When choosing a metal 3D printing technology, customers would prefer to know: Is it better to use SLS or SLM? These technologies are generally placed side by side, especially if they are going to generate complicated geometries, create lightweight parts, or 3D printing parts that can withstand hostile environments. Even though both technologies use lasers to process powder, the essence of the difference includes sintering and melting:

- SLS uses high-temperature sintering to fuse the powder together, which makes it suitable for nylon and other alloys, and parts can incorporate controlled porosity.

- SLM, on the other hand, uses full melting to create high-density pure metal parts, such as titanium or aluminum.

Simply put, if your product is an alloy, then SLS is more appropriate. If you desire a pure metal part with similar performance, use SLM. Being aware of this difference will allow you to better suit your needs.

Core answer summary:

| Comparison aspect | SLS (Selective Laser Sintering) |

SLM (Selective Laser Melting)

|

| The essence of technology | The laser heats the powder material to a “sintered” state just below the melting point, and the particles fuse together. | Laser completely melts metal powder into a liquid state, forming a completely dense molten pool. |

| Applicable materials | Mainly used in polymer materials such as nylon and TPU, and can also be applied to a few metals/ceramics. | Almost exclusively used for metal materials such as titanium alloys, aluminum alloys, nickel based high-temperature alloys, etc. |

| Part performance | Porous structure with isotropic mechanical properties, but lower strength and density than the melt. | Completely dense, with mechanical properties that can reach or even exceed the level of traditional forgings. |

| Accuracy and surface | The surface is relatively rough and has a “gravel like” texture, usually requiring post-processing. | Higher precision and smoother surface (but still requires post-processing to achieve high smoothness). |

| Support structure | No need for support! Unsintered powder is a natural support with extremely high design freedom. | Supporting structures must be added to resist thermal stress and anchor the parts, and post-processing needs to be removed. |

| Cost and efficiency | The material cost is relatively low, the chamber can be completely filled, and the cost advantage of mass production of individual pieces is obvious. | The high cost of equipment and materials limits the layout density and results in high unit costs. |

Why Should You Trust This JS Guide?

At JS, we run these machines on a day-to-day basis to produce parts for our customers. As an example, using the selective laser sintering process on nylon, nylon 12 parts consistently exceed 45 MPa, approximately the same pressure-bearing capacity as an aluminum alloy wheel. More importantly, the performance of parts produced from different batches is virtually the same with a success rate that exceeds 98%. That consistency is important to us.

“Dr. Carl Deckard, a pioneer in SLS technology, once said: ‘The true value of this process lies in the reliability and consistency with which it translates digital models into physical objects.'”

We’ve acquired a lot of production experience, and hence we know quite well the reputation of SLS when it comes to producing high-performance plastic components. Although SLM excels at metal printing, in the case of engineering plastics like nylon, SLS is superior both with respect to material availability and process maturity. If you’re looking to make robust and tough non-metal parts, SLS is a proven technology.

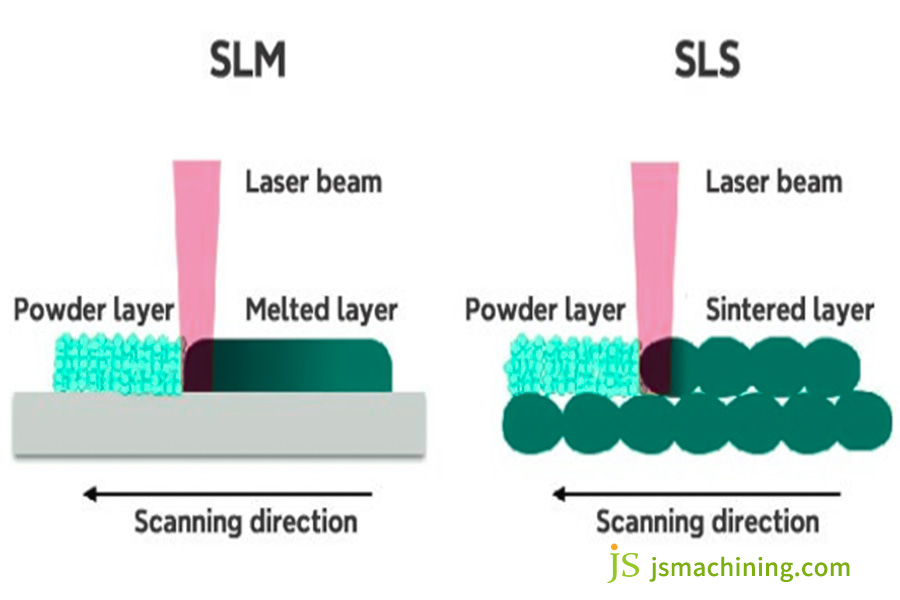

Technical Exploration: The Physical Gap Between Sintering And Melting

In our view, even though both SLS and SLM make use of lasers to create objects, their fundamental distinctions have a direct bearing on the different 3D printing parts they can produce.

