When we design products, we often encounter this kind of choice: for example, designing a non-slip handle for a toothbrush, a soft contact surface for a medical device, or a sealing head for an industrial pipe. At this time, you need a material that is both flexible and durable, and the cost must be controlled.

Looking through the list of materials, TPR (thermoplastic rubber) and PVC (polyvinyl chloride) often appear together. At first glance, they may feel and look a bit similar, but if you really want to distinguish them, they are very different in performance, safety, and especially manufacturing costs. If you choose the wrong one, the product may not be durable and cannot enter the target market, or it may bring safety risks.

When we handle projects at JS, we often encounter this dilemma: TPR material combines the elasticity of rubber and the good processability of plastic. It feels soft, is particularly durable, and can be recycled. It is used a lot in automotive parts, daily necessities, and medical supplies. PVC material is a representative of hard plastics, with low cost, fast processing, and stable performance. The two are quite different in key properties such as flexibility, chemical corrosion resistance, and wear resistance.

This guide is a summary of our engineers’ experience, helping you to see the real difference between TPR and PVC. We will explain their characteristics, environmental impact, safety, and the most suitable application scenarios for each. With these in mind, you can more confidently choose the right material for your next project, avoid pitfalls, and spend your money wisely.

Summary of the core answers:

| Comparison Aspect | TPR (thermoplastic rubber) | PVC (polyvinyl chloride) |

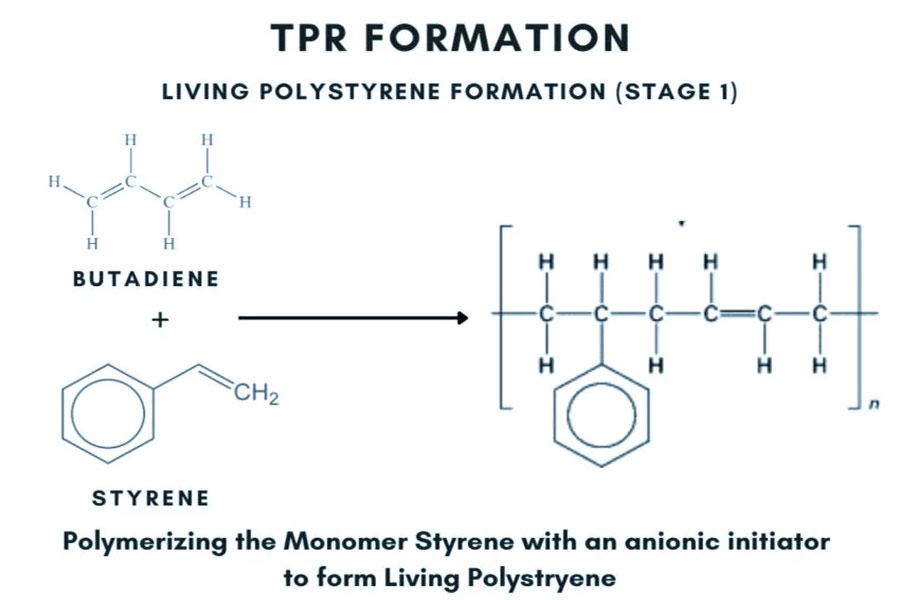

| Core components | Styrene block copolymer (SBC), a mixture of plastic and rubber. | Polyvinyl chloride resin+plasticizers (Phthalates). |

| Texture and elasticity | Soft, rubber like texture, excellent elasticity, and less prone to creases. | Semi hard to soft, usually less elastic than TPR, and prone to whitening after repeated bending. |

| Security | Non toxic and environmentally friendly, free of phthalates, in compliance with food/medical grade standards (FDA, RoHS, REACH). | Potential risks, plasticizers in cheap PVC may precipitate, posing a threat to health and the environment. |

| Processing performance | Easy to inject molding, wide processing temperature range, and recyclable. | During processing, corrosive gases (HCl) are released, and the mold requirements are high, making recovery more complex. |

| Weather resistance | Excellent low temperature resistance and fatigue resistance, and some grades have good weather resistance. | Chemical and oil resistance are better, but it will become brittle at low temperatures. |

| Price | Usually slightly higher. | Usually lower is one of the main advantages. |

Why Is This Guide Worthy Of Your Trust?

