At the time of design and casting grade selection, we often wonder, “What grade of steel do I need to use?” With the common perception that the higher the grade number, the stronger the casting. But the truth is far from simple.

Many companies are perplexed in choosing the right grade of steel in the manufacturing of metal casting parts and are baffled by the very individual influence of different grades of steel on the strength of the casting.

This article will take you deep into the extent to which steel grade actually influences casting strength, dismissing material specifications and numbering systems. It will also use a real-world case study to show how leading-edge casting technology can maximize the performance of the “right” steel, so that you can make the right decisions in custom metal casting manufacturing.

Core Answer Summary

| Core Dimension | Key Information | Impact on Casting Strength |

| Nature of steel grade | It is not a performance index, but a standardized specification for chemical composition and a small number of mechanical properties. | It only provides the lower limit of basic performance and does not directly determine the final strength. |

| Key factor determining strength | It depends on smelting, casting, and heat treatment processes, rather than the selection of a single grade. | If the process is not in place, even high-grade steel cannot reach the expected strength. |

| Logic for grade selection | Prioritize working conditions and performance requirements first, then match the steel grade, and consider the process and cost. | Only by adapting to the scenario and process can the strength value be maximized. |

| Common misunderstanding | A higher grade number does not mean higher strength, some high-grade steels focus on toughness and corrosion resistance. | Choosing a grade that focuses on non-strength properties by mistake will affect the use of castings. |

How To Select Steel For Important Castings? JS’s Choice Criteria

JS has over 15 years of real experience in metal casting business, producing castings for many industries, including energy equipment, heavy machinery, and auto components.

For example, we’ve produced wheel hub castings with diameters greater than three meters for a world-renowned wind power company, and mass-produced transmission housing castings for an automobile manufacturer. We’ve produced over 5,000 different types of metal casting parts, with consistent product qualification rate of above 99.5%.

We’ve also worked on numerous challenging custom metal casting manufacturing jobs, such as a high-heat engine component casting for an aerospace company, and overcome successfully the issue of high-temperature material strength loss.

This guidebook is the condensed result of our experience, and we’ve tested all our recommendations in real-world projects. You can be assured that it will prove to be a reliable guide for selecting steel for your castings.

When choosing steel for important castings, JS leverages its long history to accurately meet your requirements. Do you need custom metal casting manufacturing? Contact us today and we’ll give you a professional answer so that your project runs smoothly.

Decoding The Steel Grade Number: What Does The Steel Grade Really Mean?

In order to understand how to select steel, we first need to clarify what is steel material and what steel grades are all about. Most individuals wrongly believe that steel grade is a measure of performance in direct proportions, e.g., higher grades equal more strength. This isn’t the case.

Steel grade is not a performance measure, but a specified chemical composition standard and restricted range of mechanical properties. It specifies the chemical content range of elements like carbon, manganese, chromium, and nickel in the steel, as well as minimum levels for a restricted range of mechanical properties like yield strength and tensile strength. But it does not necessarily follow that the steel grade will only need to comply with these minimums.

For example, ASTM A27 Gr. 60-30 specifies a carbon level of 0.30% to 0.40%, tensile strength of not less than 414 MPa, and yield strength of not less than 207 MPa. However, with optimized melting and heat treatment procedures in actual production, this grade can deliver a tensile strength of over 450 MPa. Understanding this can help you view the relationship between steel grade and casting strength more rationally, and also provide a clearer answer to the fundamental question of what is steel material.

Global Steel Numbering Systems: The Secrets Of ASTM, AISI/SAE, And DIN

There are numerous steel numbering systems in different countries and regions that puzzle companies while selecting steel. In the following, we will introduce the three most widely used steel numbering systems: ASTM, AISI/SAE, and DIN, to explain the underlying concepts clearly.

| Numbering System | Developing Organization | Characteristics of Numbering Rules | Common Application Fields |

| ASTM | American Society for Testing and Materials | It consists of letters and numbers. Letters represent material categories, and numbers represent standard serial numbers and grades. For example, in ASTM A27, “A” represents ferrous metals, “27” is the standard serial number, and “Gr. 60-30” after it represents the grade. | Construction, machinery manufacturing, energy equipment, etc. |

| AISI/SAE | American Iron and Steel Institute / Society of Automotive Engineers | It is mainly represented by four digits. The first two digits represent the steel category, and the last two digits represent the carbon content. For example, for 1020 steel, “10” represents carbon steel, and “20” represents a carbon content of approximately 0.20%. | Auto parts, mechanical parts, etc. |

| DIN | Deutsches Institut für Normung (German Institute for Standardization) | It consists of numbers and letters with a relatively complex structure, and it reflects the chemical composition and performance of materials in detail. For example, in DIN 1.0503, “1” represents ferrous metals, and “0503” represents the specific steel type. | Precision machinery, aerospace, medical equipment, etc. |

Understanding the rules of these numbering systems can make it easier for you to select suitable steel materials globally and avoid selecting the wrong steel due to numbering misunderstandings.

