You designed and printed a drone shell. During the first outdoor test flight in the summer, the arms began to soften and bend. This situation occurred because the wrong material was chosen. It directly points to the core difference between PLA and ABS filament, which may have buried the risk of failure from the beginning.

As JS engineers, we deal with these materials every day. In short, PLA is usually easier to use, has less odor and is not easy to warp when printing, and the finished product surface is smoother, which is especially suitable for novices or some display models.

What about ABS? It is stronger and more heat-resistant, and the things it makes are more resilient and can withstand greater forces or higher temperatures, such as some parts that need to be practical. But it requires more precise control when 3D printing, such as a heated platform and a closed space, otherwise it is easy to warp or draw.

So, there is no absolute “which one is better”, the key depends on what you use it for and how much control you have over the printing process. Next, let’s talk about the differences between PLA and ABS in key points such as strength, heat resistance, and printing difficulty. Understand these clearly, and next time you use our JS printing equipment to do a project, you will have a clear mind, choose the right consumables, and get it done in one go!

Core Answer Summary:

| Comparing dimensions | PLA (Polylactic Acid) | ABS filament (Acrylonitrile butadiene styrene) |

| Core Features | Printing friendly, with good rigidity, sourced from renewable resources. | High strength, good heat resistance, and excellent toughness. |

| Printing performance | Easy to use, no need for a hot bed and not prone to warping, suitable for rapid prototyping. | Printing is difficult and requires a hot bed and insulation environment to control the risk of warping. |

| Mechanical properties | Hard but brittle, with good tensile stiffness but relatively low impact strength. | Strong and durable, with outstanding impact resistance, able to withstand bending and deformation. |

| Hot deformation temperature | Low thermal stability, prone to softening and deformation after continuous use at temperatures exceeding 60 °C. | Excellent heat resistance, able to maintain stable morphology in environments close to 100 °C. |

| Operational safety | Mild odor (slightly sweet), low ventilation requirements, and a more friendly operating environment. | There is an odor during the printing process. It is recommended to exhaust or wear protective gear to avoid inhalation. |

| Environmental attributes | Biobased materials, capable of industrial composting and degradation, with strong environmental sustainability. | Petroleum based plastics are non biodegradable and recycling is a better choice. |

This article will answer your questions:

- This guide will give you a clear overview of the core differences between PLA and ABS 3D printing.

- We will talk about material properties all the way to practical problems in printing.

- Through a real comparison, such as a drone carrier vs. a desktop ornament, you can intuitively help you decide which material to choose.

- Finally, we will answer your most concerned questions about strength, temperature resistance, and environmental protection in detail.

Why Should You Trust This Guide? JS’s Daily Material Decisions

In our daily practice at JS, material selection is directly related to whether parts can work reliably. In the process of consuming dozens of kilograms of materials every day, should we use PLA or ABS? We have experienced this question thousands of times. Our judgment is not a theoretical deduction, but a real verification of printing for aircraft engine test pieces, automotive buckles, medical device prototypes, and consumer electronics product shells.

“As injection molding expert Mike Osswald said: The cost of product failure caused by incorrect material selection is far more than a hundred times the cost of the material itself.”

We have learned this lesson, and it is these lessons that have shaped our selection logic: thermal deformation and cracking in the printing of large ABS parts led us to explore a unique chamber temperature control curve. When customers asked to show the glossiness of the building sand table, we found that a specific PLA could achieve a spray painting effect after optimizing the printing parameters. Every suggestion in this guide is a practical rule that we have repeatedly verified in success and failure cases.

Understand PLA: The Benchmark For Rapid Prototyping And Appearance Models

In daily project screening, we are well aware of the positioning of PLA. It is your good partner for quickly turning ideas into physical models. The characteristics extracted from plants such as corn starch make it the first choice for environmentally friendly projects, and the ultra-low printing threshold makes 95% of new users succeed in the first print.

Why PLA is our rapid modeling tool:

(1) Extremely easy to use: low printing temperature (190-220°C), heated bed is not required to complete printing (but neither is it prohibited), and the material will not shrink and warp a lot on cooling. The success rate for newbies can exceed 95%.

