Let’s say this scenario: You are a purchasing manager for an electronics firm. In order to produce a batch of precise brass housings, you’ve bought brass sheet metal stamped H65 at an overpriced price. But in processing, you experience the peculiar hardness and frequent cracking during bending. Not only does this delay the project by three weeks, but it also adds another $500 to your tooling loss.

Or perhaps you purchased sheet metal fabrication parts with the thickness specified as 1.2mm, yet upon delivery, the thickness is only 1.05mm. That is a material shortage of nearly 13% at the upfront cost, right away multiplying invisible costs.

Material costs make up the greatest portion of the overall cost in sheet metal fabrication, and the greatest hidden cost pitfall is in making the incorrect material selection. Through the most direct form of “accurate material selection,” this article will expose the way to save as much as 20% of the cost.

Core Answer Summary

| Cost Reduction Strategy | Core Method | Key Benefit |

| Accurate Material Selection to Avoid Performance Waste | Match the most cost-effective brass grade (such as H59, H62, H65) according to application scenarios (such as strength, plasticity, corrosion resistance) instead of blindly choosing the most expensive or cheapest one. | Directly reduce the material unit price and reduce processing difficulties and scrap rates caused by inappropriate materials. |

| Strictly Control Thickness Tolerance to Block Cost Leaks | Clearly specify the strict thickness tolerance range (such as ±0.03mm) in the order to avoid hidden costs caused by negative tolerance (insufficient material) or positive tolerance (difficult processing). | Ensure payment according to the price and full use of materials, protect molds, and improve processing stability and yield rate. |

| Optimize Specifications to Reduce Unnecessary Customization | Prioritize the supplier’s standard inventory sizes and finishes, and only customize when necessary to save cutting costs and special processing costs. | Significantly reduce the purchase unit price, shorten the delivery cycle, and accelerate the project progress. |

| Go Beyond Unit Price to Comprehensively Evaluate Suppliers | Evaluate suppliers from multiple dimensions such as material authenticity, quality stability, technical service, and delivery capability instead of only comparing the figures on the quotation. | Establish a long-term, stable, and reliable supply chain, and fundamentally eliminate huge losses caused by quality risks. |

| Learn from Cases for Practical Verification | Refer to JS’s successful cases (such as the medical equipment shell analysis in this article) to understand how cost reduction strategies are implemented in actual projects and generate benefits. | Provide a reusable methodology, avoid trial-and-error costs, and directly apply optimization solutions. |

Why Can JS Precisely Pinpoint Brass Sheet Metal? Ten Years Of Experience And Technical Summary

It is not an easy task in the sheet metal fabrication industry to determine brass sheet grades. JS has had a decade of experience and accumulated sufficient practical knowledge to handle various complicated conditions.

We have served over 300 customers from the electronics, medical, and automotive sectors since the previous decade, and handled nearly a thousand brass sheet choosing and testing cases. As an example, we remediated a batch rework issue caused by H62 and H65 contamination in an auto parts manufacturer.

Our experience extends beyond bench testing to encompass the details of actual production. For example, through summation of tens of thousands of data points, we have assembled the profile of color change of different grades of brass at a range of temperatures. By comparing over 200 lots of bending tests, we have exactly outlined the force difference range between H59 and H62 at the same bending angle.

This is the product of our decade’s experience. Every step, from grade identification to cost control, has been tested on live projects. You can trust it to give good counsel on your sheet metal fabrication work.

JS has ten actual years of experience in sheet metal fabrication and can accurately handle brass sheet selection and testing issues. If you need brass sheet metal requirements, please get in touch with us and we will offer you with professional selection advice. and testing services.

What Are The Key Grades Of Machinable Brass?

Understanding the main grades of machinable brass is key to successful sheet metal fabrication for profit. Brasses have variations in properties and applications depending on their composition. Choosing the right grade has the immediate capability of reducing processing cost and rate of defects.

Basic Brass (Cu-Zn Alloy): The Essential Composition of Brass

Common brass is made up of copper and zinc, and the property depends on the zinc content. Lower zinc reduces plasticity so that it is easier to bend and stretch. Higher zinc content gives strength and hardness but is harder to machine.

