A medical device or aerospace component prototype with complex surfaces requires a number of setups and specialized tooling on a 3-axis machine, and final accuracy is difficult to guarantee. But the same part is milled on a 5 axis machine in a single setup, where the tool moves around the workpiece, and after hours, a perfect part will be available.

It is not sorcery, but the appeal and the challenge of 5 axis machining. Being an advanced manufacturing process, 5 axis CNC machining has always been perceived as challenging and demanding. This article will objectively explore: What makes 5 axis CNC machining so challenging? Is it the key to obtain infinite design freedom, or it is an art that only the masters can execute?

Whether you are interested in knowing about 5 axis CNC machining parts or designing online 5 axis CNC machining services, this guide will be your clear reference.

Core Answer Summary

| Comparison Dimension | Traditional 3 Axis CNC | 5 Axis CNC |

| Degree of Motion Freedom | X, Y, Z three linear axes. | X, Y, Z + A, B (or C) two rotary axes. |

| Programming Complexity | Relatively simple, intuitive tool path. | Extremely complex, requiring consideration of tool orientation and collision avoidance. |

| Workholding Requirement | Multiple workholding setups for multi-face machining. | One-time workholding to complete most of the machining. |

| Precision Control | Mainly affected by machine linear axis precision. | Also affected by rotary axis precision and RTCP algorithm. |

| Cost Composition | Equipment, programming, labor. | Expensive equipment, costly programming software and high salaries for senior technicians. |

| Core Value | Efficiently completes 2.5D and simple 3D features. | Complex surface machining, shortened lead time and improved overall precision. |

Why Is 5 Axis CNC Machining Hard? Know How The JS Team Overcomes It

In producing complex parts, the difficulty of 5 axis CNC machining has kept most companies away. But JS team has been committed to this field for decades and has acquired rich practical experience.

We have machined high-precision structural parts for the aerospace industry, with tolerances as low as ±0.005mm, we have machined complex molds for the automotive industry, including various high-strength alloys, and we have produced implants with complex curves for the medical device industry, with very high surface finishes. These are all standard requirements of custom 5 axis CNC machining manufacturing.

We have also developed creative solutions for other extraordinary conditions, such as handling chatter in large-sized parts and delamination in composite material cutting.

This handbook is a summary of our experience, from theory to practice, on key issues. If you want to know the real problems of 5 axis machining and how to solve them, we believe that this practical handbook will provide you with the most reliable answers.

If you require a partner that will address complex 5 axis machining challenges, the expertise of JS team is a solid guarantee. We provide customized custom 5 axis CNC machining production solutions to ease machining complex components.

Beyond Three Directions: Analyzing The Complex Path Configurations Of 5 Axis Machine Tools

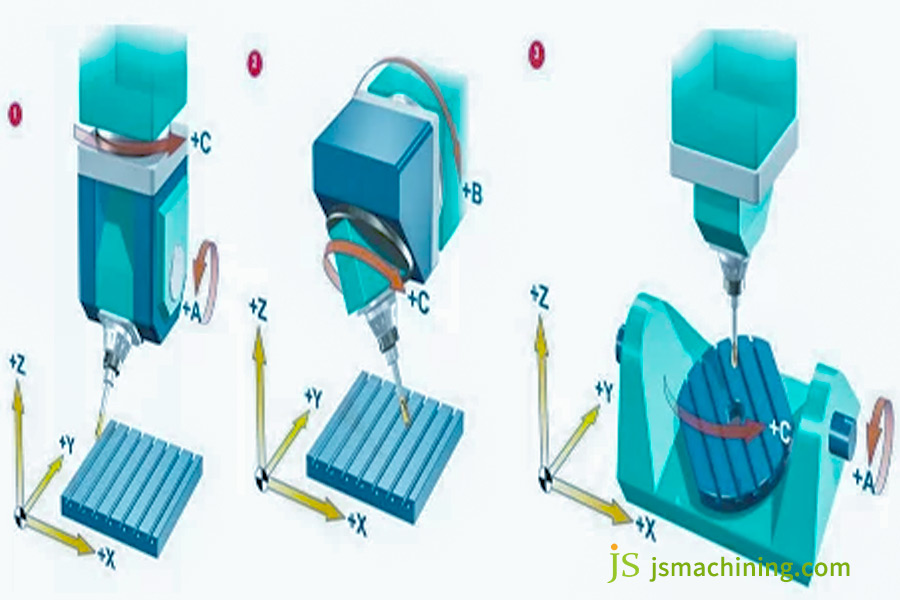

Most people believe that 5 axis machine tools are a single type of machine. Not so. 5 axis machine tools come in a multitude of configurations with specific motion and application conditions. By being aware of these configurations, you will better comprehend the complexity of 5 axis machining and be able to select more properly the optimal machine for 5 axis CNC machining parts.

