Your phone case, your MacBook aluminum front, or your expensive drone’s ultralight body—they all possess the strength of aluminum alloy but are susceptible to a shiny bright, colorful, or finely matte finish. And this mysterious ‘coating’ is in fact anodizing.

But with an unlabeled piece of aluminum in front of you, how do you know whether it is raw aluminum or on purpose anodized? This isn’t always an issue of appearance, it directly impacts the wear resistance, corrosion resistance, and value of the part.

This hands-on guide by JS will introduce you to anodizing, familiarize you with five key identification methods, outline CNC machining and anodizing processes, and demonstrate emergency response actions through case studies in order to allow you to ascertain quite easily if aluminum is anodized.

Core Answer Summary

| Judgment Dimension | Core Method | Key Basis |

| Preliminary Quick Judgment | Vision + Touch | Anodized aluminum: uniform matte finish / smooth and dry texture. Ordinary aluminum: reflective / greasy texture. |

| Reliable Non-Destructive Test | Conductivity Test | Measure resistance with a multimeter. resistance > 10MΩ indicates probable anodization. |

| Wear Resistance Verification | Steel Needle Scratching (Slight Destruction) | Anodized aluminum: no obvious scratches. Ordinary aluminum: easy to leave scratches with debris. |

| Professional Accurate Identification | Water Drop Contact Angle Test | Contact angle 60°-90°: anodized aluminum. Contact angle < 30°: ordinary aluminum. |

JS’s Experience: Is JS Reliable In Judging Anodizing?

JS possesses more than 10 years of practical experience in establishing anodizing of aluminum and can present an authoritative benchmark to be used as a reference. We have serviced various industries including aerospace, home automation, automotive components, and medical devices, processing anodizing work on aluminum alloys like 6061, 7075, and 5052.

For example, we have processed hard anodizing (Type III) of 7075 aluminum alloy parts for aviation customers, ensuring that the oxide film thickness reaches 50-60 microns and the hardness is not less than HV550.We have also processed sulfuric acid anodizing (Type II) of 6061 aluminum alloy parts for smart home customers, and dyed the parts to present a variety of customized colors.

We also perform strict research on the synergic processes between CNC machining and anodizing and precondition the order of processing to prevent damage to oxide films or reduce accuracy.

This book is a distillation of expertise from thousands of projects, with proven identification procedures and process leading points, so it is an exhaustive reference to consult. JS Precision Manufacturing always provides surface treatment solutions with professional service. Please feel free to contact us if you have any queries.

JS offers reliable custom surface finishing manufacturing services. When you have requirements for generating surface finishing parts, contact us. We will serve you according to processes formalized in standards, thus your one-stop-shop.

Reimagining The Ideal ‘Coat’ Of Aluminum: Beyond Paint

According to JS experience, we will rethink the ‘coat’ of anodizing from ground zero and the basis that underlies it.

Basic Definition

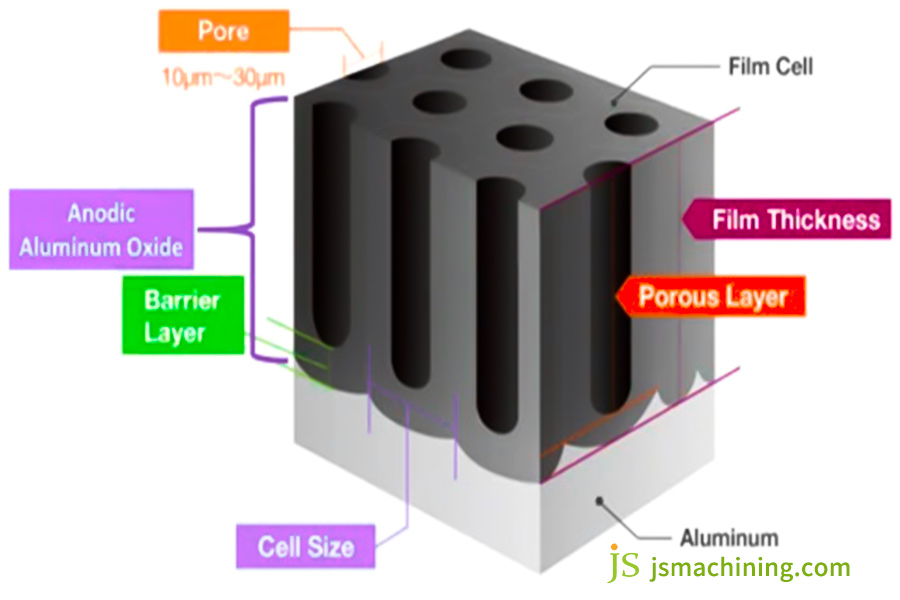

Anodizing is an electrolytic reaction, which forms a coat of oxide on the surface of the aluminum.

