A honeycomb-like structure of a superalloy part as thin as an eggshell but able to endure the thousand-degree heat of a turbine engine isn’t machined from a machine tool. Rather, it’s cast precisely in one step with a method that has been around for thousands of years.

Now, the accuracy casting choice is not a simple one between sand and investment casting, it’s a multidimensional balance of performance, cost, efficiency, and materials. The correct method creates a perfect design, the incorrect method creates a catastrophic failure and enormous cost blowouts.

This manual will help you select the right method based on material, batch size, and precision requirements, through process development discussion, most common techniques, and practical examples, to avoid pitfalls in your metal casting work.

Core Answer Summary

| Casting Method | Core Technology | Achievable Precision | Typical Wall Thickness | Suitable Materials | Economic Production Volume |

| Investment Casting | Lost-wax process, ceramic shell. | Extremely high (CT4-6) | < 1mm | Almost all alloys. | Small to medium batch. |

| Die Casting | High-pressure & high-speed, metal mold. | High (CT5-7) | 0.6mm – 3mm | Zinc, aluminum, magnesium alloys. | Extra-large batch. |

| Sand Casting | Sand mold, long history. | General (CT8-11) | ≥ 3mm | Almost all alloys. | Single piece to large batch. |

| Plaster Mold Casting | Plaster mold, low-pressure casting. | High (CT6-8) | < 2mm | Mainly aluminum alloys. | Small batch. |

| Ceramic Mold Casting | Ceramic slurry, precise cavity. | Extremely high (CT4-6) | Medium | High-temperature alloys, tool steel. | Single piece / small batch. |

Why Is This Manual Worth Reading? JS Metal Casting Technology Verification

JS has over 15 years of working experience in metal casting. We are not only specialists in standard processes such as investment casting and high pressure die casting , but we also have more than 200 successful case histories in machining high-temperature alloys (such as titanium and Inconel 718) and complex structural parts (deep cavities and small oil flow components).

Our engineering staff has over 8 years of experience in the industry and is capable of accurately estimating the potential risks of different processes in actual production. Our guide is a collection of our experience, and all our suggestions are verified in actual projects. With 10 prototypes and 10,000 metal casting parts, you will have a reliable reference that suits your requirements and avoid unnecessary costs due to the incorrect technique.

JS’s long history of metal casting provide you with reliable process guidelines. Utilize our custom metal casting manufacturing services and start your project on the right foot.

From Bronze To Steel: The Development And Evolution Of Casting Technology

In ancient times, humans used sand casting to produce bronze ritual implements. The process was simple with low accuracy and only capable of producing components of simple shapes. With steel, casting technology began evolving with improvements in mold material and pouring technology for it to accommodate the high melting point of steel.

Nowadays, accurate casting techniques can cast a wide range of materials including titanium and aluminum alloys and can meet the high-precision requirements of complex parts and provide high-quality metal casting parts for a wide range of industries. Engine parts in the aviation industry are a quintessential example of advanced development in casting technology.

If you need metal casting solutions from the traditional to the modern, JS is equipped with addressing your need through end-to-end process capabilities. Choose us for easy access to available casting services appropriate to different materials.

Modern Precision Casting: Comparison Of Mainstream And Niche Strategies

Modern precision casting is divided into mainstream and niche, with significant differences in the applicable scenarios of different methods. A clear comparison has been provided below:

| Casting Method | Suitable Production Volume | Surface Finish (Ra Value) | Suitable Materials | Advantages | Disadvantages |

| Investment Casting | Small to medium batch | 1.6-3.2μm | High-temperature alloys (titanium, steel), stainless steel. | High precision, good adaptability to complex structures. | High cost, long production cycle. |

| High-Pressure Die Casting | Large batch | 3.2-12.5μm | Aluminum alloys, zinc alloys. | High efficiency, low unit cost. | Presence of air bubbles, cannot undergo high-temperature heat treatment. |

| Sand Casting | Small batch, large-sized parts | 12.5-25μm | Cast iron, cast steel, non-ferrous metals. | Low cost, high flexibility. | Low precision, rough surface. |

| Plaster Mold Casting (Niche) | Small batch, precision parts | 0.8-3.2μm | Aluminum alloys, titanium alloys. | Extremely high precision, good adaptability to thin walls. | High cost, long production cycle. |

