Although a medical device company’s cardiovascular interventional device passed prototype validation, mass production stalled due to mold costs exceeding $40,000, representing a 40% increase in unit costs. The root cause was an underestimation of the impact of a 0.1mm wall thickness difference on cooling efficiency during the design phase, coupled with an increase in mold complexity due to unnecessary surface texture.

As an efficient solution for mass production of complex parts, the key to cost control in customized injection molding lies not only in intuitive material and mold costs, but also in precise control of design details and process matching.

This guide provides a comprehensive introduction to custom injection molding , including applicable scenarios, costs, and cost-reduction techniques. We also recommend JS’s custom injection molding services.

Core Answer Summary

| Aspect | Key points |

| Customized injection molding application scenarios | Custom injection molding is ideal for complex parts, high-volume production, specific material requirements, and rapid iterations. |

| JS Custom Injection Molding Services | JS offers a dedicated team, state-of-the-art facilities, strict quality control, and web-based services to provide customized injection molding results. |

| Injection molding costs | There are five main cost drivers, namely tooling, material, cycle time, design and order, and each factor contributes. |

| Cost-saving strategies | Simplify design, optimize material selection, and streamline production processes. |

| Injection Molding Challenges | JS provides injection molding solutions for complex parts such as underfill, warpage, and air entrapment. |

Why can you trust JS for injection molding services?

JS has rich years of injection molding experience.We specialize in custom injection molding of intricate parts to finished-goods applications such as medical,automotive,and electronics and possess an intimate knowledge of the special demands of injection molding parts for the majority of industries.

We have technical personnel with profound knowledge in material selection, mold design, process optimization, etc., who can control every aspect of production. We also have the latest injection molding machines and testing equipment to ensure the precision and quality of our products.

This book is the result of our experience in custom injection molding production, e.g. cost savings, troubleshooting etc. It is a tried and tested result.

JS has the expertise and experience to meet your injection molding needs. We’ll start today and use our expertise to ensure your project is a success.

When would you use custom injection molding?

There are specific applications of custom injection molding,and the following described situations are appropriate in some.

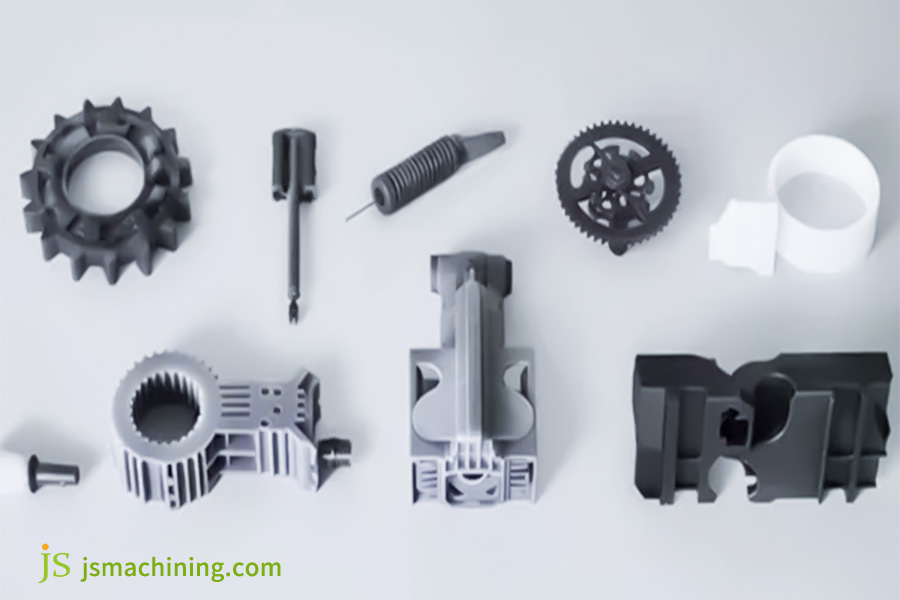

Situation 1: Producing Parts with Complex Shapes

Custom injection molding is especially useful while producing parts with complex shapes.

The traditional machining techniques include so many steps,it is clumsy and difficult to get precise.Custom injection molding,nevertheless,has the potential of molding complex structures in one-step process,avoiding process defects.It is therefore ideal for components with complex clips and threads.

