The titanium alloy frame of a supersonic fighter aircraft is light but strong, while the tungsten alloy core of an armor-penetrating warhead is indestructible. Titanium and tungsten are ‘tough guys’, but both are strong in different applications. This is not competition over which is strongest overall, but which of the two is best for application.

This piece will delve in-depth into the performance secrets of titanium and tungsten, each of their strengths, and how they contend in the high-tech arena.

Core Answer Summary

| Titanium vs. Tungsten | Key Information |

| Key Differences | Light ‘space metal’ (density approximately 4.51 g/cm³, discovered in 1791) that is titanium; dense ‘fortress metal’ (up to a density of 19.3 g/cm³, discovered in 1781) that is tungsten. |

| Performance Comparison | Titanium is lighter in density, while tungsten is heavier.Titanium at room temperature is more equal in strength, while tungsten at high temperature works best.Titanium is superior in corrosion resistance.Tungsten is harder and more expensive to process. |

| Applications | Titanium: Aerospace, medical, chemical, and sports equipment.

Tungsten: High-temperature parts, cutting tools, counterweights, and electronics. |

| Future Development | New alloys and composites will enhance performance, and titanium alloys and titanium-based composites, and tungsten alloys and tungsten-based composites possess enormous potential for application. |

Why Is This Guide Accurate?

JS has numerous years of experience in CNC machining and has extensive experience in machining titanium and tungsten.

In machining titanium, we address its chemical activity and low thermal conductivity directly. Through the use of advanced technology, we manage to achieve tolerances as low as 0.005mm, enabling customized production of aerospace titanium alloy components. In the case of tungsten, we have overcome the challenge of machining because of its hardness and toughness, enabling effective machining of highly precise components such as tungsten cutting tools.

We have experience with working with a number of diverse industries, including automotive and medical, and offer proven solutions from prototype to low-volume manufacturing. This guide, derived from that experience, contains valuable information regarding machining titanium and tungsten and is yours to request.

JS has extensive experience with titanium and tungsten machining and can successfully handle their peculiar properties. Choosing JS ensures effective, high-quality CNC machining parts solutions.

A First Look At The Kings: The Essential Differences Between Titanium And Tungsten

In order to determine who is king between titanium and tungsten, we first must know about their respective properties.

Titanium: The Lightweight ‘Space Metal’

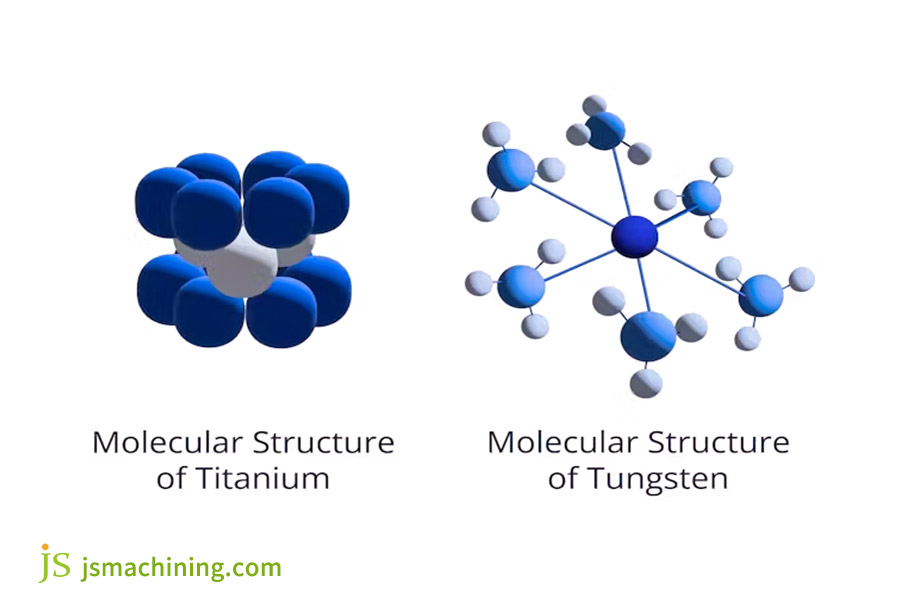

Titanium is a white-silvery transition metal discovered in 1791. It possesses an atomic number of 22 and a relative atomic mass of approximately 47.87. Its most striking property is that it is extremely light. Its density of approximately 4.51 g/cm³ is half that of steel. Further, titanium is extremely malleable at room temperature and can be easily shaped in all kinds of forms.