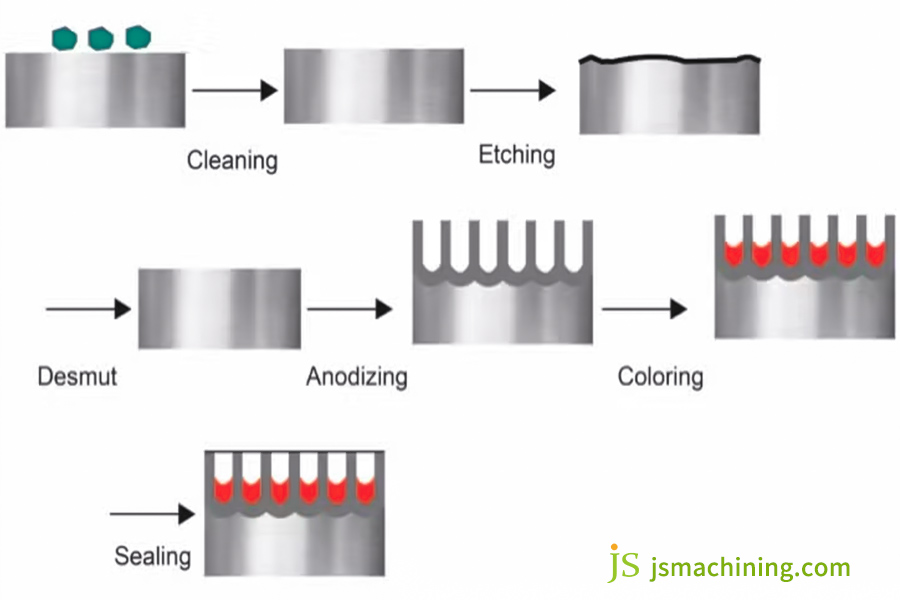

The anode is built from a piece of aluminum strip and is placed in a bath of electrolyte solution of sulfuric acid or chromic acid. Under the flow of direct current, there is a reaction of oxidation on the surface of the aluminum, and an oxide film predominantly made up of aluminum oxide is formed.

This is well bonded to the aluminum substrate and won’t peel easily, as can be said of a simple ‘paint layer.’

Core Value

This is a comparison of the contrast between common aluminum and anodized aluminum (using Type II as an example):

| Performance Indicator | Ordinary Aluminum | Anodized Aluminum (Type II) | Performance Improvement Range |

| Corrosion Resistance | Corrosion appears within 24 hours in salt spray test | No corrosion for over 500 hours in salt spray test | Over 20 times |

| Surface Hardness | Approximately HV100 | HV300-500 | 3-5 times |

| Appearance Versatility | Single color (mostly silver-white) | Dyeable (black, red, blue, etc.) | Multiple color options |

| Surface Adhesion | Paint coating easy to peel off | Anodized film firmly bonded to substrate | Stronger adhesion |

As is evident above, anodized aluminum excels over the ordinary aluminum in most of its features and is employed by smart home housings, automobile trims, and precise aviation components that all often employ anodized aluminum material.

If you require high surface finishing parts, then JS is your most appropriate choice. Once your consultation has been arranged, we shall personally update you regarding your requirements and start the process in order to ensure that your provided parts are as per your specifications.

Why Does The Process Determine The Appearance? Unveiling The Different Types Of Anodizing

Different anodizing methods produce films with different properties and appearances. There are three most widely used processes:

Chromic acid anodizing (Type I)

It uses chromic acid as the electrolyte, producing a film thickness of 2-5 microns of oxide film. It exhibits excellent substrate adhesion and does not affect aluminum’s mechanical properties and thus is best suited for fine aerospace components (e.g., aircraft structure details).

