In the injection molding industry, Overmolding and insert molding are “our right and left hands”. We’re frequently asked about these by clients, and we often assist them with day-to-day problem-solving. For example, the rubbery lip of your phone case that guards against droping is a very typical application of overmolding. And the metal key blank of your automobile key, which is resistant to droping, is one of the finest applications of insert molding.

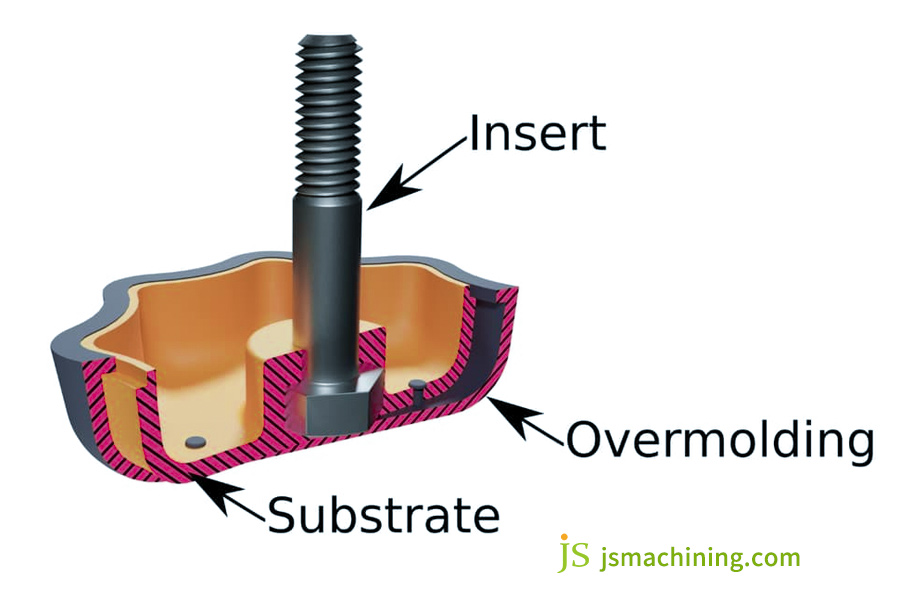

Simply put, both of them combine different materials smoothly but in different ways: Overmolding is like “wearing a coat,” making the plastic base part first and then adding a cover of the soft rubber.

Insert molding is “embedding the part,” where you insert the metal or plastic part itself into the mold for injection molding. What do you use? It all depends on what you want. In case you want a good feel and snug seal, use overmolding. In case you need embedded metal parts or protection, then insert molding is perfect.

We have helped many clients make these choices, and sometimes the wrong choice has caused the parts to crack so easily or just not work at all, so we must make this choice carefully.

Key Answer Summary:

| Comparing dimensions | Insert molding | Overmolding molding |

| Essence of craftsmanship | By pre embedding metal inserts or electronic components into molds and injecting plastic, a non removable integrated structure is formed. | On the surface of the pre formed plastic/metal substrate, another layer of functional material is coated by secondary injection molding to achieve a composite structure. |

| Core advantages | Eliminate the risk of loose threads, improve the tensile strength of the connection part, and increase it by 300% compared to traditional assembly. | Realize the chemical combination of hard substrate and soft surface, combining structural strength and ergonomic touch. |

| Typical cost composition | The complexity of the mold is moderate, and the labor cost accounts for a high proportion. | The cost of molds is relatively high, but the advantage of mass production efficiency is significant. |

| Typical application scenarios | Reinforcement of metal handle for endoscope, aluminum shell packaging for automotive sensors, integrated molding of metal shaft sleeve for high load gears. | Anti slip grip for insulin pump, titanium alloy bracket for bone conduction earphones, waterproof sealing for smart watch buttons |

| JS core technology guarantee | Military grade embedded preheating system (temperature difference ± 1 ℃), sub micron positioning accuracy (<0.02mm), in compliance with ISO 13485 medical standards. | Material compatibility AI prediction system, with warpage deformation less than 0.1mm. |

What Makes This Guide Reliable? The JS Team Reveals Its Core Process Secrets

I’ve worked in injection molding at JS for a few decades, starting with our initial BP machine housings to the current medical products. I’ve witnessed the industry evolve. Our line is certified to IATF 16949 and ISO 13485. But certifications are just the tip of the iceberg, the real expertise lies in these hands-on samples.