The following table presents common brass types and characteristics:

| Grade | Zinc Content (Approx.) | Core Performance | Applicable Processing Scenarios | Reference Unit Price (USD per Square Meter) |

| H59 | 41% | High strength and hardness. | Simple stamping parts, lock parts. | 45 – 50. |

| H62 | 38% | Good comprehensive mechanical properties. | Electrical terminals, ordinary decorative strips. | 50 – 55. |

| H65 | 35% | Excellent plasticity and good surface gloss. | Complex bent parts, brushed panels. | 55 – 60. |

| H68 | 32% | High plasticity and good ductility. | Deep-drawn parts, high-end medals. | 60 – 65. |

| H70 | 30% | Extremely high plasticity. | Cartridges, precision instrument parts. | 65 – 70. |

Special brass: High-quality varieties for special applications

Special brass is made by alloying special elements such as lead, tin, and aluminum with standard brass to meet special application requirements:

- Lead brass (e.g., HPb59-1): Excellent cutting performance, suitable for sheet metal fabrication parts having high-volume machining requirements, such as valve cores and gears. Unit price reference: $58-63/m2.

- Tin brass (e.g., HSn62-1): Highly resistant to corrosion, suitable for harsh environments like seawater. Ship fitting and marine instrument part uses. Reference unit price: $68-73/m2.

- Aluminum brass (e.g., HA177-2): Exotics strength and wear resistance, suitable for high-strength parts like high-pressure valve and bearing parts. Reference unit price: $70-75/m2.

When choosing brass grades, there is no “best” grade, only the grade that is “most suitable” for the project requirements. It is necessary to combine project processing technology, usage environment, and cost budget. For example, H70 is preferable to H59 for precision deep drawn parts, tin brass is more resilient than plain brass for corrosion-resistant parts.

JS is experienced with the performance and use conditions of various grades of brass and can recommend the ideal grade of brass for your custom sheet metal fabrication manufacturing project. If you have to purchase brass sheet metal, please give us your project specifications and we will pair you with the suitable material within a few minutes.

Avoid Low-Quality Products: Three Tips To Immediately Recognize H59, H62, And H65

When buying brass sheet metal, there’s a common tendency among suppliers to misrepresent the lower grades as higher. Here are three tips that will easily allow you to differentiate H59, H62, and H65 to steer clear of traps.

Method 1: Visual Inspection

Observing under natural light, the highest zinc has H59 with a light golden yellow and dull finish, H62 golden yellow and medium finish, and H65 less zinc content with bright golden yellow and richer finish. Before observation, wipe the surface with gauze to remove the oxide layer or oil stains.

Method 2: Test Bend (Hand Feel Method)

Take a sample and perform a 90-degree bend test. H59 has the maximum hardness, high bending resistance, and is crack-sensitive. H62 has medium resistance, is easily bent and less crack-sensitive. H65 has the maximum plasticity, minimum resistance, negligible springback when bent, and no apparent surface mark.

Method 3: Listen to the Sound (Tapping Method)

Strike softly with a light hammer. H59 is dense and has a low, short sound. H62 has a medium sound with normal sharpness. H65 is low in density and has a sharp, long sound with more sustaining sound.