Titanium has been referred to as the ‘space metal’ because of its superior overall properties and favorable use in space conditions. It is not just light but also durable and resistant to corrosion, making it capable of fulfilling the severe conditions of space.

Tungsten: The Heavy ‘Fortress Metal’

Tungsten is a steel-gray to tin-white metal that was first discovered in 1781. Its atomic number is 74 and relative atomic mass of approximately 183.84. Unlike titanium, tungsten is extremely dense with a density of 19.3 g/cm³, making it one of the densest metals known.

Tungsten is also extremely hard, resistant to deformation at room temperature, and has high wear resistance. Due to its immense strength, tungsten has also been called a ‘fortress metal’ and becomes a key factor in circumstances where extreme pressure and wear are necessary.

Want to know about titanium and tungsten? JS is familiar with their properties. Want titanium parts that are lightweight or heavy-duty tungsten pieces? We have what you need.

Performance Arena: A Six-Round Showdown

Both tungsten and titanium each possess advantages and disadvantages in various performance parameters. The comparison provided below deals with six significant factors:

Round 1: Lightweight vs. Density

Density is a key physical attribute of metals, with respective applications to their utilization in various circumstances.

The density of titanium is approximately 4.51 g/cm³, and tungsten is 19.3 g/cm³, a huge disparity between the two. This provides a definite advantage to titanium in applications where weight saving is critical, but tungsten is more feasible in applications where weight is required to deliver stability or perform specific tasks.

Round 2: Toughness vs. Strength

Strength and toughness are most crucial parameters of a metal’s mechanical properties and heavily influence its field of application. Titanium has excellent strength at room temperature, and titanium alloys can be further increased in strength through alloying and other processes. Titanium also has good toughness, which keeps it at a distance from fracture when it is subjected to shock.

Tungsten is extremely tough, especially at high temperatures, whose toughness is decreased only minimally. However, the toughness of tungsten alloys may be significantly enhanced. But tungsten has a bad toughness and develops brittleness at low temperatures.

Below is a comparative estimation of the strengths and toughness of the two:

| Performance Index | Titanium | Tungsten |

| Tensile Strength (MPa) | 300-1000 (Titanium alloys potentially higher) | 550-600 (Tungsten alloys potentially higher) |

| Toughness | Good but relatively good at low temperatures | Relatively poor, prone to brittleness at low temperatures |

Round 3: High-Temperature Resistance

Metals in most industrial applications are subjected to contact with high-temperature conditions, hence the need for high-temperature resistance.

Titanium is relatively stable in the middle temperatures, but loses a lot of strength at temperatures higher than 400°C. Tungsten has the highest melting point of all metals and has stable performance in extremely high-temperature applications. At temperatures higher than 1000°C, both its hardness and strength are stable.

The two metals’ high-temperature stability is compared in the table below:

| Metal | Melting Point (°C) | High-Temperature Stability |

| Titanium | ~1668 | Resistance is less than 400°C |

| Tungsten | ~3422 | Resistance is stable at over 1000°C |

Round 4: Corrosion Resistance

Corrosion resistance is a significant metal property in the majority of applications and has a direct impact on the metal product life.

Titanium possesses excellent corrosion resistance and forms a dense oxide skin when exposed to air, which protects it against additional oxidation and corrosion.Tungsten has good resistance to corrosion at room temperature but is oxidized at high temperatures to form tungsten trioxide, which affects its performance.

The corrosion resistance of the two metals, as illustrated below, varies.

| Metal | Room-Temperature Corrosion Resistance | High-Temperature Corrosion Resistance | Special Environment Corrosion Resistance |

| Titanium | Excellent, forms a dense oxide film | Good | Stable in seawater and most acids and alkalis |

| Tungsten | Good | Poor, easily oxidized | Corroded in some strong acids |

Round 5: Machining Difficulty Challenge

The machining difficulty of a metal influences its cost of production and range of applications, and is especially significant for parts requiring machining into other complicated shapes.

Machining of titanium is challenging, primarily due to the fact that it is extremely chemically reactive and tends to react easily with the cutting tool during machining, resulting in excessive tool wear. Further, titanium is a poor conductor of heat, which means that the generated heat from machining can easily overheat the workpiece and tool. However, with the help of experienced CNC machining parts technology and online CNC machining services, issues related to titanium machining can be easily removed.

Tungsten is even more difficult to machine. Due to its high hardness and low toughness, it is prone to cracking and breaking during machining. Moreover, its very high melting point poses huge difficulty in machining operations such as casting and forging. Unique CNC machining of tungsten products requires more advanced devices and processes, hence necessitating a comparatively higher CNC machining price.