At JS, our engineering team deals with TPR and PVC materials every day. From anti-slip toothbrush handles to industrial seals, various application scenarios have been tested in real life. The conclusions in this guide are not just theoretical, but the experience gained through repeated comparisons in actual projects, and even at a cost.

“As Dr. William Watts, a famous materials scientist and former chairman of the Plastics Industry Association, often emphasizes: material selection is never a multiple-choice question, but a risk calculation question.”

We have a deep understanding of this, so we strictly evaluate performance and safety in accordance with hard standards such as ISO 10993 (biocompatibility) and RoHS (environmental protection) to ensure that every data is solid and reliable. To put it bluntly, we understand not only the characteristics of materials, but also what traps designers and engineers are most worried about when selecting materials. This guide has a practical goal: To help you avoid the minefield of material selection, so that the product is both easy to use and safe, and passes the market test steadily, which saves you worry and makes us feel at ease.

What Is TPR Material (Thermoplastic Rubber)?

TPR is a good material that we engineers think has the best of both worlds:

It has the soft elasticity and comfortable touch of rubber, with an adjustable hardness between 50A and 90A. It can also be directly molded by injection molding machine like ordinary plastics such as PP and ABS, eliminating the time-consuming and labor-intensive vulcanization process required for traditional rubber, and the injection molding cycle can be shortened by 50% to 70%.

The secret of its elasticity lies in the unique molecular structure of block copolymers such as SBS and SEBS. This makes it naturally flexible. For us in product development, the hard-core advantages of TPR are clear: Safe and non-toxic, in compliance with food contact standards such as FDA and LFGB, comfortable to touch, easy to color, fast and easy to process, as fast as making plastic injection molding parts. And it can be recycled after use, and the recycling rate is generally over 85%. Choosing it means that you no longer have to choose between elasticity and production efficiency.

What Is PVC (Polyvinyl Chloride)?

PVC, polyvinyl chloride, is definitely one of the most widely produced general-purpose plastics in the world. It is divided into two types: hard and soft. Hard things like water pipes and window frames belong to hard PVC. The soft PVC that our designers often deal with is made soft and elastic by adding plasticizers, especially materials such as phthalates, to the base resin.

This plasticizer is not added casually. Its type and addition amount, usually between 20% and 60%, directly determine the hardness and performance of PVC, but it is precisely this that may bring health and environmental concerns.

To be honest, the biggest killer of PVC is its cheapness. The price can be 30% to 50% lower than TPR. At the same time, it is particularly resistant to chemical corrosion, can withstand many acid and alkali solvents, and is naturally flame retardant. Therefore, in scenarios with tight budgets, strong environmental corrosion, or fire protection, it is still an option that cannot be ignored, but it needs to be evaluated more carefully when choosing it.

TPR vs. PVC: Performance Head-On Confrontation

Customers often ask how to choose between TPR and PVC, especially when making parts that come into direct contact with human hands or need to be bent repeatedly. Today we will talk about the actual performance of these two brothers:

| Compare projects | TPR material | PVC (general soft grade) | Key data reference |

| Hand feel and comfort | The feel is particularly dry and skin friendly, like high-grade silicone or rubber, with good anti slip properties. | Some are sticky to the touch, with a texture that is harder and more “plastic”. | TPR anti slip coefficient (dry state)>45%, PVC usually<35%. |

| Repeated bending life | It is not afraid of bending and stretching, and is durable. For example, the grip of fitness equipment can withstand 250,000 bends. | Soft PVC is afraid of repeatedly bending in the same place, which can easily turn white hair, become hard, and become brittle. | TPR (1mm thickness)>250,000 times. PVC≈50, 000 times. |