“As John Bozzelli, a veteran in the injection molding industry, often says: Injection molding is like cooking; a single second’s difference in timing can make all the difference.”

Last week, we overcame a challenging task with a medical sensor enclosure. We produced a plastic-metal seal for the device, and the client wanted it to withstand immersion in 10 meters of water without leaking. Simply regulating the insert temperature alone had over 20 iterations and resulted in a product capable of withstanding -40°C to 120°C temperatures without cracking.

We have created a dedicated materials library over the years and have tried over 300 combinations. For example, when we were creating a charging case for a pair of earphones, we created 37 prototypes to get the perfect touch. Ultimately, we created lines on the smooth rubber surface smaller than finger prints. Users have stated that when held, it is like holding a peeled egg.

If you’ve got something you need to have designed, simply send over your designs. In 48 hours, we can provide a rough estimate using the most cost-effective materials, the most streamlined process, and if there will be any issues with mass production. After all, however good something looks on paper, it ultimately comes down to the production floor.

What are insert molding and overmolding?

Insert molding involves pre-positioning electronic components or metal parts in a mold and pouring plastic over them to cover. This eliminates assembly operations and increases strength by a significant factor. For example, metal inserts can increase tensile strength by up to 300%.

Overmolding is overmolding a secondary material onto a substrate base (plastic or metal). This allows us to combine materials with different properties (a hard PC center with a soft TPU skin, for example), to achieve functional shapes that are impossible using a single material. Overmolding is particularly suited to producing items that combine both hard and soft components.

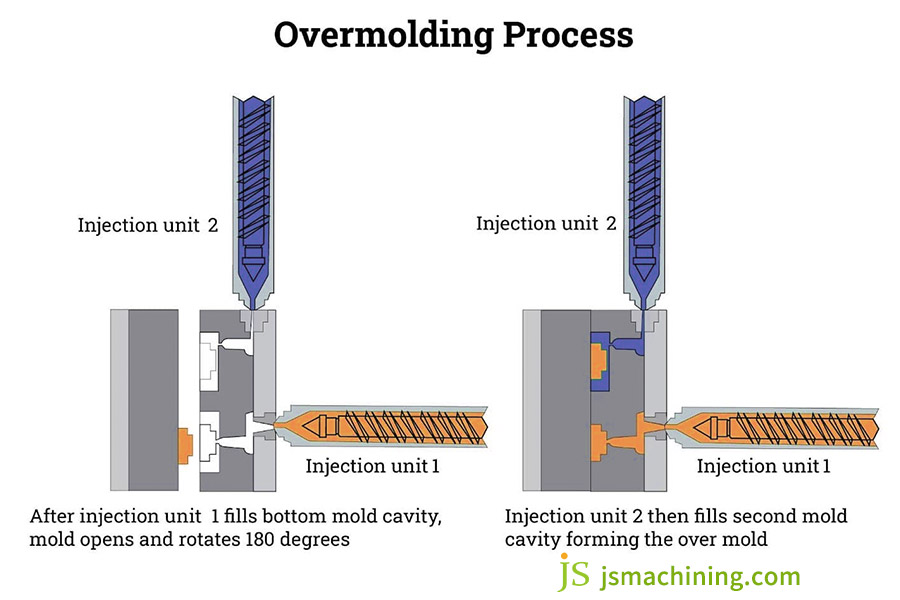

Manufacturing Secrets: How Do You Process Of Overmolding?

