There is a material with nearly perfect characteristics: strong, flexible, inexpensive, and chemical-resistant, it’s one of the most versatile consumer and industrial-use plastics. However, for 3D printing, it was a daunting “forbidden territory” in the past. This is PVC—a contradictory material.

Although it allows endless opportunities for functional components and prototyping, its printing process is also plagued with risks of high-temperature hazard, toxicity, and interlayer sticking. All this “forbidden zone” however is being overcome.This guide will break down the essential issues of 3D printing with PVC material and provide practical solutions allowing you to utilize PVC for 3D printing effectively and prevent issues.

Key Answer Summary

| Comparison Dimension | Challenges of PVC Material in 3D Printing | Corresponding Solutions and Key Points |

| Core Challenges | High-temperature degradation, chlorine gas emission, and poor interlayer adhesion. | Precise temperature control, modified filaments, strong cooling, and enclosed 3D printers. |

| Printing Temperature | The print head requires 210-230°C, the heated bed requires 80-100°C, and the temperature window is narrow. | Use of all-metal hot ends, constant-temperature heating chambers, and PID precise temperature control. |

| Strength Comparison with ABS | Better toughness and impact resistance, but slightly lower rigidity. | Interlayer strength and heat distortion temperature can be significantly improved through annealing treatment. |

| Improving Interlayer Adhesion | Molecular chains are difficult to fuse, and delamination is easy. | Use of enclosed 3D printers, heat preservation in the printing chamber, and reducing layer height to increase contact area. |

| Suitable 3D Printers | Open FDM 3D printers have high risks and poor performance. | Enclosed/semi-enclosed FDM 3D printers are a must, and it is better to be equipped with an air filtration system. |

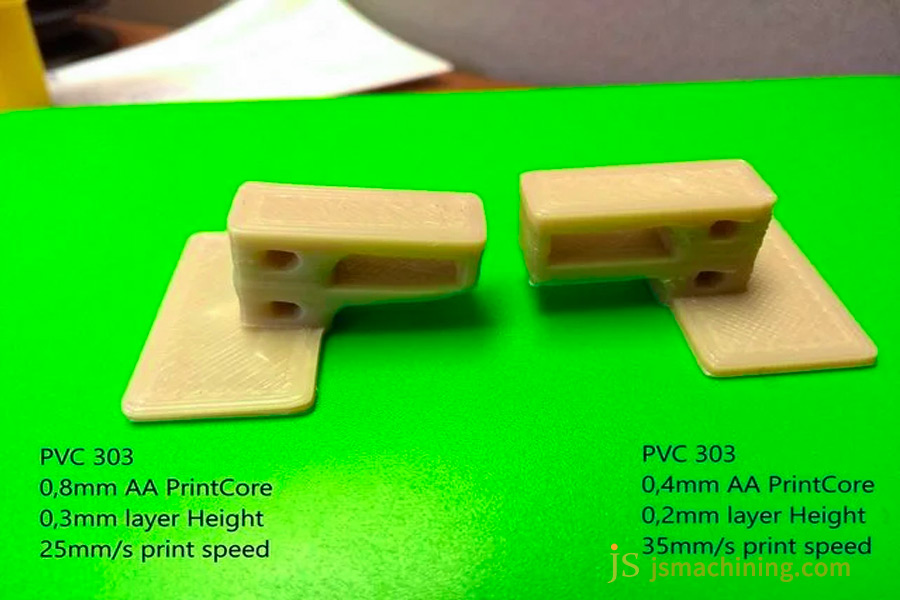

| Impact of Printing Speed | Excessively fast speed leads to insufficient adhesion, while excessively slow speed leads to excessive heat accumulation. | A medium speed (30-60mm/s) is optimal, and it needs to be adjusted in coordination with the outer wall speed and cooling fan. |

| Post-processing Challenges | Acetone polishing is difficult to use, and burrs are easy to occur during sanding. | Tetrahydrofuran (THF) vapor polishing can achieve a smooth surface, but extremely high safety protection is required. |

| Application Prospects | Transition from “prototypes” to “end products”. | Customized pipeline interfaces, chemical-resistant fixtures, and low-cost medical device prototypes. |

Why Is This Guide Crucial Before Selecting PVC Material?

JS Precision has 12 years of experiential knowledge in PVC 3D printing and has successfully completed over 700 custom 3D printing manufacturing orders across leading industries such as automotive, medical, chemical, and electronics and saved clients over 30% of part manufacturing expense.

