I’ve witnessed many designers commit this error. Imagine a drone crashing at a high altitude. On inspection, it’s discovered that the 3D printing nylon gearbox housing cracked as it had absorbed water, and its strength dropped by 50%!

The problem typically starts from a misleading assumption: Most assume “nylon” is 100% plastic with constant properties. They are unaware that its strength drops by half once it absorbs water!

Technically, nylon is petroleum-based plastic, extremely tough, strong, and resilient, and it is widely used for sports equipment and industrial components. But the point is this: To equate nylon with “normal plastic” is a grave mistake. Nylon also “likes water,” and humidity has a dramatic effect on it, like the gearbox busted in our case.

Understanding that nylon is not merely “plastic,” but an engineering material with particular properties, most importantly, moisture sensitivity, is the basis of the successful use of 3D-printed nylon, and this is what this guide will tell you about.

Core Answer Summary:

|

Nylon type

|

Basic components and modification characteristics

|

Key points of applicability for 3D printing

|

Typical application scenarios

|

|

Pure nylon (PA6/PA66)

|

100% polyamide polymer, without any filling.

|

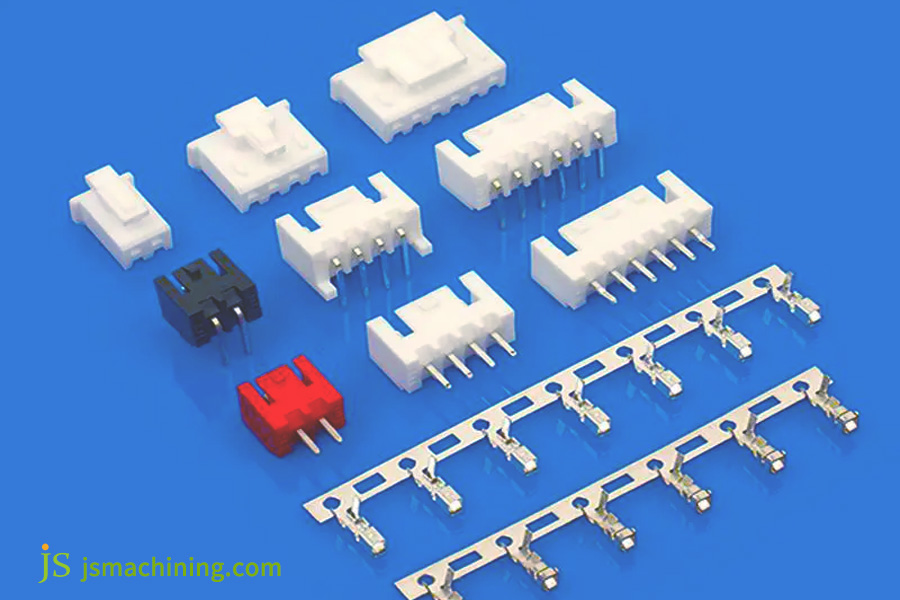

High toughness and strong moisture absorption require strict drying. | Universal functional components, connectors, wear-resistant shells. |

|

Fiberglass reinforced nylon

|

PA matrix+glass fiber (Enhance strength and rigidity).

|

Wear resistant nozzle with strong interlayer bonding.

|

Load bearing structures, automotive components, tool fixtures. |

|

Carbon fiber reinforced nylon

|

PA matrix+carbon fiber (Ultimate strength/conductivity/deformation resistance).

|

A high-temperature printer is required, and the surface of the finished product is slightly rough. | Aerospace components, sports equipment, electromagnetic shielding components. |

|

Flexible nylon

|

Special copolymerization modification (Retain toughness and increase elasticity).

|

Low temperature printing, difficult to remove support structure. |

Loose leaf hinges, shock pads, wearable devices.

|

This guide can help you overcome real-world challenges:

- We will unveil the true composition of nylon materials and compare the properties of four important classes.

- We will also cover some of the most important considerations for successful nylon 3D printing.

- Lastly, through an industrial clip failure example, you will observe how online 3D printing services can aid in matching materials precisely, preventing design errors, and providing absolutely dependable printing parts.

Why Trust This Guide? JS’s Polymer Engineering Insights

We understand that good nylon 3D printing is so much more than a question of modifying the print head temperature. The key is having the ability to anticipate the things that can destroy it: like nylon absorbing moisture and forming interlayer adhesion, adding fiberglass to the materials and speeding up print head wear, and how to use annealing (like controlling temperature when baking cake) to eliminate internal stresses. These conditions directly dictate the lifespan of your 3D printing parts and whether or not your investment is worth it.