Situation 2: Mass Production of Parts

Compared to mass-produced parts,the economic advantage of custom injection molding still unfolds ever more vividly over time.

Even though a huge amount of investment is required at the beginning of a mold,per-part cost of a mold decreases significantly with increasing product quantities.Even if production quantities are tens of thousands or thousands,unit price is lower than with other means of processing little lots.

Situation 3: Special Part Material Performance Requirements

For special part material performance requirements scenarios,special injection molding can accommodate a large number of requirements.

Different injection molding materials have different characteristics, and suitable materials can be selected according to the usage environment and functional requirements of the parts.For example,in the automotive industry,for high friction and temperature components,individualized injection molding may select respective high-performance materials.

Situation 4: Quick Product Upgrades

When quick product upgrades have to be executed,ease of individualized injection molding provides full support.

Mold design and manufacturing can be adapted as the product is adapted,allowing for faster responsiveness to change and fewer R&D cycles than with other production-line redesign-based processing technologies.

When dealing with complex parts, mass production, and other situations, JS precision manufacturing is the ideal choice. Upload design files to the official website, and we will help you efficiently solve production problems, saving you time and effort.

JS Custom Injection Molding Services’ Benefits

As you are skilled at using custom injection molding,now we can explain JS Custom Injection Molding’s benefits that allow producing complex parts efficiently.

JS has abundant experience in custome injection molding and has made excellent injection molding solutions for customers from various industries for many years.Our technical team includes veteran engineers with unique skills in deep expertise and perfection of injection molding arts and are therefore best capable of solving all kinds of advanced technical problems.

JS possesses advanced injection molding machines and the corresponding auxiliary facilities.These machines are highly precise and stable and ensure exact size and uniform quality of injection-molded products.Furthermore,the high automation rate of the machines not only improves efficiency in production but also reduces the impact of human factors on quality.

JS also possesses a large-scale quality control system.From raw material procurement and inspection to every stage of the manufacturing process and final inspection on finished products,we have strict quality procedures and inspections.We test every batch of products rigorously to determine that they are up to customer specifications.

JS also offers easy online injection molding services.Through our site,customers can monitor order status,product quality,and more at any time,communicate with us in real-time,and solve problems timely.

JS’s strong functions guarantee your custom injection molding demands.Advanced equipment,experienced staff,and rigorous quality control guarantee a smooth production process.Select materials and processes on our official site and receive a quote in 24 hours.Come and experience it!

Dismantling Injection Molding Cost—Five Huge Budget-Sucking Black Holes

In order to achieve cost reductions through custom injection molding,first of all,you need to know about the dissection of injection molding costs.Here are five huge budget-devouring cost holes.

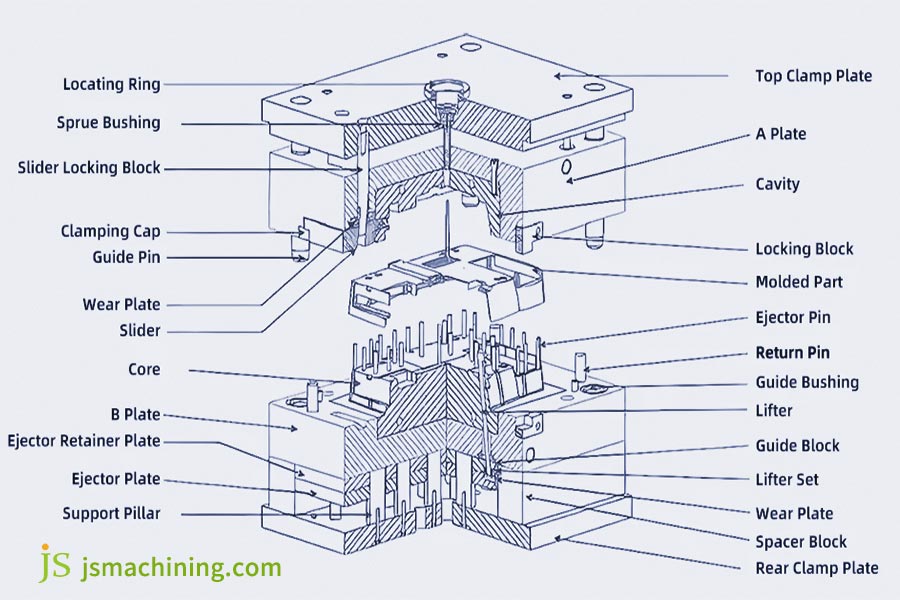

Factor 1: Mold Cost—A One-Time Charge

Molds are an integral part of custom injection molding manufacturing.Their cost is a substantial one-time charge based upon factors such as material,complexity,and size.The cost of different types of molds also varies extensively.

