In our workshop, you can often see the same beam of laser doing seemingly contradictory things: One minute it is painstakingly cutting its way through thick steel plates to create the machine’s chassis. With a snap of the fingers, it can be diverted to the most delicate mode, precision cutting refined designs such as lace onto thin paper, like those elegant wedding invitation cards.

It is no magic button. The secret is our precise control of the laser energy density – concentrate it to burn steel plates, and disperse it thin to avoid damaging such sensitive paper.

It is this ability to adapt to energy density that makes laser cutting the most important core technology to us, from hardest metal to the softest thin paper. This handbook would like to describe how we do it in our daily life, why this technology is so vital to cutting these rather diverse materials, and offer some real experience.

The key: a clear answer table

| Comparison Aspect | Laser Cutting Metal | Laser Cutting Paper |

| Core principle | Melting/Vaporization: A high-energy beam instantly heats the metal to its melting or boiling point and blows away the slag with an auxiliary gas. | Vaporization/Ablation: A precisely controlled low-energy beam instantly vaporizes paper fibers with almost no heat conduction. |

| Required laser type | Mainly fiber lasers, with concentrated energy and high metal absorption. | Mainly CO ₂ laser, the wavelength is more easily absorbed by organic materials such as paper. |

| Key parameters | High power, medium speed, high-pressure auxiliary gas (such as nitrogen to prevent oxidation). | Low power, high speed, low-pressure air assist (blowing away smoke and dust to prevent combustion). |

| Main advantages | Fast speed, smooth incision, small heat affected zone, no need for molds, capable of processing complex contours. | Extremely high precision, no physical contact (no deformation), able to achieve any complex pattern, clean edges. |

| Typical applications | Mechanical parts, automotive panels, metal signs, chassis shells, building decorations. | Card invitations, packaging models, artworks, hollow templates, fashion designs. |

Why Should You Trust Our Cutting Suggestions? Deep Laser Cutting Experience From The JS Team

Having worked in laser cutting for more than 20 years at JS, I know clearly that real technology is far more than just being able to operate the machine. Being able to press the button to operate the machine is just the beginning. The real ability is hidden in the sparks of each cutting.

“As Einstein reminded us, theory without practice is powerless.”

Our ability is cut out. We have processed countless materials (thick carbon steel, stainless steel, aluminum, acrylic and even thin paper), solved countless problems, and understood the characteristics of each material when heated. This is our core ability: Based on a solid understanding of physics and accumulated cutting data, covering high-power metal cutting to ultra-fast laser precision processing, with a stable accuracy of ±0.01mm. This is not out of thin air, but the real skills accumulated from countless projects and countless debugging.

When we see complex laser cutting parts drawings, we don’t just cut them according to the instructions. We look deeper: How much does this cutting method affect efficiency? How to control costs? Can the final quality be guaranteed? Our goal is very practical: to cut cleanly and neatly, so that you can save time, materials and output more. Every time we press the start button, behind it is the confidence and grasp we have accumulated for more than 20 years.

Whether you are cutting hard steel plates or delicate paper art, we strictly abide by safety regulations and international standards such as ISO and CE to ensure that every cut is stable and reliable. This is the source of your trusted industrial-grade solutions.