This isn’t hollow rhetoric. Think of car clips that are subjected to continual impact, brackets that operate in heat engine compartments, and medical models that must be secure. We’ve created more than a thousand one-off 3D printing production runs. We’ve intimately understood the differential characteristics of various nylon materials, whether extruder-printed, laser sintered (SLS), or stereolithographed (SLA). This, where material science and know-how of procedure meet, is the key to avoiding pitfalls and minimizing waste.

“As Terry Wohlers, an authority on additive manufacturing, often emphasizes: The key to success lies in a deep understanding of the complex interplay between material properties and process.”

This is exactly what we do on a daily basis. This guide summarizes foundational knowledge tried and tested by our JS team in real applications with the aim to empower you to use nylon 3D printing more confidently.

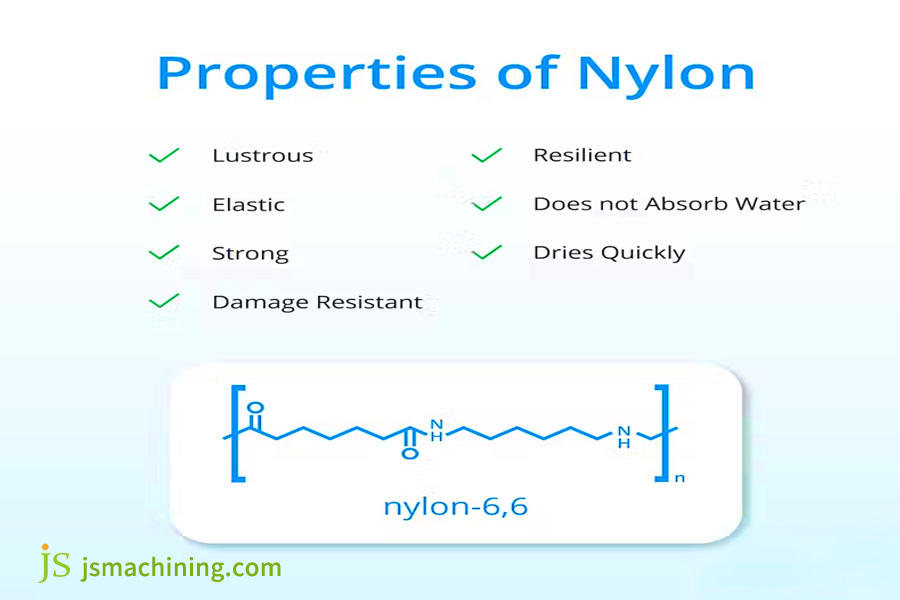

The Truth About Composition: Is Nylon Really 100% Plastic?

In our daily life material selection, customers will normally inquire about the composition of materials made of nylon. One of the most common myths is that nylon is “100% plastic.” Here’s this “composition fact”:

(1) Simple composition of nylon: Nylon is a synthetic polymer whose backbone consists of amide groups (-CONH-). In general terms, it falls squarely in the plastic category—simple and straightforward, it’s a plastic.

(2) The real scoop on pure nylon: From a chemical standpoint, pure nylon is almost 100% plastic (polyamide resin), but commercial products typically have minute amounts of additives, such as stabilizers, to render it more resilient. So, though it’s not completely “pure plastic,” the plastic content is overwhelming.

(3) The difference between nylon and modified nylon: While nylon is reinforced, say with the addition of glass fiber or carbon fiber, it becomes a composite material. The plastic in this case is only the matrix, generally 50% to 80%, and the remaining part is the reinforcement. It is no longer plain plastic any longer.

(4) Strength and heat resistance improvements and limitations: Such additives can create metal-like strength and thermal resistance in nylon. For example, 30% glass fiber achieves three times its strength. But a new problem arises, bond between layers gets weakened, and the material delaminates under load.

