Injection molding is a widely used manufacturing process in the production of various plastic products. This process involves injecting molten material into a mold cavity, which then solidifies into the desired shape. However, one of the challenges in injection molding is product shrinkage, which can affect the quality and accuracy of the final product. In this article, we will explore the effect of injection molding temperature and speed on product shrinkage.

What is product shrinkage?

Product shrinkage is a phenomenon that occurs when the plastic material shrinks after it has been molded. This shrinkage can be due to several factors, such as the cooling rate, the material used, and the design of the product. Product shrinkage can result in dimensional variations, warpage, or even cracking of the product.

What is injection molding?

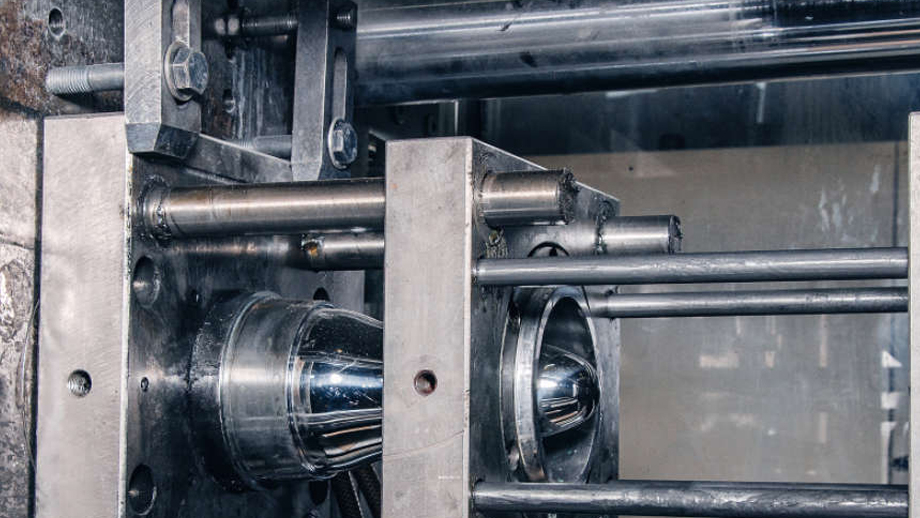

Injection molding is a manufacturing process that involves injecting molten material into a mold cavity. The molten material is then cooled and solidified into the desired shape. Injection molding is commonly used in the production of plastic products, such as toys, automotive parts, and medical devices.

Effect of temperature on product shrinkage

Temperature is one of the critical factors that affect product shrinkage in injection molding. The temperature of the molten material, mold, and cooling system can all influence the amount of shrinkage in the final product.

When the temperature is too high, the material will expand, resulting in larger part size. On the other hand, if the temperature is too low, the material will shrink, resulting in smaller part size. Therefore, it is essential to select the appropriate temperature range for the material being used and the product being produced.

Effect of Speed on product shrinkage

The speed at which the molten material is injected into the mold cavity can also affect product shrinkage. If the speed is too slow, the material may not fill the mold cavity completely, resulting in an incomplete part. On the other hand, if the speed is too fast, the material may not have enough time to cool and solidify, resulting in warpage or cracking of the part.

Therefore, it is crucial to select the appropriate injection speed for the material being used and the product being produced. The injection speed should be optimized to achieve complete filling of the mold cavity and minimize shrinkage.

How to reduce product shrinkage?

There are several ways to reduce product shrinkage in injection molding. One way is to optimize the injection molding process parameters, such as temperature and speed, to minimize shrinkage. Another way is to use materials with lower shrinkage rates, such as filled or reinforced plastics.

Additionally, the design of the product can also affect shrinkage. It is essential to design the product with uniform wall thickness and avoid sharp corners or angles, which can cause stress and lead to shrinkage.

Conclusion

Product shrinkage is a common problem in injection molding, but it can be minimized by optimizing the injection molding process parameters, using materials with lower shrinkage rates, and designing the product with uniform wall thickness. Temperature and speed are critical factors that affect product shrinkage, and it is crucial to select the appropriate range for the material being used and the product being produced. By understanding the effect of injection molding temperature and speed on product shrinkage, manufacturers can produce high-quality products that meet customer requirements.