Imagine a material that is strong and lightweight, yet extremely flexible and able to withstand a variety of adverse conditions. No science fiction, but Mylar sheet (often called by the Mylar® brand name)! Wherever you see it in emergency blankets, reflective balloons, or more advanced electronic products, the material is actually all around us, doing its part quietly.

But what is Mylar sheet, and why is it so “versatile”? Basically, it’s a type of plastic film made from polyethylene terephthalate (or PET for short). Through a special biaxial stretching procedure, it has excellent properties far exceeding the abilities of ordinary plastics. It’s these properties which make it find an essential use in electronic insulation, food packaging barrier, life-saving insulation blankets, and even in decoration.

Our team works with it every day and knows its value. Its high strength, excellent electrical insulation, dimensional stability and heat resistance have made it a material of choice from cutting-edge industrial manufacture through to everyday consumer items. Understanding Mylar sheet’s true strength contains the key to unlocking the basic design secrets of a host of contemporary products.

Core Answer Summary:

| Mylar ® (BoPET) Characteristics | Explain | Common applications |

| Strong insulation performance | We found that Mylar has good insulation and can hardly pass current, making it very suitable for high voltage environments. | We commonly use it for insulation in motors, capacitors, and circuit boards. |

| High chemical stability | It is corrosion-resistant, not easily reactive with chemicals, and has strong stability. | It is widely used in food packaging and chemical container lining. |

| Thin and tough | Although thin, it has high strength and is not easily torn or pierced. | Suitable for making cassette tapes, sailboat canvas, and packaging film. |

| Strong gas barrier capability | It can block oxygen, moisture, and odors, and has a great preservation effect. | We commonly use it for sealing long-term food bags and coffee bags. |

| Small size variation | Under different temperature and humidity conditions, it basically does not deform and maintains its shape well. | Used in drawing film and printing material substrates. |

| Good heat reflection effect | Aluminum plating can reflect most of the heat, such as solar radiation. | We use it for emergency insulation blankets and greenhouse insulation layers. |

This article will answer your questions:

- I will first explain the key characteristics of mylar sheet and explain how it is different from ordinary plastics.

- Then, I will use a practical example, such as comparing how it is used in daily consumer packaging and industrial electronic insulation gaskets, so that you can intuitively see its value.

- Next, I will answer frequently asked questions, such as whether it is conductive and how artists use it.

- Finally, I will also talk about how this film can be used in conjunction with our online injection molding services to help you make better products.

Why Trust This Guide? JS’s Material Science Practice

I often come into contact with Mylar sheet (such as Mylar®). It is much more than a name on the purchase order for us. It often plays a key “sheet partner” role when we design injection molding parts for customers.

Here is a real example:

- We have used Mylar sheet as a substrate for in-mold labeling (IML), directly embedded in the mold. When the plastic melt is injected into the mold, the exquisite pattern on the film is permanently integrated into the surface of the part, creating a wear-resistant and high-end visual effect.

- In another project, we designed a housing for a customer’s precision electronic equipment while custom-making a die-cut Mylar sheet insulation gasket. This requires us to accurately master the characteristics of the material, such as choosing the film thickness according to the insulation capacity required by the circuit, or considering how to avoid electrostatic interference in a specific application.

The insights in this guide are not from textbooks, but directly from our day-to-day work: how to combine raw plastic particles and high-performance films to create a complete solution that truly solves the problem. The actual product development we experienced gave us a deep understanding of how materials work together to achieve the effect of 1+1>2.

“Professor Michael Ashby, an authority in the field of material selection and a fellow of the Royal Academy of Engineering, emphasized that understanding the performance limits of materials is the starting point for successful design.”

We have accumulated practical experience under such boundary conditions. This guide shares the core understanding of how mylar sheet can truly play its value, which we have verified in countless practices.

Decryption Key: What Is The Real Face Of Mylar?

Being a JS developer who regularly deals with packing materials, let me talk about what Mylar is. Mylar is a trade name. Mylar is a kind of material called “biaxially oriented polyester film”, more technically named BoPET (Biaxially-oriented Polyethylene Terephthalate).

