When choosing a surface finishing for steel or aluminum, many customers ask: Should I anodize or galvanize? As a JS engineer, I usually help them weigh the option based on the material and intended use case.

Put simply, anodizing creates a colored oxide layer on the aluminum surface through electrolysis that is wear-resistant and aesthetically pleasing. It’s a form of “inner-strengthening” protection. Galvanizing, on the other hand, coats the steel surface with zinc, which, through its self-sacrificing characteristic, repels rust, an “external protection.” Both yield corrosion resistance and longer life, yet the principles and materials are completely different. The right selection will certainly maximize the product’s performance.

Key Answer Summary:

| Comparison Aspect | Anodizing | Galvanizing |

|

Core principle

|

Electrochemical Conversion Coating: In situ conversion of aluminum and other metal surfaces to a denser and thicker porous oxide film (such as Al₂O₃), which becomes a part of the substrate. | Metallic Coating: Sacrificial protective coating of zinc metal coating attached to the surface of steel or other substrates by hot dipping or electroplating. |

| Processing substrate | Mainly aluminum and aluminum alloys (can also be used to treat magnesium, titanium, etc.). |

Mainly black metals such as steel and iron.

|

| Protection mechanism | Inert Barrier Protection: Substrate separated from the external environment by a dense oxide film. Alloys with high hardness and good wear resistance. | Sacrificial Protection: Zinc is more reactive than iron and will preferentially corrode, thus protecting the internal iron matrix. |

|

Appearance features

|

Rich color and metallic texture: can be colored by dye with even and stable multi-color (silver white, black, gold, red, blue, etc.), maintaining metallic luster. | Classic “Zinc” Look: Hot dip galvanizing is with silver gray splash look, and electroplated galvanizing is with gray white look and relatively smooth texture. |

| Key performance | High hardness, excellent wear resistance, good insulation, excellent dyeing and adhesion. | Excellent corrosion resistance (especially long-time outdoor anti-corrosion), excellent damage resistance, and thick coating. |

| Typical applications | Consumer electronics casing, aerospace components, building aluminum curtain walls, precision mechanical parts, high-grade household appliances. | Power towers, highway guardrails, building steel structures, bolts and nuts, automotive chassis. |

Why This Comparison? JS’s Frontline Experience

At JS, over a decade ago, all our recommendations on anodizing and galvanizing have been experience-based and led by industry standards like ASTM and ISO so that proper guidance is given.

For example, anodized aluminum thickness is typically 5 to 25 microns and can withstand over 500 hours of rust-resistance salt spray tests, making it highly appropriate for sensitive sheet metal fabrication parts like electronic device covers.

Zinc coating on galvanized steel is between 5 to 20 microns, normally effective for protection against rust for around 240 hours, and therefore more appropriate for outdoor structural components that are exposed to the elements. Our defect rate is less than 0.3%, so these figures are totally reliable.

As surface treatment expert Joseph B. Kushner once emphasized, “The value of a protective coating ultimately lies in the reliability of the product in service.”

Surely, the precise method to utilize will depend on your budget, design, and practical usage environment. We can help guide you through these careful considerations.