| Mold Type | Material | Level of Complexity |

| Simple Small Molds | Common Steel | Low |

| Complex Large Molds | High-Strength Alloy Steel | High |

The cost recovery of the mold has a very close relationship with production quantity.The more the amount of production,the lower the price of a mold per item.Therefore,when custom injection molding,it is important to select mold materials and designs based on projected volume of production,balancing mold expense against total product expense.

Factor 2: Material Cost—Weight Per Gram is Money

Material cost accounts for the largest share of the costs of injection molding,and the prices are highly variable based on material type,performance,and brand of injection molding materials.Common plastics like polypropylene(PP)and polyethylene(PE)are inexpensive,while high-performance engineering plastics like polycarbonate(PC)and polyamide(PA)are expensive.

Part weight is also a key concern in material cost.The heavier the component,the more material required,and the higher the cost.Accordingly,when designing a component,structurally optimize and keep it as light as possible to keep costs down while still meeting performance requirements.

| Material Type | Price Range(USD/kg) |

| Polypropylene(PP) | 1-2 |

| Polyethylene(PE) | 1.5-2.5 |

| Polycarbonate(PC) | 3.5-5.5 |

| Polyamide(PA) | 3-5 |

Factor 3: Cycle Time—Every Second Counts

Injection molding cycle time refers to the process time from start to finish of a product,from mold closing to injection.Its duration directly affects production efficiency and cost.

Long cycle time reduces production volume per unit time and increases cost.Mold cooling system design,process parameter adjustment,and material properties all impact cycle time.Refining the cooling system can accelerate cooling,while adjusting process parameters correctly can enhance efficiency and reduce cycle time.

For instance,decreasing the production cycle of a specific part from 30 seconds to 25 seconds boosts volume of production in the same time period,and decreases unit product cost.

Factor 4&5: Order Strategy and Design Details

Design details and order strategy are key drivers of injection mold costs.

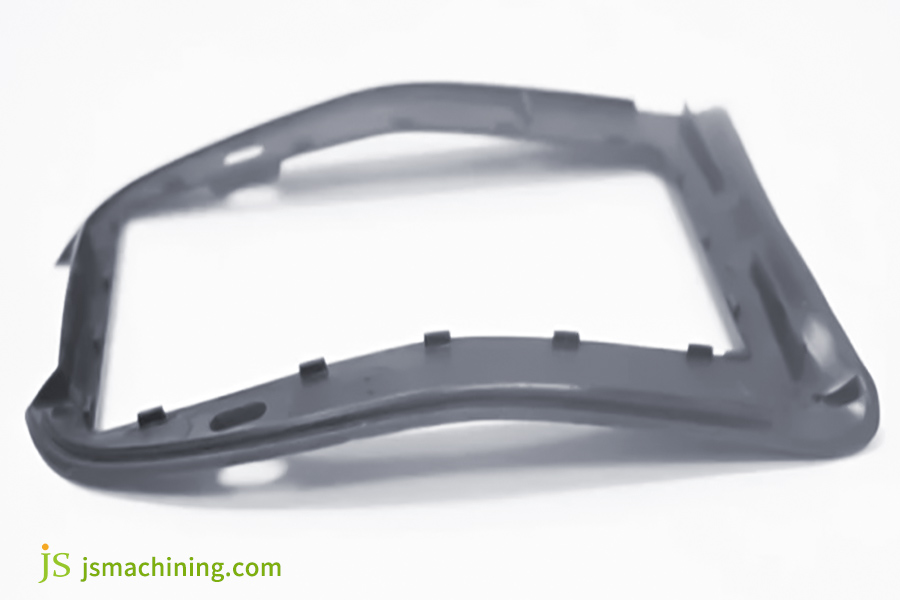

In terms of design details,improper structure part design complicates the mold and manufacturing process,increasing cost and time.For example,irregular wall thickness and sharp edges create product defects,which require numerous adjustments and repairs,incurring additional costs.