Trunnion Table

This configuration features a revolving worktable. The worktable typically has two axes of rotation which enable it to turn the workpiece at varying angles. Its advantage lies in the good stability of the workpiece after clamping, making it suitable for processing small and medium-sized parts.

Head-Head

The characteristic of head-head configuration is its rotating spindle head. The spindle head rotates with the cutting tool, and it is possible to machine for various workpiece angles. This machine is suitable for turning large-sized workpieces as it spares the effort of shifting heavy workpieces, only the angle of the spindle head can be adjusted. However, it requires high spindle stiffness.

Hybrid

A hybrid setup combines the advantages of a swinging head and a rotating table, with the addition of a rotating worktable and an oscillating spindle head. It allows greater machining flexibility and the ability to process more complex part structures. However, it is also connected with a more advanced mechanical structure and greater maintenance and operating requirements.

Unveiling The True Technical Challenges Of 5 Axis CNC Machining

The majority find the hardest aspect of 5 axis machining to be operating the machine. Really, though, it is the shift in mental model—3 axis planar thought to 5 axis spatial thought—that is the most challenging. That is a broad chasm that practitioners must traverse.

3D Spatial Reasoning

Programmers must visualize clearly the three-dimensional, real-time motion relationships between the tool, toolholder, spindle, workpiece, and fixture.3 axis machining involves consideration only of the X, Y, and Z axes, producing a simple trajectory. 5 axis machining adds two more rotary axes, producing the most complicated trajectory.

Collision avoidance

This is the most significant challenge. Multi-axis linkage possesses a high tendency towards collision among the tool, toolholder, spindle, workpiece, and fixture, which can lead to damage of both the equipment and the workpiece. Accurate calculation of the path to provide safe distances is critical in keeping 5 axis CNC machining stable.

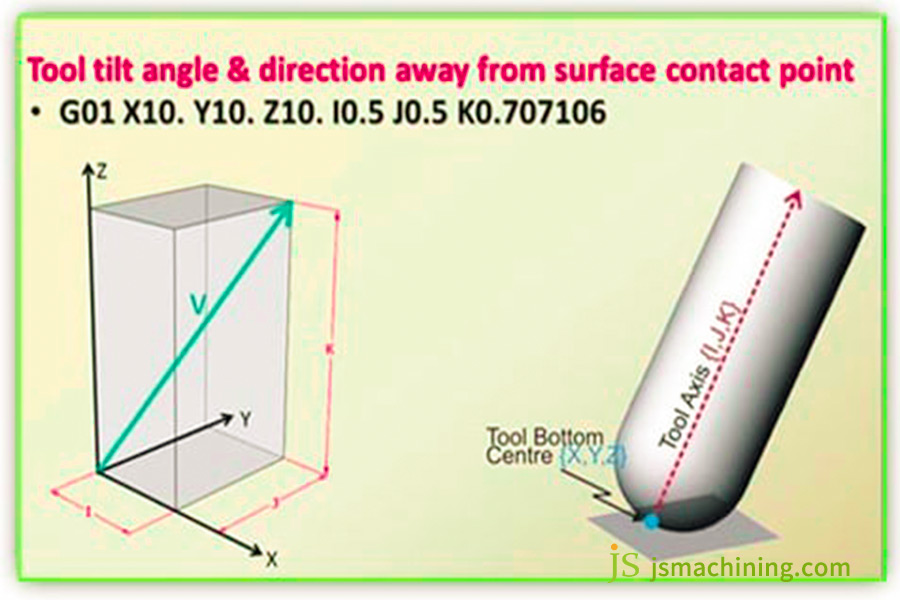

Tool vector control

The axis-workpiece surface angle of the tool must be regulated in real-time as a function of complicated surface curvature. This requires programmers with profound geometric expertise and experience to accurately set up tool angles and paths.

In order to overcome these technical challenges, we possess superior technology and professional personnel. Technical challenges become none of your business with our online 5 axis CNC machining services. You can simply submit a drawing, and we will complete high-precision machining for you.

The Core Challenge Of 5 Axis Machine Tools: Why Is It More Challenging To Achieve And Sustain High Precision

Their single strongest argument is that they have high precision of 5 axis machine tools, but its establishment and maintenance is a myriad of complexities.