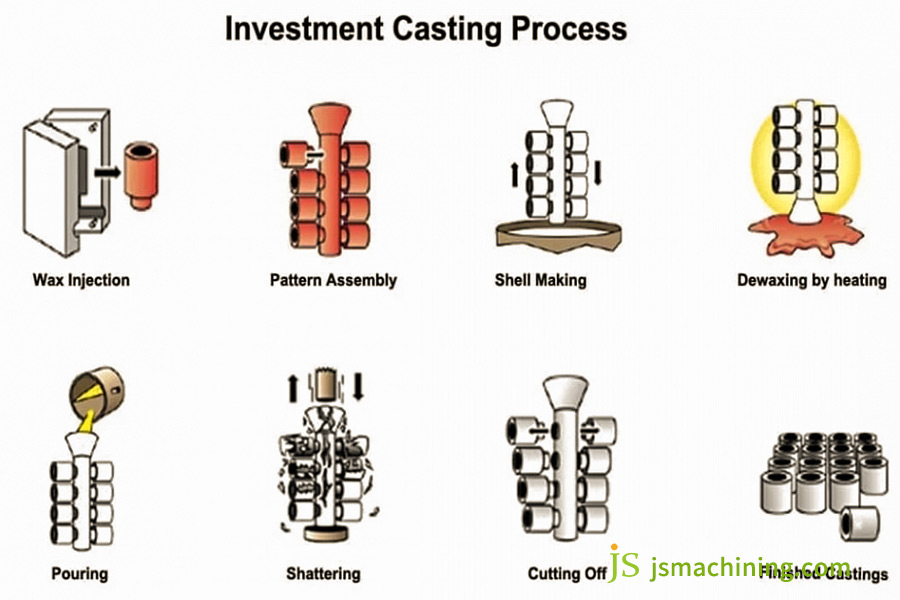

The King’s Process: Investment Casting

It can produce complex structures (e.g., multi-channel flow channels and thin-walled hollow parts) with a high surface finish. It can be used on high-temperature alloy parts that need high accuracy and is often utilized in the aviation industry.

The King of Efficiency: High Pressure Die Casting

It has high efficiency of production (1-2 parts per minute) and can be used for mass production of metal casting parts like automobile transmission housings and household appliance casings, but its mechanical characteristics are somewhat lower.

Cornerstone Process: Sand Casting

It is cost-effective (mold cost is only 1/10 of die casting) and friendly to small lots or large parts, such as large bases of machine tools.

Niche Elite: Plaster Casting and Ceramic Casting

They possess high accuracy (dimensional tolerance up to ±0.02mm) and suit thin-walled or ultra-precision products (e.g., optical instrument components). They are costly and used for specialty applications only.

JS offers the whole range of modern precision metal casting solutions. Effective high pressure die casting or high precision investment casting can be availed of with quick turnaround and short project duration through our online metal casting services.

The Final Challenge: Conquering “Thin-As-A-Cicada-Wing” Designs?

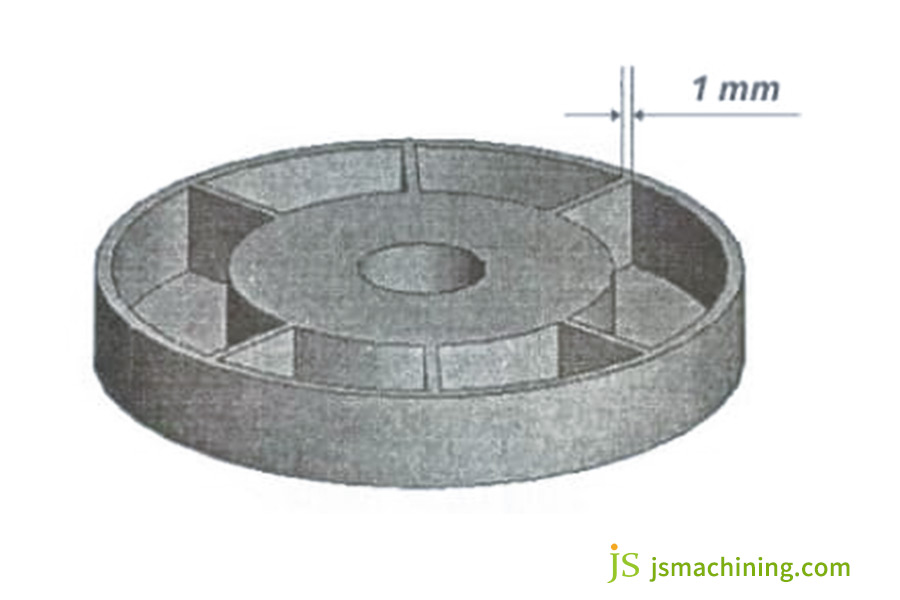

For thin-walled parts (such as electronic component housing less than 1mm thick), deformation or casting defects are of greatest concern for most companies. Investment casting and plaster casting are best to employ.

Advantages of Investment Casting

- Precision reproduction of wax patterns is very high, with tolerances fluctuating between ±0.03mm, meaning that thin-walled structures can be precisely reproduced.

- Shells of ceramic mold offer exceptionally high thermal insulation, prolonging molten metal flow time and preventing underfilling.