Four Major Nylon Families: From Basic Grades To High-Performance Variants

Here, I’ll describe the primary properties and primary use points of the four primary nylon material families employed in 3D printing. Don’t let the generic term “nylon” throw you. Different types of materials are rather distinct from one another. Selecting or using the wrong one can lead to warping of parts and scrapping at best, or even outright failure, like that drone gearbox that cracked after having absorbed moisture.

|

Nylon type

|

Core Features

|

Main shortcomings

|

Print key points

|

|

Basic Nylon (PA6/PA66)

|

Good wearability, toughness, oil resistance, and low price. | Moisture absorption rate>8%, temperature resistance<80 °C, rigidity somewhat soft. | Drying (>80 °C for >4 hours), the printing environment has to be kept constant to prevent warping. |

|

Reinforced nylon (with fiberglass/carbon fiber)

|

Fiberglass addition (PA+GF30) provides high rigidity and heat resistance. Carbon fiber addition (PA-CF) provides enhanced strength and conductance. | The intensity directionality is evident, the nozzle is very abrasive, surface is hard and can be brittle. | Use hardened steel nozzles to optimize direction. |

|

Flexible Nylon (TPE/PA, PEBA)

|

Flexible enough, fatigue bend resistant, and not brittle at subzero temperatures. | Low strength and thermal resistance as well as bad interlayer adhesion after printing are common defects. |

Printing very slow, fan off, hot bed adhesion.

|

|

High performance nylon (PPA, PA12T)

|

Ultra temperature resistance (>200 °C), chemical corrosion resistance, and very low water absorption. | The price is expensive, and printing temperature is very high (>350 °C), which cannot be accommodated by regular desktop computers. |

Printing temperature>350 °C, special coating.

|

While the table might seem intuitive, having an idea of what is behind it is more important:

Ordinary nylon (PA6/PA66) is cheap and offers adequate toughness and is a good all-round material for general everyday use. Its water exposure is the one major weakness. If not dried out or allowed to be moist, part strength and size will be weaker and distorted, like water-logged ones.

Where higher strength or heat resistance is required, such as for structural items or near sources of heat, reinforced nylon is helpful. Glass fiber does the job of stiffening parts and rendering them heat-resistant, while carbon fiber adds additional strength with conductivity (anti-static). Drawback is that it feels like sandpaper on printing, creating a more directional-oriented and rougher surface, requiring post-processing.

If you require rubbery elasticity, flexible nylon is the choice.It is resistant to bending and easy to print at low temperatures, but almost loses all of its strength and heat resistance. The most challenging hurdle to overcome while printing is poor adhesion between layers, which requires slow printing, warm temperatures, and a high-powered hot bed.

Finally, we have the “master” of hostile environments——high-performance nylon. It can endure temperatures above 200°C, doesn’t chemically corrode, is dimensionally stable, and absorbs almost no moisture. Unfortunately, its cost and extremely high printing temperatures (above 350°C) make it impractical to use with anything less than a professional-level industrial 3D printer.

Choosing the best nylon can dramatically increase your rate of printing success. For uncomplicated, high-quality outcomes, send us a try at our online 3D printing services. Professional help guarantees outcomes, and speak with JS for a customized solution!

Advanced Practice: 5 Advanced Techniques For Nylon 3D Printing

When I’m printing daily, I fight the nylon 3D printing problems all the time. Today, I’ll share with you five useful tips on how to prevent mishaps. Remember that nylon printing is a question of careful control, or else deformation or delamination can occur at ease.

(1) Dehumidification is important: Don’t mess around with raw materials!

Nylon is a “water-sucking sponge”! After opening, the raw material must be placed in a dry oven (humidity <0.1%). During printing, material tube and hopper must be purged with dry air or nitrogen. Don’t skip this! High humidity will jeopardize the adhesion between layers, so printed part will disintegrate when subjected to stress.

Performance variation in printing nylon (PA) with varying humidity

| Materials & Environmental treatment | Tensile strength (MPa) |

Interlayer bonding strength (MPa)

|

24-hour water absorption rate (%)

|

Examples of applicable industrial scenarios

|

|

PA6, Drying treatment (<0.1%)

|

82 | 21 | 1.2 |

High dynamic load gears and connectors.

|

| PA6, Normal environment (50% RH) | 58 | 8 | 3.5 |

Easy to fail, do not recommend load-bearing components.

|

| PA12, Drying treatment (<0.1%) | 50 | 18 | 0.8 |

Fluid components, wear-resistant bushings.

|

|

PA12, Normal environment (50% RH)

|

40 | 7 | 2.0 |

Unstable size, use with caution.

|

|

PPA, Drying treatment (<0.1%)

|

95 | 25 | 0.5 | High temperature engine hood components and electronic connectors. |

Dryness can vary strength by over 40%! Contrast between interlayer bond strength is even more extreme. If you want to print functional industrial-grade nylon 3D printing parts, dehumidification is the beginning and most important!

