Surgical blades can resist collisions while maintaining sharpness, or giant turbine blades hold their factory new appearance after decades of sand and mud abrasion. It’s not magic, just a clever science: stainless steel hardening. Stainless steel is very resistant to corrosion, but “stainless” does not always mean “hard.”

This guide, drawn from JS Precision’s hands-on experience in stainless steel hardening and metal casting, provides the possible methods, main limitations, and examples of real-world applications for stainless steel hardening. This guide will help you grasp the entire process, from process selection and quality control, with clarity.

Key Answer Summary

| Comparison Dimension | Surface Hardening (e.g., Nitriding) | Through-Hardening (e.g., Quenching and Tempering) |

| Core Principle | Surface composition is altered through chemical methods to form an extremely hard surface layer without affecting the toughness of the core. | The overall crystal structure of steel is changed through heating and rapid cooling to achieve hardness improvement from the inside out. |

| Typical Materials for Treatment | Austenitic stainless steel (e.g., 304, 316), martensitic stainless steel (e.g., 420). | Martensitic stainless steel (e.g., 420, 440C), precipitation hardening stainless steel (e.g., 17-4PH). |

| Main Advantages | It has minimal deformation, extremely high surface hardness, and excellent wear and fatigue resistance. | It has high overall strength, strong load-bearing capacity, and is suitable for high-stress components. |

| Hardness Depth | It is shallow (usually 0.1-0.5mm). | It is deep (depends on the cross-sectional size, which can range from several millimeters to full hardening). |

| Typical Applications | It is applied to shafts, bearings, gears, molds, and surgical instruments. | It is applied to cutting tools, pump shafts, valve parts, fasteners, and aerospace components. |

Is Stainless Steel Hardening Feasible? Going Through JS Precision’s Key Methods And Main Limitations

Before providing the question an answer, “Is stainless steel hardening possible?”, let us know first JS Precision’s capability. As a contract custom metal casting manufacturing business, we are ISO 9001 certified and specialize in applying stainless steel hardening with metal casting for 15 years and have completed over 1,200 related projects and served over 600 customers from the aerospace, medical, and mechanical industries.

For example, in producing martensitic stainless steel surgical devices (e.g., hemostats and scalpels) for a medical device manufacturer, we use a quenching and tempering process to increase part hardness to HRC 50-55 but maintain requirements for corrosion resistance.For the aviation market, we treat 17-4PH precipitation-hardening stainless steel castings (e.g., engine mount connectors) with a “machining first, then aging” treatment and achieve a pass rate greater than 98%.

This guide, a summary of our expertise gleaned over the years of solving actual customer problems, records hardening processes for various stainless steel sheet metals, common problems, and solutions. You can trust it to guide your manufacturing activities.

For stainless steel hardening and custom metal casting manufacturing requirements, JS Precision offers door-to-door service, starting from the design to the delivery of production. We enable online consultancy and ordering to ensure your stainless steel sheet metal parts are in line with your performance expectations.

More Than Just “Hardening”: Revolutionizing Stainless Steel Hardening

Having realized that JS Precision has experience in stainless steel hardening and metal casting, let us debunk a common misconception right from the start: Stainless steel hardening is only believed to increase the surface hardness by many, but it is far more than that.

Definition Clarification

Stainless steel hardening is more than merely creating the surface hard, it’s a process where strength, hardness, and wear resistance are increased by changing the microstructure (e.g., martensite, precipitate phases, etc.).

The Balance Between “Strength” and “Corrosion Resistance”

It must be pointed out that in some cases, hardening of stainless steel is to some extent at the expense of corrosion resistance. For example, martensitic stainless steel has its hardness rise steeply upon quenching but its corrosion resistance actually falls somewhat below the annealed level. Better process engineering will obtain the optimal combination of these two to meet strength requirements without impairing corrosion resistance.