Mechanical structural complexity

5 axis machines have two additional rotary axes, so their mechanical configuration is more complicated than that of three-axis machines. It requires ultra-high precision to have these axes connected, and slight errors in any one of the axes can be amplified, affecting overall machining accuracy.

Thermal Deformation

Since parts such as the machine’s motor and spindle generate heat during machining, there occurs small deformation of the machine structure. Though it is small, the deformation has the effect of causing machining errors to surpass the permitted limit for parts requiring high precision.

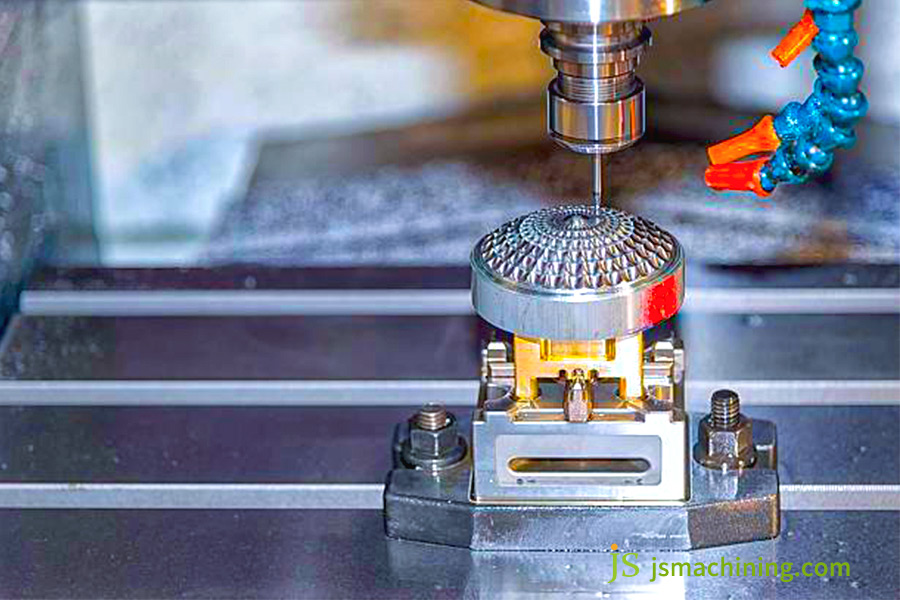

Tool Wear

High accuracy is a basic requirement for 5 axis CNC machining parts. 5 axis machining prefers to machine high-strength and high-hardness materials, which results in significant tool wear. Tool wear will vary in shape and size, affecting part accuracy. Tool changes and compensation are required often, thereby complicating precision maintenance further.

JS is cognizant of the necessity for high precision and, through imposing strict precision control procedures, ensures that each 5 axis CNC machining part meets specified prerequisites. With our in-house custom 5 axis CNC machining manufacturing services, high precision is not a problem any more.

Reducing Complexity: Systematic Solutions To Five Fundamental Challenges

5 axis CNC machining challenges are abetted by adopting the following systematic solutions:

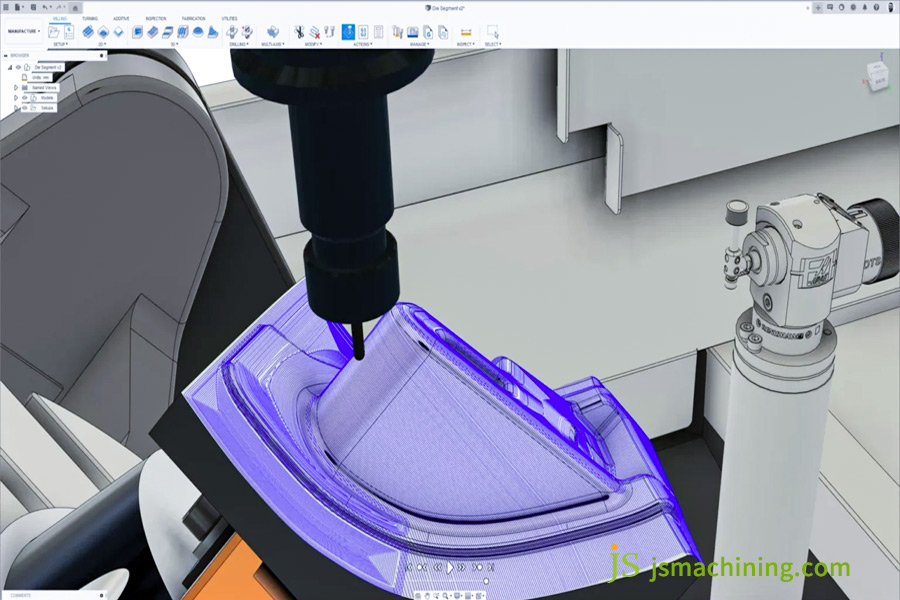

Programming Difficulty -> Invest in Advanced CAM Software

Advanced CAM software can automatically create tool paths, perform 3D simulations, predict collisions and interferences, simplify programming, and reduce reliance on programmer experience.

