A product that is smooth to the touch, can tolerate several boils in boiling water and even the high-stress hospital-grade sterilization environment, and can be injection-molded into extremely accurate and intricate geometries. It’s not just any plastic, no, it’s liquid silicone rubber (LSR). They think that it is a thermoplastic, but the reality is different.

Plastic injection molding is a standard process within production, and proper material selection has a direct influence on product performance, efficiency during production, and cost. From the hands-on experience of JS, this report will walk you through the primary differences between LSR and thermoplastics rubber by taking into account important factors such as the selection of materials, processability, and the equipment needed so that you can approach your project confidently.

Core Answer Summary

| Comparison Dimension | LSR (Liquid Silicone Rubber) | Thermoplastic (e.g., TPR) | Core Conclusion |

| Material Type | Thermosetting elastomer. | Thermoplastic elastomer/plastic. | LSR is not a thermoplastic. |

| Processing Characteristic | Cross-linking and curing, non-reworkable. | Melting by heating – solidifying by cooling, reworkable. | The processing principles are completely different. |

| Recyclability | Difficult to recycle. | Recyclable and reshapable. | Thermoplastics are easier to recycle. |

| Typical Applications | Medical CGM patches, high-temperature seals. | Toy buttons, soft parts for general consumer products. | Application scenarios are determined by performance requirements. |

LSR Or Thermoplastics? JS Practical Selection Guide

JS has a strong voice in material selection. Over the past decade, we have provided plastic injection molding and LSR-related solutions to over 500 clients across the medical, consumer electronics, and automotive sectors.

For example, in the medical field, we’ve completed over 30 high-precision projects like CGM patches, as well as insulin pen seals and ECG monitor silicone accessories. In consumer electronics, we have collaborated in designing soft buttons and seals for over 20 major brands, such as wireless earbuds for headsets and band connectors for smartwatches. In the automotive sector, we have helped produce LSR seals for over 15 car sensors.

These experiences have provided us a first-hand understanding of the challenges in selection of materials under different circumstances. This book is a distillation of our experiential knowledge, tried and tested in real projects, so you can trust it implicitly.

JS boasts a rich heritage of plastic injection molding and LSR application, and can provide customized solutions with prompt turnaround from notice of requirements to delivery of sample. Join us in helping drive your project forward successfully.

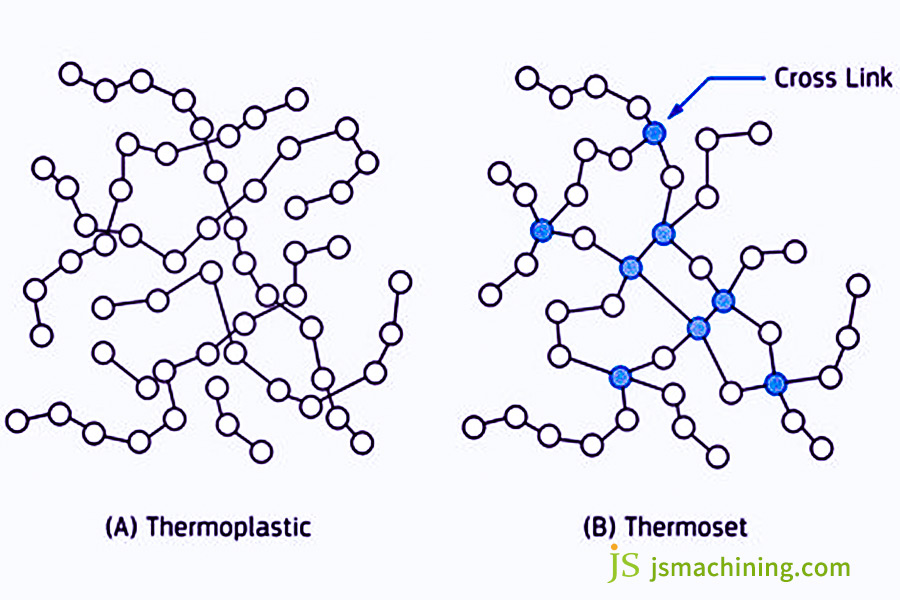

Thermosets Vs. Thermoplastics: The “Permanence” And “Reshaping” Of Molecules

To discover whether LSR is a thermoplastic or not, you need to learn first the general difference between thermoplastics and thermosets—they are similar molecules with two different “personalities”: one is “unchanging” and the other is “flexible and changeable.”