JS is familiar with the global mainstream steel numbering system and can help you accurately match the required steel materials.In case you are interested in purchasing steel or require metal casting services, kindly contact us to simplify your procurement and production.

Popular Misconception: Does Higher-Grade Steel Mean It Is Stronger?

In the process of custom metal casting manufacturing, many people fall into a misconception: stronger steel necessarily means higher strength. This is not true.

Misconception

The higher the grade number, the higher the strength. Sometimes the higher grade indicates higher toughness or corrosion resistance but not strength. For example, ASTM A352 LCB low-temperature carbon steel has a higher grade than some of the regular carbon steels, but its advantage is its low-temperature toughness and not its higher room-temperature strength.

Key Point

Strength is built and not selected. Even if the best quality steel materials are selected, unless the melting, casting, and heat treatment processes are properly carried out, the casting will never reach the anticipated high strength. But by process optimization, some medium-quality steels can produce castings with reasonable strength.

So, when selecting the steel grade, consider not only the grade number, but also the actual performance requirements and process capabilities to produce metal casting parts that meet the requirements.

JS is aware that strength relies on craftsmanship. In custom metal casting manufacturing, we use innovative techniques to harness the power of steel. When you choose our service, your castings meet your requirements for strength and do not require you to blindly look for high-grade steel.

Casting Considerations: How Does Steel Grade Affect Casting Grade?

Steel grade is the essence of casting production and directly influences casting grade. However, most people confuse steel grade with casting grade, but the two show fascinating differences.

“Casting grade” is the end product grade, and it specifies various performance requirements of the casting in the final state, for example, strength, toughness, and corrosion resistance. These indicators will be set according to specific application scenarios and requirements.Steel grade, on the other hand, is the raw material designation and is the foundation on which the required casting grade is achieved.

During the casting process, the following two factors should be considered:

Castability Factors: Carbon equivalence (CE) is a significant parameter to apply while establishing steel castability. If the carbon equivalence is too high, the steel would be susceptible to casting defects such as cracks. When the carbon equivalence is too low, the fluidity of the steel decreases and, hence, the quality of the casting will be affected. All steel grades have different carbon equivalent limits, and therefore, in selecting a steel grade, its castability has to be taken into account entirely.

Control of Defects: Different grades of steel possess differing types and possibilities of defects while being cast. For example, high-alloy steel with its intricate microstructure is more prone to inclusions and shrinkage cavities while being cast and therefore requires stricter process control practices.

JS controls castability and defects based on the steel grade’s properties to ensure the quality of castings. If you need high-quality metal casting parts, choose us and we will utilize our professional technology to provide qualified castings for you.

Laboratory To Practice: Typical Use Cases For High-Quality Steel

Understanding the application conditions of high-grade steel will allow you to more effectively select steel grades in real engineering applications. Below is the introduction to typical application conditions for high-grade steel based on a design selection pyramid.

Design Selection Pyramid

Operating Environment (Highest Priority): Normal temperature, low temperature, high temperature, wear, or corrosion? The operating environment is the first priority in the selection of steel grade, and the performance requirement for various operating environments is very different.

Performance Requirements: Is yield strength, impact toughness, or fatigue life the most significant factor? Having defined the operating conditions, determine the critical performance requirements of the casting, which will have a direct bearing on choosing the grade of steel.

Process and Cost: In satisfying the operating environment and performance requirements, balance the complexity and cost of the casting process for the selected steel grade. Some high-grade steels have complex casting processes and are very expensive, so you have to weigh the benefits of using them.

