I often see thermoplastic rubber (TPR) quietly playing an important role. Think about it: the comfortable and non-slip handle of electric toothbrushes, the soft and safe children’s toys, the reliable grip of tool handles, the sealing protection of waterproof shoes, and even the tight fit of car door seals. These experiences are inseparable from the rubber-like elasticity and unique touch brought by TPR material.

The core of its popularity in the fields of automobiles, medical care, consumer goods and construction is that TPR has found a wonderful balance: it has rubber-like elasticity, provides excellent durability, and is extremely easy to process. For us engineers, the most attractive thing about TPR material is that it does not require the complex vulcanization process of traditional rubber. We can directly use common processes such as injection molding and extrusion for rapid prototyping, and the scraps can be recycled, which is very efficient.

There are many types of TPR on the market, each with its own characteristics, but they generally perform well: they can work stably in a relatively wide temperature range, their performance is also stable at high temperatures, and they are particularly resistant to environmental tests such as sun and rain. These real characteristics are exactly what we focus on when selecting materials for our products at JS.

This guide is based on our experience in the actual application of TPR material. We want to talk to you about its core performance, from its tangible physical performance (such as hardness, elasticity), to its tolerance to various chemicals, to its safety and various processing conveniences. Let you truly understand the strengths of this versatile material.

Summary of core answers:

| Core property | Description | Significance for product design |

| Essence of materials | A polymer alloy that combines rubber elasticity and plastic processing properties. | No need for vulcanization, can be directly injection molded, greatly improving production efficiency. |

| Hardness range | Extremely wide, ranging from Shore 0A (extremely soft) to Shore 70D (semi-rigid). | Various products can be customized, from soft shock pads to tough casters. |

| Tactile feel | Soft, dry, delicate, similar to rubber or silicone. | Providing excellent user experience, it is very suitable for making handles, buttons, etc. |

| Safety | Usually non-toxic, odorless, and free of phthalates and latex. | Can meet FDA food grade, medical grade, and children’s toy safety standards. |

| Elasticity and rebound | Excellent elasticity and compressive deformation. | Suitable for making sealing rings and shock-absorbing components, which can maintain performance for a long time. |

| Processability | Excellent fluidity, easy to inject, encapsulate and color. | High design freedom, capable of achieving complex details and dual color products. |

| Weatherability | The TPR based on SEBS has excellent UV and antioxidant properties. | Products suitable for outdoor use and long-term use. |

| Recyclability | 100% recyclable, and the scraps can be directly reused. | In line with the trends of sustainable development and green manufacturing. |

Why Trust This Guide? In sights On Polymer Materials From JS Experts

The JS team has been working on TPR material applications for nearly 20 years and has handled countless projects, from small everyday items to demanding industrial parts, such as some critical plastic injection molds parts.

This has given us a thorough understanding of the characteristics of TPR: How many times can it be stretched repeatedly? How does it perform in cold and hot weather? Will it become brittle after a long time of use? These perceptions are not empty talk, but are based on our solid laboratory testing (in accordance with ISO 17349 standards), continuous R&D investment, and real feedback and data support accumulated from serving more than 300 customers.

“As materials expert David Roylance often says, material selection determines product life.”

It is precisely because of the accumulation of these practical experiences and data that we can help you select formulas more accurately, design reliable molds, and truly bring out the advantages of TPR materials. Even at temperatures between -40 and 90 degrees, it can work stably and is food-safe, making the products durable and safe. Leave it to us, and you get proven professional capabilities and a responsible attitude towards results. Feel free to request free samples and selection support.

Definition: What Exactly Is TPR?