(2) Thermal management with care: Don’t use the fan!

I always recommend deactivating the cooling fan, as the nylon will crack and shrink if cooled too quickly. Keep the print chamber temperature as stable as possible between 70-90°C and allow it to cool down slowly, lessening stress. Keep the heated bed between 110-140°C, or the first layer will never adhere and warping will have you suffer in the middle of the print.

The nozzle temperature should be correct too: 240-260°C for PA6, 240-250°C for PA12, and 350°C or higher for PPA. 5-10°C variation in temperature will alter fluidity and crystallinity, and therefore strength.

(3) Adjust parameters slowly: Don’t rush!

Print the first layer slowly (less than 20mm/s). Half the battle is having a good bond to the base. 40-60mm/s speed is fair, too fast will not achieve enough heat, causing a poor adhesion.

Increasing the layer height to 0.2-0.3mm will add strength. A small extrusion width increase to, for example, 120-130% of the nozzle diameter will allow the lines in adjacent position to be squeezed tighter together, resulting in a stronger junction.

(4) Don’t leave out post-processing: soaking or annealing.

After printing, do moisture balance: Is your newly printed object dry and brittle? Soaking in warm water (or steam) allows the nylon to absorb a small “safe moisture” and harden up again. The toughness increase is significant.

In annealing, keep the temperature 10-20°C below the material melting point and hold it for a while. This process can significantly reduce printing stress.

Finally, spray an industrial finish (e.g., epoxy or polyurethane) or impregnate it to seal off the micropores on the surface and prevent any moisture from entering. This will double the life of the part.

(5) Design Smart: Avoid Sharp Corners

Corners should be rounded. Sharp corners are stress concentration points and are a favorite starting point for cracks. Be sure to add rounded corners (R-edged corners)!

Nylon has lower rigidity (stiffness) than ABS or PLA, so avoid designs that are too “thin.” Add thickness and reinforcement where necessary to prevent sagging or deformation during use.

Nylon expands slightly when it absorbs moisture (especially PA6). For areas requiring precise fit, allow for some expansion margin (e.g., 0.3-0.5%) during design to prevent moisture from absorbing and causing the parts to become stuck and unable to fit.

These pointers can help greatly enhance the quality of nylon prints. Call JS today and let us assist you to tailor a solution to produce dependable 3D printing parts with you!

Practical Case Study: From Failure To Excellence – The Rebirth Of Nylon In Heavy-Duty Industrial Clips

Now, I’d like to share a personal anecdote from our team. We’ve transformed a factory’s breaking nylon clips into robust, steel like product through custom 3D printing manufacturing. What a total turnaround from failure to excellence!

Customer Problem:

One of the automated production lines of a factory had a critical issue. A critical nylon clip on a fixture was failing after an average of just two weeks, resulting in excessive downtime and tremendous losses. The customer had previously attempted quick design iterations and replacement parts using online 3D printing services, but the failure issue continued. They presented us with a box of failed clips, in urgent need of a solution that would actually withstand the stresses, and quickly!

JS’s In-Depth Analysis:

Upon receiving the broken clips, we immediately conducted a diagnosis:

(1) Improper material selection:

The original clips were normal PA6 nylon. This material has a fatal defect—it readily absorbs water (the water absorption rate can exceed 2.5-3%). Once it has absorbed water, it becomes extremely brittle (its impact toughness is reduced by over 50%), so it is unable to withstand the fixture impact.

(2) Printing process defects:

Earlier fast printing solutions had many problems. The material was not completely dried before printing (moisture content might be more than 0.2%), so a weak bonding between layers occurred, like loose glue.

In the absence of a constant temperature chamber while printing, the parts heated and cooled non-uniformly and deformed after printing with lots of internal damages (residual stress).

JS’s “rebirth” plan:

(1) Upgrading the “core”:

Effectively phased out PA6 and opted for PA66 with 30% glass fiber (PA66-GF30). The product boasts higher strength, higher stiffness, better heat resistance, and better dimensionally stability. Not least, it’s less water-sensitive (moisture absorption rate <1.5%) and intrinsically more impact-resistant.