(2) Fine detail recovery: The lower melt fluidity allows it to goodly bring out the model’s crisp edges, text engraving and other delicate details.

(3) Safety and environmental protection characteristics: The raw materials are from origins such as corn starch and are compliant with food contact laws. It has only a very weak popcorn odor when printing and can be operated in normal ventilation conditions.

Multidimensional visual effects: We tend to use matte models for building models, silk texture PLA for hand-skinning, and metal fillers for product prototype demonstration.

Central limitation: Environmental adaptability limitations

(1) Most afraid of high temperature: This is the biggest shortcoming of PLA! Its glass transition temperature is only about 60°C. What does this mean? If you put it on the dashboard of your car in the summer, or put it near a hot coffee cup, it may become soft and deformed. In this regard, it is far inferior to the heat-resistant ABS.

(2) Mechanical property limitations: Although the hardness is close to ABS (rigidity strength is about 3.5GPa), the impact toughness is insufficient (notch impact strength <0.5 kJ/m²). We have encountered cases where moving parts such as gears and buckles broke after 3 months.

(3) Post-processing is difficult: acetone vapor polishing is not possible, and manual polishing is prone to scratches. We usually use sandblasting to improve the surface fineness of silk-textured PLA.

“PLA is undoubtedly the first choice for rapid prototyping and the pursuit of fine visual models. Its ease of use, safety and rich expressiveness make entry-level and professional users love it. But remember that it is not heat-resistant and afraid of impact. Before selecting materials, be sure to think clearly about the environment in which your parts will eventually be used and what forces they need to withstand. If you are not sure, feel free to talk to our JS company engineers to help you accurately match the most suitable material!”

Understand ABS: The Main Material For Engineering Parts And Functional Prototypes

After talking about PLA materials, let’s talk about ABS filament (acrylonitrile-butadiene-styrene). When we talk about making truly durable, “working” parts, it is definitely a classic choice that cannot be avoided. It is not without reason that Lego bricks use it! It is a reliable choice for making truly usable 3D printing parts and functional prototypes.

The core advantages of ABS: Why choose it for functional parts?

(1) Impact resistance and tossing resistance: This is the most prominent advantage of ABS. Its special ingredients make it very tough, not easy to break when impacted or vibrated, and can absorb a lot of energy. Instead of directly brittle cracking like PLA materials, it is very suitable for application scenarios that need to withstand certain stress.

(2) More reliable heat resistance: ABS is much better than PLA in heat resistance, and its softening point (glass transition temperature) is around 100°C. This means that it can maintain its shape and strength in slightly higher temperature environments such as automotive interior parts (non-engine compartment high temperature area) and electronic equipment housings, and is not easy to soften and deform.

(3) High convenience of post-processing: The surface of ABS parts is relatively soft, and the surface of the parts made is relatively easy to grind, drill, and tap. The most critical advantage is that it is sensitive to acetone. A fumigation with acetone vapor can make the surface very smooth, even close to the gloss of injection molded parts, which is particularly useful for parts that require appearance or need to be sealed.

Mastering ABS: Challenges and solutions you need to know

(1) High temperature is the key: To successfully print ABS, the nozzle temperature must reach 230-260°C, and a heated bed is necessary, and the bed temperature must be maintained at a high level of 90-110°C to ensure that the first layer is firmly adhered.

(2) Warping is the main enemy: ABS shrinks greatly when cooling, which is particularly easy to cause the corners of the model to warp up, or even the entire piece to peel off from the printing platform. The most effective solution is to use a printer with an enclosed cabin (insulation cover). The enclosed cabin can maintain a stable and uniform internal ambient temperature, greatly reducing the shrinkage and warping problems caused by direct cold air blowing, and improving the success rate of printing.

(3) Strong smell, ventilation needed: During printing ABS, the material is melted and will emit a visible plastic odor, consisting of volatile chemicals like styrene. The odor is somewhat strong and not healthy to inhale over a period of time. So make sure to print in an airy area, e.g., opening windows, utilizing strong exhaust fans, or attaching outside exhaust ducts. Don’t work in a small area.