Its limitations include poor corrosion resistance, low hardness, and toxicity of chromic acid, resulting in high environmental disposal cost, which is $18-25 per square foot.

Sulfuric acid anodizing (Type II)

It is the most prevalent technique, using sulfuric acid as an electrolyte. Thickness of oxide film 5-20 microns. Economical cost (USD 10-15/square foot), dyeability, and fast process cycle (a batch may be processed in 24 hours) are its advantages. It’s suitable for indoor applications (e.g., smart home casing, consumer electronics enclosures).

Its disadvantage is that it is not quite as corrosion resistant in harsh conditions (high humidity and salt).

Hard anodizing (Type III)

Slightly referred to as thick film anodizing, the electrolyte is a blend of sulfuric acid. The oxide film’s thickness is 25-150 microns, hardness HV500-700, and more than 1000 hours of salt spray resistance. It is suitable for wear-resistant applications used in abrasive conditions.

Its drawbacks are long processing time (3-5 times that of sulfuric acid anodizing), high cost ($20-30/square foot), severe distortion of aluminum, and strict process parameter control necessitated.

The Differences Between the Three Anodizing Methods

| Anodizing Type | Anodized Film Thickness (μm) | Surface Hardness (HV) | Price per Square Foot (USD) | Key Advantages | Key Disadvantages | Applicable Fields |

| Chromic Acid Anodizing (Type I) | 2-5 | 150-250 | 18-25 | Strong bonding force, no impact on mechanical properties | Weak corrosion resistance, high environmental protection cost | Aerospace precision parts |

| Sulfuric Acid Anodizing (Type II) | 5-20 | 300-500 | 10-15 | Low cost, dyeable, short processing cycle | Weak corrosion resistance in extreme environments | Smart home, consumer electronics casings |

| Hard Anodizing (Type III) | 25-150 | 500-700 | 20-30 | High hardness, excellent corrosion resistance | Long processing time, high cost, large aluminum deformation | Automotive pistons, industrial machinery guide rails |

Different anodizing processes possess different fields of application. JS will guide you to the right solution and quote clear surface finishing prices. Call us and we will tailor a package that meets your requirements. The buying process is clear-cut, which is reassuring.

Five Easy Identification Methods: Novice To Mastery

After the fundamentals have been grasped, the determining factor is whether aluminum has been anodized. The following five techniques describe different scenarios.

Method 1: Initial Visual and Tactile Check (Most Basic)

Critical Points of Decision

- Visual: Anodized aluminum appears matte/semi-matte, has uniform color, and no intense glare. Painted aluminum and bare aluminum are very shiny, with painted aluminum possibly having paint bleed marks.

- Touch: Anodized aluminum material is dry and smooth. Ordinary aluminum may have a greasy feel, while spray painted aluminum may be too slippery or slightly sticky.

Note: Very good paint can look almost exactly like anodizing. This is only a rough guess.

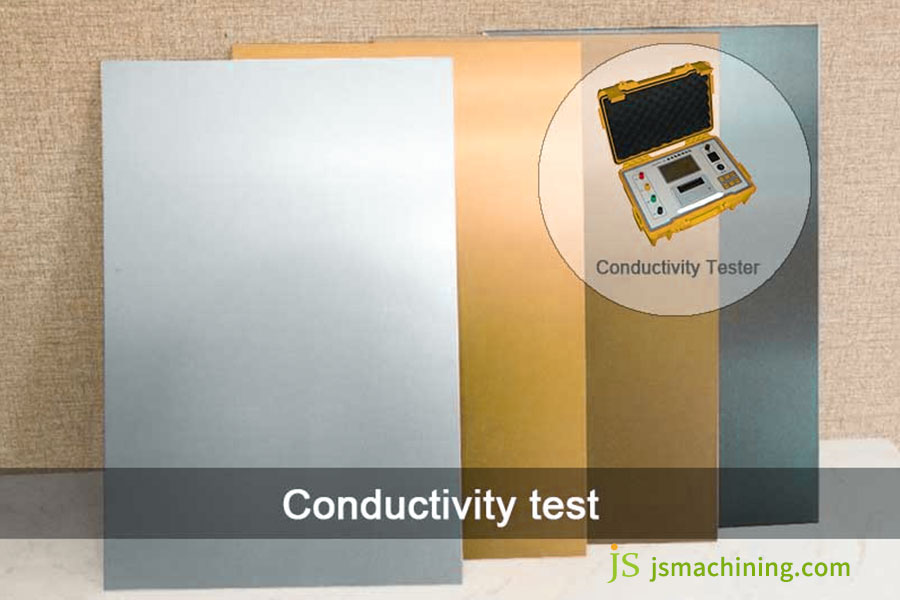

Method 2: Conductivity test (Most accurate non-destructive test)

Test Principle: Anodic oxide film (aluminum oxide) is a resistor, while aluminum is a conductor. The presence or lack of an oxide film is verified by the resistance value.