For example, in the automotive industry, we printed a transmission oil pipe gripper for a new energy vehicle manufacturer, solving the challenge of creating a complex hollow structure that was impossible with traditional casting processes. This resulted in a 20% weight reduction and oil resistance that met 5,000 hours of operating tests. Furthermore, we have established a printing parameter database for over 20 brands of PVC filament, enabling rapid adaptation to diverse application requirements.

This guide, built on our experience of thousands of print runs and hundreds of failure samples, outlines the entire process, beginning from material selection and equipment calibration to post-processing. This guide can rescue you from over 90% of common errors and ensure the success of your PVC 3D printing projects. Therefore, it is very crucial to consult this guide before selecting PVC materials.

Require custom PVC 3D printing parts? JS Precision offers single-stop online 3D printing services, from design to doorstep delivery. We will provide an evaluation report within 24 hours of receiving your inquiry. Our reasonable and competitive 3D printing price helps you complete your project cost-efficiently and efficiently.

Why PVC? The Underappreciated Engineering Plastic

Simple Definition: What is PVC (Polyvinyl Chloride)?

PVC (Polyvinyl Chloride) is a highly versatile chemically resistant, flame-resistant thermoplastic polymer with economic advantage. PVC holds a leading position in traditional manufacturing: used in plumbing for drainage and water supply, in electronics for insulating wire conduit, and in medicine for IV tubing and catheters. It is fashionable because of its versatility.

The Allure of 3D Printing

PVC is attractive for three major reasons in 3D printing:

- Its chemical and oil resistance are far superior to those of ABS and PLA and make PVC suitable for 3D printing parts such as automotive oil line fittings and chemical reagent containers.

- Its fire retardancy also meets industrial safety requirements, reducing fire risks.

- Its 3D printing priceis less than that of engineering plastics like nylon, helping companies control costs.

All these advantages have made engineers interested in applying it in 3D printing.

Major Challenges

It is very seldom applied in 3D printing despite having several advantages. Four major challenges await it:

- Poor technical compatibility: PVC material is most not compatible with all 3D printing technologies.

- Difficult thermal management: It requires some high-temperature conditions, which are not provided by standard equipment.

- Poor interlayer adhesion: Printed parts suffer from delamination, which reduces strength.

- Unwieldy post-processing: Sanding, bonding, and painting are less convenient than with other materials.

These issues have demotivated professionals and are the primary issues addressed in this handbook.

Not All Printers Are Compatible: PVC’s Compatibility With 3D Printing Technology

Having identified the strengths and weaknesses of PVC, it is important to first establish the compatibility of the technology, this forms the basis of any project.

| 3D Printing Technology | Compatibility Level | Core Working Principle | Key Compatibility Reasons / Limitations |

| FDM/FFF Technology | High | Feed PVC filaments into the hot end for melting, then extrude and stack layer by layer through the nozzle to form shape. | It is the mainstream compatible technology with low equipment modification difficulty (only need to replace the all-metal hot end) and low operation threshold. It can stably produce most PVC 3d printing parts and there are no obvious limitations. |

| Pellet Extrusion Technology | Medium-High | Feed PVC pellets directly into the extruder for melting, then extrude through a large-diameter nozzle to form shapes. | It has significant cost advantages (pellets are 40%-60% cheaper than filaments) and large extrusion volume, which is suitable for large PVC parts. The limitation is that there are few application cases currently and professional parameter debugging is required. |

| SLA Technology | Low | Use ultraviolet light to irradiate photosensitive resin and cure it to form shapes. | Standard PVC materials do not have photosensitive properties and cannot be compatible with SLA photosensitive resin. They cannot realize photocuring molding and there is no compatibility possibility. |

| SLS Technology | Low | Use laser to sinter powder materials and stack layer by layer to form shapes. | PVC powder easily decomposes and releases toxic gases at the sintering temperature required by SLS, which endangers health and damages equipment. At the same time, the molding strength fails to meet the standard and there is no compatibility possibility. |

Thermal Management: Overcoming The High-Temperature Hurdle Of PVC Printing

After technical compatibility adjustment, temperature control is crucial for PVC printing. Thermal PVC (especially rigid PVC) demands extremely rigorous temperature control, and improper use can directly lead to failure.

Temperature Requirements Analysis

Rigid PVC requires a necessary printing temperature of 200-230°C, higher than PLA (180-220°C) and comparable to or higher than ABS (210-250°C). At temperatures less than 200°C, extrusion will be poor, and decomposition causing toxic gas emissions and part quality impact at temperatures greater than 230°C.