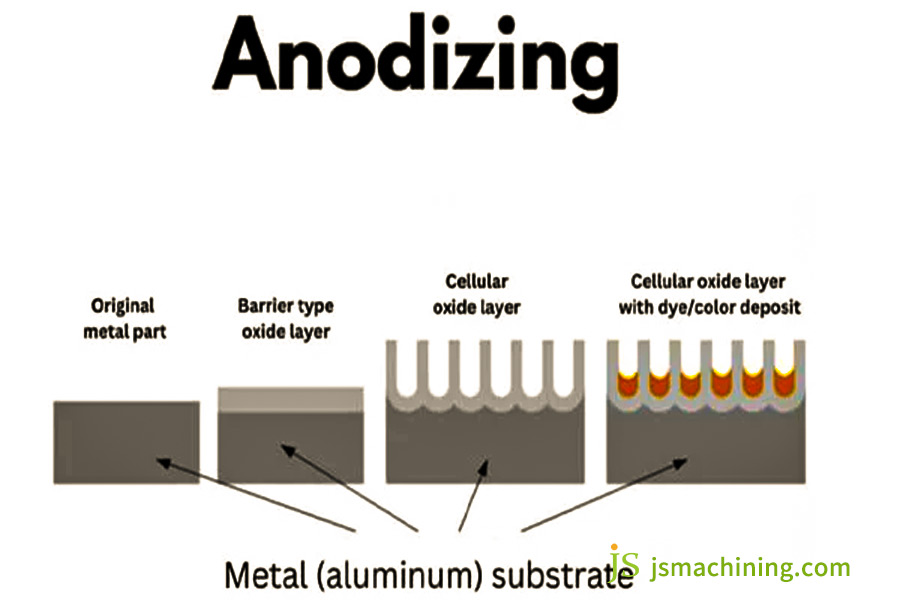

More Than Just A “Film”: The Secrets Of Anodizing

The anodizing process used by JS is not a coating but involves running electricity through an electrolyte to create a dense oxide coating directly onto the surface of the aluminum. This coating will strongly bond to the substrate and will not peel.

Why choose it?

- In the first place, it is corrosion-resistant and offers a good range of color, exactly what the brand’s look needs.

- Second, it is very hard on the surface and much scratch-resistant than galvanized sheet metal, and thus very appropriate for components subject to repeated handling or application.

- Third, the porous structure of the oxide film readily retains dyes, lubricants, and facilitates subsequent bonding.

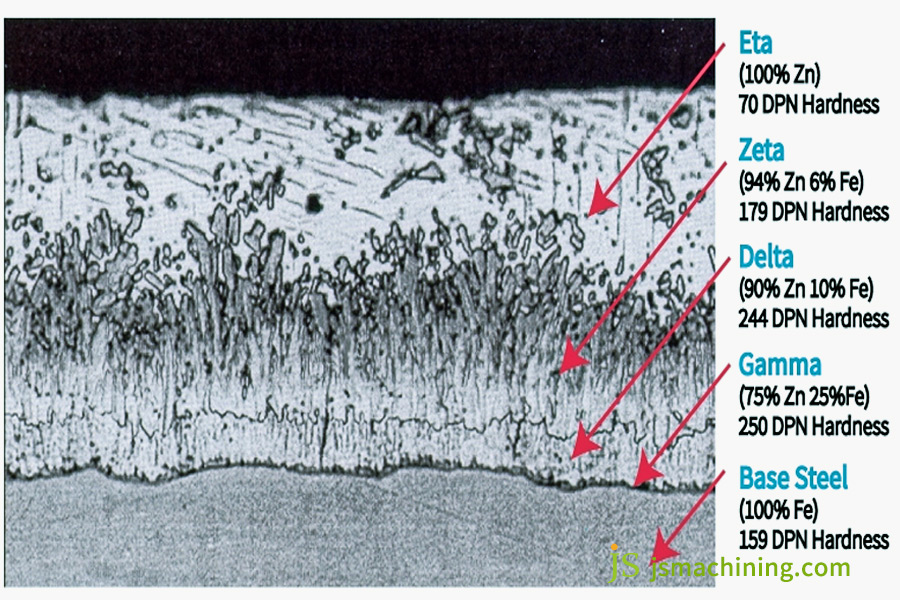

More Than Just Covering: The Art Of Active Protection In Galvanizing Technology

In my daily work, I help clients select the optimal corrosion protection system for their purposes. On this day, I’d like to discuss galvanizing technology—the philosophy behind: “Sacrificing oneself to protect steel.”