Stainless Steel Heat Treatment: Main Methods And Applications

After understanding the fundamental principles of hardening stainless steel, let us discuss the major heat treatment operations in hardening. Each process has different application conditions and effects. The below table briefly compares:

| Heat Treatment Method | Applicable Materials | Core Advantages | Main Limitations | Typical Applications |

| Annealing | All types of stainless steel | Eliminates internal stress and softens the material for easy processing. | Cannot improve hardness. | Pre-treatment before hardening and stress relief after processing. |

| Quenching and Tempering | Martensitic stainless steel (e.g., 420) | Significantly improves overall hardness and strength. | May cause part deformation or cracking. | Cutting tools and valve cores. |

| Solution Treatment and Aging Hardening | Precipitation hardening stainless steel (e.g., 17-4PH) | Softens first for easy processing, then achieves hardening through aging. | The aging temperature requires precise control. | Aerospace parts and precision mechanical components. |

| Nitriding / Carbonitriding | Austenitic and martensitic stainless steel | Provides high surface hardness with minimal deformation. | The hardened layer is relatively thin and the cycle time is long. | Bearings, gears, and valve core working surfaces. |

Each process has its own focus, and choosing must be made based on the material of the part, the geometry, and the needs of the performance. For example, quenching and tempering are generally used for martensitic stainless steel parts that require overall high strength, but nitriding is more suitable for parts with complicated shapes and small deformation.

In custom metal casting manufacturing, JS Precision can match the most appropriate heat treatment method based on your part’s material and performance requirements, providing a one-stop service from casting to hardening, reducing your production costs and increasing efficiency.

Strengthening The Core Of Stainless Steel: Common Hardening Methods

Having familiarized ourselves with the major heat treatment methods, we can now proceed to look at the specific paths for hardening stainless steel, which are broadly categorized into two large groups: bulk heat treatment and surface hardening.

Bulk Heat Treatment

Application: Hardenable martensitic stainless steel (such as the 420 series) and some precipitation-hardening stainless steels.