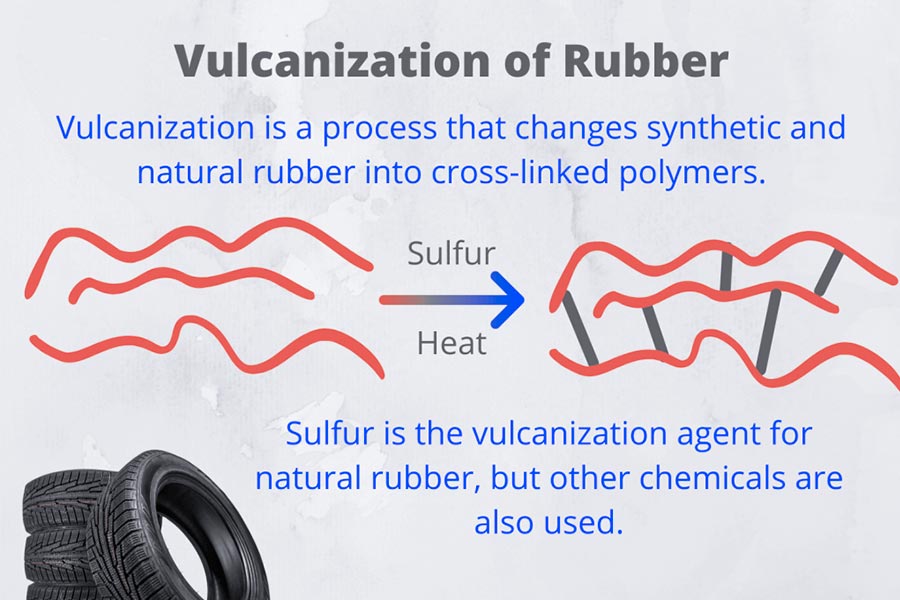

One of the materials we deal with most in daily life is TPR (thermoplastic rubber). It is very different from the traditional rubber we are familiar with. The most fundamental difference is that it does not require vulcanization.

TPR belongs to the large family of thermoplastic elastomers (TPE), and the TPR we usually refer to is specifically those materials that are mainly based on styrene polymers (such as SBS) and have been mixed and modified.

To understand its core, you can imagine that its molecules are like a special chain: the chain alternates between “hard plastic segments” (providing strength and plasticity) and “soft rubber segments” (providing elasticity and softness).

At room temperature, these hard parts will “hug” each other together, like small nodes to fix the entire structure, making the material show rubber-like elasticity.But when you heat it to a certain temperature, these hard parts will “loosen”, and the whole material can flow like hot melt adhesive, making it easier for us to process it through common thermoplastic processes such as injection molding or extrusion. This unique molecular structure design is the “secret weapon” that makes TPR elastic like rubber and easy to process and recycle like plastic.

Key Physical Properties: Why Is TPR So Versatile?

We believe that the key to TPR (thermoplastic rubber) being used in so many fields is its several very practical physical properties:

(1) First, it has a very wide range of hardness adjustment.

This is one of its biggest trump cards. Our engineers can adjust the formula to make it as soft as gummy candy (such as Shore 0A), as hard as a tire (Shore 90A), or even semi-hard (Shore D). This means that whether it is a handle or toy that needs a super soft touch, or a part that needs a certain amount of support, TPR can basically meet the softness and hardness requirements.

(2) Secondly, TPR is usually light.

Its density is generally between 0.9 and 1.2 g/cm³, which is lighter than many traditional rubber materials. This is very helpful for us to consider weight reduction and cost reduction when designing products.

(3) Finally, TPR is also very tough and elastic.

It is not only strong in itself, but more importantly, it has a strong tensile capacity – it can be stretched to several times its original length (even more than 1000%) before it may break. This makes the parts made of it not easy to be torn, can withstand repeated bending and stretching, and are more reliable and durable to use. These practical characteristics together create the versatility of TPR.

“TPR combines the elasticity of rubber, the easy processing of plastics and excellent durability, making it an ideal choice to solve your product design problems. If you are looking for a reliable, flexible and efficient material to enhance the product experience, please feel free to contact our JS engineering team to explore how TPR can create value for your project.”

Chemical And Environmental Performance: Safety And Durability

The durability and safety of the product are inseparable from the material’s tolerance to chemical environments, temperature changes and outdoor conditions. How does TPR perform? Please see the table below to help you quickly understand the key performance:

| Characteristic | Concrete manifestation | Material selection suggestions/precautions |

| Chemical resistance | Water resistance, most cleaning agents, acid and alkali are not a problem. But it has weaker resistance to organic solvents and oils such as gasoline and alcohol. | If your product comes into contact with oil or solvents, please inform us in advance. JS company has specially developed oil resistant grades to choose from. |

| Temperature resistance | Ordinary TPR can work normally within the range of -40° C to +100° C. | If the temperature of your application environment is particularly high or low, don’t worry, JS company can provide TPR with special formulas to meet more stringent requirements. |

| Weather resistance and aging resistance | TPR (sometimes referred to as TPE) based on SEBS performs better, especially withstanding sun, rain, high temperature oxidation, and has a longer lifespan. | For products that require long-term outdoor use or higher durability, such as car exteriors and outdoor equipment, we strongly recommend using JS’s SEBS based TPR solution. |

Safety: Why Is TPR The First Choice For Children And Medical Products?

