A startup owner cringes at a pricey mold estimate, but a savvy product manager gets the ideal prototype sooner and at a lower price. Their difference lies not in the budget, but in whether they have mastered the cost code of injection mold.

This guide starts with injection mold cost know-how and continues to address design for manufacturing (DFM), three underrated cost drivers, an end-to-end purchasing and manufacturing approach, and nurturing long-term vendor relationships in a bid to achieve true cost savings on your behalf.

Summary Of Core Answers

| Cost-Saving Aspect | Conventional Approach | Optimized Strategy | Potential Savings |

| Design | Intricate design with numerous parts, neglecting mold craftsmanship. | DFM (Design for Manufacturing), part consolidation, and slider/lift mechanism simplification. | 15% – 25% |

| Mold Structure | Use all-hard mold steel and a one-piece mold. | Mold Inserts,adopting a combination of soft and hard inlay structure. | 10% – 20% |

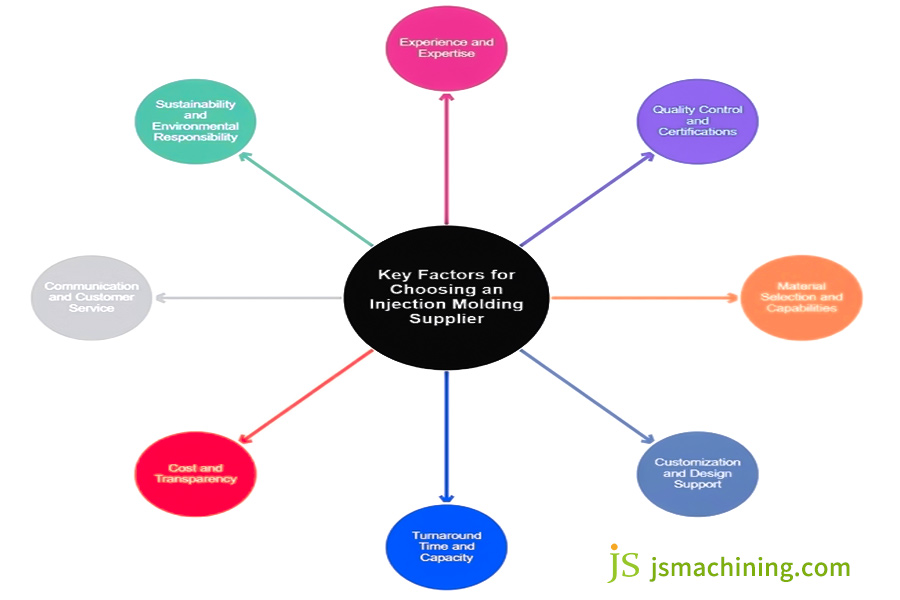

| Supplier | Blindly pursuing the lowest bid. | Search for specialized mold factories in specific fields and evaluate their overall solution capabilities. | 5% – 10% |

| Project Management | Poor communication and repeated revisions. | Provide clear and frozen 3D files at once to reduce later changes. | 5% – 15% |

| Volume Strategy | Regardless of the quantity, all molds must be made. | Small batch use of soft steel/aluminum mold+3D printing with shape cooling, and large-scale upgrade. | 20% – 40% |

Why Trust This Guide From JS?

While others are struggling with the problem of ‘how to reduce costs,’ JS has already helped customers in a succession of fields including electronics, smart home, and medicine in overcoming cost challenges with over 1,000 cases of injection molds. It is not bragging but based on our solid foundation.

From machinery to technology, we are equipped with five-axis machining centers and SLM 3D printing equipment, which enable high-precision machining of complex molds and conformal cooling technology application for 3D printing. Our engineers have an average of over eight years of experience in one-off injection molding production. They previously optimized a ‘4-in-1’ part design for a smart home customer and eliminated two undercuts and saved 40% in mold cost right away.

All of the strategy and statistics we’ve developed here are from our own experience and solutions in real service. It’s not school research, it’s live, practical cost-cutting advice—and that’s why you can trust it.

JS has over 1,000 actual injection molding real-world examples to draw upon, and our engineers average over eight years of success and experience. Just let us know your requirements and receive a quick quote for custom injection molding production services from professionals. Savings are assured with JS.

Understanding Injection Mold Costs

To reduce the cost, for the first time, mold cost drivers and structure standardize. It is the source of future cost savings.