Therefore, when designing, it is necessary to consider the characteristics of the injection molding process and optimize the structure.

As far as order strategy is concerned,cost is influenced by lead time and order quantity.Order quantity that is too low inhibits economies of scale and induces unit cost to be high,an order quantity that is too high can result in inventory and block tie-up of capital.It’s too short a lead time that may necessitate hurried production,adding to costs.

Thus,there needs to be a proper order strategy that achieves the right balance between quantity and lead time.

Want to reduce injection molding cost black holes?JS can assist you in controlling them with accuracy.Send us your design files and we’ll take care of the cost optimization.Once your order is made,we’ll rush into production and allow you to get the most out of your investment.

3 Realistic Cost Reduction Tips

After having analyzed the cost structure associated with injection molding,gaining knowledge about some realistic cost reduction techniques can help firms save additional money while manufacturing custom injection molding.

Tip 1: Optimize Product Design

Optimizing product design is one of the successful ways so that the cost of injection molding is reduced.

In the process of design,simplification of part structure,e.g.,reducing a structure with numerous protrusions and grooves to a smooth transition,can reduce mold complexity,reduce mold processing steps and time,and thereby reduce mold costs.

Thickness of the wall must also be optimized.Asymmetrical wall thickness will easily create sink marks and bubbles in the thick areas,and inadequate areas may remain unfilled.This introduces debugging time and scrap rates into production.Maintaining wall thickness within a reasonable and stable range improves production stability and shortens production cycles.

Avoiding unnecessary features,such as decorative patterns that do not affect part functionality,can avoid machining of complex structures on the mold,reducing mold costs.

At the same time,rational design can also improve material utilization.For example,consolidating numerous small,discrete parts into a single integral part for injection molding not only reduces assembly steps and costs but also increases product stability.

In one instance,an electrical component,originally assembled from five small pieces,was consolidated into a single,integral injection-molded piece through design optimization,with a 40% savings in assembly cost and 25% savings in material usage.

Tip 2: The Right Material Selection

The right material selection is also important to save costs.In achieving product performance requirements,use cheaper materials when possible.An example of a daily usage part originally used more expensive ABS.Through testing,it was found that PP also met the required strength and temperature resistance.The redesign saved material cost by 30%.

Also,look at the moldability of the material and choose materials that are injection moldable to minimize scrap during production.Some of the materials lack good flowability,which may readily result in underfilling and surface defects when injection molding is done,leading to increased scrap rates.Materials that possess good flowability,however,fill the mold cavity more smoothly,minimizing scrap.

Costs can also be minimized through recycling of the material.For individuals with lower material performance levels,such as some of the injection molded packaging parts,recycled material may be used.However,the performance stability of the recycled material will have to be extensively tested and studied methodically before use to ensure that they won’t affect the product’s fundamental functionality.

Tip 3: Production Process Optimization

Production process optimization can improve production efficiency and reduce costs.With proper adjustment of injection molding machine settings,such as injection speed,holding pressure,and temperature,product quality and manufacturing efficiency can be improved,and cycle time minimized.

For example,by increasing injection speed for materials with good flowability,the filling time can be shortened,for materials with easy degradation,the melt temperature should be adjusted properly to prevent the deterioration of material properties.

On the other hand,maximizing productivity and reducing waste also go hand in hand.In order to reduce material waste,accurately calculate material required per shot to avoid unnecessary material slugs and flash.Crush any small amount of waste and reuse it in a legitimate ratio.

Reducing idle equipment can also be an effective method for saving money.Prioritizing the production schedules can prevent idle equipment.For instance,in the same injection molding machine,the production sequence of various products can be reasonably coordinated in terms of mold change times and production cycles to keep it running continuously.

Want to avoid the cost black hole of injection molding? JS helps you with precise control. Submit design documents, and we will optimize costs for you. After confirming the order, we will quickly produce and deliver, allowing your budget to be put into practice.

JS Overcomes Challenges In Injection Molding Of Complex Structural Parts

Injection molding of complex structural parts is filled with numerous challenges such as underfill,warpage,and bubbles.Based on the years of experience and technical know-how gained,JS has overcome the challenges to supply high-quality custom injection molding manufacturing services for complex structural parts to customers.

Challenge 1: Underfill

Underfill is a common challenge in injection molding of structural complex parts,primarily due to complicated mold structures and high melt flow resistance.