When it comes to children’s products and medical products, we have almost stringent requirements for the safety of materials. The core of why TPR is the first choice in these fields lies in the three characteristics that we value most:

(1) Really non-toxic and reliable:

Our strictly screened TPR formula fundamentally eliminates hidden dangers such as phthalates (those harmful plasticizers), BPA and heavy metals. This allows the TPR materials we deliver, whether made into baby teethers or medical devices, to easily meet the stringent global safety regulations such as RoHS and REACH, giving you and the end user peace of mind.

(2) Good news for people allergic to natural latex:

For medical environments (such as tourniquets, catheters) or daily necessities (yoga mats, goggle straps), the risk of allergies caused by traditional latex is a big problem. TPR is an ideal alternative to latex-free (Latex Free), effectively avoiding this concern.

(3) Fresh and odorless, improved quality:

Compared to some plastics or rubbers with pungent odors, high-quality TPR materials themselves have almost no unpleasant odors. This not only brings a better user experience when unboxing, but is especially important for products that require a delicate environment (such as internal parts of medical equipment) or are close to the mouth and nose (such as cutlery handles and baby bottle accessories). Even for plastic injection molds parts that have been injection molded at high temperatures, TPR can maintain this low odor property, ensuring the high quality of the final product.

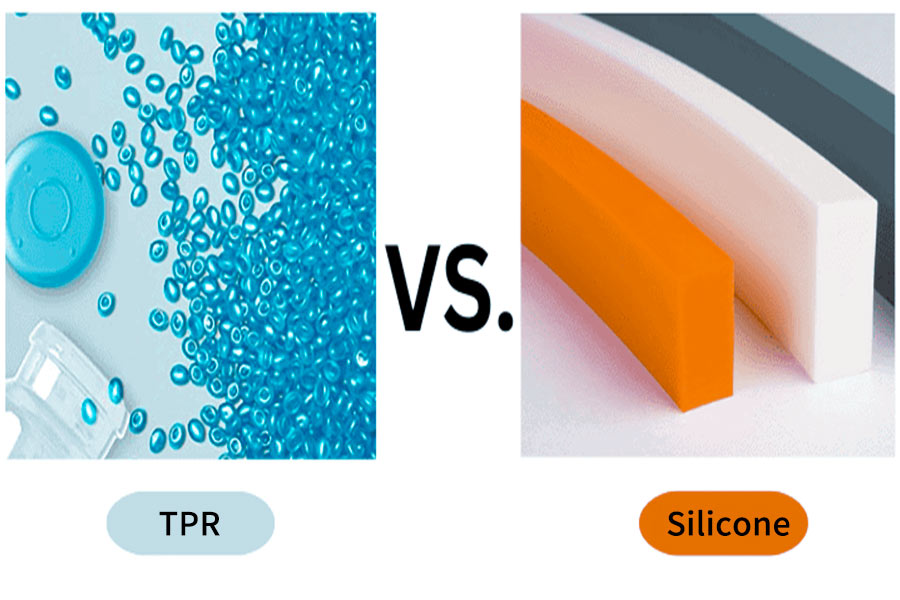

TPR vs. Silicone: How To Choose?

When recommending materials to customers, especially when doing online Plastic injection molds services projects, how to choose TPR and Silicone is often asked. Let me simply compare the key points to help you quickly judge:

(1) High temperature resistance: Silicone is stronger

Silicone is really heat-resistant and can easily cope with ovens and steamer environments above 200°C. It is good at making baking molds and high-temperature seals. TPR is much weaker in this regard. It generally cannot reach such high temperatures and is easily deformed and damaged.

(2) Cost considerations: TPR is more cost-effective

From the material itself to the processing fee, TPR is cheaper than silicone in most cases. TPR has obvious advantages for cost-sensitive projects.

(3) Feeling: Different

Both are soft. TPR has a drier surface and is not easy to get dusty and sticky. Silicone sometimes feels a little sticky, although it is very slight.

(4) “Merge” with hard plastic (two-color injection molding): TPR is more convenient

Want to wrap soft glue around hard plastic (such as PP, ABS, PC)? TPR is the first choice. It can “bite” these hard plastics very firmly through two-color injection molding, the process is mature, and the cost is controllable. It is much more troublesome to combine silicone with hard plastic, the process is complicated, the cost increases accordingly, and the effect may not be ideal.