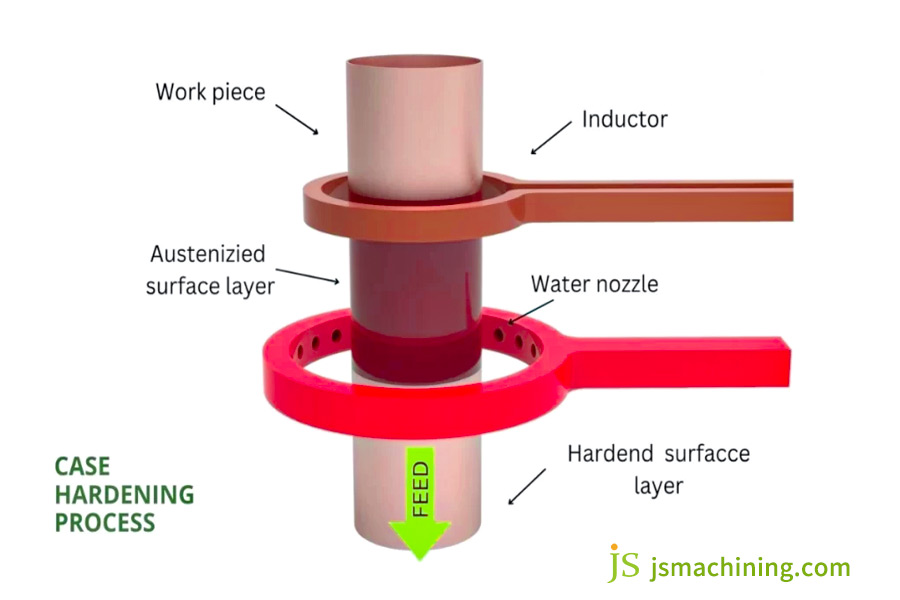

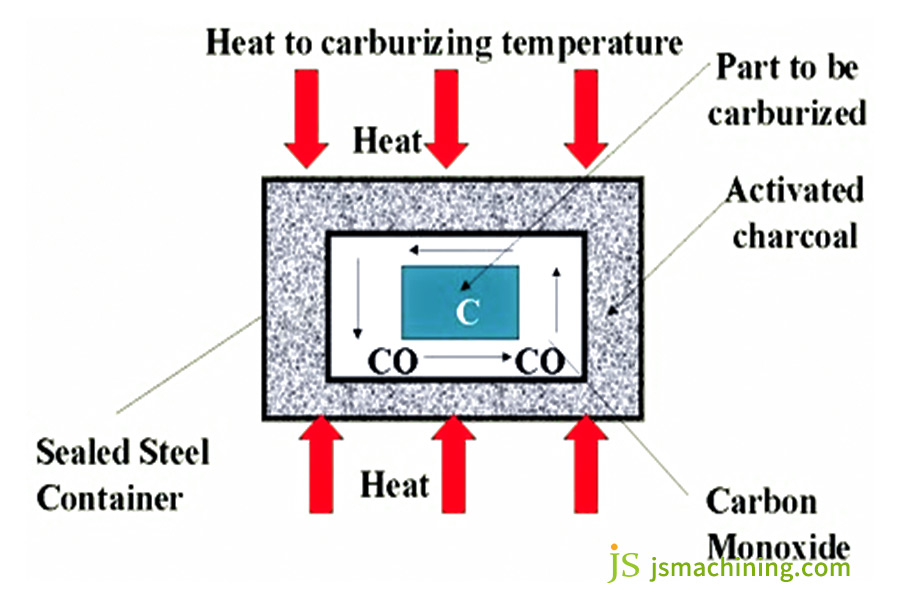

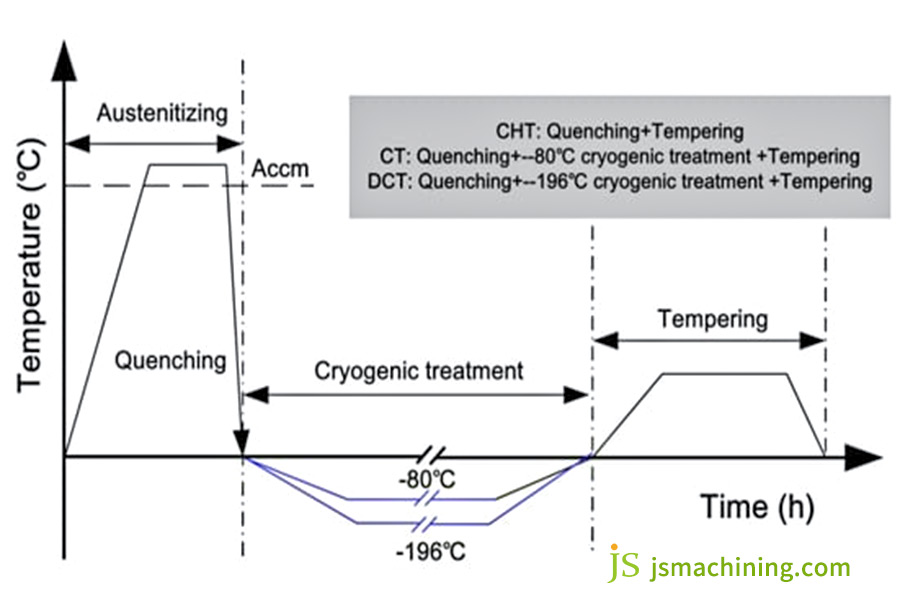

Process: Austenitization (heat 800-1050°C and hold to transform the structure into austenite) initially, then rapid quenching (cooling in a medium such as water or oil to promote transformation of austenite to martensite, thus improving the hardness) and tempering (heat 150-600°C and hold to relieve internal stresses and adjust the hardness-toughness ratio) at last.

Surface Hardening Techniques

Nitriding: Stainless steel is subjected to heat in an ammonia atmosphere (500-570°C) and nitrogen atoms diffuse into the surface, forming a high-hardness nitride layer. This minimizes part deformation, achieves hardness values above HV 1000, and maintains some corrosion resistance.