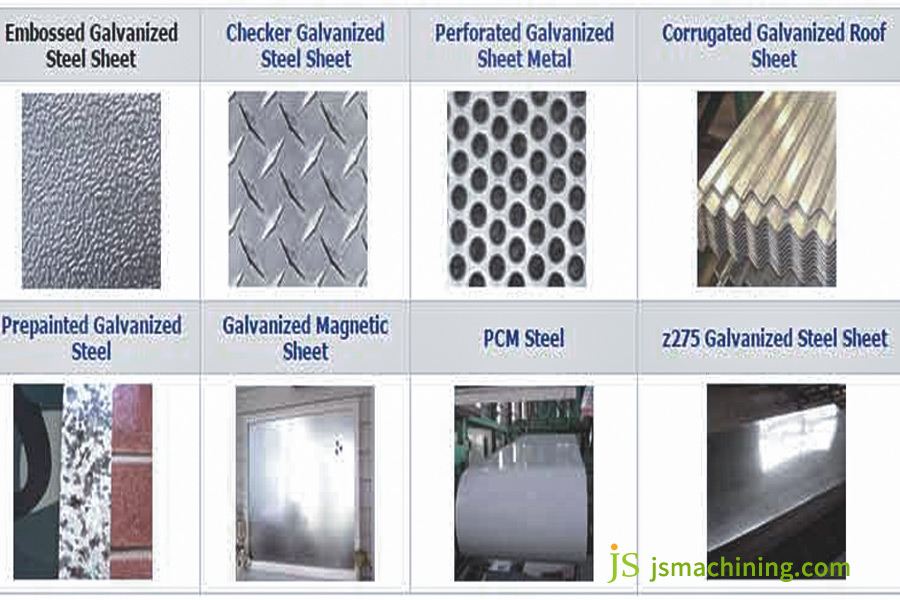

Types of Galvanized Sheet Metal :

- Hot-dip galvanizing: The steel sheet is immersed in molten zinc, resulting in a thicker coating, typically 50-150 microns thick. It is a coating particularly suitable for harsh outdoor environments, e.g., high-voltage transmission towers.

- Electrogalvanizing: The zinc coating is formed by electrolysis, typically only 5-30 microns thick, with a smooth and even surface. It is commonly used on automotive exteriors and appliance panels.

- Alloyed galvanizing: A heat treatment is given after galvanizing in order to form a zinc-iron alloy layer, which is more resistant to scratches and is widely used in building structures.

Why Use It?

- Long Protection Life: In normal atmospheric conditions, hot-dip galvanizing can provide 20-50 years of protection with no maintenance on a regular basis.

- Cost-Effective: While the initial investment is approximately 20% higher than painting, the life-cost can be saved by over 40% as it is virtually maintenance-free.

- Active Protection: Even if the surface is damaged, the zinc continues to protect the steel substrate through a “sacrificial anode” effect, which most coatings cannot offer.

Whether you’re contemplating corrosion protection for your initiative, we encourage you to get in touch with the JS team—we can help you select the proper galvanizing process for reliable, cost-effective, and long-lasting protection.

Head-To-Head Comparison: Core Technology Attributes Of Anodizing And Galvanizing

When conducting custom sheet metal fabrication manufacturing for clients, surface treatment selection is crucial. Today, I’ll compare anodizing and galvanizing, two mainstream technologies, from a practical application perspective.

| Comparison aspect | Anodizing | Galvanizing |

|

Core technical characteristics

|

Through electrolysis, a thick layer of 5-25 μm alumina is developed on the aluminum surface, which originates from the substrate itself and has better adhesion. | Mainly by hot-dip or electroplating, a zinc layer is attached to the steel surface with a usual thickness of 5-30 μ m or more as a sacrificial protective coating. |

| Substrate selection | Specifically formulated for aluminum and aluminum alloys. Aluminum plate anodizing is the industry’s preferred process for enhancing gears in custom sheet metal fabrication manufacturing. | Used mainly on steel (steel), such as cold rolled plates, structure steel, etc. |

| Appearance and Performance | The surface can form all manner of color (silver white, black, champagne gold, etc.), which is extremely beautiful and has high surface hardness (HV 300-500) and good wear resistance. | The appearance is a typical silver gray stripe (zinc pattern), which may be slightly rough. The maximum salt spray testing time can reach over 1,000 hours (red rust). |

| Usage environment | Good weather resistance, used in indoor decoration, shells of electronic devices, etc. Long-term application in coastal or high salt alkali humidity environment (level C5) can not be ensured. | Good rust prevention performance, especially applied to exterior structural components, chassis cabinets, etc. Salt spray testing time can normally be over 500 hours (white rust). |

| Material costs | The process is complex and the cost is relatively high. The processing fee per square meter varies depending on the thickness and color requirements, ranging from tens to hundreds of dollars. | Governing technology, economical, hot-dip galvanizing requires about half or even less time compared to anodizing, and thus is very suitable for large-scale applications. |

I hope this comparison illuminates your thought process. The choice of process ultimately depends on your product positioning, substrate, and application conditions. Feel free to contact the JS engineering team for guidance from experts tailored to your specific selection and manufacturing needs.