Steps:

- Set the multimeter to the 200MΩ position.

- Use the surface (potential oxide film) and interior/unprocessed area (no oxide film) of the component as test points.

- Place the test leads on the test points and record the resistance reading. Over 10MΩ indicates anodization,around 0Ω indicates plain aluminum or a simple surface treatment.

Method 3: Water Drop Contact Angle Test (Sophisticated, Specialized, but Interesting)

Test Principle: Anodized finishes are water-repelling, but plain aluminum is water-attracting. Contact angles are used to distinguish them.

Steps:

- Place part on instrument surface, flat and clean.

- Add 5 μL of distilled water and measure contact angle.

- Interpretation of result: A contact angle of 60°-90° is an oxide film,<30° is normal aluminum.

Relevant Scenario: Can be utilized in a lab environment. If there is no equipment, you can outsource a professional testing agency through online surface finishing services.

Method 4: Abrasion Resistance and Hardness Test (Relatively Destructive)

Test Principle: Use the high hardness of the anodic oxide film and test the hardness by scratching it.

Steps:

- Take a steel needle with a minimum HRC of 55 and a weight of 500g.

- Set the weight on the steel needle and slowly scratch the surface of the aluminum.

- Check for results: If there are no scratches, then it is likely anodized aluminum material. If there are metal debris scratches, then it is likely painted aluminum or bare aluminum.

Method 5: Chemical Dye Test (Destructive Test, Last Resort)

Test Principle:The porosity of the anodic oxide film allows it to adsorb dyes, a structure which does not take place in bare aluminum.

Steps:

- Prepare an acid dye (e.g. Congo red) and water.

- Stain a 1 cm² test spot on a cotton swab and allow to remain for 5-10 minutes.

- Wash and inspect:If stained, there is an oxide film.If unstained, there is none.

Precautions:Oxidation tests permanently stain and only to be performed when other tests are negative and some damage acceptable.

Even if you master these identification methods, if you still have difficulty making judgments, you can choose JS’s online surface finishing services. We will respond efficiently, provide accurate identification results according to the process, and offer professional services to ensure you have no worries.

Collaborative Creation: The Enigma Of The CNC Machining And Anodizing Sequence

In the aluminium part production process, CNC machining and anodizing sequence determines part quality. What is to be discussed below explains the optimal sequence and further processing options after anodizing.

Machining Firstly, Oxidising Secondly: The Golden Production Rule

Core Reasons

- Anodised film hardness reaches a maximum of HV300-700. Pre-oxidising and then machining causes a wear on CNC tools (initial cost $50-100 per tool), which increases production costs and reduces accuracy from ±0.05mm to ±0.1mm.

- Oxidation post-machining will scratch the coating and expose unoxidised aluminium below, reducing corrosion resistance.

- Machining after permits deburring before oxidation, which allows the coating to coat smoothly.

Post-Anodizing Secondary Processing: A Limited Supplemental Option

Process Types

- Light Grinding/Polishing: Removes superficial scratches without removing the oxide coating.

- Drilling Holes > 5mm: Avoids exposing too much of the inner aluminum.

- Laser Engraving: Only engaged with the surface of the oxide coating.

Key Considerations

- The depth of machining should be less than the thickness of the oxide film, or exposed unoxidized aluminum will be left behind.

- Machining speed should be low to avoid the high heat stripping off the oxide coating.

JS has matured solutions for synergism of anodizing and CNC machining and can provide custom surface finishing manufacturing service. In case of part machining needs, please contact us.