During processing of the thermoset material, the molecules cross-link with one another and form a three-dimensional network structure. Once this structure is formed, it cannot be reversed, and even if heated again, it will not melt and can only be burned.Thermoplastic polymers have linear or branched molecular structures. These melt on heating and solidify on cooling. This process is reversible, like wax, that can be reformed a large number of times.

In practice, thermoset LSR is utilized in medical device seals because it will retain a stable performance upon molding and can endure long-term sterilizing environments. Thermoplastic TPR is more commonly used in children’s toys because it can be recycled and reshaped, which can reduce production costs, especially suitable for mass production of low-cost plastic injection molding parts.

Comparison of Core Differences Between Thermoset and Thermoplastic Materials

| Comparison Dimension | Thermosetting Materials | Thermoplastic Materials |

| Molecular Structure | Three-dimensional cross-linked network structure. | Linear or branched structure. |

| Processing Characteristic | One-time curing and molding, non-reworkable. | Repeated melting by heating and solidifying by cooling. |

| Recyclability | Difficult to recycle and reuse. | Recyclable and reshapable. |

| Representative Materials | LSR, epoxy resin. | Polyethylene, PEEK, TPR. |

| Change After Heating | No melting, decomposes at excessively high temperatures. | Melts when heated, returns to solid state after cooling. |

Conclusion: LSR is a thermoset elastomer and not a thermoplastic. The LSR forms a cross-linked structure during processing through a platinum-catalyzed addition reaction. It cannot be melted or reworked after molding, unlike thermoplastics.

JS can provide professional custom plastic injection molding manufacturing services to meet the processing needs of different materials, ensuring precise production of all types of products.

LSR Vs. TPR: How To Get The Soft Touch In Products

Typically, materials are fragile and require a light touch, and liquid silicone rubber(LSR) and thermoplastic rubber (TPR) are the most commonly utilized favorites. But when do you employ the one over the other? Let’s start by knowing what TPE/TPR is.

What is TPE/TPR?

TPE (thermoplastic elastomer) is a generic term used to describe a broad group of materials. TPR is a type of TPE as well as a thermoplastic rubber. It provides the rubber-like feel and resilience of rubber combined with the ease of processing of plastic.

It can be produced through standard plastic injection molding with no specialized equipment, with comparatively low processing cost. For example, in the production of ordinary toy buttons, the plastic injection molding price using TPR material is usually 30% -50% lower than LSR, making it more suitable for budget limited mass market products.

Comparison in Depth of LSR and TPR Performance

| Performance Dimension | LSR (Liquid Silicone Rubber) | TPR (Thermoplastic Rubber) |

| Softness | Soft with long-lasting elasticity and delicate touch. | Adjustable softness, but tends to harden after long-term use. |

| Temperature Resistance | Resistant to high and low temperatures (-50℃~200℃). | Narrow temperature resistance range (-30℃~100℃). |

| Chemical Resistance | Strong resistance to sweat, alcohol, etc., with high stability. | Easily eroded by oil and solvents. |

| Biocompatibility | Medical-grade, suitable for long-term skin contact. | General-grade, may cause allergies with long-term contact. |

| Processing Efficiency | Requires special equipment, fast curing. | Compatible with general equipment, long processing cycle. |

Selection Guide

- For medical devices (such as CGM patches) or those that require long-term skin contact, LSR is preferred due to its superior biocompatibility and chemical resistance, which can prevent irritation from long-term use.

- If your product is for general consumer goods (such as toy buttons) and your budget is limited, TPR is an option. It meets basic softness requirements, requires low-tech processing equipment, and can effectively control overall production costs.