Decision Moment: The Final Thought In Selecting The Technology For Your Project

I am an engineer with JS and regularly help clients choose between anodizing and galvanizing. It is not that complicated, by the way, just ask yourself the following important questions, and the answer will be clear.

First, let’s take a look at the substrate: this is the first and most fundamental step

- If you are working on an aluminum or aluminum alloy material, I typically recommend anodizing because of its better compatibility.

- If it is steel or iron that is to be used as a substrate, galvanizing is the obvious option, specifically hot-dip galvanizing, which is more rust-protective.

Then there is the work environment: This determines what level of protection

Your environment matters to your selection, and both processes require extremely different protection procedures:

| Usage environment |

Recommended process

|

Reason explanation

|

Main application scenarios

|

| High indoor and exterior requirements | Anodizing | Not only can it provide excellent wear resistance, but also rich and beautiful color formation, meeting the product look and brand requirement. | Such as consumer electronics product casings, interior decorative parts, etc. |

|

Outdoor and high corrosion environment

|

Hot dip galvanizing

|

The coating is heavy (usually greater than 80 μm), providing ultimate physical barrier and sacrificial protection with highest durability and low lifecycle cost. | Such as highway guardrails, transmission towers, steel structure frames, etc. |

|

Environment containing chemicals/salt spray

|

Hot dip galvanizing

|

The sacrificial anodic protection characteristic of Zinc possesses great benefits in such conditions, resisting electrochemical corrosion efficiently and protecting the substrate steel. | Such as coastal facilities and chemical plant equipment. Attention: Strong acid or strong alkali environments require additional evaluation. |

How important is appearance?

- In search of a special color, a luxury metallic look, or a special matching your corporate colors? Anodizing is your only choice.

- Is operation most critical, an ordinary industrial finish sufficient, or do you plan on painting it eventually? Galvanizing (especially electroplating) is a less expensive base coat alternative.

Do you have special performance requirements?

- Need high surface hardness, wear, or insulation? Anodizing (especially hard anodizing) is the solution.

- Require mechanical resistance to impact, damage healing by themselves (sacrificial anodic protection), or electrical conductivity? Galvanizing is the best option.

Take budget and project size into consideration:

- For small lots and intricate shapes, flexibility and sheet metal fabrication price of anodizing is usually beneficial.

- For heavy structural components, hot-dip galvanizing presents the best option based on cost because of its maximum durability and lowest cost per unit area.

We trust that this guide to decision making will help you navigate your way. If you are still uncertain, we urge you to call us and JS Precision Manufacturing will provide free selection guidance and a quotation.

Uncommon Knowledge: “Unsung Heroes” And Special Processes

I am often queried by customers about these surface treatment details. Understanding the underlying principles clarifies many phenomena:

Galvanizing’s “Rainbow Colors” and “White Rust”:

We usually see rainbow-colored color on galvanized parts. Don’t worry, it is a typical sign of protective film formation, and it is a good indication. But in case the warehouse is damp and has bad air circulation, “white rust” can develop—this largely affects the appearance and largely doesn’t affect the rust-proofing function.

Hard Anodizing: A Master of Wear Resistance

It is a very unique process. It leaves a very hard and heavy film on the surface of aluminum, and this yields excellent hardness and toughness. Therefore, components like those within military devices and hydraulic systems that experience extreme everyday rubbing often rely on it.

Post-Galvanizing “Passivation” Treatment:

The majority of our customers ask if we can galvanize both rust-resistant and good-looking parts. The answer is in our passivation process. Not only does our passivation process sufficiently slow the onset of “white rust,” but it also allows for color choice in terms of military green and black, effectively giving another boost to the protective effect.

25-Year Maintenance-Free vs. Stunning Appearance? See How JS Provides The Perfect Solution For A Coastal Landmark

Project Background:

This beachside city giant outdoor viewing platform project requires the main supporting structure to be maintenance-free for 25 years minimum. Guardrails and decorative panels must be of the latest metallic finish (dark gray color) representative of the city’s overall visual identity.