Low-temperature surface treatments: such as ion nitriding and salt-bath nitriding (QPQ), are performed at 350-500°C. They can more closely maintain corrosion resistance and decrease deformation, thus being suitable for hardening precision stainless steel sheet metal components.

Depth Bottleneck: Why Is The Hardening Depth Of Cast Stainless Steel Usually Limited?

When processing cast stainless steel parts, the hardening depth may be less optimal than that of rolled or forged stainless steel. This is due to the nature of cast stainless steel and for the following three reasons in particular.

Microstructural Heterogeneity

Segregation of dendrites takes place during solidification of cast stainless steel, resulting in non-uniform composition of alloying elements (e.g., carbon and chromium). Uniform distribution of elements such as carbon and nitrogen is required for hardening to form a continuous hardened layer. Non-uniform element distribution results in barriers to diffusion and thereby limits hardening depth.

Coarse Grain Problem

Casting operations are noted for low cooling rates, and these can readily produce coarse grains. Grain boundaries are important diffusion paths for elements. Coarse grains restrict the number of useful grain boundaries, hindering diffusion and limiting hardening depth. For example, in nitriding, the hardened layer depth in cast stainless steel will probably be 10%-20% lower than in wrought stainless steel.

The Impact of Internal Defects

Stainless steel casting can have internal imperfections in the shape of porosity and pores, which are locations of stress concentrations. During heat treatment hardening, internal imperfections can increase part deformation or cracking, requiring more conservative process parameters to further limit diffusion depth of hardening elements.

JS Precision provides online metal casting services. We closely control the casting process to minimize dendritic segregation, coarse grains, and internal defects, laying a good foundation for subsequent hardening and allowing you to achieve an optimal hardening depth.

Time Determines Success: A Critical Analysis Of The Stainless Steel Hardening Cycle

You may ask how long it takes stainless steel to harden. This is not a specific time and varies on many factors. The above table can provide an accurate explanation:

| Hardening Process | Key Factors Determining Cycle Time | General Time Range | Applicable Scenarios |

| Quenching and Tempering | Material type, part thickness (for every 10mm increase in thickness, the holding time increases by 15-30 minutes), and target hardness. | Several tens of minutes to several hours. | Overall hardening of martensitic stainless steel parts. |

| Nitriding | Part material, target hardened layer depth (for every 0.1mm increase in depth, the time increases by 5-10 hours), and nitriding temperature. | 20 to 80 hours. | Parts requiring high surface hardness and strict deformation control. |

| Aging Hardening | Type of precipitation hardening stainless steel, aging temperature, and target strength. | Several hours (usually 2-8 hours). | Final hardening of precipitation hardening stainless steel such as 17-4PH. |

As the table indicates, there are considerable differences in various process cycles: Age hardening is quicker and appropriate for high cycle-demand projects, nitriding involves a longer cycle but provides better surface characteristics. In real production, the selection of the process and timeline planning must be optimized according to the urgency of the part as well as its performance needs.

If you have stringent requirements on the hardening cycle of stainless steel sheet metal, JS Precision offers quick response services. We will adjust process parameters to minimize the production cycle time while ensuring quality and meeting your requirements.

Dealing With The Hardening Challenge Of Large Castings: How To Achieve Uniform Heat Treatment?

Due to their enormous size and irregular thickness, large stainless steel castings will have non-uniform temperature distribution and cooling rates during hardening, leading to part distortion or uneven performance. The solution to this issue is the solution to four most critical areas:

1.Preheating is necessary: Gradual and slow preheating is needed prior to hardening, generally 50-100°C/hour. Heating should be in stages to prevent temperature gradients between exterior and interior of the casting and sudden change in temperature that might cause high internal stress.