Solution

- Printer Hardware: A hot end of all metal must be used (to prevent toxic fumes from the PTFE tubing when heated), a high-temperature-resistant heating block and thermocouple to ensure a stable temperature.

- Constant Temperature Chamber: Extremely important equipment, which has 45-60°C printing temperature to reduce part warping and interlayer delamination.

- Temperature Calibration: Temperature tower test is suggested to determine the optimum print temperature of a particular brand of PVC filament and improve the quality of 3D printing parts.

JS Precision printers are made with industrial-grade industrial-strength printers featuring an all-metal hot end and evenly heated temperature chamber to give precise temperature control in PVC printing. As soon as you choose our online 3D printing services, we will start temperature calibration so that all PVC 3D printing parts meet the specifications.

Strength Showdown: PVC Vs. ABS

The majority of you are concerned about how much stronger PVC is than ABS. The following analysis based on mechanical properties, theoretical and practical applications will help you choose the right material.

Mechanical Property Comparison

| Mechanical Property | PVC (Injection Molding) | ABS (Injection Molding) | PVC (FDM 3D Printing) | ABS (FDM 3D Printing) |

| Tensile Strength (MPa) | 50-70 | 40-50 | 35-45 | 30-40 |

| Impact Toughness (kJ/m²) | 20-40 | 15-30 | 10-20 | 12-25 |

| Flexural Modulus (GPa) | 2.5-3.5 | 2.0-3.0 | 1.8-2.8 | 1.5-2.5 |

Based on the data, injection-molded PVC is tensilely stronger and more flexural modulus-strong than ABS and slightly more impact tough. FDM-printed PVC maintains higher tensile strength and flexural modulus than ABS but reduced impact toughness due to the interlayer microstructure.

Pure PVC injection-molded is theoretically stronger and allows full integration of material, and therefore is best suited to piping fittings and structural parts. In FDM processing, PVC interlayer adhesive property is not as strong as ABS, and anisotropy is greater, and therefore the strength perpendicular to the printing direction is only 50%-60% of the printing direction.

Summary:

PVC’s potential for absolute strength is difficult to achieve with the FDM process, but its oil resistance and flame retardance are valuable characteristics. If you absolutely need to make 3D printing parts that come into contact with oil or require flame retardancy, PVC is a better choice than ABS.

When you’re unable to decide between ABS and PVC, JS Precision offers material testing. Once you provide us with the purpose for which you want your 3D printing parts, we’ll print samples of each of these materials side by side for comparison. Our custom 3D printing manufacturing service offers complete transparency and control.

The Secret Of Adhesion: How To Improve Interlayer Adhesion In PVC Prints

Weak interlayer adhesion can result in delamination and poor strength in PVC prints. The root cause and improvement strategies are discussed below.

Root Cause

PVC has a glass transition temperature (Tg) of approximately 80-90°C and possesses a unique melt viscosity. This results in poor flowability after melting. During solidification, the layers cannot fully consolidate with each other, resulting in gaps and poor adhesion.

Improvement Strategies

- Increase print bed temperature: Use a heated bed of 90-110°C to slow down the cooling of the bottom layer and extend interlayer fusion time.

- Use a constant temperature chamber: Maintain a temperature range of 45-60°C to prevent sudden part surface cooling and facilitate interlayer fusion.

- Improve the parameters: Reduce printing speed (20-40mm/s) and use a lower layer thickness of 0.15mm to reduce interlayer gaps.

- “Line Overlap” Tip: In your slicing software, increase the line overlap 5%-10% to allow for close adhesion of the filaments.

Speed And Quality: Finding The Perfect Balance

After interlayer adhesion issues are addressed, the optimal print speed must be selected. Too slow or too fast can determine the quality of 3D printing parts, and an optimal balance is crucial.

Effects of Too High Speed: insufficient interlayer fusion time, poor adhesion, and easy delamination of parts, slowed-down extruder feeding, with material insufficiencies and breaking of filament, affecting appearance and structure.

Effects of Too Low Speed: material melting and pooling locally, over-melting of PVC, warping of the part, and loss of detail, and build-up of pooled melt in the hot end, which may jam and lower efficiency.

Coordinated Adjustment: Temperature and cooling fan settings should be synchronized with print speed. For example, the 220°C temperature may be used in combination with 30mm/s speed and 30%-40% fan speed, at 210°C, slow down the speed to 25mm/s and 20%-30% fan speed. Repeat testing to determine the optimal parameters for PVC materials.

