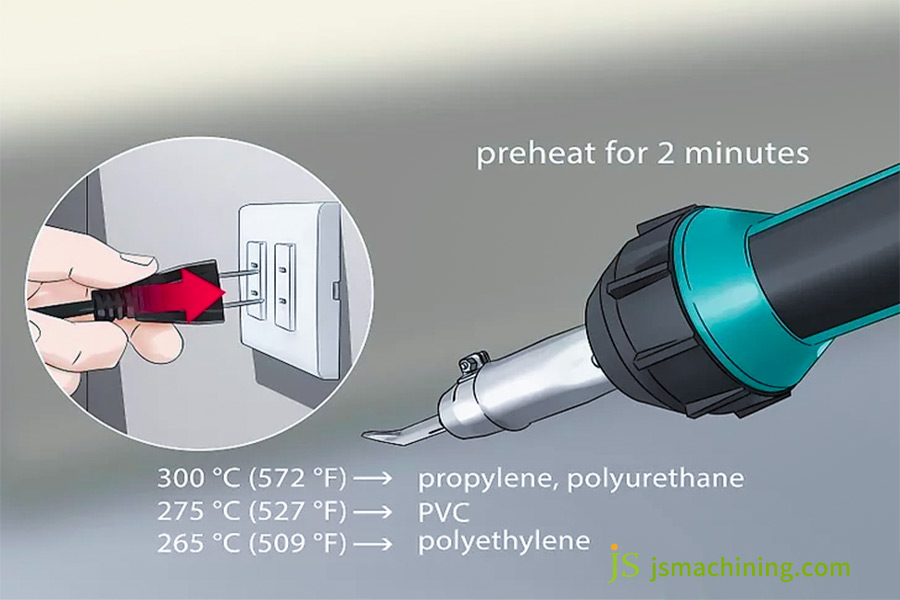

2.Beveling: Create a V-groove (about 2/3 component depth) along the crack to allow for complete solder fill.

3.Preheating: Preheat with hot air gun (80°C for PP, 60°C for ABS) to minimize temperature gradients and cracking.

4.Soldering: Soldering iron heat should be set at the correct level (e.g., 320°C for PP) and fill with molten solder into the groove with full fill.

5.Pressure-Pressure Cooling: Press for several seconds, then withdraw tool and allow to cool naturally (do not rapidly cool with cold water so that embrittlement will not occur).

6.Trimming and Inspection: Remove excess solder by trimming, pry off to release cautiously, and inspect seals for airtightness.

From Beginner To Master: Key Skills For Productive And Strong Welding

Once you are familiar with the overall process, then you need to familiarize yourself with the basic techniques outlined by the JS team:

Temperature is crucial

Plastics of different types weld at different temperatures, and even the same plastic of different thicknesses must be set:

- PP (thickness: 3-5mm): 300-320°C. Low temperature will not melt sufficiently, whilst too high temperature will easily carbonise.

- ABS (2-4mm thick): 250-280°C. Too high temperature will easily decompose and release foul-smelling gases.

Check welding temperature with waste plastic to determine melting without carbonization.

Suitable welding rods

Weld using rods of the same grade (i.e., PP rods for PP parts). The others will easily crack. JS uses homogeneous PP welding rods when pallets have more than 90% return to original design strength.

“Butterfly Nail” Reinforcement Technique (Cracks Larger Than 50mm)

- Drill 2-3mm holes at the ends/middle of the crack.

- Construct “butterfly nails” of the same material.

- Weld using welding rods in order to distribute the force and determine appropriate load-bearing sections.

Some Helpful Tips

Slowly weld for heavy components and quickly for lightweight components, avoid repeated heating, Ventilation is required while welding PVC.

Plastic Welding Technology Smackdown: Industrial Mechanisms Of Hot Plate Welding And Ultrasonic Welding

Hot plate welding and ultrasonic welding are equally common in industrial production, yet they have unique characteristics and usage environments:

| Comparison Dimension | Hot Plate Welding | Ultrasonic Welding |

| Core Mechanism | Heat plastic to melt with a hot plate, remove the plate, press and cool. | Generate heat to melt plastic via high-frequency vibration, press and cool. |

| Advantages | 1. Suitable for large-area / complex parts. 2. Easy temperature/pressure control, stable quality. | 1. Fast welding (seconds per cycle), suitable for mass production. 2. No obvious marks. |

| Disadvantages | 1. Long cycle, low efficiency. 2. Hot plate easily sticks to plastic, requiring cleaning. | 1. Suitable for small-area / simple parts. 2. High customization cost for welding heads. |

| Application Scenarios | Large automotive plastic parts (bumpers, trays), home appliance housings. | Electronic connectors, small plastic accessories (buckles), medical device parts. |

JS usually utilizes hot plate welding for large auto PP pallets and ultrasonic welding for small ABS parts. The technology is selected based on the specific characteristics of the component.