Operation/Setup Difficulty -> Generating Rigid Standardized Processes

Develop operating manuals and setup specifications, train personnel, and establish rigid standards for all steps from setup through parameter adjustments, reducing human intervention and improving machining uniformity.

Precision Control Difficulty -> Periodically Certify 5 axis Machine Tool Accuracy

Use machines such as laser interferometers and ballbars to regularly check and calibrate machine tools, rectify faults in a timely manner, and yield high accuracy in the long term.

High Cost -> Calculate Total Return on Investment (ROI)

The initial investment of 5 axis CNC machining is high, but it can reduce the use of clamping and fixtures, shorten the total manufacturing time, and have a high long-term return rate. From the long-term accounting of 5 axis CNC machining price, it has more advantages.

Talent Shortage -> Collaborate with a Professional Team

We collaborate with professional training institutions and engineering staffs to implement a talent development system and leverage outside technical services to make up for internal talent shortages.

JS have developed complete solutions to tackle these challenges. Our 5 axis CNC machining price is reasonable and we can provide you with cost-effective services, allowing you to easily tackle various challenges in 5 axis CNC machining.

5 Axis Vs. 3+2 Axis Vs. 3 Axis: Not ASimple Replacement

Most people believe that 5 axis CNC machining can completely replace 3+2 axis and 3 axis machining, but it is a common misconception. All the aforementioned processes have their own nature and conditions of application. The table below provides the in-depth distinction between them.

| Machining Type | Advantages | Disadvantages | Application Scenarios |

| 3 Axis Machining | Low equipment cost. Simple programming. Easy operation. | Can only machine one face of the workpiece. Multiple workholding setups are needed for complex parts. | Simple machining of flat, stepped, and perforated parts. |

| 3+2 Axis Machining | Fewer workholding setups than 3-axis machining. Higher efficiency than 3-axis machining. | Cannot achieve true 5 axis simultaneous machining. Limited precision for complex surfaces. | Medium-complexity parts requiring multi-angle machining without real-time synchronization. |

| 5 Axis Machining | One-time workholding for multi-face machining. Capable of complex surface machining. High precision. | High equipment cost. Complex programming and operation. High requirement for technicians. | Complex surface parts. High-precision parts. Large complex structural parts. |

This is a prime example of the point that while 5 axis machining is robust, it’s not necessarily well-suited for all tasks. Part complexity, accuracy requirements, and batch quantity all factor into the choice of machining process.

Regardless of the machining operation you require, we offer expert services. As your local 5 axis CNC machine near me, we can recommend the most appropriate machining solution based on your needs.

Getting Maximum Value Out Of 5 Axis Machine Tools: Four Strategies For Effective Finishing

Maximize the value of 5 axis machine tools and achieve effective finishing by mastering the following strategies:

Optimize tool paths

Reduce tool idle travel to enable uniform tool force distribution, and use CAM software to generate optimal paths depending on the material and part.

Use high-speed machining technology

High-speed spindles and feed systems coupled with correct tool parameters are utilized to increase efficiency and reduce cutting forces and thermal deformation.

Real-time Monitoring and Compensation

Cutting force, vibration, and other parameters are sensed using sensors, compensating when there are abnormalities to avoid defects in machining.

Optimal Tool Management

Install a tool management system to track tool life and wear, allow for timely replacement and compensation, and make optimal decisions on tool material and parameters.

Real-World Case Study: How 5 Axis CNC Technology Saved An “Impossible” Composite Drone Wing Mold

Background

A manufacturer of drones required to make a 1.5-meter-long carbon fiber composite wing mold with very complex aerodynamic curves. It must have a mirror finish and ±0.05mm surface tolerance,with parts containing large complex surfaces and deep cavity negative angles.This type of part is precisely the high difficulty type in 5 axis CNC machining parts, and traditional machining is difficult to meet the requirements.