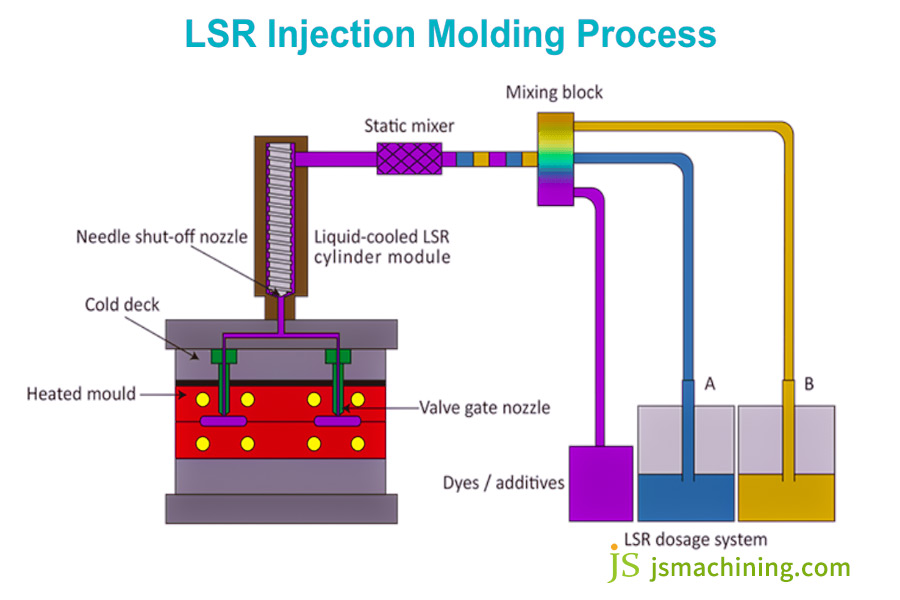

LSR Injection Molding Process: A Precision-Controlled “Chemical Reaction”

Unlike standard plastic injection molding, LSR processing is not a simple melt-and-cool process, but an accurately controlled chemical reaction. The processing is primarily based on a platinum-catalyzed addition reaction, and every step cannot be wrong. The slightest variation of the parameters at any step can result in product failure.

- Feeding

LSR raw materials are two-component (A + B) products. The two components must be kept in a special barrel at low temperature (typically 0°C to 10°C) to prevent premature curing. JS has a precision metering pump that delivers components A and B in a 1:1 ratio to downstream operations. Precision of the metering pump is controlled to within ±0.1%, enabling precise raw material ratio and preventing imbalances that could render product performance.

- Blending

After components A and B are loaded into the static mixer, they are thoroughly agitated and mixed. The mixer speed is kept at 300-500 rpm, giving 15-20 mixing cycles per milliliter of material. This leads to initiating the initial stages of the crosslinking reaction but not final curing to prepare the material for the next injection molding.

- Injection

The mixed liquid LSR is then injected into a preheated mold. Temperature of the mold is usually controlled between 170°C and 200°C with not more than ±5°C difference in temperature. The temperature provides the most favorable conditions to the subsequent curing reaction as well as preventing premature curing resulting from too high a temperature.

- Curing

The LSR pumped into the mold cross-links quickly in heat. For products of 1-3mm thickness, curing time is typically 30-60 seconds, for products of 3-5mm thickness, curing time is boosted to 60-90 seconds. This technique converts the liquid LSR to a solid product in one step. The precise time is adjusted based on the thickness of the product.

- Ejection

Because the LSR is fully cured in the mold, the product can be demolded directly without cooling as necessary in traditional plastic injection molding. This significantly shortens the production cycle. Taking precision plastic injection molding parts such as CGM patches as an example, the production cycle using LSR injection molding technology is shortened by about 40% compared to traditional plastic injection molding.

Breaking The Mold: Yes, Special Equipment Is Needed!

Most people believe that LSR can be processed on typical plastic injection molding machines. But they are quite different. Typical plastic injection molding machines are simply not capable of processing LSR. A small equipment mismatch can lead to more than 10% material loss.

Core Differences Between Traditional Plastic Injection Molding and LSR Molding

| Difference Dimension | Traditional Plastic Injection Molding | LSR Injection Molding |

| Material Storage | Can be stored at room temperature. | Requires low-temperature storage (0℃~10℃). |

| Material Mixing | No additional mixing steps needed. | Requires a dedicated static mixer to mix components A and B. |

| Mold Temperature | Adjustable temperature, mostly low-temperature cooling. | Requires high-temperature heating (170℃~200℃). |

| Equipment Sealing Requirement | Regular sealing is sufficient. | Requires special sealing that is low-temperature resistant and leak-proof. |

Conclusion:

Regular plastic injection molding machines cannot be used for processing LSR.Special LSR injection molding machines must be utilized, or the current ones must be drastically refurbished, replacing major components such as the barrel, metering pump, and mixing system.

The barrel must be made of low-temperature-resistant stainless steel and would be 2mm thicker than the regular one, and the metering pump would need to be replaced with a high-precision ceramic rotor pump. Not doing this step will result in material loss and low-quality products.

If you want to learn about equipment modification solutions or obtain technical support, JS’s online plastic injection molding services can provide you with one-on-one consultation at any time to help solve equipment problems.

When Is LSR The Best Choice For Your Product?

Not all products are suitable for LSR. LSR is the best solution if your product possesses the following attributes. For these applications, LSR’s performance advantage can be maximized to increase the value of the product.