If you need to select plastic welding technology for an industrial project, either hot plate welding, ultrasonic welding, or electric iron welding, we can tailor our services to suit your needs and provide you with a transparent sheet metal fabrication price quote.

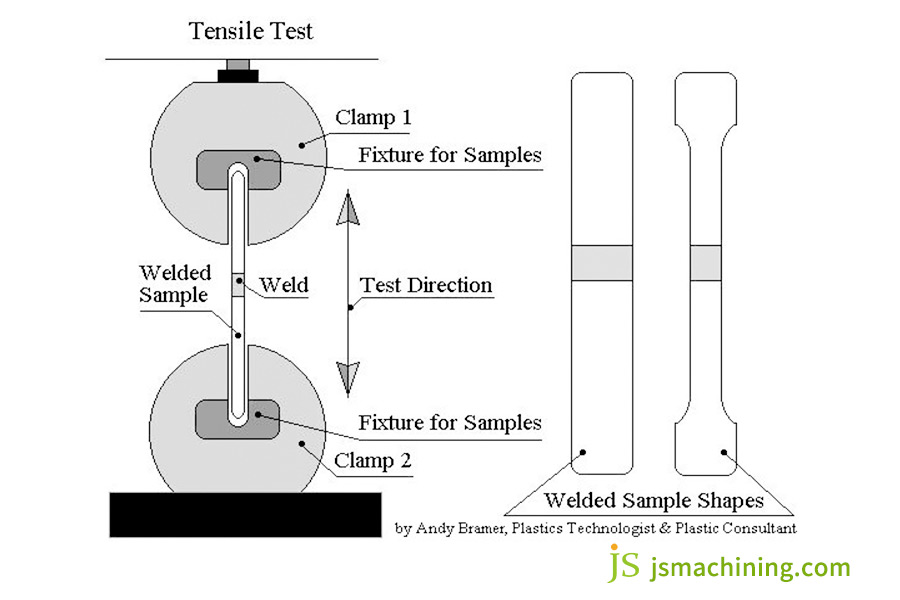

A High Strength Test: How Do We Test And Guarantee Your Welding Quality?

Quality inspection is required after welding, and JS has a rigorous procedure:

Welding Quality Inspection Methods

- Appearance Inspection: No bubbles, cracks, or smooth surface.

- Tensile Test: Strength should be no less than 90% of the original material (for instance, PP original strength is 20MPa, ≥18MPa after welding).

- Airtightness Test: The seal is pressurized with 0.5-1MPa air in water, and there are no bubbles.

- High-Low-Temperature Cycle Test: -40°C/2h → 120°C/2h, 10 cycles without cracking.

- Vibration Test: Vibration at 10-500Hz for 24h. The weld should be acceptable if it remains in tact.

Welding quality assurance measures

- Stringent selection of materials: Use qualified material, sample and test each batch to ensure material consistency.

- Standardized procedure: Install SOP, train and test operator to prevent operation errors.

- Monitor in real time: Sensors monitor temperature/pressure/time, and stop automatically if abnormal.

- Inspection sampling: Inspect sample of every batch (e.g., 5/100 pieces), and conduct lengthy inspection on unqualified parts.

JS team owns welding quality inspection facilities and can conduct thorough quality assurance for your plastic welding project. In case you need mass production or customized sheet metal fabrication parts, we can ensure the welding quality of every part conforms to standard.

JS’s Cost Reduction And Efficiency Improvement Case: Online Repair And Value Recovery In Automotive Parts Manufacturing

Background

One of the leading automative component suppliers produces big PP (polypropylene) battery trays for its latest models. After injection molding, about 15% of the trays get cracked at the inner reinforcement and claw roots because of demolding stress or poor mold venting, as identified through factory inspection. According to the traditional quality process, these parts are scrapped directly, resulting in wastage of material, energy and man hours.

Challenges

- Economic pressure: Expensive molds, expensive unit cost, and 15% scrap rate erode profi.

- Performance requirements: The restored component must perform to -40°C to 120°C, vibration-resistant, and retain over 90% strength of the original design.

- Efficiency and aesthetics: The repair must be consistent with the rhythm of production and no trace is to be seen.