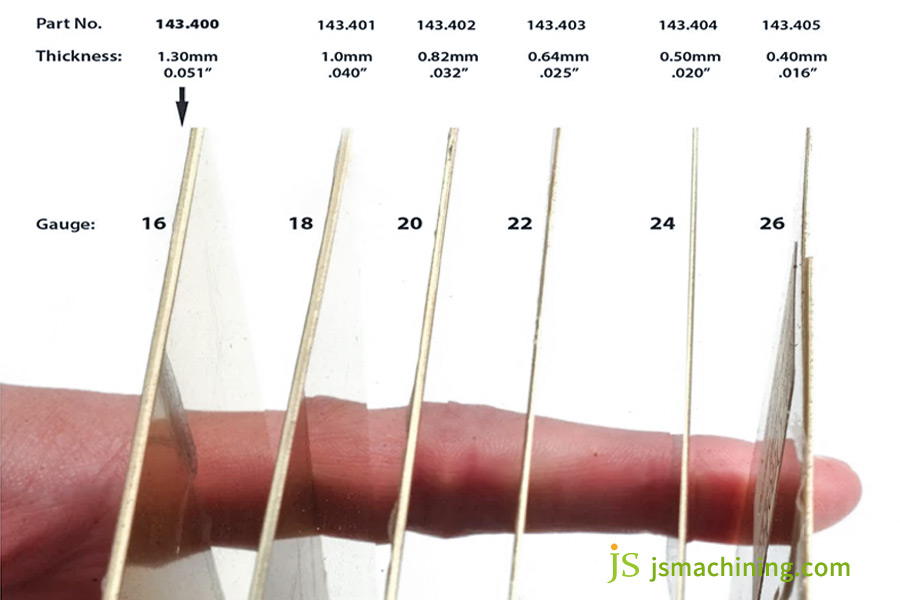

Dimension Deviation = Money Down The Drain! A Close Look At The Invisible Relationship Between Thickness Tolerance And Expense

Brass sheet thickness tolerance, although negligible, has a significant impact on expenses. The majority of people are concerned about the sheet metal fabrication price only and do not account for the hidden wastage due to tolerance, hence actual costs exceeding expected budgets.

What is real cost effect of thickness tolerance?

Scenario 1: Negative Tolerance Trap

If the producer delivers 1.0mm thick brass metal sheet at the negative tolerance level of the national standard (say, -0.09mm), the thickness will be as low as 0.91mm. Buying 0.91mm material based on 1.0mm is 10% extra per unit area. At a 1,000 square meter plant where the cost is $50 per square meter, this amounts to extra $450 in expenses.

Scenario 2: Positive Tolerance Trap

If a mold is designed to work with 1.0mm brass sheet metal but the incoming material is 1.05mm, processing becomes more difficult, energy consumption increases, and mold wear accelerates. A mold that would normally be suitable for 1,000 parts may need replacement after making only 800 parts, tripling mold costs by 25%. This hidden cost is far larger than the differential in material cost.

Cost Differences for Different Tolerance Accuracy

| Tolerance Accuracy Level | Thickness Tolerance Range (Taking 1.0mm as an Example) | Material Unit Price Increase Ratio | Applicable Scenarios | Additional Purchase Cost for 1000 Square Meters (USD) |

| Ordinary Accuracy | ±0.08mm | 0% | Ordinary structural parts, decorative parts. | 0 |

| Higher Accuracy | ±0.05mm | 5% – 8% | Electrical terminals, simple bent parts. | 250 – 400 |

| High Accuracy | ±0.03mm | 10% – 15% | Precision instrument parts, deep-drawn parts. | 500 – 750 |

| Positive Tolerance | +0.05/-0mm | 15% – 20% | Panels with extremely high flatness requirements. | 750 – 1000 |

How to Avoid This?

- Define the tolerance range of thickness(e.g., 1.0mm ± 0.03mm) in making quotations and when placing orders, cite it in the contract, and have a mutually agreed compensation scheme.

- Prioritize selecting suppliers with available stock and stable tolerances. Customized dimensions require prior communication on the feasibility of tolerances to avoid cost increases.

JS has very tight control of thickness tolerances in custom sheet metal fabrication manufacturing and can provide brass sheet metal with close tolerance to your requirements. Just inform us of your specific tolerance needs when you order, and we will adhere to them rigorously and provide a test report.

Compare Suppliers, Beyond Price: Five Strategies For Finding The Best Supplier

When selecting a supplier of brass sheet metal, look beyond price. Compare five telling features, including material authenticity and quality consistency. This is a comparison table of suppliers:

| Comparison Dimension | fictiv | 3erp | xometry | JS Precision |

| Material Authenticity Guarantee | Provides material certification reports only for bulk orders (over 500 pieces), no piece-by-piece inspection for small-batch orders, with the risk of material mixing. | Supports spectral testing, a one-time fee of 50 USD is required, and the test results take 3-5 working days to issue. | Provides guarantees only for high-grade brass (such as H68, H70), no special testing for ordinary brass (such as H59, H62). | Free spectral non-destructive testing regardless of order size, test results are issued within 1 working day. |

| Quality Stability and Tolerance Control | Tolerance is ±0.1mm, which only meets the needs of ordinary sheet metal fabrication parts, an additional 20% fee is required for high-precision projects. | Tolerance is ±0.05mm, but the quality stability fluctuates greatly, and the hardness difference between different batches can reach 10%. | Stable quality, but only supports standard tolerances and does not accept customized tolerances. | Can provide high-precision tolerance of ±0.03mm, the difference in hardness and plasticity of materials between different batches is controlled within 5%, no additional fee for customized tolerances. |