Typical Application Examples

| Steel Grade | Application Scenario | Performance Advantages |

| ASTM A27 Gr. 60-30 (GS-45) | General carbon steel castings, used for structural parts with low strength requirements such as machine bases and door hinges. | It has low cost and good castability, and can meet the strength requirements of general structural parts. |

| ASTM A148 Gr. 80-50 (GX-5CrNi13-4) | High-strength low-alloy steel, used for gears and turbine casings. | It has high strength and good toughness, and can bear large loads. |

| ASTM A352 LCB/LC1/LC2 | Low-temperature carbon steel, used for energy equipment at -46°C to -101°C. | It has good toughness at low temperatures and is not prone to brittle fracture. |

| ASTM A217 WC6/WC9 | Chromium-molybdenum alloy steel, used for high-temperature and high-pressure valves and pump casings. | It has good high-temperature resistance and maintains high strength and stability in high-temperature and high-pressure environments. |

Different grades of steel materials are utilized for different applications. Only by properly matching the grade of steel to such applications can the performance advantages of the steel be maximized while, concurrently, maintaining metal casting price in control.

JS is familiar with different high-grade steels’ application conditions and can recommend suitable steel materials which maximize performance and metal casting price. Talk over your project requirements with us and we will provide you with an economical solution.

Case Study: JS Casts Alloy Steel Cylinder BlocKS FOR heavy-Duty Gas Turbines

Background

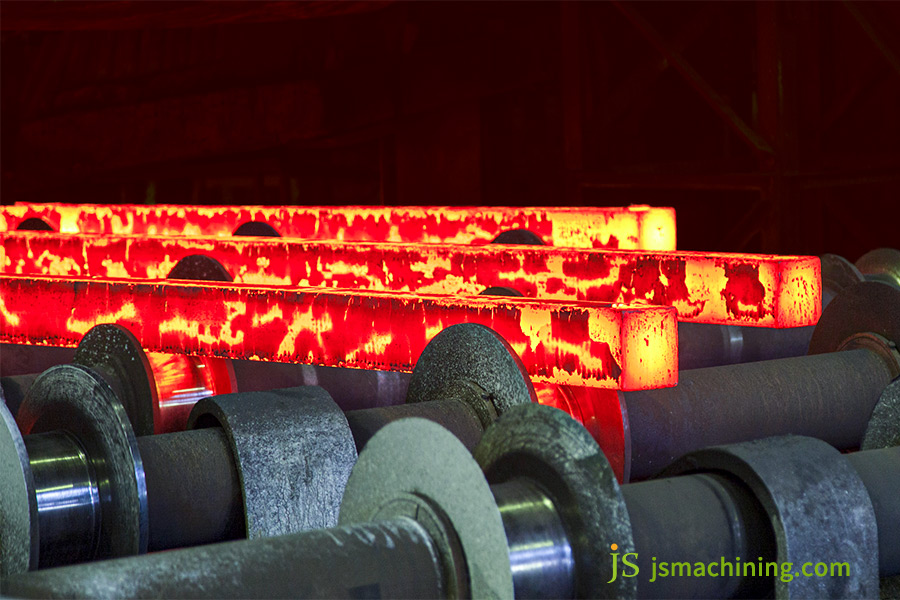

The outer cylinder block of a heavy-duty gas turbine is enormous (tens of tons in weight) and multi-layered in structure. It must operate stably and longevously at high temperatures (>500°C) and pressures. As one of the most significant components of the gas turbine, the stability and strength of the cylinder block are directly correlated with the general operational safety and efficiency of the gas turbine and thus have extremely strict demands for the quality of metal casting parts.

Challenges

- Material Selection: Cr-Mo-V alloy steel with extremely high high-temperature creep strength (e.g., ASTM A217 WC9) is required. This steel material is expensive to procure and difficult to cast.

- Casting Challenges: The low fluidity of the material makes under-pouring and cold shuts difficult to create, so it is difficult to ensure casting quality. Internal porosity and inclusions also have to be managed.

- Requirements of Performance: Apart from strength at room temperature, there also needs to be high-temperature endurance strength and creep resistance,otherwise, cracking and deformation are going to result.

JS Solutions and Technologies Used

- Design and Simulation: Computer solidification simulation and investment casting or resin sand molds are used to prevent defects and optimize the process. The pouring and riser are adjusted to create symmetrical solidification of the casting and minimize defects.

- Melting and Pouring: Purifying and refining the molten steel is achieved in an electric arc furnace. Temperature and pouring rate are well controlled to ensure smooth mold filling and avoid molding defects.

- Heat Treatment: Multi-stage heat treatment (such as normalizing followed by multiple tempering) is carried out in order to strengthen the microstructure, increase the high-temperature endurance strength as well as the creep resistance, and meet the requirements of the cylinder body.