“TPR is chosen because it is cost-effective and has easy process encapsulation, and silicone is chosen because it has high heat resistance and low deformation under operation. Guess no more!Forward your specific requirements to our JS engineers, and find the most reliable solution with online plastic injection molds services for instant proofing and validation!”

TPR vs. Traditional Vulcanized Rubber: Benefits Of New-Age Manufacturing

When we provide online plastic injection molds services, many customers are asking: Which one should I use, TPR or traditional vulcanized rubber? From the perspective of modern manufacturing, the advantages of TPR are very real. I am going to speak speaking of facts and statistics:

(1) Much faster production speed:

Manufacturing TPR parts is as fast as standard plastic injection molding, with an average cycle only 25-50 seconds in duration, and the machine almost never stands idle. Traditional rubber vulcanization is much slower! Hot vulcanization requires 3-15 minutes or longer, several times less productive.

(2) Higher design freedom:

TPR possesses excellent melt flowability (average MFR: 10-40 g/10min, 190°C/2.16kg), and neither struggles to fill into the corners of complex and thin molds, thus the product finishes are fine. Regular rubber is relatively “sticky”, and there are numerous restrictions when meeting extremely slim or extremely fine designs.

(3) Less power consumption and more eco-friendly:

No high temperature and high pressure vulcanization is required in the processing of TPR, thus power saving is inevitable. The overall energy use is some 35-50% less than in conventional rubber processes. Of greater significance, though, is that TPR is 100% thermoplastic and recyclable, and waste and scraps can be re-granulated immediately and reused. When the normal rubber is vulcanized and completed, the molecular structure cannot be regained and recycling is fundamentally not possible. The world’s recycling rate is below 15% on average, and it can literally only be discarded, which isn’t all that green.

“TPR is superior to traditional rubber in speed, accuracy, and protection of the environment, and is particularly suitable for advanced and efficient production. Want to find out if it’s suitable for your product? Don’t fret, produce a sample in a hurry through JS’s online Plastic injection molds services and the efficiency will be maximized instantly!”

Case Study: Material Innovation For A Medical Device Handle

Recently, we helped a medical device company solve the key challenges of the handle of its new handheld diagnostic device.

What challenges did the customer encounter?

A medical device company designed a handheld diagnostic device and came to us with three rigid requirements for the handle:

- The material must be absolutely safe and pass the most stringent international biocompatibility standards (ISO 10993).

- The doctor must feel comfortable using it, have good anti-slip effect, and not feel tired after holding it for a long time.

- The handle must form an inseparable whole with the device body (ABS hard plastic) and cannot be loose or have gaps. These three points are indispensable.

JS’s breakthrough solution

(1) Material selection: beyond the norm

Usually people think of medical silicone or rubber, but this time we took a different path. We recommended a medical-grade TPR material (based on SEBS).

The key advantage is that it has passed ISO 10993 certification, so customers no longer need to spend months doing biocompatibility testing from scratch, saving valuable time. At the same time, this TPR has moderate hardness and is excellent in anti-slip and grip.

(2) Core technology:Custom plastic injection molds manufacturing and combination technology

Having good materials is not enough, the key is how to make it perfectly combined with the ABS body. We fully utilized the good natural adhesion between this TPR and ABS, and specially designed and manufactured a set of two-color injection molds. This mold is customized, and the core lies in two points:

- Physical lock: When designing the mold, a tiny barb structure (mechanical lock) is precisely reserved on the ABS part.

- Chemical bonding: When the TPR soft glue is injected at high temperature, it will fuse with the ABS surface to form a chemical bond.

This physical + chemical dual combination mechanism makes the TPR soft glue handle and ABS shell as firm and seamless as if they grow together.