| Technical Service Support | Only provides pre-sales consultation, no technical guidance for post-sales processing issues. | Provides processing technical suggestions, but the response speed is slow (within 24 hours), and the suggestions lack pertinence. | Only serves large customers (with an annual purchase volume of over 100,000 USD). | Equips all customers with exclusive technical consultants, provides pre-sales material selection suggestions and post-sales processing technology guidance, response time is no more than 4 hours, one-on-one service is available even for small-batch orders (fewer than 10 pieces). |

| Delivery Punctuality Rate and Inventory Capacity | Delivery punctuality rate is about 85%, there is a small amount of inventory (about 500 square meters) for common grades (such as H62), special grades (such as HSn62-1) require customization, with a delivery cycle of 2-3 weeks. | Delivery punctuality rate is about 90%, inventory types are limited (only H59, H62), and inventory quantity is unstable, prone to out-of-stock situations, delivery cycle is 1-2 weeks. | Delivery punctuality rate is about 92%, inventory is abundant, but the inventory locations are scattered, and national delivery takes 3-5 days. | Delivery punctuality rate reaches 98%, more than 10,000 square meters of brass sheet metal are stocked in 3 warehouses nationwide, covering ordinary brass and special brass, most orders can be shipped on the same day, the cycle for special customized orders is only 5-7 days. |

| Price Transparency and Reasonableness | Price is not transparent, the quotation includes many hidden costs (such as testing fees, packaging fees), the actual cost is 10%-15% higher than the quotation. | Price is transparent, but the overall price is 8%-12% higher than the market average, no bulk discount is provided. | Price is medium, a 10% discount is available for purchases over 1000 square meters, but the payment method is strict (50% advance payment is required). | Price is fully transparent, a detailed quotation is provided during the consultation stage, there are no hidden costs, a 5% discount is available for purchases over 500 square meters, and an 12% discount is available for purchases over 1000 square meters, monthly settlement payment is supported. |

JS outclasses its competition in five ways like material authenticity and consistency of quality, providing you with low-cost brass sheet metal and online sheet metal fabrication services. In case you have purchasing needs, please contact us for a detailed quote. The ordering process is simple and hassle-free, with follow-up by committed consultants at each stage.

Case Study: JS Saves 18% On Brass Sheet Metal For Medical Device Enclosures

In a custom sheet metal fabrication manufacturing, the cost can be decreased significantly by selecting the correct grade and tolerance of brass sheet. The example is a typical example of JS optimizing and saving cost.

Background

There is a medical company that produces high-end monitor enclosure panels with the requirement of higher rigidity, antibacterial, electrical shield, and a higher-level brushed finish.

The original plan: Use 1.5mm thick H62 brass sheet metal with a high precision positive tolerance of +0.05/-0mm, which is commonly used. They believed that the high strength of H62 would meet rigidity, and the positive tolerance would ensure the flatness of the panel, without considering practical application and economy.

Problem discovery

After docking the project, JS discovered three key issues:

- Material overperformance: H62 tensile strength was more than what was required for static enclosures, which called for additional machinery and excessive energy to bend.

- Wasting cost: In order to achieve absolute flatness, there was a positive tolerance added which raised the unit cost of the material by 10%. The project demanded 1,000 panels (0.5 square meters per panel), but the material itself was $250 (normal H62 is $50 per square meter).

- Difficulty in processing: Due to its hardness, wire drawing process grinding wheel wear rate was 30%, and this brought a 43% cost increase of tools.

JS’s Optimization Solutions

To these challenges, JS team, relying on their experience in sheet metal fabrication, developed three optimization solutions:

- Material Substitution: H65 brass sheet metal was utilized according to testing and on the advice of suppliers. H65 is more plastic, less difficult to bend and wire draw, and with fine surface gloss.

- Tolerance Modification: Relax the thickness tolerance to the standard precision of ± 0.08mm, fully meeting the requirements for shell structure and assembly.

- Optimum Specification: Purchase suppliers’ inventory of H65 large boards with a width of 2 meters, using JS laser cutting to reduce procurement costs.

Achievements

By these three cost-saving solutions, the overall cost of the project was greatly reduced. The material cost was reduced by 10%, processing energy cost by 15%, and tool wear cost by 43%, with an overall cost saving of approximately 18%.