Injection Mold Cost Structure and Cost Ratios

The various elements of injection mold have different costs by a large margin with major component costs in between. The actual ratio is presented below in the table that follows:

| Mold Components | Cost Proportion | Description |

| Mold Frame | 20%-30% | Common frame, made of ordinary steel, easy to process and moderately expensive. |

| Cavity and Core | 30%-40% | Determine the shape and size of injection molding parts, high-precision machining and high-quality mold steel are required, and the price is the most expensive. |

| Guiding and Positioning System | 5%-10% | Ensures accurate opening and closing of the mold, high machining precision but low structure and cost. |

| Gating System | 5%-10% | Transports molten plastic, with fewer components, simple processing, and low cost proportion. |

| Ejector System | 5%-10% | Ejects the molded product, with low production costs. |

| Cooling System | 5%-10% | Speeds up cooling, with controlled processing costs. |

Major Cost Influencers

- Size and Complexity: Both are significant determinants of the cost. The larger size and complexity (e.g., undercuts) contribute to the processing cost, even doubling it.

- Steel Selection: Highly influential. Pre-hardened steel ($10-15/kg, suitable for less than 100,000 pieces) and quenched and tempered steel ($20-25/kg, suitable for runs over 500,000 pieces or for corrosive plastics).

- Lifecycle and Production Volume: Moderately influential.Match mold lifecycle based on production volume. For large production volumes, choose long-life molds (lower unit cost),for small production volumes, choose short-life molds (lower total cost).

- Surface Treatment: Moderately influential. Mirror polishing increases cost by 20%-30%, and texturing by 15%-25%.

Baffled by what goes into injection mold price? JS can simplify it for you. Send us your product specs, and we’ll itemize costs, recommend materials, and help you get your project off to a smooth start. JS’s transparent, cost-reducing solutions are dependable.

Winning By The Drawing: How DFM Becomes The Most Powerful Cost-Saving Tool?

By solving manufacturing feasibility and economics at the design phase, DFM reduces costs from the earliest time and prevents rework and waste in the future.

The Basic Logic of DFM in Reducing Costs

The goal of DFM is ‘to prevent manufacturing issues early in the design process‘. Inappropriate designs may necessitate rework, re-cutting of mold, or even redesign, which consume time and financial cost. Through DFM, manufacturing engineers and designers communicate proactively and incorporate optimization techniques for injection mold processes, equipment, and material properties to simplify manufacturing and reduce difficulty while maintaining functionality.

Cost-Saving Applications of DFM in Specific Design Steps

Step 1: Product Wall Thickness Optimizing

Excessively thick walls can lead to uneven plastic shrinkage (creating bubbles and sinks, which requires more adjustments),too thin walls can lead to underfill (requires more injection pressure, with higher energy consumption and longer cycle time). DFM recommends a uniform wall thickness of 1-3mm for most plastic products. For example, for PP products, the wall thickness must be kept within 1.5-2.5mm in order to reduce mold adjustment costs.

Step 2: Simplify the mold parting surface

Complex parting surfaces (curved surfaces and sharp corners) require numerous steps and high-precision equipment, increasing the processing cost by over 30% and potentially leading to flash (which requires additional cleaning). DFM recommends simple parting surfaces such as planes or bevels. For example, a flat parting surface for cylindrical products can be completed by milling process with high efficiency and low cost.

Step 3: Gates’ proper positioning

Incorrect positioning of gates is fast to result in warpage of a product produced, and unnecessary gates add to processing and trimming expense DFM employs gates depending on product shape and plastic material.For big flat products employ a single center gate-to provide even fill-for the small, complicated shape products, employ a single gate or two gates for quality assurance and cost reduction.

Data has shown that DFM reduces mold cost by 15%-25% on average and trims manufacturing cycle time by 10%-20%, and thus it is a valuable cost-saving tool.

Three Often Overlooked Cost Reduction Levers

The following three levers are not discussed as much but have a significant contribution to cost savings: mold inserts, conformal cooling for 3D printing, and dynamic mold material selection.