(2) Strictly Controlled Manufacturing:

With our in-house, industrial-grade 3D printing equipment:

- Material is sealed and dry throughout the entire process, including storage to print head (with less than 0.05% moisture content at the time of printing).

- Print chamber is maintained at a stringently constant temperature of 80°C, allowing parts to slowly “set” in a manner similar to the warm environment, preventing deformation and stress that occurs internally.

- A wear-resistance harder nozzle is utilized in an effort to provide accuracy and consistency of the print.

(3) Optimized Ribs:

Building on the existing design, we added ribs to significant stress-carrying regions and rounded off all razor-sharp corners to reduce uneven stress distribution and localized collapse.

(4) Eliminating Hidden Dangers:

After printing, the parts undergo a constant-temperature annealing treatment, like a deep “SPA” treatment, completely releasing any residual internal stress.

The result: a leap in lifespan from two weeks to a year

The moment this solution was implemented, the result became clear instantly. The customer’s production line was finally rid of its “clip-on nightmare”.The new clip’s lifespan jumped to over 12 months, eliminating production downtime. The customer saved on repairs and downtime, and doubled their productivity.

This case demonstrates that resolving industrial component failure requires more than simply redesigning the design. A thorough understanding of material properties and a precise matching manufacturing process chain are essential. By utilizing engineering-grade materials and rigorous custom 3D printing manufacturing processes, we have increased the lifespan of a small part by dozens of times, effectively ending our customer’s costly production downtime nightmare.

If your production line is also plagued by critical plastic component failures and downtime, don’t worry! Contact JS engineering team to identify the root cause and help you resolve the issue thoroughly!

FAQs

Q1: Nylon performance drops after it has absorbed moisture. Is it still usable?

JS has discovered that nylon performance does drop after it has absorbed moisture, yet it remains completely usable.

The trick is to actively control moisture: First, make sure that the raw material is completely dry before printing; second, it is best to condition the printed parts prior to use.For extremely critical components, we prefer to print with nylons such as PA12 or PPA, which are less absorptive in nature, or seal the surface of the part for added precaution.

Q2: Why is 3D printing nylon so costly, primarily?

We’ve found that in 3D printing nylon, if the temperature fluctuates over 5 degrees Celsius, it can readily cause delamination between layers, which has a direct influence on the weakening of the part’s strength. The primary function of a closed chamber is to insulate and stabilize the temperature in order to ensure the strength of the printed part.

Q3: What are the main reasons for the high cost of nylon 3D printing?

The high cost of nylon 3D printing is caused by several factors:

- First, the material. High-quality nylons like PPA or carbon fiber nylons are significantly more expensive than standard PA6.

- Second, the printing process is difficult, requiring specialized drying and moisture-proof equipment, a consistent temperature chamber, and heat treatment after print, all of which increase equipment and electricity costs.

- Additionally, the more complex the part geometry, the more supports, and the longer the print, the higher the cost.

- Finally, fiber-reinforced materials are nozzle-killers and degrade quickly.

However, for a specialized factory like ourselves, mass production can help spread out the cost per part.

Q4: Is it possible for nylon 3D-printed parts to be as strong as injection molded parts?

In our real-world testing, the strength of 3D printing nylon components is actually less than injection molded components.

- Components produced using the SLS process can achieve close to the strength of injection molded components, at about 80% to 90%.

- Components produced using the FDM process tend to have reduced strength, at only about 70% to 80% of the strength of injection molded components.

Summary

Nylon is actually more than a commodity plastic. It is a family of materials with very different properties. Succeeding in 3D printing parts with it requires a good knowledge of additives, selecting the right specific materials, and closely controlling the print process. Failure to respect its water absorption, temperature control, or the principles of material modification can lead to part failures and durability issues, which ultimately generate a loss of confidence in the material. To successfully use engineered nylon, these specifications are essential.

Call to Action:

- Are material selection or process instability issues? If your nylon components suffer from variable performance or recurring print failure, don’t spend money on trial and error.

- Contact JS for comprehensive solutions: Our professional online 3D printing services is provided by our deep understanding of materials. We handle everything from helping you select the most suitable nylon material and optimizing your design for printing to custom 3D printing manufacturing at an industrial level.

- Performance and value: We assist your engineered nylon parts in reaching their full potential while having open 3D printing price. We ensure you receive every cent’s value of your investment.

Reach out to us today for a customized material solution and a quote!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Classification Of Filament Used In 3D Printers - JUSHENG