1.Creating a solid basis: Substrate pretreatment

First, let us prepare the substrate’s (which may be plastic or metal) surface in order to “stick” the new plastic. Especially in plastics such as PP and PE, which naturally are not as adhesive, we activate the surface by treating it with plasma, thus greatly increasing adhesion.

2. Mold Design: Locking and matching

(1) Crittall role for mechanical interlocking: The mold has exact micropore arrays and dovetail grooves, and the overmolding material that is injected later can “catch” the substrate and create a physical lock, which plays a critical role in preventing delamination.

(2) Accurately compute thermal expansion and contraction: Do the two materials expand and contract at different rates? No problem! Mold design correctly calculates the compensation such that a leak-free, snug fit between the substrate and overmolding layer is created upon cooling.

3. Injection molding control: Temperature and pressure are key

(1) Correct Melt Temperature: For overmolding TPU, we must maintain the temperature precisely within the 190-220°C (±2°C is standard) optimal range. Any deviation in temperature immediately lowers the bond strength.

(2) High-pressure penetration is essential: Pressure during the injection and holding phase must be sufficient, typically above 800 bar, to allow for thorough penetration of the melted plastic into the substrate surface microtexture and interlocking features, with a good bond. The final injection molding parts are a perfect fusion of the base material and the new material.

4. Challenges and choices:

(1) Material matching is a skill: Not just any two plastics will bond well. We rely on our accumulated database and experience to select material combinations that “play well together.”

(2) Runner system is of your choice: Cold runner or hot runner? Hot runners save scrap, make the process more efficient, reduce the cost of multi-cavity molds by approximately 30% for high-volume production and multi-cavities, but start-up cost is more, so this is a trade-off.

Overmolding demands precise substrate preparation, keen mold locking, precise injection temperature and pressure management, and the selection of suitable materials. Want to produce dependable and functionally distinctive composite injection molded parts? Talk with a JS about your application!

Comparison Of Similarities And Differences: What Are The Similarities Between Overmolding And Insert Molding? What Are Their Main Differences?

Overmolding vs insert molding, most individuals are confused between these two techniques. Both, in fact, are used to create more complex plastic components by joining different pieces or materials into a single unit, but they function differently.

1. How are they similar?

(1) Shared Goal: Underneath it all, both involve “binding” two unlike components together to create a more durable component. Overmolding is soft plastic around hard plastic or hard plastic around hard plastic, and insert molding is plastic over non-plastic material such as metal, ceramic, or pre-made electronic components.

(2) They both utilize injection molding machines: Whether by method, an injection molding machine injects (at least one time) plastic that is molten into a mold to form the part. This is required for its capability to form the part.

(3) Improved Performance and Efficiency: Both eliminate the hassles of post-production assembly, such as gluing and screwing. The resulting parts have better integrity, with tighter seals where necessary (especially when covered with soft rubber), and more durability where necessary, such as when plastic covers metal inserts.

2. What are the main differences?

| Difference points | Overmolding | Insert molding |

| Core object | Mainly plastic packaging (first shot+second shot). | Plastic packaging refers to non plastic components such as metal, ceramics, circuit boards, prefabricated parts, etc. |

| Forming sequence | Generally, the first shot of the substrate is made first, and the second shot of the coating is shot while hot or in the same the first mock examination. | Prepare the insert in advance, place it in the mold cavity, and then inject plastic to wrap it. |

| Combining essence | Dependent on thermal bonding, chemical compatibility, or mechanical interlocking between molten plastics. | Mainly relying on the mechanical wrapping force generated by plastic cooling shrinkage, sometimes combined with surface treatment. |

| mold design | More complex molds (such as turntable molds and sliders) are often required to handle multiple shots. | Molds are relatively more concerned with the positioning accuracy and stability of embedded parts. |

| Cost focus | The material cost (two types of plastics) and mold cost may be higher. | The cost of the insert itself and the cost of pre positioning/locating the insert are key factors. |

| Typical applications | Toothbrush handle (soft rubber), tool handle, multi-color button, seal. | Plastic parts with metal threads, electronic packaging, automotive sensors, razor heads with blades. |

3. Let’s look at some technical information:

We’ve produced several automotive sensor housings, frequently utilizing insert molding. For instance, we must encapsulate a brass threaded insert in PPS plastic. The difficulty is getting the insert into the correct position. Inadequate temperature and pressure control during injection molding can cause misalignment of the insert or a faulty seal, resulting in seal failure. For overmolding, for instance, covering with flexible plastic a handle, adhesion and thermal compatibility of the two plastics matter, debonding and delamination are otherwise inevitable.