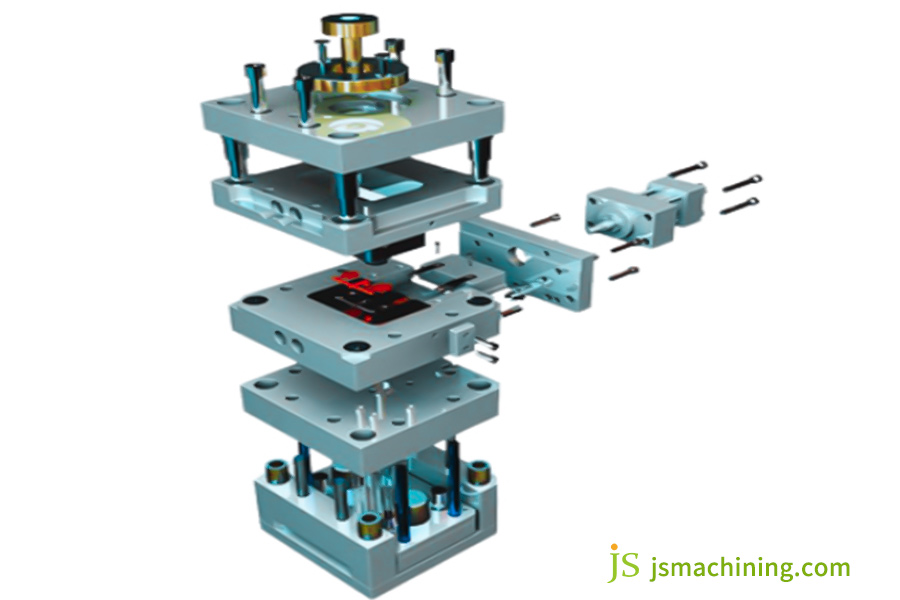

Mold Inserts Strategy

Traditional molds integrate the cavity, core, and mold base. Partial product change or model change requires re-molding the entire thing. Mold inserts render essential parts into independent modules. Model changes require only the changing of inserts, not the mold, reducing manufacturing cost and cycle time.

Revolution in Cooling Channels: 3D Printing Conformal Cooling

Comparison between Conventional and Conformal Cooling Channels:

| Comparison Items | Conventional Cooling Channels | 3D Printing Conformal Cooling Channels |

| Processing Method | Drilling Process | SLM(Selective Laser Melting) |

| Channel Shape | Straight Line / Simple Polyline | Follows Complex Curves of the Product |

| Cooling Uniformity | Poor (Prone to Porosity and Warpage) | Good (Reduces Defects) |

| Cooling Time | 50%-70% of the Injection Molding Cycle | Decreased by 20%-40% |

| Production Efficiency | Low (Long Cycle Time) | High (Increased Output per Unit Time) |

| Maintenance Cost | High (Prone to Impurity Accumulation) | Low (Smooth Inner Wall for Easy Cleaning) |

Dynamic Mold Material Selection

Selection Based on Production Batch:

| Product Production Batch | Recommended Mold Material | Cost Advantage |

| Small Batch (Under 10,000 Parts) | Aluminum Alloy | Cost 30%-50% Lower than Mold Steel, with a Processing Cycle Time of 1 Week. |

| Medium Production Run (10,000-100,000 Pieces) | Pre-hardened Steel (718H) | 10%-20% less expensive than quenched and tempered steel and does not require further heat treatment. |

| Large quantities (over 100000 pieces) | Quenched and tempered steel (such as H13), stainless steel (such as S136) | Long lifespan, reducing the cost of mold replacement, downtime, and debugging, making it more economical in the long runProduct Production Batch. |

Selection based on the Type of Plastics:

- For corrosive plastics (e.g., PVC), choose stainless steel (S136) to avoid the corrosion-prone mold change of normal pre-hardened steel after 10,000-20,000 pieces.

- For glass fiber reinforced plastics, choose quenched and tempered steel (H13) to reduce cavity wear and maintenance costs of normal pre-hardened steel.

Need to benefit from cost savings? JS is a specialist in mold inserts and 3D cooling technology. Tell us your production run size, and we’ll match you with the optimal method. Once you’ve received a quote and signed off on specifications, your project can begin. JS makes it easy to save money.

Comprehensive Cost Reduction Plan: Procurement Through Production

The costs have to be controlled throughout the entire process, from design, procurement, and project management.

Mould Design and Material Strategy

Optimization during the Design Phase:

- Standardized Design: The use of standard parts for guide pins, ejector pins, and other components reduces costs by 20%-30% compared to custom parts as well as shortens lead times.

- Reasonable Precision Control: Reducing the precision of non-matching surfaces from IT5 to IT7 reduces processing cost by approximately 15%.

Cost Control in Material Procurement:

- Bulk Procurement: Bulk procurement of common steel materials is 5%-10% less costly compared to bulk purchasing, with savings in procurement and management costs.

- Long-term Cooperation with Material Suppliers: Ensures stable supply and priority price hedging in case of an increase in raw material cost, avoiding cost fluctuation.