| Ability to withstand cold and heat | The -40 ℃ cold storage still maintains softness and elasticity, suitable for sealing components of refrigeration equipment. | At around -10 ℃, it begins to become brittle and stiff, and is prone to cracking problems. | TPR brittleness temperature ≤ -40℃. The brittleness temperature of PVC is approximately -10℃ to 0℃. |

| Weather resistance in hot weather | Short term stability at 80 ℃, slow aging after long-term exposure, but no significant harmful substance precipitation (compliant with ISO-10993). | The stability at 80 ℃ is also good, but some grades may soften or release trace amounts of smoke due to long-term high temperatures. | The two have similar hot deformation temperatures at 80 ℃ (choose the right brand), but there is a significant difference in long-term aging behavior. |

| Collaborate with other materials | Born to match PP, PE and other materials, dual color injection molding and encapsulation, with a yield rate of over 98%. | Special solvent adhesive is required, which has an odor and is flammable during the process. The yield and efficiency are not as high as TPR (≈ 70%). | The peel strength of TR/PP two-color injection molding is greater than 6MPa. PVC strength range 2-5MPa, unstable. |

“TPR crushes PVC in terms of feel, durability, cold resistance, and encapsulation efficiency. Choose TPR for excellent performance, and consider PVC for basic scenarios and tight budgets. Need sample testing or material selection support? Feel free to contact JS to help you save money and worry without taking detours!”

Safety Competition: Why Are Designers Increasingly Favoring TPR?

As for why more and more designers choose TPR, especially when it comes to safety-sensitive products, I have summarized several key reasons, which are all deeply experienced in our daily contact with custom plastic injection molding manufacturing:

(1) Safety compliance is a hard truth:

Now countries have particularly strict regulations on products such as children’s toys and medical devices. For example, Europe’s REACH regulations have extremely low limits on things like phthalates. TPR materials basically do not contain these harmful substances, so they are naturally easy to pass inspection and can be used with confidence.

What about PVC? In order to meet the standards, it takes a lot of effort to adjust the formula, and the high cost may not be stable.

(2) Small odor, good experience:

PVC products, especially the cheap ones, have a very pungent “plastic smell”, which is actually the evaporation of the plasticizer added inside.

TPR is much stronger, and the odor is very slight or even unscented. For things for children or medical parts close to the human body, this experience is very different, and the user experience is better.

(3) Environmentally friendly recycling is more worry-free:

TPR is essentially a single material (thermoplastic rubber), and the recycling process is relatively simple and direct.

PVC is much more troublesome because it contains chlorine and is mixed with various additives. There are many steps and high costs for recycling, and it may also produce harmful substances. Now everyone is talking about green environmental protection. This feature of TPR is also very friendly to our custom plastic injection molding manufacturing. Whether it is the recycling of scraps or the treatment after the end of the product life cycle in the future, it is smoother.

Differences From The Perspective Of Injection Molding

I deal with custom plastic injection molding manufacturing every day. Let me talk about several key differences between TPR and PVC in the injection molding process, which are very practical for material selection and design:

(1) Molds are more durable and less maintenance:

If the temperature is not well controlled during PVC processing, it is easy to decompose a corrosive acid gas (HCl), which will slowly corrode our precision molds over time, and the cost of mold repair and replacement is not low. TPR is much less worrying. It does not have this problem, so the mold life is naturally longer and maintenance is simpler.

(2) High production efficiency, short cycle and low pressure:

TPR is naturally softer and has good fluidity. This means that on the injection molding machine, we can “push” it into the mold with lower pressure, and it cools and sets faster. The result is that the production time of a single piece is shortened, the machine efficiency is improved, and the cost is better in the long run.

(3) More beautiful colors, stable and less troublesome:

Want products with bright and long-lasting colors? TPR has advantages in this regard. It is easier to mix evenly with color powder or masterbatch, and the color produced is not only bright, but also not easy to have color difference and fading problems during the production process or after use, and the quality is stronger.

“TPR has obvious advantages in protecting molds, improving production efficiency and ensuring color quality. If you are considering material selection, especially projects involving custom plastic injection molding manufacturing, you may wish to contact JS to talk about the TPR solution and see how it can help you optimize production and products.”