4. In regard to bond strength:

The below table compares the bond/holding strength of two processes in specific applications based on industry testing (ASTM D638/D6671). Overmolding has higher bond strength at the plastic-to-plastic interface, especially where material pairing is highly compatible. Insert molding, on the other hand, relies heavily on plastic shrinkage and holding force around the insert.

|

Process type

|

Testing combined with interface |

Typical material combination

|

Average peel/tensile strength (MPa) | Main source of intensity | Data sources |

| Overmolding | TPE soft rubber/PC-ABS hard rubber | Compatibility modified TPE+PC-ABS | 3.5 – 6.0 | Hot melt bonding and mechanical interlocking of materials | ASTM D638 (adapted) |

| Insert molding | PPS plastic/brass inserts | 30% fiberglass reinforced PPS+smooth brass | 15.0 – 25.0 (drawing) | Mechanical wrapping force generated by plastic shrinkage | ASTM D6671 (Drawing) |

Overmolding involves layering plastic on top of plastic, focusing on the intimate bonding between the materials. Insert molding involves plastic encasing an outsider (non-plastic part), relying on a firm grip. Which one to choose? First, consider your part combination (plastic + plastic or plastic + other components) and second, core performance (strong bonding vs. strong encapsulation).

At JS, we do it all from complex two-color encapsulation to projects with precise insert positioning. Want to test out which process is best for your design? Just upload your 3D file to our online injection molding services platform, and our engineers will assess and analyze it for you!

Critical Application Scenes: Overmolded Parts Are Everywhere

Overmolding might appear subtle, but it’s actually present in millions of amazing things you’ve handled. It’s not hyperbole to say it’s “ubiquitous.” Why? Because it addresses pain points that individual materials can’t.

Key Application Scenarios: Overmolding Shows Its Power

| Application area |

Typical component examples

|

The benefits it brings | Industry penetration rate |

Data sources

|

| Consumer electronics | Phone/tablet protective case grip area, headphone headband, control buttons of game controller. | Anti slip and anti drop, added tactile sensation, personalized looks (in various colors), shock absorption and cushioning. | ~85% of high-end devices are used. | Strategy Analytics 2024 |

| Tools & Appliances | Handle of electric tool, handle of kitchenware, handle of shaver. | Good shock absorption, easy grip, insulation safety, oil and sweat resistance. | ~70% of professional level tools are standard. | Freedonia Group 2023 |

| Automotive interior & Functional components | Steering wheel cover, button panel, door handle, sealing plug, sheath of wire harness. | Enhance luxury feel, multi-function integration, fine sealing, and noise prevention. | >90% of new car interior applications. | S&P Global Mobility 2025 |

|

medical equipment

|

Handle of surgical instrument and contact area of monitor housing. | Biocompatibility, ease of cleaning and disinfection, anti slip and antibacteriality, and reduced hand fatigue for health workers. |

~65% use handheld devices.

|

ISO 13485 Industry Practice Report |

Overmolding is like placing a bespoke soft armor (cover) over a hard shell (base material), addressing the complex requirements of feel, function, and protection. The next time you reach for something with soft adhesive, remember, it might be an overmolding work of art!

Do you have an injection molded parts with similar design requirements? You can discuss openly with JS and we’ll work together to make it a product that is functional and long-lasting!