“ABS is a reliable choice for the creation of functional parts and engineering prototypes with high toughness, excellent temperature resistance, and deep post-processing. But to this, its very high printing threshold and odor control needs must be especially noted. Should your intent be the creation of practical parts to endure outside forces, extreme temperatures, and chase surface finish, then ABS is an excellent quality material to invest in. If you are having material selection or printing problems, don’t think twice to bring your parts needs to JS Company and let us collaborate with you to find the solution!”

Material Case Analysis: When Desktop Figures Meet Drone Landing Gear

I have worked on countless custom 3d printing manufacturing projects. Choosing the right material is the key to success! Today, we will use two real cases to show you how PLA and ABS perform their respective functions in practical applications:

Case 1: Customized anime figures – a visual feast of PLA

Customer needs: Urgent customization of a 20cm high anime character desktop ornament, requiring sharp details, smooth surface, rich colors, and strict cost control.

Core challenges: Need to restore the ultimate appearance (hair, clothing lines), complex drape structure, and safe printing in an office environment.

JS’s choice: PLA (Silk White)

Decision basis:

(1) Detail restoration master: PLA has low melt fluidity (similar to thick honey), can accurately fill tiny features, and ensure that details <0.2mm such as hair and wrinkles are clear and sharp, which is an advantage that ABS cannot achieve.

(2) High printing success rate: This complex model has many suspended structures, low printing temperature (195±5°C), low hot bed requirement (50-60°C), cooling shrinkage rate of only 0.2-0.5%, almost no warping, and ensure that complex structures are formed in one go.

(3) Native aesthetic performance: Silk white PLA has a ceramic glaze gloss (60° gloss ≥ 85), which saves customers the trouble of later polishing and the effect is very satisfactory.

(4) Office environment friendly: Printing in an office environment, VOC emissions <5ppm (in line with ISO 16000 standards), PLA’s light sweet corn smell is almost imperceptible, safe and reliable.

Key data:

| Performance parameter | The actual measured value of PLA in this case | Testing standards | The significance of opponent’s production |

| Melt Flow Rate (MFR) | 7.2 g/10min (210°C). | ASTM D1238. | Low liquidity ensures that micro details do not scatter and have high sharpness. |

| Thermal shrinkage rate | 0.35% (ΔT=190°C→25°C). | JS-SHRINK-03. | The total deformation of the 20cm model is less than 0.7mm, to prevent warping and demolding. |

| 60 ° glossiness (native) | 89 ± 2. | ASTM D523. | Approaching the effect of ceramic glaze, no need for spraying. |

| Interlayer bonding strength | 38 MPa. | ASTM D638 (transverse). | Ensure the structural integrity of hanging parts (such as hair tips). |

Test method description: JS uses a 200×200×1mm thin plate, and measures the deformation by laser scanning after cooling from the printing temperature to room temperature, simulating the actual shrinkage of large parts.

Results: Deliver a zero-defect display model within 48 hours, with a detail accuracy of ±0.1mm, and the cost is controlled within 90% of the budget.