What Is Laser Cutting? A Quick Overview

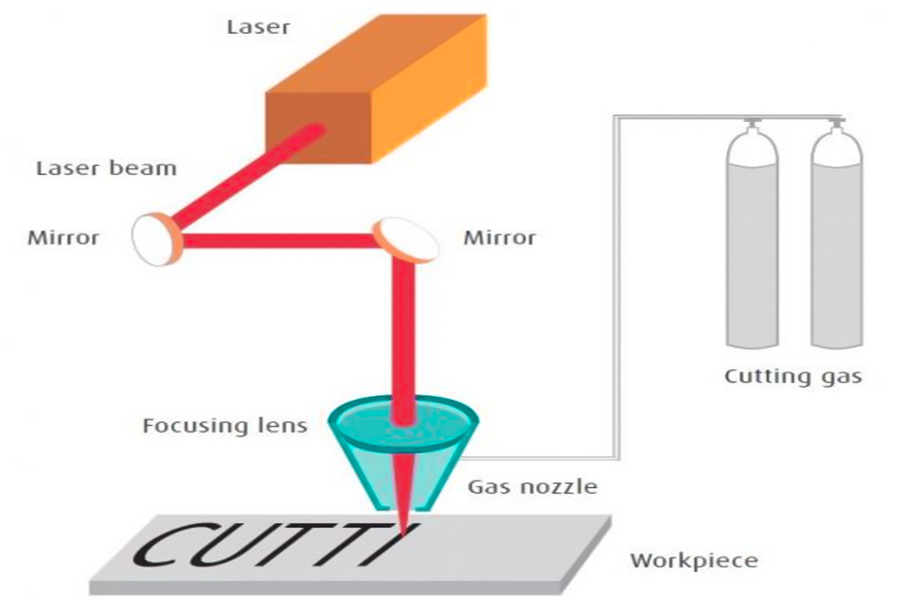

In simple terms, it uses a very strong and fine laser beam, like an invisible “hot knife”, to precisely cut materials. This “knife” does not directly touch the material, but relies on heat processing.

How does it work specifically?

First, the laser generates the beam of light, and then focuses it into a very small point through a lens group, which hits the material you need to cut. This beam of light has extremely concentrated energy and extremely high temperature, which can melt or vaporize the material in an instant. At the same time, a stream of auxiliary gas follows the laser beam, like a small hair dryer, blowing away the melted or vaporized material residue from the cut, and the cut is made.

What is its core capability?

It’s like having an extremely precise power knob. We can finely control the intensity of the laser output energy like adjusting the volume. This programmable energy output allows us to use the same device to cut through thick steel plates and carve patterns on fragile paper, achieving truly precise processing.

The Science: How One Technology Masters Both Worlds

Let me talk about the core of laser cutting – control. The cutting process is not about who has more strength. The key is to accurately master several key parameters like tuning a musical instrument, and “tailor-made” cutting solutions for different materials:

(1) Power: High power is required to cut 20mm thick steel plates. For cutting 0.1mm delicate paper sculptures, the power must be adjusted to be as gentle as “simmering fire” (low power), otherwise, it will burn through in an instant.

(2) Speed: When cutting thin paper or film, it must be cut quickly. If it is slower, the heat will accumulate and burn. Cutting thick metals should be slower, and the laser must be given some time to “eat” through the material.

(3) Frequency (Pulse Laser): This is a secret weapon for dealing with sensitive materials. It uses high-frequency short pulses, like a dragonfly touching the water. Each action time is extremely short, which greatly reduces the heat transferred to the material, and the edge of the cut is smooth and not black.

(4) Assist Gas: This is not just blowing air! When cutting stainless steel, spray high-pressure nitrogen to isolate oxygen, and the cut is bright white without oxidation. When cutting paper or acrylic, gentle compressed air gently brushes away smoke and debris in time to avoid yellowing or melting edges.

Different materials have very different control limit requirements:

| Material type | Current industrial grade stable processing thickness range |

Typical machining accuracy (tolerance)

|

Key control challenges |

| Carbon steel (S235) | 0.5mm – 40mm+ | ± 0.1mm or ≤ 0.1% plate thickness | Slag adhesion, heat affected zone (HAZ) control, slag hanging. |

| Stainless steel (304) | 0.1mm – 30mm | ± 0.05mm (thin plate) | Oxidation control (requires nitrogen), thermal deformation, burrs. |

|

Aluminum alloy (6061)

|

0.2mm – 25mm | ±0.1mm | High reflectivity (requiring special wavelengths/parameters), remelting of molten aluminum, burrs |

| Polypropylene (PP) plastic | 0.5mm – 12mm | ±0.2mm | Melting rather than gasification, edge control, and smoke adhesion. |

| Advanced cardboard/art paper |

0.05mm -5mm (multi-layer stacking)

|

±0.15mm | Thermal damage (carbonization, yellowing), smoke pollution, material warping. |

| Titanium alloy (Grade 5) | 0.5mm – 15mm | ±0.08mm | High activity (requiring argon protection), HAZ embrittlement, and incision quality. |

Data source: TRUMPF Process Reports, Bystronic App Notes.

Laser Institute of America (LIA) Publications.

ESAB Fine Cutting Case Studies, Trotec Material Database.

This deep understanding of control and database accumulation is the core advantage of JS. It allows us to efficiently and reliably turn your design into reality through the online Laser cutting services platform. Whether it is a micro titanium alloy part or an artistic paper sculpture, we can accurately control and ensure consistent quality.