JS minimizes the gate design of the mold and runner layout to enhance melt flow and ensure sufficient filling of the mold cavity.Moreover,reasonably adjusting injection molding process parameters,such as increasing injection pressure and rate and melt temperature,can also effectively cure underfill.

Challenge 2: Warpage

Warpage can impact part dimensional accuracy and assembly performance.

JS simulates the part structure and material properties to predict potential warpage trends and executes appropriate mold design practices,e.g.,ribs reinforcement addition and wall thickness distribution optimization,to minimize warpage.Furthermore,control of the cooling rate and uniformity during production can effectively prevent warping.

Challenge 3: Air Bubbles

The air bubbles may compromise the strength of the part and sealability.

JS combats air bubble issues with focus on raw material drying and control of injection molding process parameters.Raw materials are dried thoroughly prior to manufacture to remove water.When injecting,injection speed,holding pressure,and time are carefully regulated to prevent air from becoming trapped in the melt,thus restricting air bubbles.

JS can easily overcome the limitation of injection molding complex structural parts.Choose us,and you never have to worry about quality.The order process is straightforward,and we’ll deliver quality parts on time.

Case Study: Minimizing Endoscope Handle Costs By 35%

Client Background:

A medical device manufacturer required eight stainless steel inserts with precise positioning,a medical tolerance of 0.05mm,and an objective unit price of less than $30 for an endoscope handle.The first proposal quoted $68,000 for the mold and $46.50 per unit.Apart from that,due to the lack of precision in insert positioning,the pilot production scrap rate was as high as 12%.

JS’s solution

- In mold design,JS adopted a modular insert structure instead of traditional discrete positioning,which controlled the positioning error of eight inserts to 0.02mm.Meanwhile,this also decreased the mold cavity complexity,bringing down the mold cost to $42,000.

- In regard to materials,CAE simulation analysis led to the utilization of altered PC in place of imported material.Although the medical-grade corrosion resistance was not sacrificed,the unit price reduced by 22% and the weight of the part decreased by 8%.

- In regard to the process of production,pressure holding curve and cooling water circuit optimization reduced the production cycle from 45 seconds to 38 seconds,increasing equipment utilization by 15%.

The ultimate result:

Mold expenses dropped by 38%,the unit cost dropped to $30.2,and the overall cost dropped by 35%.The pilot production scrap rate dropped to 1.5%,fully achieving medical-grade precision standards and fully demonstrating the cost advantage and quality control performance of custom injection molding in producing complex injection molding parts.

JS can save you a lot of money,as demonstrated in the example of the endoscope handle.From start to finish,we provide high-quality service from uploading your file to delivery,tailoring your solution to maximize money for value.

FAQs

Q1: What do I do if mold costs are too expensive?

Replacing steel molds with aluminum molds can significantly reduce costs by 60%. For example, the cost of using a steel mold for a certain product is $38000, but after switching to an aluminum mold, the cost is only $15000. Alternatively, reusing standard mold frames can save 40% of mold costs.

Q2: How to balance precision and cost when injecting complex parts?

Local high-precision machining can be combined with overall injection molding, and tolerances can be relaxed in non critical areas. At the same time, modular molds can be used to reduce complex structures and control costs while ensuring core accuracy.

Q3: Aluminum molds vs. steel molds: How to choose to avoid adverse effects?

Aluminum molds save 60% ($15,000) but have a lifespan of only 5,000 pieces. Steel molds cost 2.5 times more ($38,000) and have a lifespan of 500,000 pieces. Breakpoint: Use aluminum molds for orders under 3,000 pieces; steel molds are required for orders over 8,000 pieces.

Summary

Custom injection molding is an efficient, cost-effective, high-quality method for producing complex parts. Continuous advancements in custom injection molding technology are making the production of injection molded parts more efficient and cost-effective.

As a skilled custom injection molding factory,JS offers beneficial injection molding prices and warm customer services through online injection molding services.If you require custom design requirements for detailed parts,you may want to take a look at JS’s custom injection molding.We believe they have the potential to surprise you with cost reduction and guaranteed quality.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: How To Save 40% Of Injection Mold Costs? Comprehensive Cost Reduction Strategy - JUSHENG

Pingback: How Long Does It Take To Plastic Mold Injection? - JUSHENG