Supplier and Procurement Strategy: Localization vs. Overseas Sourcing

| Comparison Items | Local Sourcing | Overseas Sourcing |

| Procurement Costs | Small batches yield manageable cost and low transport and tariffs, large batches yield poor cost benefit. | Southeast Asian labor costs are 20%-35% lower, European and U.S. steel costs are 5%-10% lower. Large batches yield benefits, small batches are expensive. |

| Communication Efficiency | No time or place limitations, issues resolved within 1-2 days, global transactions entail additional compliance communication. | Foreign clients are handled by a multilingual staff familiar with local legislation. Time zones reduce emergency response times by 1-2 days. |

| Delivery Time | Small quantities are 3-5 days, and exports require additional shipping time, influenced by domestic ports. | Stocking and local warehousing are 2-3 weeks, with the possibility of overseas customers picking up goods locally, reliant on international logistics. |

| Quality Control | On-site supervision is possible and conforms to domestic standards, lack of high-end precision technology. | Mold trial success rate is 95%+, superior to international certification, difficult with frequent on-site monitoring. |

| After-Sales Service | On-site after-sales service in 24 hours, repair in 3-5 days, repair charges for foreign customers are exorbitant. | Retail outlets in major markets, a few of which offer free consumable parts, extended after-sales service for non-priority customers. |

Project Management Strategy

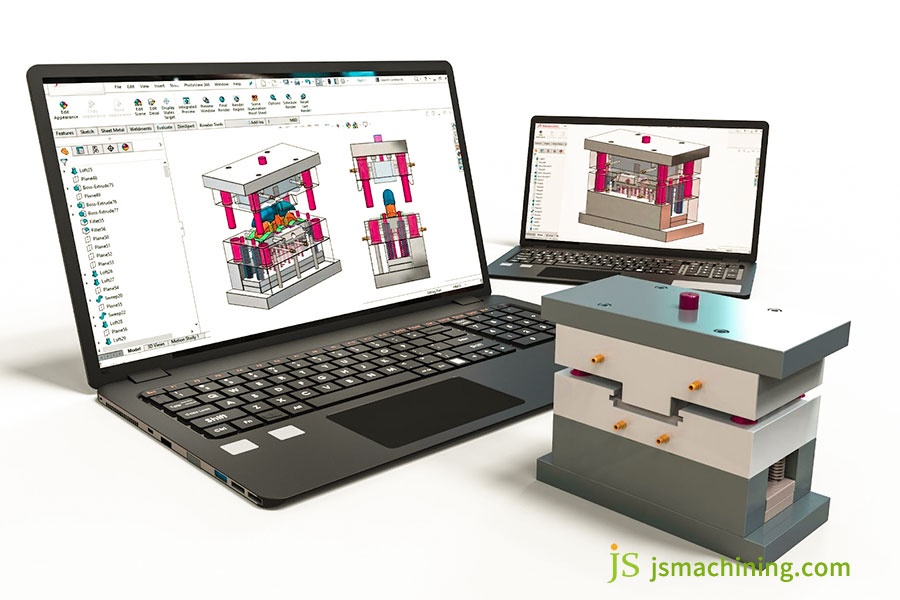

JS Precision Machining supports organizations in controlling cost with professional project management. Our core strengths include:

Specialized Team: JS Precision Machining realizes early feedback of design feasibility, material availability guarantee, and avoidance of cost escalation through delay with specialized manufacturing and design teams.

Open Tracking: Establishes a system of progress tracking whereby customers are able to monitor the machining and design progress in real time and timely communicate and make changes for prevention of information asymmetry-induced efficiency losses.

Low Cost Control: Develops comprehensive material, labor, and other expense budgets prior to project completion and monitors them in real-time as they are being implemented.In case of material price increases,JS Precision Machining gets price reductions or buys substitute materials in real-time.

Quick Issue Resolution: Seasoned technical teams resolve issues such as machining issues and equipment faults in timely fashion, preventing delay that generates longer cycles and additional cost.

Unconventional Strategy: Building Long-Term Partnerships

The focus on the cost of one partnership can easily overlook the cost-benefit value of a long-term partnership. Long-term partnerships with JS can generate ongoing cost savings and value additions.There are two essential values for long-term cooperation:

Cost Advantage

JSturns long-term customers into strategic partners: 5% discount for first collaboration,once one year of cooperation and all orders reach the required amount, the discount ratio is 10%-15%. Besides, the communication cost is saved, and try-and-error cost is saved by more than 60%.

Value Addition

We prioritize long-term customer orders in season. We offer personalized service (e.g.,designing efficient molds for expansion and providing online injection molding services),technical support for free (24/7 on-site support during production) and training.