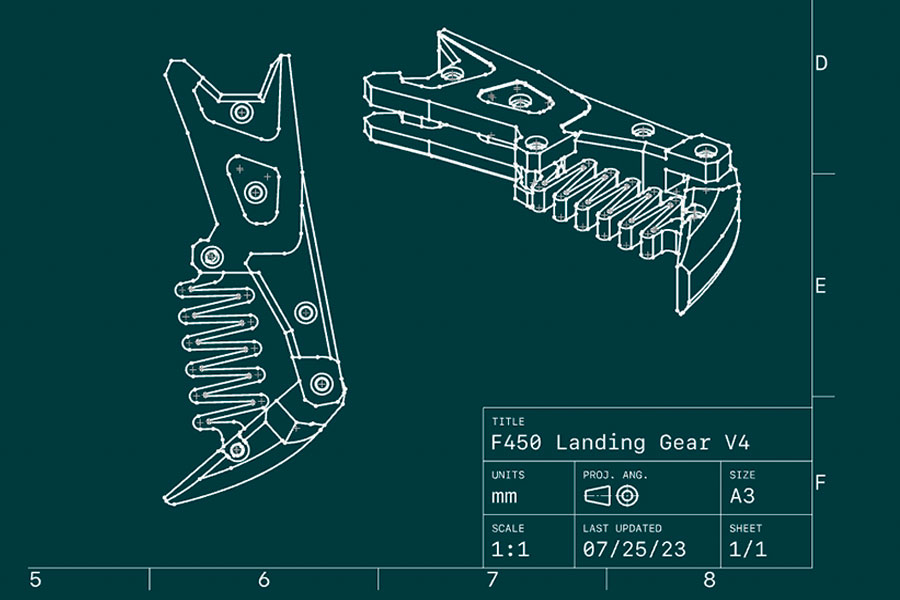

Case 2: Emergency manufacturing of drone landing gear – functional verification of ABS

Customer needs: Urgent! To deliver the agricultural drone landing gear in 8 hours, a replacement part needs to be printed quickly for on-site repair. It is required to withstand a 2-meter hard landing impact and withstand a local high temperature of 65°C.

Project features: Functional parts must withstand landing impact, may be exposed to the sun, and the speed must be fast!

JS’s choice: ABS (black)

Decision basis:

(1) Impact resistance is king: The impact of the drone landing is not small. ABS has good toughness and can “absorb energy” like rubber, and is not easy to break like PLA.

Key data of ABS filament:

| Performance parameter | ABS measured values in this case | Testing standards | The significance of landing gear |

| Impact strength (Izod) | 41 kJ/m² | ASTM D256 | There are no cracks after 10 impacts from a 2-meter free fall. |

| Hot deformation temperature (HDT) | 105°C (0.45MPa) | ASTM D648 | The thermal radiation zone of the motor compartment (measured at 82 ° C) does not deform. |

| Fatigue life cycle | >15000 times (σ=20MPa) | ASTM D7774 | The daily average of 30 takeoffs and landings has a lifespan of ≥ 18 months. |

| Drilling torque | 1.8 N·m | JS-MACH-01 | The carbon steel drill bit has no cracking during processing. |

Test method description: JS uses a φ4mm carbide drill bit and feeds 0.1mm/rev to measure the tearing torque of the ABS hole wall.

(2) Heat resistance must be passed: The temperature in the field is high in summer, and it is even hotter near the motor. ABS can withstand about 100°C, but PLA may become soft and deformed above 60°C and cannot be used at all.

(3) Convenient for post-fine-tuning: After printing, you need to drill holes at the connection for fine-tuning. ABS is relatively soft and easy to polish and drill. Although fumigation was not done this time, this feature of ABS ensures the possibility of rapid modification.

Results: We responded quickly, and the black ABS landing gear of custom 3D printing manufacturing was delivered after 3 hours of printing + simple processing. The customer’s drone returned to farmland operations that afternoon! The performance of ABS perfectly withstood the harsh test in the field, and after delivery, it has accumulated more than 1,200 take-offs and landings without any faults.

“Material selection is to select “genes”! PLA is an expert in visual presentation, with beautiful details and good printing; ABS is a master of functional durability, resistant to falling and heat, and capable of taking on heavy tasks. When your parts need to face harsh environments, ABS data will not lie. Bring your working parameters to JS engineers for in-depth focus. We rely on more than 200 material gene libraries and full-working test platforms to provide the best solution for your custom 3D printing manufacturing!”

FAQ – End Your Final Confusion About PLA And ABS

PLA and ABS, which one is stronger?

I am often asked which one is stronger, PLA or ABS. It depends on what strength you are referring to.

In terms of tensile strength and rigidity: PLA is usually better. Its molecular structure is denser, like a hard ruler, and its ability to resist stretching and bending deformation is slightly better (PLA tensile strength is about 60MPa vs ABS’s 40MPa).

But in terms of impact resistance and tossing resistance, ABS wins in crushing! Its internal rubber phase component can absorb impact energy, just like a tough buckle, which is not easy to break even after multiple bends (ABS impact strength is 10 times more than PLA).