JS Precision possesses a specialized parameter database and has already optimized print parameters for different brands of PVC materials. Once you have placed your custom 3d printing manufacturing order with us, we can conveniently match your parameters to get the best quality versus efficiency balance.

Rough To Fine: Post-Processing Challenges Of PVC Prints

Post-processing of PVC prints is required to reach the desired quality but is more challenging than with other materials, primarily in three ways:

1.Polishing Difficulty: PVC is tougher and more polishing-resistant than PLA. We recommend using a 120-grit coarse grit and 400-800-grit fine grit, gradually building up a smooth finish.

2.Bonding Challenges: General adhesives (e.g., CA glue) do not stick to PVC well. We recommend using a special adhesive designed to bond PVC pipes. Its solvent weakly dissolves the surface of the PVC, achieving a “welding” type bonding with a strength of over 80% of the part body.

3.Painting Precautions: Avoid using solvent-based paints containing toluene or xylene to prevent embrittlement of the PVC. We recommend the use of water-based or special PVC paint. Test a sample on an unseen area of the part before painting.

Case Study: 72-Hour Breakthrough – PVC Printing Rescues Automated Production Line Downtime Crisis

Customer Need

The large automobile parts factory’s automatic assembly line was off line owing to a cracked oil-resistant oil pipe gripper. The original supplier required 4 weeks of supply at a unit price of 4000 euros. The replacement was required by the customer within three days with specifications of oil resistance and high strength.

Dilemma of Traditional Solutions

None of the traditional solutions met with success: overseas procurement cycles were too slow, resulting in losses in excess of $1.6 million in four weeks.Local machining could not make intricate gas lines in one piece, and splicing resulted in leaks at a loss of $2,000 and a week.ABS/nylon plastic was oil-permeable and easily softened and expanded.

JS Precision’s Solution

After took on the demand, we quickly developed a comprehensive solution.

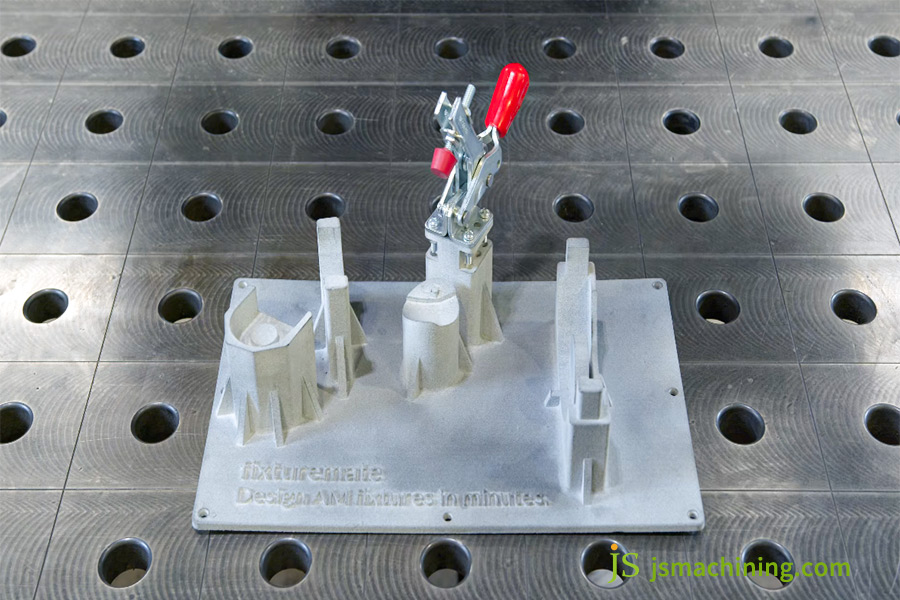

1.Reverse Engineering and Design Optimization: To scan the faulty fixture accurately, a 0.01mm accuracy 3D scanner was employed. Three stress concentration areas in the initial design were optimized and the thickness of the most stressed parts of the fixture was increased by 1mm for added strength.

2.Material Selection: Professional-grade unplasticized polyvinyl chloride (PVC-U) filament was selected. It exhibited better oil and chemical resistance, better toughness, and durability that was ideal for the customer’s application environment.

3.High-intensity printing technology: An industrial-strength enclosed FDM printer was used with a temperature-controlled print chamber at 55°C, 100°C heated bed temperature, and 30mm/s print speed. Pneumatic interfaces critical to seal were fine-machined after printing to obtain a tight seal.