Case Study: JS Designs and Manufactures a Wireless Earphone Charging Case

Working as an engineer at JS, I’d like to share our experience designing and manufacturing a charging case for wireless earphones for a prominent consumer electronics business and explain why we employed overmolding:

Customer Challenge: When “Perfection” Meets Challenges

This big client I worked with had very strict requirements on their next-gen high-end wireless earphone charging case: richly soft touch, excellent shock absorption, two-tone matte finish, no glare, and IP67 water resistance.

Their previous approach involved a hard plastic shell covered in a silicone sleeve. There were numerous issues: the device was thick and heavy, assembly was incredibly cumbersome, and it looked a bit cheap. Most importantly, the waterproofing was constantly problematic and unreliable. This fell far short of the high-end experience they were looking for.

JS’s Solution: Overmolding, a Single Strategy

Faced with these competing requirements, especially the combination of superior feel and exceptional waterproofness, the JS team carefully evaluated and decisively recommended overmolding, abandoning insert molding.

Why Overmolding?

The trick is that it creates a two-tone exterior in a single process: A rigid inner structure is first injection-molded with a hard plastic (e.g., PC/ABS), and then a flexible TPE rubber is overmolded directly in the same tool when still molten. The two components blend into one in an unbroken, integrated part.

What’s the magic of this solution?

- First, the soft rubber layer well delivers the soft, luxurious texture and great cushioning the customer was missing.

- Secondly, openings are eradicated with single-shot molding, which is necessary for delivering IP67-rated waterproof and dustproofing, totally eliminating the issue of leaks with which traditional methods are plagued.

- Furthermore, the matte surface and dual-tone effect are readily achieved in a single stage, creating a high-end aesthetic.

- Finally, the entire shape is 15% lighter than with traditional solutions, and assembly operations are greatly reduced, so production efficiency is much improved. This is a best case of our unique injection molding manufacturing capabilities.

Exceeding expectations and value:

The client was extremely satisfied with the completed charging case. The touch truly surpassed their spec’d “luxurious softness,” and it survived extreme drop tests without a hitch, displaying excellent protection. The signature dual-tone matte finish is slim and easy to identify. It also earns IP67 waterproof certification, with zero water immersion test failures.

Above all, through overmolding, we helped the customer to break free from the inconvenience of bulk and assembly, making a more advanced, reliable, and premium product. It was not just about making a box, it helped to enhance their overall product competitiveness as well as customer experience.

When a superior feel, stringent protection (especially waterproofing), and a unique appearance are all required, overmolding is often more efficient and reliable than insert molding. If you’re looking for solutions for similar demanding products, feel free to chat. JS is happy to use our custom injection molding experience to help you turn your ideas into reality.

Why choose JS for your injection molding project?