What is the wonder of “biaxially oriented”?

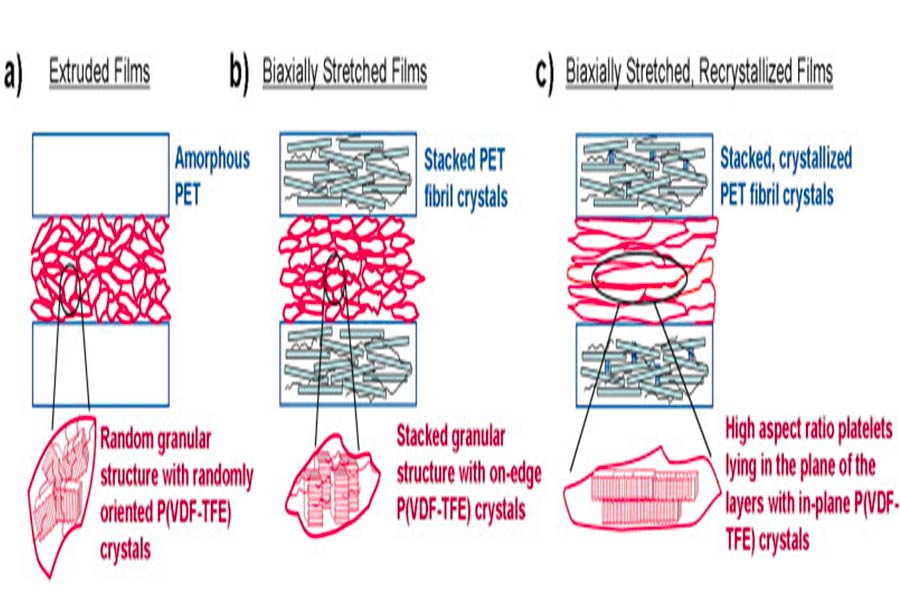

I see that the name is misleading, but the key is in the four words “biaxially oriented”. This is the basic manufacturing process that bestows its performance with such durability! We can think of it as making noodles: first, the raw material (molten PET) gets pressed into a plain film sheet (extrusion), which is just ordinary.

The real magic is in the second operation: stretching. We have to make this film stretched hard in one direction (such as longitudinal direction) in the machine, and then again in a second horizontal direction. This two-way stretching action is the essence of “biaxially oriented”.

Why do we have to do this?

The problem is the molecular arrangement. The molecules within the normal unstretched PET plastic bottle raw material are random. After we stretched it in two directions, the molecules within were placed in line and arranged neatly the moment it was done, and the direction became highly uniform. Such a change had several hard-core advantages:

(1) High strength:

The tensile strength of the stretched film is significantly higher than that of ordinary PET. Briefly, the tensile strength of ordinary PET materials can be around 50-60 MPa. After stretching, it can be simply above 100 MPa or even higher, and the strength can be doubled or even higher. We have tested that the tear resistance is at least improved by 2 to 5 times.

(2) Good dimensional stability:

The molecules are close-packed and shrinking and expanding when heated and cooled are significantly smaller, compared to ordinary plastics. The heat shrinkage rate of ordinary PET can exceed 5%, while that of BoPET after biaxial stretching is as low as 1% or even lower than 0.5%. It is a blessing to our precision parts packaging, and there is no need to worry about the bulging and wrinkle of film bag.

(3) High transparence:

Molecules are well-ordered, and the disturbance is smaller when the light is transmitted. The haze is as low as 0.5%, while normal PET can be above 5%. No matter if it is used on transparent window package or optical performance demand, it is visually bright and clear. In addition, the degree of crystallization is also improved by 20-30% compared with normal PET, which is more stable.

It is this one biaxial stretching step which makes available a monumental performance gap between the final BoPET film (such as the highly acclaimed Mylar®) and the standard PET bottle material we are accustomed to.

Is Mylar® a plastic?