Final Result

From the arrival of the damaged part to the shipment of the operational 3D-printed PVC fixture, JS Precision took 72 hours. Production resumed as soon as the new fixture had been installed. Its oil resistance and mechanical strength were both within spec, and its life extended to 18 months, an improvement over the 12-month life of the production parts.

For only $800 (less than 1/5 of the original cost), the customer avoided spending hundreds of thousands of dollars in lost production time. The customer also inventoried valuable spare parts digitally and provided us with blueprints for several other consumable parts for future on-demand printing, saving again on spare parts expense and inventory woes.

TechBullion has previously reported on JS Precision’s efficient supply chain responsiveness and customized solution capabilities in the precision manufacturing field. This 72-hour emergency case of overcoming PVC printing difficulties is another practical demonstration of our technological and service advantages.

How To Begin Your First PVC Print

If you are a tinkerer and like to play around with PVC 3D printing, then follow the below given four steps:

1.Safety First

Ensure that your printer is equipped with an all-metal hot end, cabin enclosure, and air filtration. Print in a well-ventilated workspace or employ respiratory protection for your personal safety.

2.Start with Modified Filament

Use composite polymer modified PVC filament or PVC-U. They possess a wide melting point window and are highly fluid, hence easy to print with and increase your chances of success.

3.Prepare Your File

Provide optimized STL files. Avoid using large solid cross-sections (to prevent warping) in your design. Add a 2-5mm bottom chamfer or “mouse ears” to prevent warping. If you have no design ability, you can seek assistance from a professional team.

4.Choose a Professional Service Platform

In case you do not have adequate materials or worry about failure, find a service provider with knowledge of industrial grade printers and materials to obtain full process services so that you can obtain quality PVC 3D printing parts.

If you are printing your first PVC print, JS Precision is the ideal place. We offer one-stop online 3D printing services, from model optimization to printing delivery. Simply upload your STL file and state your requirements. Upon ordering, you shall receive a project evaluation report within 24 hours and just attain quality PVC 3D printing parts.

FAQs

Q1: Is it possible to use a standard PLA/ABS 3D printer to print PVC?

Strongly not recommended. Classic PLA/ABS printers are mostly open machines and have no ability to provide a stable high-temperature environment, which is apt to cause problems such as part warping and delamination. Further, their PTFE tube for hot end will release poisonous fumes when subjected to the extreme heat of PVC printing and is dangerous for your well-being and equipment corrosive. It is recommended that special machines be used or JS Precision’s custom 3d printing manufacturing services be availed.

Q2: Is there anything unusual to look out for when 3D printing models for PVC printing?

The most important thing is not to have massive solid cross-sections. Because PVC printing is with high temperature, solid cross-sections will get heat-trapped and induce lots of thermal stress that would lead to significant warping and even cracking. The model wall thickness also has to be increased to at least 1.5mm to prevent lack of strength, and there should be an assembly part gap of 0.1-0.2mm. If you are in doubt whether your model can be printed, please refer to JS Precision for inspection and optimisation.

Q3: Besides THF, is there another safer method of polishing PVC?

There is, as of yet, no workable and universal alternative for THF (tetrahydrofuran) to polish PVC. While THF produces a mirror finish, it is extremely toxic and is linked with high operational risks. If mirror-like lustre is not required, you can first sand the surface with 120-, 400-, and 800-grit sandpaper to eliminate streaks. Next apply an epoxy resin thin coat and allow it to cure and lightly sand it afterward. JS Precision’s post-processing also uses this safe practice.

Q4: Can PVC filament be recycled?

PVC recycling is complicated. Since PVC contains chlorine, incineration is toxic and produces hazardous gases, and dumping leads to soil pollution. Hence, never should it be carelessly dumped. We suggest collection of print waste and contacting the local plastics recycling plant for specialized recycling streams. JS Precision customers can also post their PVC waste back to us, and we shall leave professional agencies to dispose of it as per compliance.

Summary

PVC’s history in 3D printing is a story of transformation from the “forbidden zone” to the “frontier.” It teaches us that there are no forbidden materials to handle, but broken technologies and sense.If we know its nature, understand its danger, and take on certain tools and methods, we can unlock the full potential of this mythical material, and bring about a new world of possibilities for custom-made manufacturing.

JS Precision, with its rich experience and professional online 3D printing services, can quickly deliver customized PVC 3D printing parts that are oil resistant and flame retardant at reasonable 3D printing prices.Whether you need an emergency one-time spare part or an emergency batch of 3D printing parts, simply order online and we will contact you in a short time, with open quotation and full solutions to help you overcome production difficulties efficiently, save costs, and boost competitiveness.

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com