Final Result

With the application of a combination of precise process controls, we succeeded in manufacturing the heavy-duty gas turbine alloy steel cylinder block to the required specification. Testing confirmed that the cylinder block recorded a room-temperature tensile strength of over 650 MPa. Its endurance limit at 500°C was in line with the design requirements, and the casting contained no significant internal defects, meeting the quality requirements of the customer to the letter.

The above example illustrates that good-quality materials require advanced casting and heat treatment technologies. Simple specification of a high-grade grade without considering the production process will be unable to provide the intended “high-strength” performance.

How Do I Choose The Right Steel Grade For My Project?

In choosing the best steel grade for a project, there is a need to apply a scientific process in order to select the steel grade that satisfies project needs but contains the costs. Certain guidelines and steps are presented below:

1.Define service conditions: First, determine the service conditions of the casting, e.g., load type (impact/dynamic/static), temperature, and environment (wear/corrosion). For example, castings subject to dynamic loads and castings subject to static loads require varying toughness levels for steel,castings that face corrosive environments require a corrosion-resistant grade of steel.

2.Grade second, performance first: Determine first the necessary mechanical properties (σb, σs, δ, AKV, etc.), then reverse engineer to establish the grade and process combination that meets these properties. Don’t choose the steel grade first and then verify its performance. This is too rapid a step and can quite readily create a steel grade not acceptable to the project or result in a cost penalty.

3.Cooperate with JS: Involve JS casting experts in the design process. Process capabilities determine what steel grades can be economically and in high quality produced. Our experts will recommend appropriate steel grades based on your project’s performance requirement and process capabilities, and provide optimized casting process solutions that will allow you to save money and preserve quality.

4.Determine the total cost: The cost of more costly materials, the cost of tighter process control, and potential scrap rates all have to be incorporated into the total cost. For example, some high-grade steels cost more to procure, and the complicated cast process also involves more scrap rates, which can increase overall costs. Therefore, while selecting a steel grade, material cost, process cost, and scrap rates must be considered as a whole to select the one that reduces overall cost.

FAQs

Q1: Are cast and forged steel grades of same grade similar in properties?

No. Since the forgings microstructure generally would be denser, less anisotropic in the forging process, forgings would have somewhat higher strength and better toughness compared to castings with the same chemical composition. Furthermore, relevant standards distinguish various performance requirements for steel castings and forgings.The two’s requirements will not be confused, neither can their performance in actual application simply be assumed to be equal.

Q2: Which grade is more stable at elevated temperatures?

When exposed to hot temperature conditions, molybdenum and vanadium alloy steels (such as P91) exhibit superior creep resistance, thus making the steel grades more stable at hot temperatures. Molybdenum and vanadium improve the high-temperature strength and creep resistance of steel, making it more resistant to deformation under long hot temperature conditions and more able to maintain its properties, meeting high-temperature operating conditions specifications.

Q3: Can the properties of high-carbon steel be achieved by heat treatment from a low-carbon steel casting?

No. Because heat treatment merely alters within the range set by the chemical content of the material, while the carbon content difference between low carbon steel and high carbon steel is significant, which is a hard limitation.You can’t heat treat 1020 steel (low carbon steel) to its equivalent strength of 4140 steel (high carbon steel). Why? 1020 steel has less carbon, and its inherent performance capability is below that of 4140 steel, so heat treatment can’t close this compositional gap.

Q4: Where can I get complete performance data for various cast steel grades?

The most trustworthy sources are the original standards which have been published by standardization organizations such as ASTM and DIN. These standards give the chemical composition, mechanical properties, and other complete performance data for various cast steel grades. Apart from these, certain large steel manufacturers and first-grade foundries also publish comprehensive material data sheets (MDSs)and you can also obtain complete performance data of cast steel grades from these channels.

Summary

Steel grade does not determine casting strength by itself, it is rather a “blueprint” for casting strength. Actual casting strength relies on the best balance of steel grade and casting process. During actual production, do not blindly chase high-grade steel. Rather, consider the conditions of working, performance requirements, and process capacity to select an appropriate steel grade, and release the performance potential of the steel fully with advanced craftsmanship.

JS has extensive experience and professional knowledge in metal casting, providing one-stop online metal casting services from steel grade selection to castings production. We can help you produce metal casting parts with capable strength and high cost-effectiveness. If you share the same requirements, please feel free to contact us.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: The Composition Of Brass Material:Why It's Not 100% Copper - JUSHENG