Laser Cutting Metal: The Powerhouse Of Fabrication

Among materials to laser cut, I prefer laser cutting when dealing with metals such as stainless steel, carbon steel, aluminum alloy, brass and titanium because it is so important. Why? Let me explain to you:

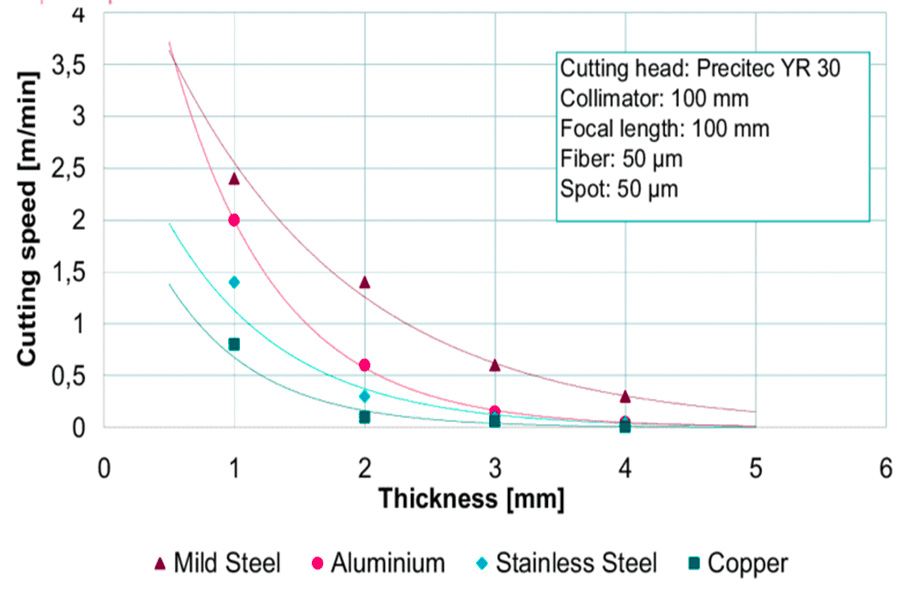

(1) Leading efficiency (for medium and thin plates): Compared with traditional mechanical cutting, the speed advantage of laser cutting is very obvious, saving a lot of time

(2) Excellent precision and surface quality: It can obtain an extremely vertical cut and a smooth cut surface, usually without the need for additional grinding or finishing. Save the trouble of secondary grinding.

(3) Flexible adaptation to production needs: We don’t have to spend a lot of money to make stamping dies. We can start work with a CAD drawing, which can perfectly handle small batches, multiple types or custom orders.

(4) Unrestricted design capabilities: It can easily achieve sharp corners, narrow gaps and complex curved contour designs that are difficult or even impossible to handle with traditional processes.

Laser cutting material technology is our key technology to improve production efficiency and cost-effectiveness and realize complex and high-quality workpiece manufacturing.

Laser Cutting Paper: The Artist’s Delicate Touch

Let me talk about why laser on paper is a tool for artistic creation and fine processing, focusing on three points:

(1) Precision beyond imagination:

Our equipment can stably cut lines with a width of 0.05mm to 0.1mm, which is thinner than most people’s hair (about 0.07mm). This kind of precision is completely impossible to make complex hollowing on cardboard or art paper, such as extremely fine patterns or tiny text, with traditional knife molds. We have tested that the limit of manual engraving is about 0.3mm, and it is very easy to make mistakes, while laser can easily break through this limit.

(2) True “pressure-free” contact:

The laser head does not touch the paper surface, completely avoiding indentation, tearing or deformation. This is especially critical when dealing with thick cardboard (more than 300 grams) or fragile paper (such as parchment), where traditional methods are prone to dents or even cracks. The finished product of laser cutting is flat, with a deviation of less than 0.2mm, making post-processing easier, and the yield rate is stable at more than 90%, significantly reducing rework.

(3) There are practical ways to overcome the problem of burning:

For the problem of paper cutting being easy to burn black, we have found an effective method: the key lies in precise control of heat. Use low power (such as 10-15W) + high speed (more than 600mm/s) + strong air blowing (air pressure is adjusted as needed, such as 0.8~1.2 Bar). Low power reduces heat accumulation, high speed shortens the action time, and strong airflow takes away the melt and heat in time. After this treatment, more than 98% of the cutting edges are clean and neat, with almost no yellowing or carbonization.

Laser on paper relies on these three points – ultra-high precision, non-destructive contact and effective anti-burning strategy, becoming JS’s core solution to solve the problem of fine art processing and efficient production. Customers are particularly satisfied with high-end paper art or packaging samples.

The Universal Benefits Driving Its Adoption

First, there are almost no constraints on design. As long as you can draw a 2D graphic on the computer, no matter how complex and delicate the pattern is, our laser equipment can basically cut it out accurately, which gives designers great room for play.