- Non-parting surface design prevents mold misalignment hazards in thin-walled parts.

Advantages of Plaster Casting

- Low permeability of the mold, preventing air from entering the molten metal and causing pores.

- High dimensional stability, preventing shrinkage and deformation during solidification of thin-walled parts.

- Highly even surface finish, reducing follow-on thin-walled part machining.

Application Examples

- Electronics Case Study: One electronics company used investment casting with a stepped gate design to produce a 0.8mm thick sensor cover with a stable production and more than 95% yield rate.

- Medical Case Study: JSCompany created a 0.5mm thick titanium alloy microfluidic component for a medical customer using plaster casting technology, perfectly meeting fluid flow requirements and ensuring a smooth, burr-free channel interior.

Tested By Fire: Casting Techniques To High-Melting-Point Alloys

Casting high-melting-point alloys (such as titanium and steel) is a high-temperature resisting process. The below are the methods outlined in the table below:

| Casting Method | Capable of Casting High-melting-point Alloys | Reasons | Precautions Needed |

| Investment Casting | Yes | Ceramic shell is heat-resistant (can withstand above 1700℃). | Need vacuum environment to avoid oxidation. |

| High-Pressure Die Casting | No | Metal mold has limited heat resistance (usually not exceeding 400℃) and is easy to damage. | – |

| Sand Casting | Yes (partial) | Sand mold is heat-resistant but has low precision. | Need to optimize sand mold formula (add chromite sand). |

| Ceramic Mold Casting | Yes | Ceramic mold is heat-resistant and has high precision. | High cost, suitable for small batches. |

The Only Alternative: Investment Casting

Ceramic shells can withstand the impact of high-temperature molten steel from high melting point alloys, ensuring the formation of metal castings. It is the mainstream process for titanium and steel parts, such as titanium alloy blades for aeroplane engines.

Why Die Casting Isn’t Suitable

Die casting metal molds possess minimal resistance to temperature, and molten steel from high-melting-point alloys can readily damage the mold. Die casting is also prone to developing pores that could weaken the strength of the alloy.

Key Process Requirements: Vacuum Environment

Vacuum conditions reduce interaction between molten steel and air, preventing oxidation (e.g., titanium alloys can react easily with oxygen to form a brittle layer at high temperatures), and improve the purity and mechanical properties of high-melting-point alloy castings. It is an important step for JS in treating such metal casting parts.

For high-melting alloy casting needs, JS’s investment casting plant, augmented by vacuum technology, guarantees quality of metal casting parts. You do not have to worry about defects caused by high temperature with our custom metal casting manufacturing services for bespoke solutions.

Economic Calculation: Cost Optimization For Small-Batch Prototypes And Production

The cost optimization of different batches of production is extremely diverse. The alternatives for the same are explained in the below table:

| Production Volume | Recommended Casting Process | Cost Advantages | Application Scenarios | Reference for metal casting price (per unit) |

| 1-50 pieces (Prototypes) | Sand Casting / Investment Casting | Sand casting has low cost (mold cost: approx 500-1000 USD).Investment casting has high precision. | Product trial production, small-batch customization. | Sand casting: 50-150 USD. Investment casting: 100-300 USD. |

| 50-10,000 pieces | Investment Casting | Moderate batch size, controllable unit cost (30% lower than small-batch production). | Medium and small-batch precision part production. | 80-200 USD |

| >10,000 pieces | High-Pressure Die Casting | Large batch spreads mold cost (mold cost: approx 5000-20000 USD), high efficiency. | Mass-produced parts for automobiles, home appliances. | 20-80 USD |

Whether you require miniature trial production or mass production, JS offers the most cost-saving option. Buy through our online metal casting services for simple process and reasonable metal casting price quotes.

Case Study: Two Fates Of An Aviation Sensor Bracket

Project Background

An aerospace industry required the production of a high-temperature alloy sensor bracket of Inconel 718 for a new engine. This component was in a complicated structure—three deep holes with a depth of 15mm and two fine oil holes with a diameter of 2mm. The size of the batch was 500 pieces, and the specifications were extremely stringent for accuracy (dimensional tolerance ±0.1mm) and strength (tensile strength ≥1300MPa).

Alternative Selection and Comparison

- Alternative A (Incorrect Option): Silica Sol Investment Casting

In a cost-saving effort, one of the suppliers used an inexpensive silica sol-ethyl silicate composite shell casting process (a silica sol content of only 60%). Such a shell mold was not strong (room-temperature flexural strength ≤15MPa) and had low resistance to high temperatures (only to 1400°C).