Simply put: Choose PLA for static parts that are hard and non-deformed, and ABS for functional parts that need to withstand falls and bends. For specific material selection, you are welcome to bring working condition parameters to our laboratory for actual measurement and verification. Data speaks for itself!

For beginners, which one is more suitable, ABS or PLA?

I strongly recommend that novices start with PLA. It has a low printing temperature (190-220°C) and almost no warping. Ordinary printers can easily control it, and the success rate can reach more than 97%. You can see the results of making a small ornament or a model verification part in a few hours, which is particularly rewarding.

When you have mastered the basic settings and need to make functional parts that are resistant to falling and heat, such as buckles and shells, then challenge ABS. By then, you will have a thorough understanding of the performance of the printer and can handle high temperatures (230°C+) and closed cabins.

Remember: PLA is for beginners, ABS is for advanced users. If you are still hesitating about which one to choose, feel free to bring your design to us for a trial run and we will test it on site!

In terms of environmental protection, which one is a better choice, ABS or PLA?

In terms of environmental protection, PLA is much better than ABS.

The reason is simple: PLA is what we often call “bioplastic”, and its raw materials are corn stalks, sugar cane and other things that grow every year. What’s even better is that PLA can be decomposed in a special composting plant.

ABS is a traditional plastic refined from petroleum, which is produced by fossil fuels and thrown into the natural environment after use, and it will not rot for hundreds of years.

Of course, we can recycle and reuse both plastics, but the key is to have a place to collect them and have the technology to process them. So if we only look at environmental protection, PLA is greener.

How about PETG? Is it a perfect combination of the two?

I often think of PETG as a practical compromise between PLA and ABS. It does combine some advantages:

It is stronger and more heat-resistant than PLA, much less troublesome to print than ABS, and is food contact safe (such as containers for food).

But it is not a panacea. It is more likely to draw wires when printing (need to adjust the retraction settings), and the surface of the finished product is also soft and easy to scratch.

Therefore, PETG is not to completely replace anyone, but a very handy new choice in the toolbox when you need to balance strength, easy to print and food safety.

Summary

After the previous analysis, the core conclusion is clear: PLA and ABS, the two mainstream materials, have no absolute advantages or disadvantages. The key lies in which one better matches your specific project needs. Understand their key differences:

- PLA: More user-friendly, the appearance of the printed parts is usually more delicate.

- ABS: Provides higher structural strength, heat resistance and durability.

Choosing the wrong material may not only lead to printing failure or insufficient part performance, but also waste design investment and time. Accurately matching materials is the first step to project success.Don’t worry about choosing materials anymore! Let the JS team help you:

- Upload the model, and the experts will help you choose the material! Are you still worried about whether to use PLA, ABS or PETG? Or even other more professional engineering plastics? Upload your 3D file to the JS platform, and our intelligent system and engineer team will immediately conduct a comprehensive evaluation and recommend the most reliable material solution to you!

- Instant quotation, transparent and no hidden! Want to know how much it costs to print with the recommended materials? You can see the detailed 3D printing price immediately! Our online quotation system is clear and concise, and the material cost and labor cost are listed separately. There are no hidden costs, so you can have a clear budget.

- Professional printing, quality assurance! Choosing the right material is only half the battle, and accurate printing is also critical. JS’s online 3D printing services are checked by professional equipment and experienced engineers, speaking with strength, so that your creativity can really come to fruition!

Don’t let the material selection block your good design. Upload your files to JS now, get exclusive materials and instant quotes, and let’s make something that is both beautiful and useful together!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It’s the buyer’s responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: PLA vs. PETG: The Ultimate Filament Guide - JUSHENG

Pingback: Classification Of Filament Used In 3D Printers - JUSHENG

Pingback: What Is ABS Acrylonitrile Butadiene Styrene Used For? - JUSHENG

Pingback: What Is The Quotation Structure Of SLS 3D Printing? - JUSHENG

Pingback: What Are The Core Challenges Facing PVC Materials In 3D Printing Technology? - JUSHENG