Second, the quality consistency is really reliable. Each laser cutting part is exactly the same as the original CAD design drawing, which is crucial for projects that require mass production and require each product to be strictly unified, saving a lot of quality control troubles.

In addition, the speed advantage is too obvious. It often only takes a few hours from modifying the design file to getting the physical sample, which greatly compresses the development and testing cycle, allowing us to iterate and confirm the solution faster.

Finally, it does save materials. The laser cutting seam itself is very narrow, and the intelligent layout software can efficiently arrange the parts like a puzzle, making the most of every inch of material, significantly reducing costs, and also in line with our lean production philosophy. These points combined make laser cutting a seamless bridge from rapid prototyping to efficient mass production.

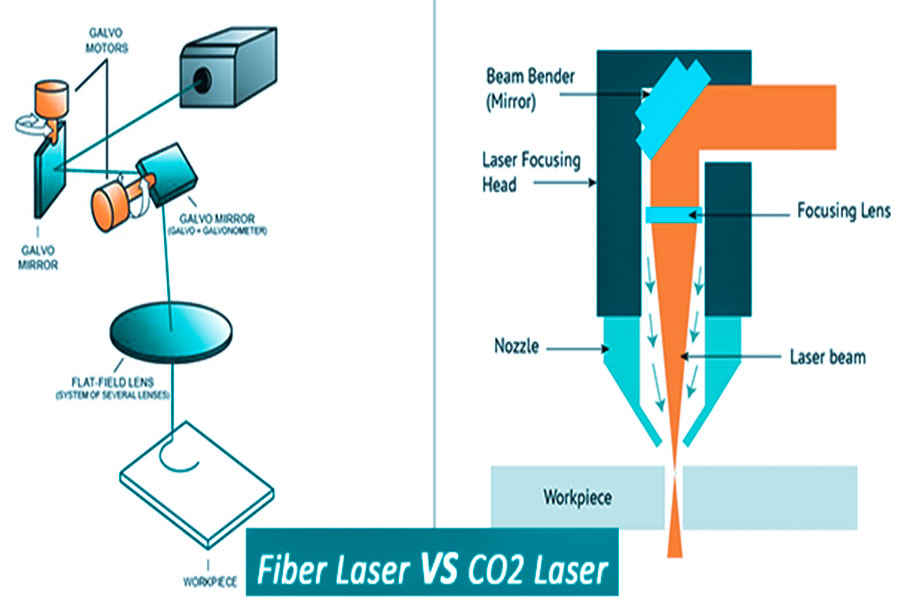

Fiber Laser vs. CO₂ Laser: Choosing The Right Tool

I deal with these two types of lasers every day. Choosing the right equipment is not a trivial matter, and it is directly related to the cutting effect and cost. Let me briefly talk about their “expertise”:

Fiber laser: the “efficiency king” of metal cutting

(1) The core advantage is metal:

The light it emits (wavelength of about 1 micron) is particularly easy to be absorbed by metal and converted into cutting heat energy. This makes it fast and energy-saving when cutting metal. For example, when cutting 1mm thick stainless steel, our laser metal cutter (fiber type) can easily run at 25-30 meters/minute, which is several times faster than CO₂ with the same power.

(2) Energy-saving and durable:

The “electro-optical conversion efficiency” of the fiber laser itself can reach more than 35% (CO₂ is usually less than 15%), which saves a lot of electricity bills in the long run. Moreover, it has low environmental requirements and a longer lens maintenance cycle, which is particularly suitable for factory workshop environments.

(3) Strong ability to cut thick plates:

Take cutting carbon steel as an example. A 6kW fiber laser can stably cut through 25mm with good edge verticality (angle deviation <1°) and less slag, eliminating the need for subsequent grinding. Cutting highly reflective metals (such as brass and copper) is also its strength, and its stability is much better than CO2.

CO2 laser: “finisher” of non-metallic materials

(1) Non-metal cutting “master”:

Its light wavelength is relatively long (about 10.6 microns), which is relatively easy to be absorbed by organic or non-metal materials such as paper, acrylic, wood, leather, and cloth. During cutting 3mm acrylic, the cutting edge is more even and flat (surface roughness Ra < 3.2μm), difficult to achieve with fiber lasers.

(2) Materials widely usable:

Capable of cutting high quality ranging from ultra-thin 0.1mm art paper to 20mm thickness density board (MDF). Especially for organic materials or composite materials, it can avert things that may be caused by fiber lasers, such as burning and melting.