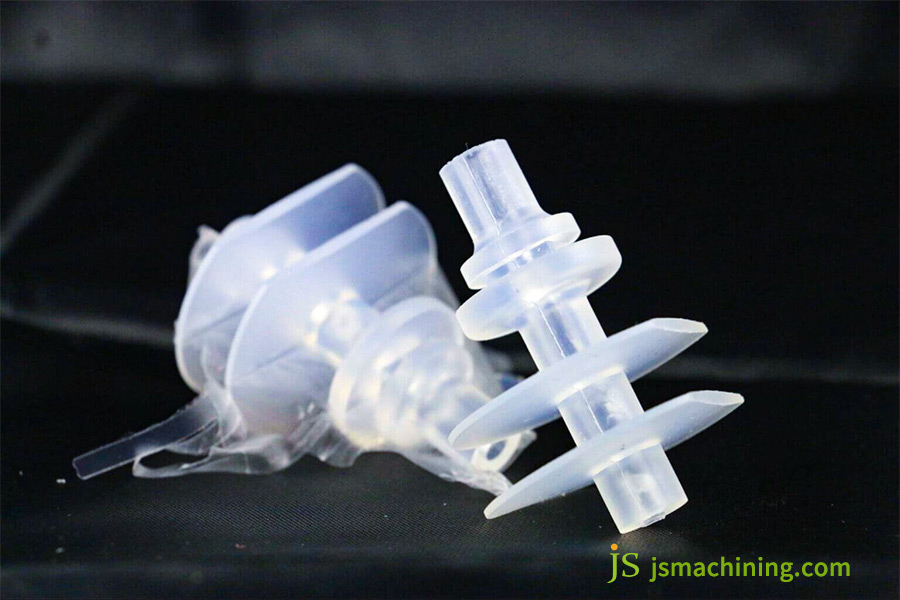

1.Medical or Skin Contact Applications

If the product requires extended direct skin contact, such as CGM patches, baby pacifiers, IV connector tubing, and ventilator gaskets, LSR’s medical-grade biocompatibility, following rigorous allergy and cytotoxicity testing, poses no toxicity to the human body and particularly safe for infants and patients with weakened immune systems.

For this type of medical product, JS can provide custom plastic injection molding manufacturing services to customize exclusive production processes based on the product’s special structure and performance requirements.

2.High-Temperature or Harsh Environments

If the product needs to be durable under high temperature (e.g., proximity to car engines) or chemical exposure (e.g., sweat or alcohol), such as oven seals, car engine compartment wiring harness covers, and laboratory seals for chemical bottles, LSR’s high-temperature and low-temperature resistance and chemical resistance offer long-lasting stability without deforming or losing function.

3.Needs Precision and Microstructures

Where products require injection molding of micron-sized features, e.g., sensor covers, micro-seals, micro-buttons for electronic products, and precision connectors, LSR’s high fluidity allows it to fill microscopic mold cavities with a fill rate as high as 99.9%, meeting precision requirements.

4.Search for Long-Term Stability

If products require long-term usage (such as accessories for medical devices), such as armrest covers for wheelchairs or smart bracelet bands that are wearable for long periods of time, LSR offers long-term elasticity. Aging tests have shown that it still has over 90% of its original elasticity after five years of use. Whereas TPR becomes hard or aged when used for a long time, LSR offers long-term user satisfaction.

JS Technology Breakthrough: How Can LSR Precision Injection Solve The Production Problem Of Blood Glucose Monitoring Equipment?

Customer Needs

A pioneering company created a CGM patch. In addition to meeting the basic requirements of biocompatibility, comfort, accuracy, and chemical resistance, they also faced the problem of mass production efficiency. The customer required over 100,000 patches/month with a product qualification rate of at least 99% on production, which could not be met with conventional processes.

Traditional TPEs could not offer long-term biostability and perspiration resistance. Traditional silicone molding was inefficient, not highly accurate, and produced batch quality that was uneven. The product qualifying rate from the former supplier was only around 95%.

JS’s LSR Solution

Material Selection:

JS selected high-purity, medical-grade, breathable LSR material. The material is both FDA approved and EU CE approved and meets the needs of hypoallergenicity for prolonged skin contact. Its rate of sensitization has been shown to be less than 0.01% through testing.

Precision Injection Molding:

JS uses a micro LSR injection molding machine that supports a high-precision cold runner system with an accuracy of ±0.005mm. This allows high-precision molding of the protection structure of the micron-scale sensor on the patch. It also reduces material waste by 30%. The patch is also equipped with an in-line cosmetic defect detection system with 0.01mm accuracy, enabling real-time cosmetic defect detection.