More significantly, however, the appearance quality of the product was enhanced. The gloss and flatness of brushed panel were greater than the initial design, and this further increased customer satisfaction with the end product.

Selecting The Right Brass Sheet For Different Applications

Different applications require different performances of brass sheet metal. The correct grade selection can ensure sheet metal fabrication parts meet these requirements at affordable costs.

Application Scenario 1: Components that must possess high strength and wear resistance (gears, locks)

- Recommended Grade: H59

- Why: Excellent strength and hardness, friction pressure resistance, economic price, and can reduce sheet metal fabrication prices.

Application Scenario 2: Multi-operation bending, stamping, and drawing sheet metal parts (e.g., electrical terminals, decoration strips)

- Recommended Grades: H62 and H65

- Why: H62 offers a balance of strength and ductility, and H65 offers additional ductility, high process yields, and minimal rework scrap. It is best for products where appearance and accuracy are most critical.

Application Scenario 3: High-finish, high-precision deep-drawn parts (e.g., bullet casings, high-quality medals)

- Recommended grades: H68 and H70

- Why: Excellent plasticity and ductility, resistance to wrinkling and cracking when deep drawing, high surface glossiness,and obviates the need for additional polishing, ensuring the quality of custom sheet metal fabrication manufacturing.

Application Scenario 4: Corrosion-resistant applications (e.g., ship fittings and valves)

- Recommended grade: Tin brass (HSn62-1)

- Why: Tin forms a thick oxide layer that is much more corrosion-resistant than plain brass, extending part life and reducing replacement cost. Most suitable for sheet metal fabrication parts exposed to severe environments.

JS can accurately recommend the most suitable brass sheet metal grade for your specific application case and offers additional online sheet metal fabrication services, providing you with complete assistance from material to process to delivery. For your specific requirements, please feel free to contact us for details.

FAQs

Q1: What is the price difference between H59 and H62?

H59 is the cheapest of the regular brasses, and H62 is $3-5 higher per square meter. Cost difference is based on market prices of copper. For parts that have complex sheet metal fabrication operations like repeat bend and stretch, using H62 will improve processing yields significantly and reduce rework losses. Cost savings quite often are much larger than cost difference.

Q2: Is material damage required to carry out JS testing? Is there a fee?

JS uses advanced high-tech spectral testing devices. The test is conducted by light touching of the probe on the brass sheet metal surface without cutting or harming the material and therefore it is a non-destructive test. We provide free incoming material inspection service on big orders such as custom sheet metal fabrication items and bulk orders, without any additional test fee.

Q3: Apart from sheet metal, do you supply semi-finished or finished brass products?

Yes, JS offers one-stop custom sheet metal fabrication manufacturing services. Apart from supplying brass sheet metal in various grades and specifications, we also have cutting-edge laser cutting, bending, and CNC machining equipment, and surface treatment processes like polishing and electroplating. We can process brass sheet metal into semi-finished and finished products. From a simple cut piece to a high-precision complex assembly, we can perform it.

Q4: Some brasses are a point of concern when it comes to dezincification corrosion. How is this prevented in material selection?

Dezincification corrosion occurs most often in typical brasses containing a high proportion of zinc, like H62, particularly in severe environments where there is a high acidity, alkalinity, or salinity. If your product is to be used in such environments for an extended period, avoid typical brass and instead use tin brass (HSn62-1) or aluminium brass (HA177-2). JS technical team will also assist the customer to avoid this material selection hazard.

Summary

With true cost optimization resulting from accurate material selection expertise, careful control of specifications, and assurance through JS technology, the best means of profiting is by not substituting inferior with superior materials and spec waste.

With a decade of experience in sheet metal processing, JS provides a practical cost control process, from material testing to solution optimization, from comparison of suppliers to scenario-based selection. By choosing JS, you can not only receive high-quality brass sheet metal and professional custom sheet metal fabrication manufacturing services, but also enjoy transparent CNC machining prices and thoughtful technical support.

No more pay for uncertain materials!Submit your project specs to us today and receive an accurate quote from actual JS-certified material and skilled material specification recommendations. Let us assist you in putting that 20% secret profit on lock!

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: The Composition Of Brass Material:Why It's Not 100% Copper - JUSHENG