1. We specialize in challenging work, with experience to prove it:

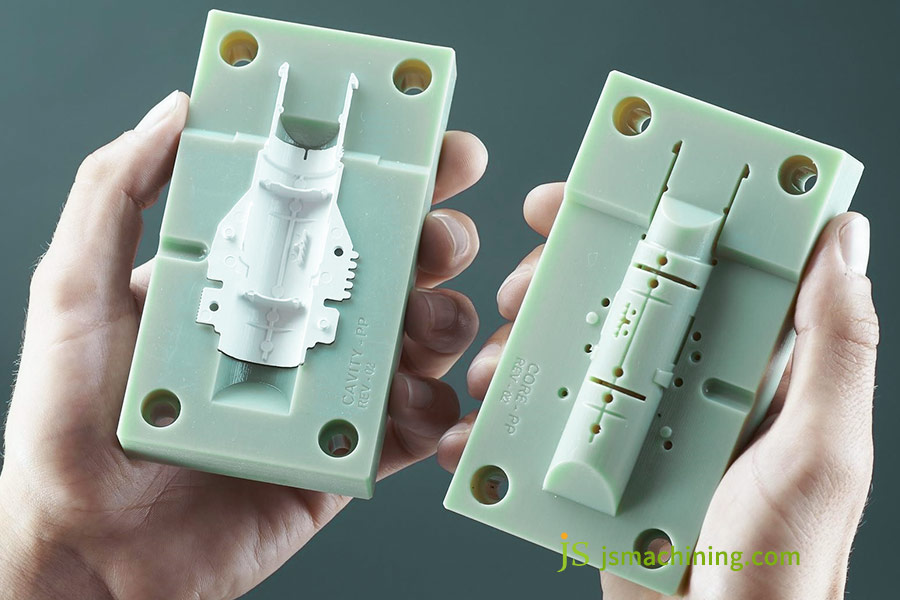

Like the above wireless earphone charging case, these complex and challenging injection molding parts are our expertise. Simply provide your specifications, and we’ll devise the most suitable process to make your vision a reality, regardless of the complexity.

2. “Quick” and “quality” aren’t add-ons, we strive for:

You do not wish to lose too much time between prototype and high-volume production, for sure. Our personnel ensures a smooth process and easy communication, from design review and mold development through pilot production. It is our goal to provide your high standards with rapid prototypes, then transfer smoothly into stable, high-volume production in order to allow you to capture market opportunities.

3. We are cautious and make you invest money effectively:

We examine not just the price of single injection molding parts, but the finished product. By optimizing design, right material selection, and improving yield, we allow you to control total costs and make your products more competitive in price and performance.

FAQs

Q1: Is the bond strength of overmolded parts consistent? Will they peel?

The bond strength of overmolded parts is very consistent and will not peel.

The secret lies in the selection of compatible materials, incorporating tiny hooks and roughened zones into the mold design, and tightly managing temperature and pressure. We aggressively test materials, closely monitor processes, and perform tensile tests to ensure strength far exceeds actual demands.

Q2: Is two-shot molding and overmolding the same?

We regularly perform overmolding, which is very similar to two-shot molding and is commonly confused. Simply speaking, two-shot molding is focused on the attainment of a good look with different colors or materials and is a common overmolding method. Overmolding is more generic in nature and is essentially used to apply a functional layer to a part, such as a soft rubber grip. We can perform both.

Q3: Will there be gaps between the metal and plastic during insert molding?

As long as the process is done correctly, gaps between the metal and plastic parts are virtually nonexistent.

JS’s typical approach is to preheat the metal part to ensure proper placement in the mold, increase pressure during injection, and design small textures into the metal part itself. If the customer requires a particularly tight seal, we can also coat the metal part with a layer of soft adhesive for added security.

Q4: How can I get a quote for overmolding through your online service?

Getting a quote for overmolding is easy! Simply visit our website, click “Contact Us,” upload your 3D design, select the desired hardness and color of the soft adhesive, and provide an estimated quantity. The system will instantly calculate a price for you, and our engineers will also review the design and provide optimization suggestions.

Summary

The choice between overmolding and insert molding depends on the essential functionalities required for your injection molding parts and the project constraints. Insert molding is better at adding metal/electronic components while maintaining a secure package and electrical isolation. Overmolding offers advantages in enhancing tactile comfort, optimizing shock absorption, or developing multi-material aesthetics. In making decisions, consider functional priorities, production volume estimated, material compatibility, precision needed, and the influence of mold investment on overall injection molding price. There is no one-size-fits-all solution, but the optimal fit for your specific needs.

Submit your challenge to JS now, and we’ll help you resolve it:

- Send us your drawings: Our engineers will promptly examine and determine whether overmolding or inserts are best suited to your needs and budget.

- Get a customized cost analysis: Based on your production quantity, we’ll accurately estimate mold investment and unit price to identify the most cost-effective process.

- Rapid Prototyping: Test the waters with a small trial run to see the output and verify performance yourself, gearing up confidently for mass production.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Customized Injection Molding Of Complex Parts,Saving 35% Of Costs - JUSHENG

Pingback: How To Save 40% Of Injection Mold Costs? Comprehensive Cost Reduction Strategy - JUSHENG