For comparison of the machining difficulty of the two materials, see below:

| Metal | Machining Difficulty | Impact on CNC Machining Price |

| Titanium | High chemical reactivity and low thermal conductivity | Have some impact but are relatively manageable |

| Tungsten | High hardness, low toughness, and high melting point | Have significant impact and are relatively expensive |

Round 6: Cost and Economic Factors

Cost is another crucial factor determining the consumption of metal materials, like raw material and processing cost.

The raw material cost of titanium is very high, primarily due to the advanced extraction and smelting processes. However, due to continuous development in production technology and its relatively lower machinability than tungsten, its total cost is moderate.

Tungsten’s relatively lower raw material reserves, as well as the complex extraction and machining process, result in higher raw material and processing cost. Especially in custom CNC machining manufacturing, the increased complexity in machining raises the CNC machining price, thus a relatively higher overall cost for tungsten.

A rough estimate of the two cost structures is as follows:

| Cost Structure | Titanium | Tungsten |

| Raw Material Cost | High | Very high |

| Processing Cost | Medium | Very high |

| Overall Cost | Medium | High |

Both titanium and tungsten have their own strengths and weaknesses. JS is expert at utilizing these traits to create parts to your specification. From density to cost, we are in complete control.

Champions: Applications Where Each Excels

Because of the differences in performance, titanium and tungsten each excel in their own areas:

Titanium Applications

- Aerospace: Due to its light weight, high strength, and resistance to corrosion, titanium is widely used in the manufacture of aircraft fuselage and engine components. In space vehicles as well, titanium can face the tough conditions of space.

- Medical Devices: Titanium is biocompatible and not easily rejectible by the human body, and therefore is widely applied to artificial joints and orthopedic implants.

- Chemical Industry: Corrosion resistance of titanium makes it find extensive use in chemical reactors and equipment, where it can withstand the corrosive effect of chemicals.

- Sports equipment: Light yet very strong titanium is used to make sports equipment performance better, such as bicycle frames and tennis rackets.

Tungsten Applications

- High temperature applications: The high melting point of tungsten enables it to work normally even at very high temperatures, e.g., rocket engine nozzles and nuclear reactor core components.

- Cutting tools: Tungsten knives are very hard and wear-resistant, and thus suitable for cutting any kind of hard materials and widely used in machining.

- Counterweights: Tungsten, due to its high density, finds application as counterweights in aircraft and vessels, and parts balancing for precision tools.

- Electronics: Tungsten wire, with its excellent conductivity and high-temperature resistance, is a vital material for electronic components such as tubes and lamps. High-precision components in such applications can be supported by custom CNC machining manufacturing.

Titanium and tungsten truly shine in many applications. JS has extensive experience in aerospace, medical, and other markets, and can custom-configure to your needs. Choose JS to ensure the right material in the right application.

Case Study: Choosing The Proper Component For A Supersonic Aircraft

Project Pain Points

An aerospace company engineered a hot-end component for a supersonic flight, the challenge of which was 800°C temperatures and severe weight reduction. Titanium alloy (Ti-6Al-4V) did not have sufficient temperature resistance (up to 600°C), while tungsten alloy had high-temperature resistance but was outside density bounds (four times titanium density) and processing cost is not feasible.

JS’s Solution

- Multiphysics simulation forecast thermal stresses with accurate precision.

- A ground-breaking titanium-tungsten hybrid structure was adopted: the structure’s bulk was reduced with a high-strength titanium alloy, and a thin-walled tungsten alloy reinforcing layer was embedded into the severe high-temperature area.

- An all-tungsten solution was ruled out, considering cost and performance.

Final Results

The hybrid concept achieved three breakthroughs:

- A 35% weight reduction (compared to nickel-base alloys) without tungsten alloy weight penalty defects.

- Passed 800°C harsh environment testing, good on strength and creep resistance specifications.

- Manufacturing cost was reduced by over 50%, and engineering cycle time by 40%, setting a new benchmark in supersonic aircraft material design.

JS has a solution to supersonic aircraft component issues. We specialize in novel material combinations with performance-versus-cost optimization. Choose us to conquer the project challenges.

Future Battlefields: The Emergence Of New Alloys And Composites

Technological advancements in industry are setting higher performance demands on metal materials. No single metal like titanium or tungsten can meet all these needs, so the development of new alloys and composites is a major future trend.

Incorporating materials such as aluminum, vanadium, and molybdenum into titanium alloys enhances strength, heat resistance, and corrosion resistance. For example, some titanium alloys for high temperatures can be employed at temperatures of more than 600°C, extending their uses to aerospace and other fields.