Simple answer: Yes. The chemical essence of Mylar® / BoPET is a high-performance polyester plastic (Polyester plastic), specifically a special form of PET.

More accurate positioning: However, in actual material classification and application, due to its biaxial stretching process and the resulting excellent performance combination, we usually regard it as an independent high-performance film category. It has significant hierarchical differences in performance and application fields from common plastics such as ordinary PET bottles, common PP (polypropylene) or PE (polyethylene) plastic bags that we come into contact with every day.

“Mylar is essentially a high-performance polyester plastic film (BoPET) that has been specially “biaxially stretched” to strengthen it. You can see why it can play a key role in the fields of electronics, packaging, and industry. Behind this seemingly simple film is the exquisite crystallization of material science. If you are looking for a film solution that combines strength, stability and insulation, please contact our JS team. We will discuss how BoPET can create core value for your product based on your specific application needs.”

Functional Reveal: What Can Mylar Do?

Combining the actual projects and applications I come into contact with on a daily basis, now, let me talk about the impressive “superpowers” of mylar sheet (often referred to as Mylar®):

“Guardian” of electrical insulation

Core characteristics: It is particularly difficult for current to penetrate it (high dielectric strength + volume resistivity), and it is thin and tough. Simply put, it has first-class power blocking ability.

Key applications: This is one of its most core and valuable stages in the industrial field! It is used as “insulating armor” for internal coils in motor slots, and it is used to wrap and isolate wires and cables. It is a key dielectric layer in capacitors, especially the popular flexible circuit board (FPC), which is both a substrate for carrying circuits and a covering film for protecting circuits. It is very valuable in the industrial world.

For example: In the micro motors we designed for our customers, the Mylar insulation sheet less than 0.05mm thick can withstand thousands of volts, ensuring that the equipment is safe and compact.

“Terminator” of gas and moisture

Core characteristics: It has a particularly strong barrier ability to gas (especially oxygen) and moisture, like a solid shield, keeping out those gases that will cause things to deteriorate and get damp.

Key applications: long-shelf-life food storage bags (Mylar bags), valved fresh-keeping bags that lock in the aroma of coffee beans, the shiny lining in potato chip packaging bags (usually aluminized), and pharmaceutical packaging that requires strict moisture and oxidation protection, all of which are inseparable from its barrier properties. It keeps the contents fresh and safe.

Key data: Good aluminized Mylar can achieve a water vapor transmission rate of less than 5 grams per square meter per day (@38°C, 90% humidity), and an extremely low oxygen transmission rate, which is a key barrier to freshness.

The “stabilizing force” of strength and size

Core characteristics: Although it is thin, it has very high tensile strength and is not easy to be torn. What’s more, it has excellent dimensional stability. It is not easy to shrink, deform or stretch under temperature changes or stress, and its size is kept stable.

Key applications: The tape base material in old audio/video tapes. The transparent film substrate used by engineers for drawing and mapping. High-performance sailboats require light, thin and strong canvas materials. Screen printing requires templates with precise patterns.

Why use it?

When making the tape base film, the thickness tolerance can be controlled within ±1 micron to ensure signal stability. When making sail materials, the strength is comparable to traditional canvas, but the weight is much lighter.

“Reflection Master” of Light and Heat

Core skills: Transparent mylar sheet itself has good light transmittance. But what’s more amazing is that if it is coated with a layer of aluminum (metallized), it becomes a super reflector of light and heat, which can reflect most of the light and heat radiation back.

Key applications: Space blankets used for emergency rescue rely on it to reflect body heat to save lives. Greenhouses and plant growth tents use it to reflect light and improve efficiency. The glittering letter balloons at parties are also due to it. The attractive metallic luster layer on food packaging is also a masterpiece of aluminized film. It can both transmit light and reflect efficiently.

How does it work?

Aluminized Mylar easily reflects more than 97% of thermal radiation. When used in space blankets, it can lock up to 80% of human body radiation heat at critical moments.