(3) Cutting of thin metals is achievable, but efficiency is poor:

While it can cut some thin metals (such as aluminum plate or galvanized plates with 0.8mm or less), speed and outcome are not as good as optical fiber, which may be only 1/3 to 1/2 of optical fiber, and power consumption is relatively greater, and edge quality is usually not as satisfactory as optical fiber.

For metal cutting, look for fiber laser; for non-metal cutting, CO₂ laser is the first choice. Don’t waste money by choosing the wrong equipment! Contact JS at any time and provide your specific material list and thickness. We will match you with the most efficient and cost-effective laser solution one-on-one!

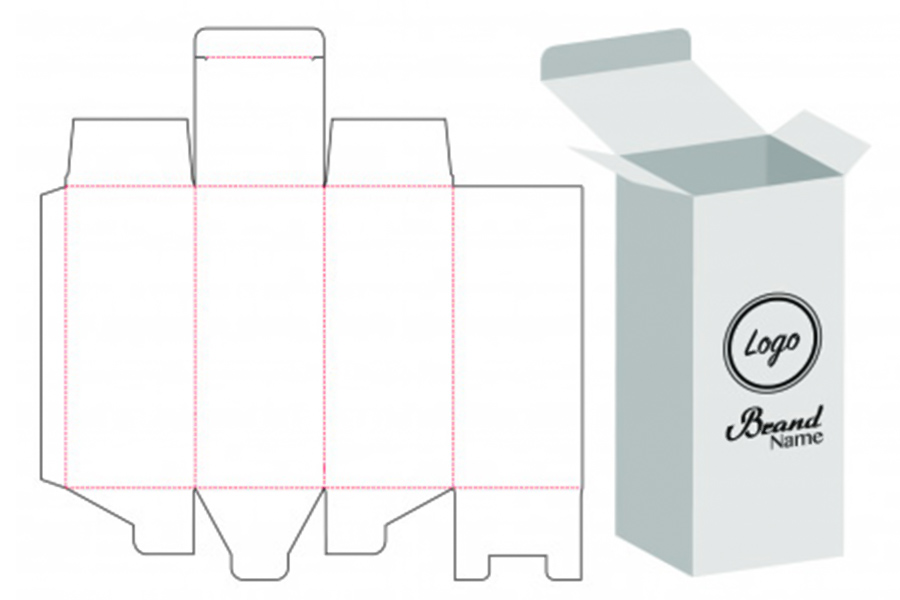

Case Study: A Luxury Brand’s Packaging Project

As an engineer who personally participated in this project at JS, I will share how we used custom laser cutting manufacturing to help a top perfume brand solve the challenge of its limited edition packaging. This project requires both metal and ultra-fine paper:

What the customer wants:

A unique packaging box, the core is two parts:

- Metal parts: brushed stainless steel outer decorative plate (1mm thick) with hollow brand logo, the edge must be absolutely sharp and bright, and cannot be blackened.

- Paper: Lining made of special art paper, the pattern is extremely complex and delicate (think of fine patterns), requiring zero burning and zero yellowing, and perfectly presenting the texture of paper.

JS’s solution:

Stainless steel logo plate – handed over to the fiber laser cutting machine:

Using our 3kW fiber laser, this machine is particularly good at cutting metal sheets with high precision.

Key step: Cut with high-purity nitrogen (>99.95%). Nitrogen can isolate oxygen and prevent the edges of stainless steel from oxidizing and turning black during cutting. It can keep the original bright texture of the metal, and the lines of the logo are as sharp as a knife.

Actual effect measurement: The thickness of the edge oxide layer is < 5μm, and the color change is completely invisible to the naked eye. Every detail of the logo is perfectly restored, and the “high-end feeling” that customers want is immediately presented.

Art paper lining – leave it to high-precision CO₂ laser cutting machine:

The difficulty of this processing is to cut through the complex pattern without damaging the delicate surface of the art paper (burning or yellowing will ruin it).

We did dozens of rounds of parameter tests and finally locked in the “golden combination”: Power only 15%, speed soaring to 800mm/s, with precisely controlled low-pressure air assistance (about 0.3 Bar). This combination allows the laser energy to “stop at the right time”, completing the cutting and gasification before heat accumulation causes the paper to change color.

Result verification: Check the edge under a 100x magnifying glass, there is no visible carbonization or yellowing, the pattern details (including lines <0.2mm) are clear and sharp, and the paper flatness remains perfect.