Desire to save injection mold costs in the future? JS gives a maximum of a 15% discount and priority service. Sign a long-term contract, enjoy free technical consulting, and grow together. JS is your reliable partner in custom injection molding manufacturing.

Case Study: Saving 40% Mold Costs For ASmart Home Brand

Client’s Primary Challenge

A smart home enterprise designed an intelligent smart home hub enclosure. Original design consisted of four distinct plastic parts, which snapped and screwed into one another.

Due to the vast part number and complex layout, the initial supplier’s quote to produce an injection mold was as high as $35,000, about twice the client’s budget of $2,500. Secondly, the large number of assembly operations undermined future production efficiency, posing a challenge to the customer.

JS’s Layered Solution

After securing the order, JS Precision Manufacturing combined its in-house custom injection molding manufacturing expertise with design-for-function (DFM) analysis to solve out a multi-dimensional optimization approach:

- DFM-optimized Component and Structure Optimization

We proposed the combination of four individual pieces into two huge components. The design adopted a ‘living hinge’approach, where the front and back covers were attached directly onto one another, utilizing the inherent plastic toughness to provide the opening and closing mechanism without an internal frame.

In addition, by optimizing hole diameter (3mm to 3.2mm) and the position of supports, we removed two of the three undercuts of the original design, leaving one which can be finished up by a simple slider mechanism, significantly reducing mold processing complexity.

- Proper Matching of Mold Inserts and Material

In the only remaining slider mechanism, replaceable hardened steel inserts (H13 quenched and tempered steel) are utilized in the region of core collision. 718H pre-hardened steel is utilized elsewhere. This ensures mold life without resulting in the cost increase caused by the general use of high-cost steel.

- Cooling System Rationalized and Optimized

With product structure redesign, the initial six discrete cooling channels were consolidated into four, employing linear channels (no longer necessitating complicated machining), again reducing mold processing operations and time.

Final Results

Through this complete solution, cost of customer mold was reduced from the initial quotation of $35,000 to $21,000, with a direct cost saving of 40%, within budget. In addition, with component reduction from four to two, the assembly time for the product was reduced from initial 120 seconds per unit to 48 seconds per unit while the efficiency of assembly increased by 60%. This also saved labor and time cost in additional mass production.

FAQs

Q1: What is the cheapest mold steel option?

P20 pre hardened steel is usually a low-cost choice for mold steel, suitable for scenarios with low production volume and processing of non corrosive materials, such as the production of small household appliance casings. However, it cannot be used for high-yield production and is not suitable for processing corrosive materials such as PVC, which can easily cause surface damage problems.

Q2: Will reduced mold costs have to be at the expense of product quality?

No. As long as scientific cost reduction methods are adopted, such as optimizing mold structure design, selecting cost-effective materials reasonably, and efficiently managing production processes to reduce waste, it is possible to reduce costs while ensuring product quality is not compromised and improving production efficiency.

Q3: Are aluminum molds actually reliable?

Very reliable. Aluminum molds are lightweight and have good thermal conductivity, suitable for processing most ordinary plastics such as ABS, PP, PE, etc. For example, plastic water cup shells commonly used in daily life are made of aluminum molds. However, when facing materials with strong wear resistance such as glass fiber reinforcement or materials that require high mold temperatures such as PC, they are not very suitable and can easily affect the life of the mold.

Q4: Do you go for the lowest price bidder among the suppliers?

Be cautious. The lowest quotation may contain many hidden dangers, such as suppliers not optimizing necessary mold design, secretly using inferior steel to reduce costs, or intentionally underestimating the difficulty of complex processes. In the future, there may be hidden costs such as frequent mold maintenance, delayed production delivery, and poor part quality, which may increase total expenses.

Summary

The key to injection mold cost reduction is detailed care to every step: initially, become acquainted with cost drivers and organization, then utilize Design for Manufacturing (DFM) to reduce costs from the point of design. Implement mold inserts, 3D conformal cooling printing, and dynamic material specification to reduce costs from procurement and production management integration.Finally, commit to long-term collaboration with specialized vendors like JS in an effort to leverage the strength of continuous cost reduction.

Cost reduction is not a single task but a continuous process of efficiency. JS Precision Manufacturing offers custom injection molding manufacturing professionally to help you become a master at injection molding cost control and obtain high-quality injection molding parts, eliminating mold cost as an obstacle to your growth!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: How Long Does It Take To Plastic Mold Injection? - JUSHENG