“From insulating layers that protect delicate circuits to packaging shields that lock in fresh flavors. From industrial materials that require absolute dimensional stability to life-saving blankets that reflect light and heat – mylar sheet (Mylar®) is far more capable than ordinary plastics. If your project requires these unique performance combinations to improve product reliability, life or function, the JS team is ready to discuss with you how to incorporate this “superpower material” into your solution to create better products together.”

Success Case Analysis: Dazzling Decorator vs. Low-key Guardian

The true value of a material lies in whether it can perform critical tasks. Take Mylar for example. It can provide a striking surface in exquisite packaging, and silently undertakes an indispensable protection function inside electromechanical equipment. This reliability in different fields is its core advantage.

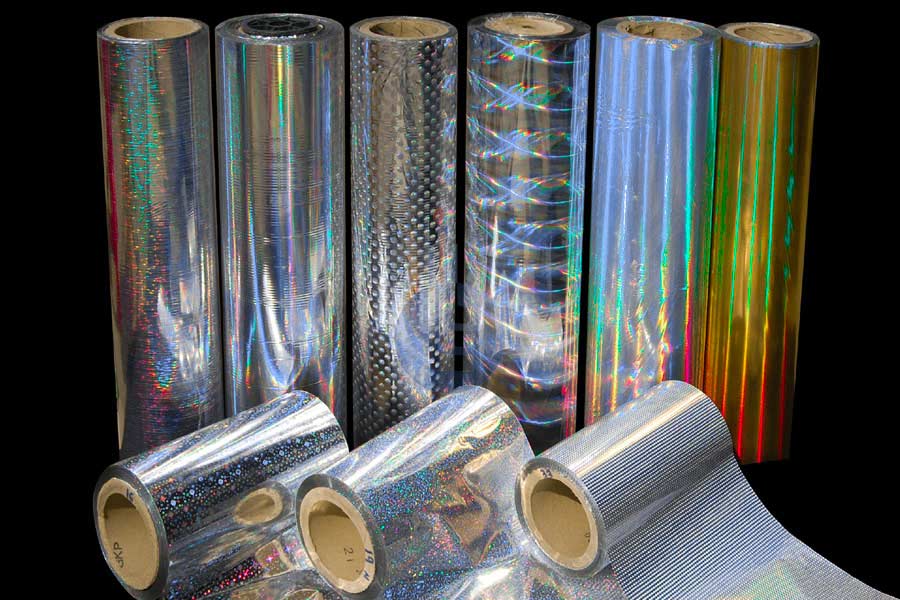

Case 1: “Rainbow” Outer Box of High-end Cosmetics

Customer Goal: A new essence needs a packaging box that can “instantly attract attention” on the shelf. It is required to show dynamic rainbow or laser effects under light, and it must be wear-resistant enough to protect the delicate printed patterns.

What is the difficulty? It requires both extremely dazzling visual effects and durability of the packaging, and it cannot be scratched or look cheap.

How does JS solve it?

The core of the solution: Use composite laser Mylar film.

Reasons for choosing Mylar film:

(1) Dazzling optical effect: The surface of this Mylar film is embossed with precise microstructures, which can diffract ordinary light into a charming rainbow or laser effect, full of dynamics and visual impact.

(2) Strong wear-resistant protective layer: We laminate the colorful Mylar film to the cardboard box. Mylar’s own super wear-resistant and scratch-resistant properties perfectly protect the exquisite printing on the bottom layer, making the packaging box shiny and able to withstand the test of transportation and placement.

Result: The final packaging is highly recognizable on the shelf, successfully helping the new product to gain high attention, and the customer is very satisfied with the effect and texture.