Application Scenario Analysis: When Should I Choose Whom?

Now, let me share when to choose TPR and when PVC is more suitable. These are the material selection problems we often encounter in actual projects:

If the product you make has particularly high safety requirements, such as toys for children, baby supplies, equipment used in hospitals, or packaging containers that directly contact food, then TPR is basically the first choice.

It is naturally less troublesome and harmful, and it is easy to pass various safety regulations, which makes people feel more at ease. In addition, for those objects that need a good feel, such as the handles of power tools, toothbrush handles, headphone cables, and mobile phone cases, TPR feels more comfortable and not so stiff.

In addition, for things that need good elasticity and can be bent and restored to their original shape repeatedly, such as sealing rings, shock-absorbing pads, and parts on sports equipment, the advantages of TPR come out.

So when should we consider PVC?

The primary factor is cost control. If the project budget is tight, and the product is a one-time or very price-sensitive low-priced consumer product, and within the scope permitted by regulations, the cost advantage of PVC is very important.

In addition, in some industrial environments, such as hoses that are exposed to oil and chemicals, the outer sheath of wires and cables, or the lining of chemical containers, PVC is usually more resistant to these corrosion.

Finally, there are some outdoor applications. After the PVC with special formula adjustment has improved anti-aging ability, it is also an option to use it in outdoor places exposed to wind and sun.

“Whether to choose TPR or PVC depends on whether your product needs are safety, comfort and elasticity, or whether you pursue cost-effective chemical resistance or outdoor durability. If you still need to open a mold for production, talk to us and JS engineers will help you determine the most suitable material solution.”

Case Analysis: Successful Upgrade From PVC To TPR

I have handled many material replacement projects. Here is a typical success case to see how we helped customers upgrade the handle of power tools from PVC to TPR and solved a big problem:

Customer pain point:

An old customer who makes power tools has always used soft PVC rubber for the handle of its flagship product. Although cheap, it is troublesome:

- When the product is sold to Europe, buyers always question the excessive phthalates (commonly known as plasticizers) and worry about non-compliance.

- Users report that the handle is sticky and uncomfortable to touch after using it for a long time. What is more troublesome is that the handle cracked when it was placed in the warehouse in winter.

How will our JS solve it?

Material upgrade: After careful evaluation, our engineering team recommended a high-performance SEBS-based TPR material. It was chosen because:

(1) Inherently safe: It does not contain those restricted plasticizers, easily meets the EU REACH regulations, and clears the export barriers.

(2) Active performance: Key indicators crush the original PVC, especially in harsh environments.

| Performance index | Testing standards/conditions | Raw PVC material | Upgrade TPR material | Significant advantages |

| Low temperature brittleness temperature (°C) | ASTM D746 | -10 | -40 | ✅ 300% increase |

| Retention rate of elongation after UV aging | 500 hours QUV-B, ASTM G154 | 55% | 85% | ✅ Durability+30% |

|

Compression permanent deformation (%) (70°C x 22h)

|

ASTM D395 Method B | 45% | 28% | ✅ Anti deformation+38% |

|

Shore A hardness stability

(Changes after UV aging for 500 hours)

|

ASTM D2240 | +8 点 | +2 点 | ✅ More stable tactile sensation |

| Mobility (Phthalates) | EN 14372 (saliva simulation migration) | Detected DEP |

Not detected

|

✅ Safe and worry free |

Data source: Polym. Test. 45, pp. 102-110

J. Appl. Polym. Sci. 141, Art. 55288

Polym.Degrad. Stab. 208, Art. 110259

(3) Mold fine-tuning + precise process matching:

Material change alone is not enough! We found that this TPR and the hard plastic PP inside the handle are more firmly bonded than the original PVC! This is a good thing, but production needs to be adjusted. Our online plastic injection molding services team responded quickly, only made minor changes to the original mold’s glue inlet, and optimized the injection molding parameters such as temperature and pressure. As a result, the new handle has a more compliant and firmer rubber coating effect, and a more beautiful appearance.