Problems of Traditional Methods

Three-axis machines have complicated reversal setups, which can easily cause positioning error and tool marks. The tool is also unable to reach deep negative angles. Manually grinding is not accurate, and the project is near failure.

JS’s 5 axis Solution

Process Selection:

A 5 axis machine tool of the gantry type has enough room to mill deep negative angles through rotating the spindle angle without the movement of the workpiece, which saves setup time and avoids tool marks.

Programming and Collision Avoidance:

With the assistance of advanced CAM software, the paths of the tools are automatically generated after the development of a 3D model. Different 3D simulations are executed to simulate kinematic relations, and possible collision dangers are removed in advance. Path optimization is also manually available to ensure safety and efficiency.

Tools and Precision Control:

Enabling the RTCP operation ensures accurate positioning of the tool tip. Long-edge ball-end milling cutters are used to trace curves and minimize cutting marks. In machining, parameters are constantly supervised and corrected in real time, and tool compensation is verified on a routine basis.

Results

The mold achieved a true accuracy of ±0.03mm, having a mirror finish. This was much quicker than traditional methods and saved weeks of lead time, allowing the customer to complete development and manufacturing of drone wings and allowing 5 axis machining and JS’s precision manufacturing abilities to justify themselves.

Why JS Your First Choice In 5 Axis CNC Machining?

JS has rich experience and accumulated technical expertise in 5 axis CNC machining, so you can trust us as your reliable partner.

We possess a range of 5 axis machine tools, including rotary table, swing head, and hybrid, that can meet the processing needs of different parts. Our team of very experienced programmers, operators, and engineers have intimate understanding and vast hands-on experience and are therefore capable of handling many types of 5 axis CNC machining parts with maximum efficiency and tackling intricate machining problems.

We apply sophisticated CAM software and testing tools in order to make sure that every 5 axis CNC machining parts meet precision standards. We also have developed a strict standardized procedure, with precise specifications for each step, starting from receipt of the order and drawing analysis, programming, machining, through testing, so as to guarantee stable and efficient machining.

We offer competitive 5 axis CNC machining prices and can offer customized services according to your requirements. As the 5 axis CNC machine near me, we can offer quick response and timely service, which reduces your production cycle.

FAQs

Q1: Is RTCP required for a 5 axis machining centre?

Yes, RTCP is an essential function for true 5 axis simultaneous machining. It allows programmers to focus solely on tool tip path and tool attitude. The control system automatically and precisely calculates each axis’s motion, significantly simplifying programming and improving efficiency. Without RTCP, machine tools are usually limited to 3+2 positioning machining, and high-precision simultaneous machining of complex surfaces is difficult to accomplish.

Q2: Why are 5 axis machines so expensive?

The main reason that 5 axis machines are so expensive:

- Compared to 3-axis machines, they have two additional rotary axes with additional precision transmission parts and structure design required to ensure accuracy of linkage.

- The control system is also under the processing of data from additional axes with high computation and control requirements, resulting in high R&D costs.

- The high accuracies of material and machining of major components all contribute to higher costs.

Q3: Does programming time for 5 axis CNC machining greatly increase?

Yes.5 axis machining entails the control of more axis motion and more complex tool paths. Programmers must consider spatial relationships between parts to avoid collisions and perform intense simulations to validate path rationality and safety. Especially with deeply curved components, path parameters must be optimized over and over again. This takes much more time than three-axis machining, in some cases several times as much programming time.

Q4: Can it machine any material?

5 axis machining can machine a range of materials, but not every one of them can be effectively machined. The machining parameters must be adjusted based on the nature of the material. While 5 axis machining can reliably machine metals as well as non-metallic materials, there are tough materials such as ceramics that can be machined with specially coated tools and special processes that affect efficiency. In addition, proper tool choice has to be adjusted to the hardness and toughness of the material.

Summary

5 axis CNC machining definitely comes with a formidable learning curve, pushing manufacturers’ technical expertise, capability, and resources to the limits. But the reward is no less rewarding: unparalleled machining capability, benchmark productivity, and world-class product quality. With the proper strategy, strategy, and partner, you can maximize 5 axis CNC machining and utilize it as an active capability for manufacturing complex parts and improved product quality.

Do you have a challenging part project on hold because of machining concerns? Do you need to know if 5 axis technology could present new opportunities for your organization?

Our experts and advanced 5 axis CNC machining centers give turnkey solutions with technical consulting and process validation to small-volume production. Be it 5 axis CNC machining parts or designing custom 5 axis CNC machining manufacturing, we are here to serve you. Join hands with us and begin a new era of accurate and efficient production.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com