SLS: The Delicate Art of “Sintering”

SLS is really just a sophisticated “heat bonding” process. The laser heats particles of material like nylon selectively to the extent that they just weld together, but not completely melt. This results in lower internal stress and improved toughness, and is well suited for complex structures requiring some flexibility and strength.

SLM: The Ultimate Science of “Melting”

SLM has an entire “melting and re-shaping” procedure. It uses a high energy laser to melt fully metal powder, with dense metallurgical bonding being formed when it solidifies. The produced metal parts are extremely strong, the performance being extremely close to or even as equal to forgings, perfectly applicable to manufacturing of high-load metal functional components.

For durable metal parts, apply SLM, for abrasion-resistant nylon parts, apply SLS. If there are specific project specifications, please don’t be shy to consult JS engineers so that we can find the best match for the most suitable process for you.

Hardcore Performance Showdown: Precision, Strength, And Materials

In our daily custom 3D printing manufacturing services at JS, clients often ask: “Other than the materials, how do SLS and SLM differ in performance?” This has direct relevance to the success of your product.

Material Range: What materials can SLM print that SLM can’t?

The greatest distinction is that SLM focuses almost exclusively on the metal world. It can process “hardcore” materials like high-strength aluminum alloys and titanium alloys, and even high-end materials like cobalt-chromium alloys and nickel-based superalloys used in aerospace and medicine. These are materials that SLS’s nylon powders cannot match.

Simply put, if you need load-carrying, heat-resistant, or biocompatible metal functional parts, SLM is the best choice.

Mechanical Performance: Are you looking for ultra-strength or overall robustness?

That is the gist of it. Through complete melting of the metal, SLM can produce parts that have a density of more than 99.9%, and strength and hardness that are nearly comparable with traditional forgings, so that they could be utilized directly for final product functional testing. The advantage of SLS printing nylon parts is that they have a high impact strength and toughness, which makes them more resilient to impact and tumble, and hence suitable for movable hinges, housings, or complex snap-fit components that require minute deformation.

|

Performance metrics

|

SLS (Nylon PA12) | SLM (Aluminum Silicon 10Mg) |

SLM (Stainless Steel 316L)

|

Test Standard |

| Tensile strength (MPa) | 48 | 345 | 580 | ASTM E8 / ISO 527 |

| Tensile elongation at break (%) | 20 | 8 | 35 | ASTM E8 / ISO 527 |

| Hardness | Shaw Brothers D 75 | Brinell HB 95 | Brinell HB 215 | ASTM E384 |

| Impact strength (KJ/m²) | 40 | 12 | Not applicable | ISO 179 |

Data Source: MMC, 2023 Report

Accuracy and Post-Processing: The Final Step to the Finished Part

Both processes can produce high-accuracy parts, but they do so in differing ways. SLM metal printing requires support structures to withstand the high thermal stresses. It is a challenging task to remove those solid metal supports in post-processing and can affect efficiency. Because of the support provided by the surrounding powder, SLS requires virtually no specialized support structures. Once the part is removed, it is possible to achieve a good surface finish through sandblasting or other treatments. It offers excellent advantages while machining complex internal flow channels and other features.

I hope the above comparison will help guide you on your way. The choice of which process to use depends entirely on the problems your final part will solve. If you have some design requirements, feel free to contact JS, our engineers will be happy to provide technical advice.

Application And Economics: How To Choose?

Today, I will reveal how to choose between Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) based on key issues such as material properties, industry uptake, and production economics.