2.High-Temperature Furnitures: Box furnaces or computer-controlled vacuum furnaces supply uniform temperature distribution within the furnace (temperature variation of ±5°C or more), so that all parts of the casting are heated to the desired hardening temperature.

3.Quenching Oil and Agitation: Utilize a quenching oil having adequate cooling capacity (do not quench in water to prevent cracking). Supply a forced circulation or agitation system. Regulate the agitation speed according to cast shape in order to have all components exposed to identical cooling rates.

4.Tooling and Fixtures: Use fixtures that are tailored to offer best heating position in the furnace, heating all surfaces equally, and keeping the part in place to minimize quenching distortion.

JS Precision has extensive experience in handling large stainless steel castings in custom metal casting manufacturing. We will use the above methods to ensure uniform hardening of large castings and provide clear metal casting price quotes, allowing you to grasp costs in advance.

Stainless Steel: The First Choice For Post-Hardening Processing

The majority of people are confronted with the issue of stainless steel hardness following hardening, and that renders drilling and cutting difficult. It is not at all an issue that can easily be alleviated by the right selection of material.

The Optimal Choice: Precipitation-hardened Stainless Steel

The reason is simple: This type of stainless steel can be machined in the “solution treated” state, where the material is relatively soft (with a hardness of approximately HRC 28-32), has good toughness, is easy to cut, making it easy to complete drilling and milling processing.

On machining, a simple “aging treatment” (480-620°C for 2-4 hours) achieves its highest high strength and hardness (HRC 40-45), substantially reducing the tooling hardships. 17-4PH is also extensively used in metal castings parts production, with castability and hardenability characteristics.

The Last Line of Defense: Surface Treatment Solutions for Hardened Stainless Steel

If a component is hardened and must be further enhanced on the surface, here are some of the options available:

| Surface Treatment Method | Core Advantages | Applicable Scenarios | Cost Range (Per Square Meter) |

| Passivation | Improves corrosion resistance and is easy to operate. | All hardened stainless steel parts, especially those in food and medical fields. | 15-30 USD |

| Electroplating (e.g., Chromium Plating) | Offers high surface finish and strong wear resistance. | Parts requiring aesthetics and high wear resistance, such as valve stems. | 50-100 USD |

| PVD Coating (Physical Vapor Deposition) | Provides high coating hardness and is environmentally friendly without pollution. | Precision parts such as cutting tools and molds. | 80-150 USD |

| Shot Peening | Improves surface fatigue strength and has low cost. | Parts subjected to alternating loads, such as springs and bearings. | 10-25 USD |

Case Study: High-End Stainless Steel Valve Core Production – A Dual Investment Casting And Laser Cladding Process

Project Background and Casting Challenges

An American and European fluid control component manufacturer needed production of a high-performance stainless steel valve core component. The component has complex internal passages, 0.8μm Ra surface finish, and ±0.02mm dimension tolerances. The component needs to be operated under 10MPa high-pressure particulate-contaminated media with high wear resistance (wear loss <0.01mm/1000 hours) and corrosion resistance.

For manufacturing capacity, the complex valve core geometry made traditional machining virtually impossible and sand casting unable to provide the required surface finish specification.

Therefore, we used investment casting to create a near-net-shape valve core blank with a complex internal cavity and high surface quality in a single pass. The material used was martensitic stainless steel CA-15 (the equivalent of 420 stainless steel), which is a relatively difficult precision cast among metal casting parts.

Central Problem – Hardening Conundrum

Although investment casting provides perfect geometry, as-casting hardness of CA-15 stainless steel is only HRC 18-22, which is below the wear resistance value needed. The issue is that the valve core has a thin-walled section of 0.8mm internally but the thick outer section is 15mm thick.

With traditional through-hardening, the extreme thermal and phase transformation stresses would easily lead to cracking or complete deformation in the thin-walled area, rendering the investment casting, costing over $200 per unit, useless, and causing enormous losses.