At casting, 1550°C Inconel 718 molten metal impacted the shell mold, causing 30% of the shell to deform and become softened and 15% experience flashover (leakage of molten steel). Ultimately, the entire tree of castings also led to a scrap rate of 35%, a yield rate only of 65%, an additional 20kg loss of high-temperature alloy material, and an extended rework cycle time of 15 days. The ultimate price was 40% more than the budget.

- Option B (JS’s Option): Investment Casting with Bauxite

JS Precision Manufacturing advised utilizing a bauxite-supported slurry shell mold, owing to the high-temperature nature of Inconel 718, which is more heat-resistant (tolerates 1600°C) and possesses greater strength (room-temperature flexural strength ≥ 25 MPa). In addition, the gate design was optimized (using a bottom-injection gate to minimize impact).

The resulting shell mold was hard, casting was even, and the yielding rate exceeded 98%. Although the cost of a single shell mold was 10% higher, the overall cost was 30% lower, and the delivery cycle decreased by three days.

Core Lessons

Process details create or destroy success: Even within the same category of casting process (for example, investment casting), subtle differences in material content (silica sol level, shell mold base material) and process control (gating system) can directly influence project results.

A Win-Win Future: What Will You Gain From Synchronous Design With JS?

The Core Value of Synchronous Design

In high precision casting projects, synchronous design in initial-stage design can help gain huge amounts of time and cost savings. According to industry statistics, synchronous design can save 40% on late-stage modifications’ cost and reduce project cycles by 30%.

Three Core Benefits of Concurrent Design

1. Process Optimization: Reducing Defects at Source

Our engineers will intervene in the early stages of design and optimize the casting process based on the structure of the parts. For example, they can convert a closed deep cavity to a semi-open one to facilitate easy removal of the core, and make uneven wall thickness flat to a gradual variation to avoid shrinkage, thereby removing the defect in the casting at their very source.

2. Material Recommendations: Balancing Performance and Cost

We give material selection suggestions. For instance, while fulfilling strength needs, we can substitute titanium alloy with aluminum alloy to decrease metal casting prices (cost per part can be minimized more than 50%).

3.Process Simulation: Preemptive Risk Avoidance

Simultaneous design is process simulation-based. We model the metal flow and solidification of molten metal through CAST-Designer software and predict cold shuts and air holes in advance, thus avoiding trial and error.

Actual Collaboration Case Studies

For example, a new energy company worked with JS on a motor end cap project. Through simultaneous design, they optimized gate location and wall thickness distribution, reducing the casting defect rate from 20% to 5% and shortening the project cycle from 45 days to 30 days.

FAQs

Q1: Which method produces the best surface finish?

Currently, investment casting gives the best surface finish with Ra values of 1.6-3.2μm. It reduces downstream machining and is economic. It replicates the part geometry by a wax pattern. The wax pattern is very accurate and lacks any parting surfaces, eliminating burrs. This is ideal for metal casting parts requiring high surface quality. For example, precision blades for aircraft engines usually use investment casting to deliver a smooth surface.

Q2: Which produces stronger components, investment casting or die casting?

Investment casting will be superior mechanically. Because die castings harden the mold quickly under pressure, they easily trap air and create pores. They cannot also be subjected to high-temperature heat treatment to improve performance and therefore possess less strength and toughness than investment castings of equal material. However, with long runs of production where there are less stringent mechanical demands, the high efficiency of die casting still offers advantages.

Q3: I wonder if I can cast a solid metal sphere?

Yes, it is accomplished with core technology, and that can be achieved with sand casting and investment casting. Investment casting can utilize ceramic or soluble cores to create very complex internal passages, such as the inside cavity of a hollow metal ball, which can be made using ceramic cores. Sand casting uses sand cores to achieve hollow products. The choice is depending upon volume of production and precision requirement.

Q4: Which of these castings has superior mechanical properties?

There is no absolutely “better” mechanical property for a casting, it primarily depends on the alloy and the process. For example, in high-volume production of aluminum alloys, die-cast parts could offer higher strength with their fine grain size. But for high-melting-point alloys like Inconel 718, investment castings avoid porosity and can be heat-treated at high temperatures, resulting in higher toughness and strength.

Summary

Choosing a casting method is a balancing act among design innovation, material limitations, cost, and schedules. There is no single best method, just the best for your project’s DNA.

Don’t take on these complex decisions by yourself! JS’s team of engineers, well familiar with the complexities of various casting processes, can properly recommend a type of casting according to your design drawings and real needs. We provide accurate custom metal casting manufacturing services and transparent metal casting prices, and your investment casting project is finished economically and efficiently.

Post your 3D model file today and we will help you step by step, idea to casting, with our technical technical know-how.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Resource

Pingback: How Does Steel Material Grade Affect The Strength Of Castings? - JUSHENG

Pingback: Your Buyer's Guide To Die Casting: Maximizing Value While Minimizing Cost - JS Precision