Cross-material process capability comparison

| Process requirements | Metal components (1mm brushed stainless steel) | Paper components (special art paper) |

| Core challenge |

Prevent oxidation and blackening of cutting edges.

|

Avoid burning/yellowing and maintain the original color of the paper. |

| Select equipment |

High power fiber laser cutting machine (3kW).

|

High precision CO ₂ laser cutting machine.

|

| Key process parameters |

Nitrogen assisted (>99.95 % purity).

|

15% power/800mm/s/low-pressure air (0.3 Bar).

|

| Achieve quality indicators |

Edge oxide layer<5 μm, as bright as the raw material.

|

No visible burn marks, no yellowing at 100x magnification.

|

| Difficulties in comparing traditional methods | Water jet/stamping is prone to deformation, and chemical etching pollution is significant. | The pressure of the cutting die causes indentation/tearing, making it impossible to make extremely fine hollows. |

Data source: Laser Focus World 2024 Annual Processing Report

Final result:

Most pleasing to customers is that JS has performed the precision processing of metal and paper, two of the most dissimilar materials themselves. It saves the trouble of communicating and coordinating with multiple suppliers, and it ensures a great deal of consistency in style of design and delivery time. Final product: The metallic logo is in the new luxury feel, and the inner paper is extremely soft and thin, perfectly suitable for the high-end positioning of the perfume.

This case shows you the elite benefits of custom Laser cutting manufacturing for cross-material, high-precision, and non-destructive processing. No matter dominating metal or dominating delicate materials, JS can provide integrated solutions to refine your creativity!

How To Get Your Parts Laser Cut Just Right?

I’ll share with you a few key things so laser cutting parts are completed properly the first time, which will also help in being able to estimate the cost of laser cutting more accurately:

(1) The file must be clear: Provide clear 2D drawings (preferably DXF, DWG, AI or SVG format). The lines are closed and there is no overlap, and the drawings can be read directly, saving us time for corrections and avoiding errors that affect costs and delivery time.

(2) Material & thickness: Be sure to clearly tell us what material and exact thickness you are using. Material and thickness are the core factors that determine what machine to use, process parameters and laser cutting price.

(3) Talk about the subsequent steps in advance: If you need to bending, welding, paint or electroplate after cutting, be sure to tell us in advance. This will affect the process design during cutting and avoid problems in subsequent processing that lead to scrapped parts.

(4) Choose a reliable service provider: Find a supplier with a professional online platform (such as our JS). A good platform can quickly calculate the price, and engineers can help you review the drawings and optimize the process to ensure quality and efficiency from the source. This is the real way to save money and worry.

FAQs

Q1: How to cut paper with laser without leaving burn marks?

I have experience in dealing with the problem of laser cutting paper burn marks.

The trick is: use a relatively low power, a faster cutting speed, and add a little airflow to purge. In this way, the laser can accurately evaporate the paper fibers instead of burning the paper and leaving ugly black edges.

Q2: How much power laser is needed to cut paper?

We usually use 30 to 100 watt CO₂ lasers to cut paper. This wattage range is sufficient for everything from ordinary paper to thick cardboard. Anything larger will easily damage it.

Q3: Can all papers be laser cut?

We have no problem cutting ordinary paper, cardboard or corrugated paper in daily life, as they are all made of natural fibers. But you have to be careful when you encounter paper with plastic film or high chlorine coating. Once the laser hits it, it is easy to emit toxic smoke. We will never touch this kind of paper. Safety first, don’t take risks.

Q4: What files do I need to provide for my project?

The most worry-free thing is to give us vector files, such as DXF, AI or SVG. They come with precise cutting lines and are the smoothest for the machine to read. You can upload these files directly to our system, and I can immediately see the size and process requirements, and calculate the price for you on the spot, which is fast and accurate.

Summary

The real power of laser cutting is that it can handle a variety of different materials and combine power and delicate work just right. It is not only an indispensable core tool in our heavy industry production line, but also a powerful assistant for designers to realize their creativity. Understanding it and using it well will definitely make your product design and manufacturing path wider and more creative.

Want to try what laser cutting can bring to your project? It’s very simple:

- Prepare your design drawings: Vector files such as CAD, DXF, AI, and SVG are the best, and the machine can read them most clearly.

- Upload to our online platform: Upload your CAD or vector file.

- Get a quote within 30 seconds: The system automatically calculates the price, which also includes professional suggestions from our engineers. This laser cutting price will be transparently calculated based on the thickness of your material and the complexity of processing.

Don’t wait, upload your design drawings now and let you see the effect immediately!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com