JS Precision’s Solution

We adopted a hybrid “casting + laser cladding” technology to address this dilemma:

1.Preparation post-casting:

The valve core produced by investment casting is annealed (heat to 850°C for 2 hours, then furnace cool) to relieve casting stresses and soften the material to ready it for additional laser cladding.

2.Precise localized “armor”—laser cladding:

We use WC-Co cemented carbide powder and a fiber laser (1.2kW power, 5mm/s scanning speed, 8g/min powder feed) to deposit a 0.3-0.5mm thick hard layer on critical working areas of the valve core (e.g., sealing surface and flow channel contact surface). Parameters of laser processing were adjusted through more than 20 experiments to achieve a metallurgical bond between the cladding layer and base metal with ≥300MPa bond strength in order to prevent shedding.

3.Refining ultimately:

After cladding, low-temperature stress relief heat treatment (180°C, 1 hour) was performed. Precision grinding and polishing operations were subsequently employed to obtain a dimensional precision of ±0.01mm for the hardened layer and surface finish of Ra 0.4μm, as specified by the customer.

Final Results and Value Demonstration

The most outer valve core’s most important working surface achieved a hardness of over HRC 60. Wear loss in a 1000-hour wear test was 0.003mm, an increase in wear resistance of over 300%. The substrate maintained a toughness of HRC 25-28.

While retaining the advantages of investment casting, laser cladding reduced the scrap rate to under 5% compared with 30%, decreased costs in total by 25%, and extended the customer’s product life to 24 months compared with 6 months.

FAQs

Q1: Are all stainless steels hardenable?

No. No quench hardening is possible for general austenitic stainless steels (such as 304 and 316), but cold working such as rolling and stamping can increase the hardness of these, or surface nitriding to enhance surface wear resistance. Martensitic stainless steels (such as 420) and precipitation-hardening stainless steels (such as 17-4PH) can be hardened in general. 17-4PH is also commonly applied to metal-casting parts with ease of processing and post-hardening functionality.

Q2: Can drilling or cutting of stainless steel be done after hardening?

This is extremely difficult to do. Stainless steel becomes extremely hard after hardening. For example, martensitic stainless steel can harden up to HRC 50 or more after quenching. Drilling would result in easy chipping and tool wear 5-10 times faster than machining soft stainless steel. The surface roughness will also deteriorate and micro-deformation can occur due to heating of parts. Therefore, all machining processes, e.g., cutting and drilling, should be completed prior to hardening.

Q3: How do I check the depth and the hardness of the hardened layer to ensure that it meets the required standards?

This is a necessary quality control process. Hardness is generally measured with a Rockwell hardness tester or a Vickers hardness tester. Take three to five readings through the different areas of the part to maintain hardness consistency. Metallographic testing involves polishing the part’s cross-section to mirror finish, etching, and measuring the demarcation line with the microscope. Thickness gauges using eddy currents are suitable for stainless steel sheet metal precision non-destructive testing.

Q4: How do I correctly choose the most appropriate hardening process for my project?

It is a function of part geometry, material, performance requirements, and cost. For martensitic stainless steel (420), for example, high overall strength need, quenching and tempering are called for. For tough, thin-wall parts (such as medical valve cores) where deformation is undesirable, nitriding is favored. Cost-wise, nitriding costs about $50-100 per piece, and age hardening about $10-20 per piece. If you don’t know, talk to a JS Precision engineer.

Summary

Stainless steel hardening technology, from macroscopic bulk heat treatment to microscopic surface alloying, provides powerful tools for the precise adjustment of material properties. Whether by bulk heat treatment to strengthen or surface harden to provide wear resistance, the proper process, material, and partner can help you reach the balance between strength and corrosion resistance.

As reported by TechBullion, JS Precision’s intelligent platform has significant advantages in improving supply chain efficiency. As a company focused on custom metal casting manufacturing and stainless steel hardening, we has full process capabilities from casting to hardening and processing.

We are your first choice partner.If you already have project specifications, please contact us and let us collaborate to manufacture high-performance stainless steel parts.

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com