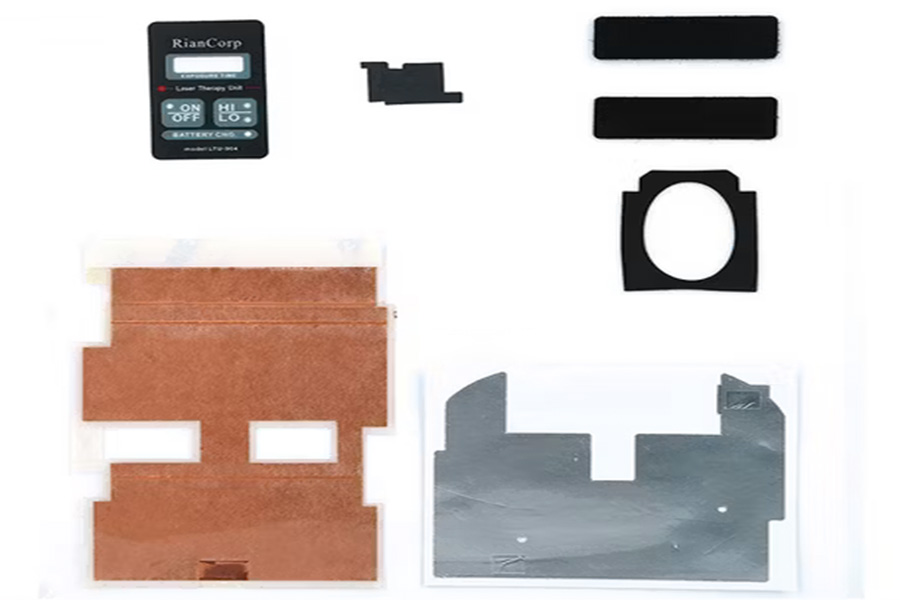

Case 2: Guarding the “lifeline” of medical equipment

Customer goal: Design a key insulation layer for a compact power module. This insulating gasket must be placed tightly between the high-voltage circuit board and the metal casing to absolutely eliminate the risk of short circuits, and must withstand the high temperature inside the equipment and ensure long-term stability and reliability.

Core Challenge: Functionality is paramount, personal safety is concerned, no mistakes can be made, space is extremely limited, and dimensional accuracy is demanding.

How did JS solve it?

Solution Core: Custom die-cut UL certified Mylar insulation sheet + matching custom injection molded shell.

Reasons for choosing it:

(1) Ensure electrical safety: Select Mylar sheets that meet the medical grade UL 94VTM-2 flame retardant standard. Its dielectric strength easily reaches > 300 V/μm, far exceeding the customer’s required 150 V/μm safety line, and is as stable as Mount Tai under high pressure.

(2) Precision collaborative manufacturing: Based on the 3D model provided by the customer, we also design a matching custom injection molding manufacturing shell, and use precision laser die-cutting technology to cut the Mylar sheet into a complex shape that perfectly fits the internal structure of the shell and the edge of the circuit board. The tolerance is controlled within ±0.1 mm to ensure a perfect fit and eliminate any short circuit risks.

(3) Ensure long-term stability: Mylar’s chemical inertness and super dimensional stability (heat shrinkage < 0.5% @ 150°C) ensure that the insulating gasket will not decay throughout the life cycle of the device, even if it experiences temperature fluctuations and humidity changes.

The final result: We delivered not only an insulating sheet, but a complete solution with precise matching (customized shell + customized gasket). The customer solved the two major problems of insulation safety and structural matching at one time, and the equipment successfully passed the most stringent safety certification and was put on the market.

JS customized solution core advantages and value reference:

| Key link | Advantages of JS customized solutions | Customer value generated | The typical range of capabilities for JS |

| Material selection certification | Provide UL, FDA and other pre certified Mylar material libraries to quickly match application requirements. | Shorten the certification cycle and reduce compliance risks. | Common certification material library>50 types, matching cycle<3 working days. |

| Precision die-cutting processing | High precision laser/die cutting with complex shape tolerance control. | Ensure precise assembly of components to improve product yield and reliability. | Tolerance control: ± 0.05mm – ± 0.2mm (depending on material thickness). |

| Supporting structural design | Custom injection molding manufacturing shell and Mylar component collaborative design. | Resolve system level matching issues, optimize space utilization, and enhance overall performance. | The delivery cycle of collaborative design projects has been shortened by 15-30%. |

| Small batch customization cost | Optimized process paths reduce losses, and flexible production supports small batch economy. | Reduce the threshold for new product development/trial production and accelerate its launch. | The processing loss rate for small batches (<5000 pieces) is<8% (industry average>15%). |

| Comprehensive service value | Provide one-stop services from material selection, structural design, precision machining to testing and verification. | Simplify the supply chain and reduce communication and management costs. | The average docking window for customer projects has decreased by 50%. |