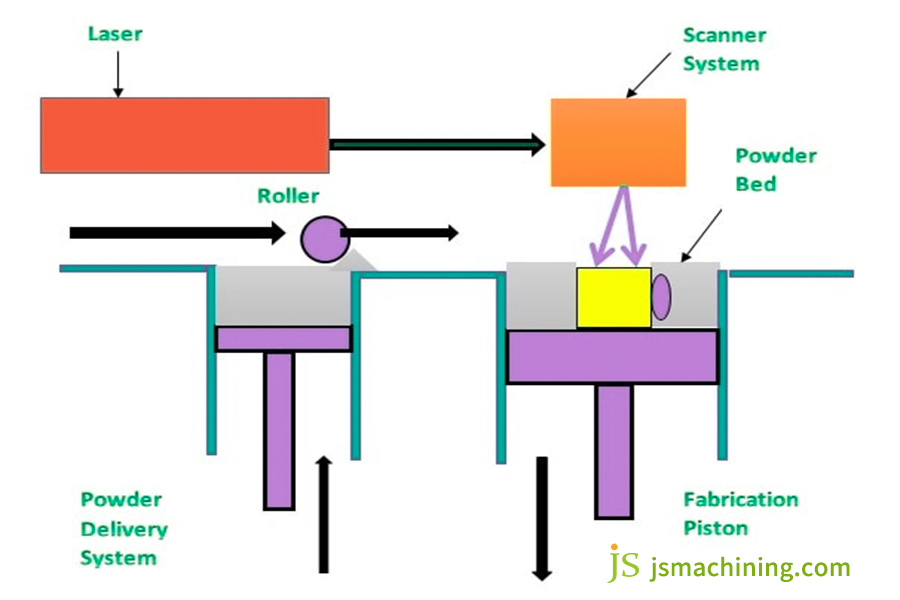

SLS’s Achilles’ Heel: Material Aging

Selective laser sintering technology uses a laser to sinter plastic powders, such as nylon, layer by layer. One of the main advantages is that it does not require supports during molding, the powder bed itself supports the part, which makes it extremely suitable for complex structures. This sintering process does create very small pores in the part, so. The most challenging aspect this creates is the long-term degradation of the performance of materials—especially under constant external stresses or in hot and humid environments, where the part can gradually become brittle or warp. We call this “aging”.

For example, an SLS nylon gear installed in equipment for years may experience a decrease of several percentage points in fatigue strength each year. This is a challenge for long-term, high-demand applications, and something we always consider when selecting a model for clients.

Industry Preference: SLM vs. SLS,Which is More Popular?

In fact, there is no “preferred” approach in the industry, each manufacturer determines what they need.

SLM is used primarily on metals, such as titanium and aluminum alloys. It is intended to create components with near-100% density and mechanical properties comparable to forgings. Accordingly, SLS is used primarily in such applications as aerospace and medical implants, where ultimate performance and reliability are needed.

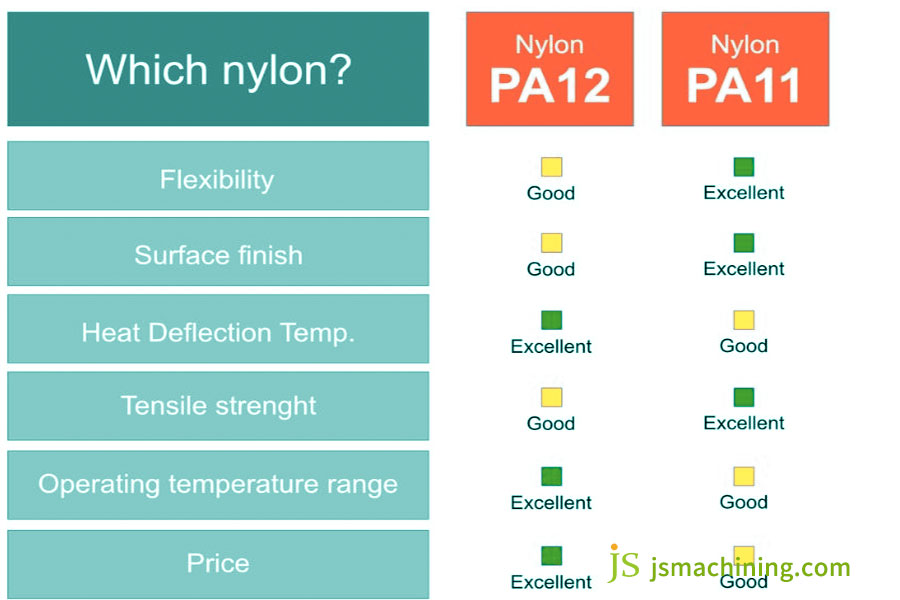

SLS primarily aims at engineering plastics such as nylon (PA12 and PA11). It is ideally suited for functional parts that do not require ultimate strength but require light weight, moderate toughness, and rapid prototyping. Examples include automotive pipe brackets and consumer electronics housings for prototypes. Due to its lower cost and higher efficiency, it has wide uses in consumer products, automotive prototypes, and small-series end-use parts.

Market feedback shows that SLM is more popular in heavy industry and the medical sector. In contrast, SLS is more popular in sectors like consumer goods and automotive components because it is less expensive and has a quicker prototype speed.

Why is SLS better adapted to small-batch production?

Our team has found that SLS technology is particularly well-suited for small-batch production.

Its greatest benefit is that it does not require the use of a mold, thereby eliminating the costly mold expense and lengthy waiting period of traditional production. SLS is able to print any complex structure directly, and a great number of parts can be closely grouped together while they are being printed, completing a batch at a time. This creates high material utilization and almost zero waste.

This is particularly well-suited for projects in which customers would need to quickly review designs or minute-scale trial production. Even during production half-way through, design changes only mean changing the model file, something that is highly flexible and convenient. We now provide this flexible and efficient manufacturing method to our clients through online 3D printing services, which are particularly in demand by R&D and small batch production teams.