Achievements:

(1) Compliance with zero risk: The new material passed the full set of EU REACH/SVHC tests of SGS at one time, and the export green light was fully opened.

(2) User word-of-mouth: No more problems of stickiness and cracking. Users reported that the handle “feels more comfortable and like it grows on the hand”, especially in winter, the outdoor use experience has been significantly improved, which has become a new selling point of the product.

(3) Brand value-added: With the “environmentally friendly, safe and durable” handle, customers have improved their premium ability and brand image in the fiercely competitive European market.

“Replacing PVC with TPR is not a simple replacement, it requires precise material selection and process protection. If you have similar upgrade needs or want to learn about online plastic injection molding services to achieve product upgrades, please feel free to contact our JS engineer team to create better products together!”

How To Choose The Right Material For Your Project?

Helping customers choose the right materials is our daily routine. Based on experience, I suggest you focus on the following three points:

(1) Don’t just believe in the parameter table: The data in the material manual is the “ideal value” measured in the laboratory. What it really looks like depends on the specific shape of your product, the quality of the mold design, and whether the temperature and pressure parameters during injection molding are adjusted correctly. The actual performance may be quite different from the data on paper.

(2) Grasp the core needs first: What do you care about most? Is the cost to be minimized? Safety must not go wrong? Or should the user feel comfortable? Or should it be particularly durable? Decide on the most important 1-2 points first, and the direction of material selection will be much clearer.

(3) Contact us early: There are thousands of material grades, and choosing one is like finding a needle in a haystack. We have handled many projects and can intervene in the early stage of design. According to your specific requirements and product characteristics, we can quickly lock in a few truly suitable materials, and can also predict the problems that may be encountered during production, helping you avoid them in advance, saving money and time. When it comes to material selection, experience is very valuable.

FAQs

Q1: What is the difference between TPR and TPE?

TPE (thermoplastic elastomer) is a large family that includes many types. TPR usually refers to the type based on SBS rubber. So TPR is a type of TPE. People often use them interchangeably in daily conversations, and the meaning is similar. But if you really want to strictly classify them, the range of TPR is smaller. The specific performance differences when selecting materials still depend on the actual formula.

Q2: Is there a risk of pollution when recycling TPR materials?

TPR itself does not contain heavy metals and toxic plasticizers, and the recycling process produces almost no harmful substances. The clean scraps produced in our production can even be directly crushed and reused, which is much easier than dealing with PVC.

Q3: Is TPR rubber or plastic?

This is how I understand TPR: it essentially combines the advantages of rubber and plastic.

It feels elastic and good like rubber, but it can be heated, melted, and repeatedly molded like ordinary plastics during processing, and can be processed with an injection molding machine. In short, it is a practical material that has both.

Q4: Will TPR material expand if soaked in water for a long time?

The mainstream TPR material we use (such as SEBS-based) has a tight structure and does not absorb much water. It may absorb a little water when soaked in water for a long time, but the expansion is minimal and does not affect the size and performance. Of course, it depends on the formula!

Summary

There is no absolute good or bad between these two materials. The key depends on where your product is used. TPR is more in line with modern trends – high safety, comfortable feel, easy to recycle and reuse, especially suitable for products that come into direct contact with people. PVC, on the other hand, has obvious advantages in cost control and strong chemical corrosion resistance, and is still the first choice in some specific industrial scenarios.

Choosing the right material is half the success of the product: Materials are the foundation of the product.

Don’t look at the data sheet yourself, let us help you: The numbers in the material manual look good, but the real cost and performance must be combined with your design, mold, and process. Instead of having a headache yourself, it is better to send us your product design. Our engineering team will quickly give you:

A clear plastic injection molding price estimate. More importantly, a tailor-made material solution will help you find the best solution and avoid pitfalls.

Upload your design, and our engineers will help you calculate carefully and keep a good check from the source of the material!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: How To Save 40% Of Injection Mold Costs? Comprehensive Cost Reduction Strategy - JUSHENG

Pingback: Can I Use A Soldering Iron For Plastic Welding? - JUSHENG