(3) Strict verification: performance data speaks

After the mold was completed, we conducted a small batch trial production and conducted rigorous testing on the samples that far exceeded the standards to ensure that they met the high requirements of the medical environment:

Key performance data of TPR handles vs. traditional silicone:

| Performance index |

TPR handle value for this project | Typical medical silicone | Testing standards |

| Biocompatibility certification | ISO 10993 (pre certified) | ISO 10993 (requires testing from June to September) | ISO 10993 series |

| Anti slip coefficient (dry state) | 1.28 ± 0.03 | 0.92 ± 0.08 | ASTM D1894 (Static Friction Coefficient) |

| TPR-ABS bonding strength | > 4.5 MPa (body failure) | 1.0 – 3.0 MPa (adhesive required) | ASTM D638 (Stretching, Modified Fixture) |

| Wear resistance (Taber, CS-10) | 35 mg/1000 cycles | 25 mg/1000 cycles | ASTM D4060 |

| Resistant to wiping with isopropanol | >500 times (no appearance/performance degradation) | >300 times | Internal method (simulated clinical disinfection) |

| Tear strength | 45 kN/m | 30 kN/m | ASTM D624 (Die C) |

| Hardness (Shore A) | 55 ± 3 | 40-60 (commonly used) | ASTM D2240 |

Note: The “body damage” of the bonding strength refers to the damage that occurs in the TPR or ABS material itself during the test, rather than the bonding interface, proving that the bonding is extremely strong.

Final Result: Victory Beyond Expectations

After the mold was completed, we immediately carried out a small batch trial production. The results fully met or even exceeded the stringent requirements of medical equipment. In the end, the handles received by the customer were not only safe and compliant, but also felt much more comfortable than expected. More importantly, the one-piece two-color injection molding design saves the troublesome steps of subsequent bonding or assembly, and the overall cost is reduced. Our solution successfully helped the customer to bring the product to market at least three months earlier.

“This case proves that choosing the right material and precision custom plastic injection molds manufacturing can solve the problems of safety, comfort and reliability at the same time. If you have similar product challenges, please contact the JS engineering team and let us help you quickly find the optimal solution and accelerate your success!”

How To Choose The Right TPR Material For Your Project?

I suggest you choose the right TPR material in this way, grasping three key points:

(1) Find out the details of the product: First find out where your product is used (indoor/outdoor?), will it come into contact with oil or chemicals? What are the specific requirements for the softness and hardness of the hand feel and the size of the elasticity? These are the foundation of material selection.

(2) Keep an eye on the regulatory threshold: Strictly identify the regulatory standards that the product must comply with, such as food contact (FDA, LFGB), environmental protection (RoHS) or medical device safety (such as ISO 10993). The selected material must have the corresponding certification qualifications.

(3) Rely on professional strength: There are thousands of TPR grades, and the subtle differences have a huge impact. Find a partner like JS who can accurately match the material you need and regulations, and ensure that it is perfectly adapted to your plastic injection molds parts production, from fluidity to demolding, to avoid subsequent troubles. Don’t guess, professional support can save time and effort.

FAQs

Q1: Is TPR material wear-resistant?

In our actual application, TPR material is usually quite wear-resistant, which I often come into contact with. However, how wear-resistant it is depends on the specific formula used. Our company has specially developed some types with strong wear resistance, such as casters.

Q2: What is the TPR material melting point?

In fact, TPR does not have an exact melting point like metal. It softens slowly within a temperature range. When we do injection molding, we usually operate in the temperature range of 140°C to 220°C, which is much lower than metal, which is a feature of its convenient processing.

Q3: Is TPR plastic or rubber?

As an engineer at JS, I often explain to customers like this:

TPR material, strictly speaking, is neither ordinary plastic nor traditional rubber. It is more like a fusion of the advantages of both. It has the elasticity of rubber and can be easily processed and recycled like plastic. It is a very special type of our material.

Q4: How to distinguish TPR from silicone?

- The most intuitive way is to burn it and see, safety first!

- Silicone emits white smoke when it burns, and white ash is left after burning.

- TPR materials usually emit black smoke when burned, and they will drip like wax. This is a common method used in our workshop, and it is quite practical.

Summary

TPR material is indeed easy to use, flexible in design, safe and reliable, and efficient in processing, which has opened up many new ways for the application of flexible materials. Now it is not just a substitute for cheap rubber. If used well, it can actually enhance the value of products, improve user experience, and is more in line with the trend of environmental protection and recycling.

Of course, understanding the material properties is the beginning. The real difficulty lies in how to turn these characteristics into successful products. This is very dependent on professional mold design and precise manufacturing technology. You can send us the design files directly. We can provide much more than just a plastic injection molds price. We will give you professional instructions and support from the beginning of how to choose the most suitable materials to qualified product manufacturing to help you achieve your ideas.

Let’s work together to create products that are both safe and excellent!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com