“Whether it is cosmetic packaging that needs to be “eye-catching” or medical insulation that requires “absolute peace of mind”, Mylar can play a key role with its designable characteristics. The key is to deeply understand the needs and unleash their potential in combination with precision processing. If you have a project challenge that needs to be “amazing” or “protected”, bring your needs to JS and we will work together to create a reliable solution!”

FAQ – Quickly Answer Your Remaining Confusion About Mylar

Can current pass through Mylar?

It depends on which type. The pure Mylar used in our company has excellent insulation properties, so it is often used in the electronics industry. But the shiny silver Mylar (like the inner layer of a potato chip bag) is actually coated with a very thin layer of metal aluminum, which is conductive.

The key difference is here: transparent or white Mylar is not conductive, while the Mylar with aluminum coating on the surface and looks silver is conductive on the surface, which is very important in practical applications.

Mylar vs. ordinary plastic: What’s the difference?

Let me explain the main differences between Mylar and ordinary plastics (such as PET in beverage bottles):

(1) Different processing methods: Mylar has undergone a special biaxial stretching process, which makes its internal structure (molecular arrangement) more regular and compact.

(2) Stronger performance: Because of this stretching, Mylar is stronger and less likely to deform than ordinary plastics at the same thinness, and is better at blocking the penetration of gases (such as oxygen).

(3) Different uses: Ordinary plastics are usually used in places with low requirements such as bottles and ordinary packaging bags. These advantages of Mylar make it more suitable for use in electronic components, industrial materials and special packaging that requires high-performance barriers.

I need Mylar, where can I find it?

(1) Small quantity, general needs: If you only need a small amount of standard Mylar sheets or coils, you can try large art supply stores, electronic parts stores, or large online platforms such as Amazon and McMaster-Carr. These places are more convenient to buy.

(2) Professional and specific needs: But if you need a specific thickness (for example, accurate to microns), special properties, or parts that need to be precisely die-cut into specific shapes, these general channels are difficult to meet. At this time, you need to find a professional material supplier and manufacturer like our JS company, and we can customize production according to your requirements.

What can Mylar do in artistic creation?

(1) It is particularly good for templates: Mylar is strong and not afraid of being soaked in paint and solvents, and can cut out particularly fine edges. It is an ideal material for reusable templates.

(2) Play with visual effects: It has a shiny, smooth or special texture on the surface. Artists like to use it in mixed media works, installation art or collages to create unique light and texture effects.

(3) Protect precious works: Because Mylar itself has stable performance, transparency and good durability, it is very suitable for covering and protecting paintings, sketches or important documents to help them be preserved for a long time.

Summary

Mylar is more than just “shiny plastic paper”. It is a special plastic film with excellent performance. The key is to really understand its strengths and then use it in the most appropriate place. Whether it is to protect the electronic components in your product or make the product packaging more eye-catching, Mylar is a practical and capable all-rounder.

What we can do for you:

- Innovative design relies on combination: To make a product outstanding, it is often necessary to combine the advantages of different materials. For example, accurately combine Mylar film with the plastic parts manufacturing technology we are good at.

- Professional fusion solution: At JS, we not only provide online injection molding services to quickly make plastic parts, but also know how to perfectly integrate high-performance films such as Mylar into your design. The products made by this combination are more reliable, more powerful, and more attractive in appearance.

- Optimize from the material: If you want to optimize the product design from the fundamental link of material selection to make it better and more cost-effective, we are the manufacturing partner you are looking for.

- Clear and transparent next step: Don’t hesitate, contact us now to talk about your project! We will provide you with professional manufacturing solution suggestions and tell you the clear injection molding price at the first time.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It’s the buyer’s responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com