Challenges:

The structural steel is exposed in the long term to a harsh corrosive environment with high humidity and salt and is therefore highly susceptible to rust. The guardrails and decorative panels are mostly complex aluminum profiles and therefore require exceptional weather resistance without sacrificing a pleasing visual appearance. They must resist frequent rubbing and contact to withstand long-term sea breeze erosion and tourist exposure.

JS’s Solution:

The main steel frame utilizes dark gray high-build paint and hot-dip galvanizing (two-protection system). The galvanizing coating provides general cathodic protection, and the paint additionally protects against salt spray corrosion while achieving even color.

The aluminum guardrails and decorative panels are electrolytically anodized to provide a uniform, durable dark gray surface with a high-quality and durable visual appearance.

None of the project’s complex components were well-fitted and pre-finished by way of our online sheet metal fabrication services, which significantly improved construction efficiency and assembly accuracy.

The following is a comparison of some typical protection technologies’ actual performances:

|

Protection method

|

Expected service life of marine environment

|

Appearance stability (after 5 years)

|

Maintenance cycle

|

Data source

|

| Traditional hot-dip galvanizing | 15-20 years | Possible local whitening |

5-8 years to check

|

NCCE Annual Report 2023

|

| Ordinary paint protection | 3-7 years |

Obvious powdering and peeling

|

2-3 years need to be repainted

|

MPRA 2022

|

| JS dual system (galvanized+coated) | >25 years |

No discoloration, no peeling

|

Maintenance-free

|

JS2024 Coastal Project Actual Measurement |

Achievements:

The work was successfully completed and has been operating consistently for a complete year. From our site inspections, it was assured that galvanized coating thickness on the primary structure is greater than 85μm, and coating adhesion met the ISO 12944 standard Level 1 requirement.

Salt spray testing also showed that the dual protection system did not show any sign of red rust after 3,000 hours of testing. The anodic coating over the aluminum guardrail surface was approximately 25μm in thickness, and the color evenness was ΔE ≤ 1.5 while wearability was more than 5,000 friction cycles.

All the total design specifications were met, and the system is expected to last for over 25 years with no major overhauls.

If you have similar exterior metal structure projects in highly corrosive environments, JS can provide you with professional integrated solutions. For in-depth case studies and technical advice, kindly contact our team.

FAQs

Q1: Can galvanized steel parts be anodized?

No. Anodizing is possible only on metals such as aluminum, magnesium, and titanium. Steel parts (galvanized steel too) will not only fail to form a film during electrolytic anodizing, but will even corrode at a very fast rate. In the case of steel materials, we traditionally use other protective methods such as galvanizing, phosphating, or spray coating.

Q2: Why do some galvanized parts appear colored?

We prefer to use chromate passivation in order to add a colorful appearance to galvanized parts. Besides the fact that the conversion coating creates colors like rainbow and military green, which enhance the appearance, more importantly it significantly enhances the corrosion resistance of the parts.

Q3: Which is more durable, anodizing or painting?

In actual JS applications, anodizing would rather be wear-resistance as the oxide coating is a product of the metal’s natural change and cannot be easily removed. Paint is a surface secondary coating, though. When damaged, it can easily rust from the affected area. High-grade fluorocarbon spray coatings also have excellent weather resistance, however. The choice depends on the specific application scenario.

Q4: How can I determine whether a part is anodized or electroplated?

- Smooth to the touch, evenly colored, and non-magnetic aluminum surfaces are usually anodized.

- Shiny, perhaps magnetic, and delammable steel surfaces are usually electroplated.

- You can make an initial estimate based on appearance and substrate material.

Summary

Galvanizing and anodizing are the two most commonly used metal surface coatings. They both operate with distinct mechanisms, but both are extremely utilitarian. There is no absolute superiority or inferiority of one over the other, the choice depends on your material and application scenario. Further, sheet metal fabrication price vary with the surface treatment, so wise choice is crucial in order to achieve a fair performance and cost-effectiveness.

If you’re still struggling to choose a process or material, don’t stress! Our team can effectively assist you in choosing a solution:

✅ Visit our online quote page → Upload a part drawing (STEP/X-T file formats are supported) → Input the material, quantity, and requirements → Get a 30-second feasibility study and quote.

Come on down and make your solution your own today! JS’s hands-on experience will have your product running!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Choosing The Right Aluminum: Comparison Of Material 6061 Aluminum And 6063 Aluminum - JS Precision