JS solution

1. Process evaluation and choice:

Hot air welding (low efficiency and high skill requirement for operators) and glue solutions (poor durability and temperature resistance) were ruled out. Controlled hot press welding was selected, and the central tool was a modified high-precision constant temperature electric soldering iron system.

2. Tool and material tailoring:

- Tools: Design specialized copper soldering iron tips for cracks in different areas, with a shape that perfectly fits the contour of the reinforcing rib, achieving uniform heating.

- Materials: Special welding rods are made of PP material that is completely homogeneous with the tray.

- Tooling: Design a simple positioning fixture so that the component position is fixed and force is distributed evenly while repairing.

3. Standardized operation procedure (SOP):

- Surface treatment: Clean the crack surface with a detergent to eliminate release agents and other foreign particles.

- Beveling: Remove a V-shaped groove at the crack using a micro-grinding wheel.

- Preheating: Preheat the welding region employing a hot air gun to around 80°C.

- Welding: The operator places a particularly developed soldering iron tip (at 320°C) over the solder rod and forges it into the V-shaped recess, overflowing it to the top.

- Pressure-retaining cooling: After welding, keep the tool under pressure for a few seconds and then move it away to allow it to naturally cool and solidify in the air.

- Trimming and inspection: Remove excess solder by scraping with a scraper after cooling, and inspect for strength of repair through airtightness testing and torque testing.

Results and value

Economic benefits: Successfully reduced the rate of component scrap from 15% to less than 2% (only very defective components which cannot be repaired are scrapped). This saves the company over $100,000 in direct annual costs.

Quality Performance: All repaired parts have 100% passed OEM requirements in vibration table testing, high and low temperature cycling tests, and tensile tests and have been fully approved by the quality department.

Process Optimization: The repair station is incorporated at the end of the production line, being one of the quality inspection process steps. All operations can be handled by a single operator, which allows for instant on-line value recovery and greatly enhances the flexibility of production.

Sustainability: This reduces plastic waste and carbon footprint of the product, in keeping with the company’s environmentally friendly manufacturing process.

FAQs

Q1: Can I weld different types of plastics?

Welding different forms of plastics is not desirable because they have different physical characteristics, melting points, and molecular structures,which consequently does not provide a high molecular bond. For example, when welding PP and ABS, the interface is prone to delamination and cracking due to temperature changes, which cannot guarantee strength and durability. It is therefore essential to use plastics and welding rods of the same material.

Q2: What can I do to prevent soldering iron sticking?

Three ways exist to prevent soldering iron from sticking on plastic.

- Apply a light coating of Teflon to reduce sticking, but not so heavy that heat transfer is prevented.

- Regulate temperature precisely. The temperature should be set according to the type of plastic and tested in advance.

- Move the soldering iron tip evenly while welding and never leave the tip stationary for an extended time. Remove the tip once you’re done.

Q3: What if I don’t have a specific welding rod?

There are two temporary solutions that can be applied but only to non-load-bearing and non-critical areas.It is recommended to replace the dedicated welding rod as soon as possible after the emergency.

- To web plastic shreds of the same material from a concealed area of the part (e.g., the inside or the underside), melt and heat them up, and fill the void.

- To find scrap plastic of the same material (e.g., discarded PP toys) and cut it into thin strips and use them as temporary welding rods.

Q4: What do I do when the weld is aesthetically unpleasing with marks?

It is natural for weld marks. To refine the finish, you can process the weld after it has cooled down completely: sand off excess solder first with 200-grit coarse sandpaper, and polish it with 800-grit and 1200-grit fine sandpaper afterward. Then polish using polishing paste and polishing cloth to refine the finish. Fixing textured plastic surfaces is not simple. Stick to maintaining strength and avoid destroying the weld structure by sanding too frequently for aesthetics.

Summary

Plastic welding is a rewarding skill that smooths the divide between consumption and production, making “damage” into “repairable.” It does not require expensive equipment but expertise, time, and some practical courage.

From simple plastic component repairs to complex custom sheet metal fabrication manufacturing projects, the proper approach and a dedicated team can make plastic welding an invaluable addition to your plant.

If you need plastic welding, whether for vehicle components repair or electronic device welding, JS offers experienced and dependable custom services. We also offer transparent sheet metal fabrication price estimates and an easy order process. Simply contact us to begin a working relationship that will maximize your production efficiency and save your money.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Resource

Pingback: How To TIG Welding Of Aluminum In 3 Hours? - JUSHENG