Joint Production:

LSR injection molding structures the basic morphology of the patch, and the hard exterior connector is structured through biocompatible PEEK plastic through traditional plastic injection molding. JS has seamlessly integrated two processes in one workshop, creating exclusive material transfer channels so that transport of products between workshops will not result in product damage and ensuring product integrity and reliability.

Throughout the entire project process, customers can view production progress and testing data in real-time through JS’s online plastic injection molding services, achieving transparent collaboration.

Results

The proper application of LSR ensures that this CGM patch is medical-grade standards safe. Not only is it strictly tested for allergy and cytotoxicity, but it also achieves a monthly production of 150,000 pieces with a product qualification rate as high as 99.5%, meeting customer needs very well.

After the customer’s product was launched, with stable performance and comfortable wearing experience, the market share increased by 15% within six months, gaining widespread recognition in the market and providing a feasible solution for the mass production of plastic injection molding parts in the same medical field.

JS has extensive mass production experience in medical devices and can seamlessly integrate LSR with traditional plastic injection molding processes without compromising product quality and mass production efficiency. We welcome orders and cooperation.

Striving For Success: How To Start Your LSR Project?

To carry your LSR project smoothly, you need to prepare stage by stage. JS will provide you with full support throughout the process, with a special team following up at every stage to ensure smooth project progress.

1.Early Consultation

First, inform your product requirements to JS’s technical department, including application areas, performance requirements, and manufacturing capacities. We will recommend suitable LSR materials based on your requirements and provide you with transparent plastic injection molding prices and LSR processing quotes so that you can prepare costs in advance.

2.Prototyping and Testing

After the design and solution has been determined, JS will quickly produce sample prototypes, which are delivered typically within 7-10 days. Samples undergo performance testing, including elasticity, temperature resistance, and biocompatibility (if required), to ensure that they meet your requirements. Online plastic injection molding service is also supported with us, allowing you to view sample test results online.

3.Partner Selection

It is necessary to select a manufacturer having specialized LSR equipment, cleanroom facilities, and medical field experience. JS has a medical standard cleanroom, dedicated LSR molding equipment, and a professional technical team. We also offer custom plastic injection molding manufacturing service, tailoring the manufacturing process to your needs.

FAQs

Q1: Is bonding liquid silicone rubber products complicated?

Yes, the surface of liquid silicone rubber is inert and thus direct bonding to other materials is not feasible. Usually, it is necessary to use a specialized primer to treat its surface, or use plasma surface treatment technology, in order to achieve a strong bonding effect between liquid silicone rubber and other materials and avoid detachment problems during use.

Q2: Are liquid silicone rubber products colorable?

Yes! Liquid silicone rubber is also possible to be colored in shades of transparent or bright colors to meet the cosmetic needs of many products. But remember that the masterbatch must also be platinum-catalyzed, as non-platinum-catalyzed masterbatches will decatalyze during cure and hinder the LSR curing reaction, causing the product not to cure properly and affecting product performance and appearance.

Q3: Can LSR achieve a fast molding cycle?

Yes. JS has effectively shortened the molding cycle of LSR by 30% compared to the industry’s conventional level through low-temperature curing technology.This technology not only ensures molding efficiency, but also ensures that the elasticity, temperature resistance, and other properties of LSR products are not affected, making it particularly suitable for mass production projects with high delivery cycle requirements.

Q4: Why are raw materials to be stored at low temperatures?

Liquid silicone rubber (LSR) will tend to be prematurely cured at room temperature. In case of premature cure, it is no longer fluid and cannot be injected into the mold in a timely manner, which will cause material waste and downtime in production. JS possesses a complete cold chain warehousing system with low-temperature conditions from raw material procurement to storage and transportation to ensure the stability of the raw material.

Summary

Liquid silicone rubber (LSR) is far more than a generic “plastic”, it is a material science triumph developed for high-end applications. It breaks the performance boundaries of common materials and has a vital role to play in the pursuit of next-generation products that are safe, durable, and extremely comfortable. From material selection to process adoption, from equipment conversion to project fulfillment, choosing the right partner is crucial.

JS provides whole-process support from material selection to plastic injection molding and plastic injection molding parts processing.We also offer online plastic injection molding services, with remote collaboration and prompt response upon receiving orders, for effective project implementation. We are your trusty partner.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Is Thermoplastic Polyurethane Hard Or Soft? - JUSHENG

Pingback: Insert Molding Vs Overmolding Selection Guide: 5 Key Factors Based On Substrate Characteristics - JS Precision