From Suspicion To Conclusion: A Quality Inspection Dispute Over Aviation-Grade Components

Client Background

Smart home team one of the teams was designing the second-generation smart door lock. They were anodizing the 6061 aluminum alloy case with sulfuric acid. A week before shipping, the original case cracked at the edges when it was struck by 5N during testing.

The team redesigned under time pressure and added reinforcement. They needed to deliver 10 pieces within three days (CNC tolerance ±0.05mm). It would affect cash, and there was no one else available to catch up with orders but JS.

JS’s Emergency Solution

- Quick Response and Quote

The customer uploaded a new design file at 10:00 PM on the same evening, and the system automatically generated a quote within 10 minutes. The shipping took three days, and the customer confirmed the order within 15 minutes.

- Production and Inventory Integration

The system indicated that they had 100 pieces of 5mm thickness 6061 aluminum alloy plates in stock, and since they were going to have a night shift that night, the warehouse sent the 10 plates to the CNC shop at 10:30 AM without going through the purchase order.

- DFM Optimization and Progress Monitoring

Within 30 minutes, the engineer concluded that 0.5mm corner radius of reinforcement rib is prone to cracking and proposed that it should be raised to 1.5mm. The customer accepted this within 15 minutes. Upon ordering, the customer received a production schedule and, a day after that, pictures of processed parts and oxidized ones, making possible work progress monitoring in real time.

Customer’s Successful Project Achievements

Day three, 12:00 PM, 10 housings arrived via express mail and were delivered to the customer one day earlier than launch. It demonstrated a 40% increase in structural strength, no crack under 5N impact, even color of even oxide coating, and dimension tolerances within specifications.

The press conference was a complete success, and the team received $5 million in financing. Subsequently, a long-term cooperation agreement was signed with JS to provide customized anodizing and laser engraving services, while ensuring a stable surface finishing price.

When You’re Not Sure, JS Is The Expert Solution

If you have difficult cases and can’t use your own judgment, call JS, a professional services corporation.JS has the following core services:

Free Initial Inspection

Inspection report (film thickness, hardness, integrity) is received within 24 hours of shipping the parts.

Special Surface Treatment

Our engineers develop the process to product specifications (application, performance, and aesthetics). For example, we use clean and green electrolytes for medical parts and recommend hard anodizing for products exposed outdoors.

Rapid Turnaround Time

Design optimization, CNC machining, and anodizing are completed within 3 days, with transparent quotes and no surprises.

FAQs

Q1: Sandblasted aluminum and anodized aluminum are extremely similar. How would I be able to differentiate between them?

Sandblasting also gives a matte finish on its own. It may or may not be oxidized. Two main methods to distinguish between them are color and conductivity:

- Uncoated sandblasted aluminum is silvery white and conductive to the naked eye, and this can be verified by using a multimeter.

- Oxide can be any color after sandblasting and is a poorer conductor, so the two properties can be distinguished very easily.

Q2: Is the anodized aluminum surface color even?

Anodized aluminum has a delicate and uniform color on the exterior. In regular light, it is normally with a glossy or matt sheen like most metals. Spray-coating or electroplated appearances, however, have a more shiny appearance and are prone to localized color change. The two significantly vary in terms of evenness of color and texture.

Q3: What do I say when anodizing aluminium parts with JS?

When you place an order for anodizing aluminum components with JS, you need to specify the alloy model of aluminum (e.g., 6061, 7075), desired color to be attained (Pantone color code or actual sample), film thickness to be attained (e.g., MIL-A-8625 Type III, 50μm), and whether sealing is required. This will enable JS to prepare a process plan accurately.

Q4: Will anodized aluminum stain?

Good color results from dye molecule entrapment in the oxide film micropores. Under use conditions, e.g., in interior furniture and electronic component covers, the color will not readily fade. Rough polishing, or prolonged contact with severe acids or alkalis, can, however, ruin the structure of the oxide film, producing a surface coloration.

Summary

It is most critical to become skilled at identifying anodized products in product quality, supply line control, and making product configuration choices. It’s more than cosmetic and tactile, it’s field work that includes observation with some testing and good judgment.

If you need services for anodized aluminum materials or custom surface finishing manufacturing, JS is your best option. Once you call upon us, we will carefully listen to your needs and guarantee meticulous service from start to finish so that your project is finished smoothly and your products are sure to be of premium quality.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Is FDM Printing Better Than MJF? - JUSHENG