Composites based on titanium include titanium reinforced by materials such as carbon fiber, which has low weight yet high strength, and hold vast possibilities in the aircraft and automobile industries.

Tungsten alloys, when combined with metals such as nickel, iron, and copper, improve processing and toughness properties.

Composites based on tungsten are combinations of tungsten with other corrosion-resistant and high-temperature-resistant materials to achieve improved performance in extreme conditions. For example, in nuclear applications, tungsten-based composites are expected to be more durable and safer structural materials.

Furthermore, tungsten cutting tools are improving day by day, as composite materials and alloying improve their life cycle and machining performance. They can be used in conjunction with other CNC machining parts in order to achieve enhanced efficiency.

New composite materials and alloys are the future trend. JS follows the latest trends and leads in innovative processing technologies. We work with any new material. Choose JS and stay one step ahead.

FAQs

Q1: Are titanium alloys applicable at temperatures over 1000°C?

No! Titanium alloys degenerate in strength rapidly above 600°C and oxidize rapidly above 800°C. Ultra-high-temperature conditions require tungsten or niobium-based alloys.

Q2: Why isn’t tungsten used in aircraft? Too heavy!

Yes, and the density of tungsten is roughly four times greater than that of titanium. Weight saving in aircraft helps reduce fuel consumption and improve efficiency, and the high specific strength of titanium makes it a perfect match. The weight of tungsten would render an airplane incapable of flight.

Q3: Why is special protection necessary when welding titanium alloys?

Over 300°C, titanium absorbs oxygen, nitrogen, and hydrogen at a high rate, leading to weld embrittlement. This requires the use of an argon atmosphere or vacuum condition to maintain the air isolated, which is extremely costly.

Q4: Why is tungsten rarely used in making complex parts?

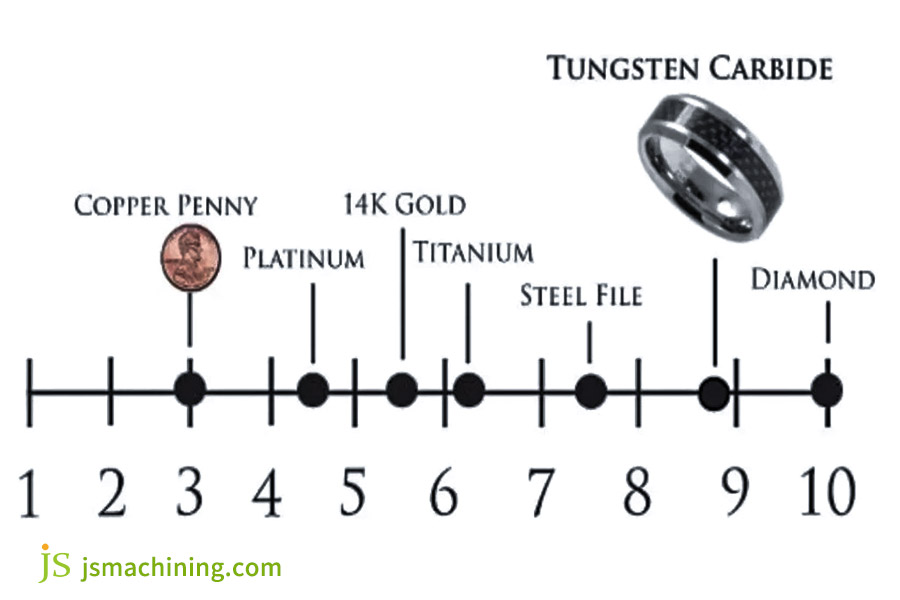

Tungsten is extremely hard (Mohs 7.5) and extremely brittle as well. The machining tools consume 100 times faster than steel, and melting and casting require specialized equipment above 3000°C.

Summary

Titanium and tungsten each possess their own strengths, and it is difficult to say that one is the sole, undisputed winner. In terms of performance, titanium has ligh tweighting, room-temperature overall performance, and cost benefits, but tungsten possesses high-temperature capability, hardness, and density benefits. In terms of application, both materials perform well.

Need a project that requires the perfect material and process? JS’s machining services are an intelligent decision. We have extensive long-term experience in CNC machining parts and machining tungsten knives for strict quality control. We are able to offer you prompt CNC machining price quotes or on-time delivery according to your specifications. We pursue to ensure the accuracy and strength of our parts from design through production. We appreciate your selection and helping you achieve project success.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: What Special Designs Do Tools In Cutting Need For Cutting Composite Materials? - JUSHENG