Whether to choose SLM or SLS depends on your application: Do you need super-high strength metal parts or flexible and resilient plastic parts? If you are considering creating small batches of functional parts, SLS might be a cheaper route. Feel free to get in touch with JS to discuss the best solution for printing on you.

How Does SLS Help Top Sports Cars Revolutionize Traditional Braking Systems? JS’s Case Study

Client Problem:

A premier sports car manufacturer, in the design of a new concept vehicle, wished to completely remake the brake pedal assembly—a lighter, heat-dissipating solution. The existing CNC machining process was not only time-consuming and expensive, but also missing the one feature they desired: internal conformal cooling channels. Braking system temperatures soared under intense racing, especially on the track, and traditional manufacturing methods simply weren’t able to keep pace with the heat dissipation required.

JS’s approach:

We recommend using Selective Laser Sintering (SLS) technology, with glass-fiber-reinforced nylon. The most significant benefit of this technology is the lack of support structures, allowing us to freely design very complex internal geometries. We’ve incorporated a lightweight honeycomb pattern within the pedal, which gives rigidity without weight, actually saving over 40% in weight. Additionally, the internal void has been optimized for airflow, which improves heat dissipation significantly.

What were the actual results?

We printed and nested four pedals at once in a single print job, with a total make time under 48 hours. The ultimate 3D printing price per part was only a fifth that of CNC machining. The part passed all bench tests with flying colors and was among the technical showstoppers of the entire concept car.

If you would also be interested in seeking cost-saving, high-performance, and quick-delivery component solutions, please let the JS team know. With the 3D printing technology, we can help you realize a win-win situation between innovation and mass production.

Selection Guide: Should I Use SLS Or SLM?

In my work, many clients inquire from me the following: How do I choose between SLS and SLM 3D printing technologies? The decision is entirely based on your application context and material requirements. As a JS engineer, I can help you understand this from a practical perspective:

|

Consideration factors

|

SLS (Selective Laser Sintering) |

SLM (Selective Laser Melting)

|

|

Cost

|

Very low, the material can be reused and partially recycled. | Higher relative equipment and material expense, best suited for mass-producing small quantities of high-performance parts. |

|

post-processing

|

The surface is relatively rough and can require polishing or coating. | Normally, the support structure has to be removed and heat treated to release stress. |

| Material Type | Mainly suitable for plastic powder materials such as nylon. | Mainly used in metal powders, such as aluminum alloys, titanium alloys, etc. |

|

Strength and performance of parts

|

Good strength, high heat resistance, anti-friction, suitable for functional prototypes and complex structures. | High strength with a density that is almost similar to forged parts and best suited for load-bearing or high-temperature conditions. |

|

Applicable scenarios

|

Suitable for making prototypes or 3D printing parts with complex structures and with some hardness. | Best utilized for the manufacturing of high-demand locations such as metal functional parts, molds, or aerospace. |

If you’re creating functional plastic prototypes, small batches of complex structural parts, or don’t require extreme strength, SLS is more economical and practical. However, if you’re manufacturing metal parts subject to high loads and high temperatures, SLM, while more expensive, is a more reliable option.

If you are still in doubt about which technology to utilize, do not hesitate to contact the JS team. We will evaluate your requirements and recommend the most suitable printing solution to bring your product to market quickly and efficiently.

FAQs

Q1: Can SLM technology completely replace traditional CNC machining?

Currently, SLM cannot completely replace traditional CNC machining. It excels at producing complex shapes, integrated parts, or lightweight parts with lattices. However, CNC remains more reliable in terms of efficiency, surface quality, and precision for processing large, simple parts. In practice, we often combine them depending on the needs.

Q2: Can SLS technology print metal?

Yes, but it is not direct metal melting SLM. We prefer to use indirect metal SLS, first printing the part prototype with a binder-doped metal powder, then we debind and sinter to have a dense metal part. Its process is longer, and its general performance is generally worse than SLM.

Q3: Are SLS parts really brittle?

Obviously not. Our SLS parts, printed in high-quality PA12 material, can actually be more than 50 MPa strong and exhibit excellent toughness, fully meeting the requirements of most functional prototypes and end-use non-metallic parts. But there is a big difference in performance with metal 3D printing dense parts, and their application scenarios are different.

Summary

According to me, SLM and SLS are not mutually exclusive of each other, but a “golden partnership.” Each of them is good, and the choice is yours based on your project requirements.

For example, SLS, a technology that does not require support structures, is extremely well-suited to produce intricate, light non-metallic parts at an affordable price. SLM, on the other hand, excels in producing strong metal parts, even surpassing conventional methods. Having the right technology can translate into making the real 3D printing potential.

Confused about which process is best for your product? Talk to us. The JS team offers free technology selection guidance and custom 3D printing manufacturing trials to help you quickly validate your ideas and advance your project. After all, practice makes perfect, you’ll find out.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com