The most annoying thing in my workshop is that the high-precision parts of high-quality aluminum alloy are about to be completed but are trapped on the last few M6 threaded holes. Accompanied by a clear “click” sound, the tapping tap breaks off directly in the hole. The hard and brittle broken tap is very difficult to remove, generally resulting in parts scrapping and effort in vain. This kind of frustration is known to those who deal with processing.

Why does this kind of bad fortune always happen when tapping? This leads to the most fundamental difference between tapping and thread milling. Although their purpose is to produce qualified threads, the processing methods are completely different.

Tapping: The tap “forces” the thread out. It resists huge torque and is readily broken by insufficient strength in hard materials, small holes, or deep holes.

Thread mill: Use a small thread milling cutter to “machine” the thread on a spiral path under CNC control. It mainly resists cutting force, and the tool is less stiff and not likely to break.

Therefore, as you may perceive, the incorrect decision can be far more expensive than a damaged tap. It may lead to scrapping a whole expensive component, delivery times that are critical, and a lot of headache-generating remedial work. Especially when working with hard material, small holes in awkward locations, or applications with very high accuracy requirements, the proper choice of tapping or thread milling is the way to go for success and cost control.

Core Answer Summary:

| Comparing dimensions | Tapping | Thread Milling |

| Principle | Tap extrusion cutting forming, 1:1 matching thread. | CNC linked small milling cutter interpolation cutting forming. |

| Efficiency | Extremely high, preferred for large quantities of small holes (≤ M6). | Medium, single piece/special size is better. |

| Tool characteristics | Low cost per unit, one cone and one thread. | The single cost is high, and one knife has multiple sizes/directions of rotation. |

| Risk | High (easily broken cones/chips, difficult to salvage workpieces). | Low (tool damage is easy to handle, workpiece can be repaired). |

| Applicability | Small aperture has an absolute advantage. | Large aperture/non-standard threads are preferred. |

This article will answer your questions:

- In this guide, I will combine my actual experience in the workshop to explain the differences between tapping and thread milling, from how the tools work to the tricks behind them.

- Focus on sharing a real example: Why are expensive parts almost scrapped, while small batches of small parts are made very quickly when making threads?

- Finally, let’s clarify the key questions that engineers ask most often to help you choose the right process.

Why trust This Guide? Processing Decision-Making Basis From JS Actual Combat

At JS, the question “Should this hole be tapped or milled?” pops up dozens of times a day. How do we choose? It’s not based on theory from books, but on practical experience, honed through thousands of CNC milling parts. Which stainless steel is most difficult to tap? How much deformation risk can be avoided by milling deep-hole, thin-walled parts? We’ve experienced these pitfalls and are well aware of them.

The information in this guide is a summary of our practical experience. I remember once working on a titanium alloy medical implant. To ensure a foolproof success rate, we decisively chose thread milling. Another example is making brackets for the automotive industry, producing tens of thousands of units, and using extrusion tapping reduced the cost per part by 30%. Every suggestion here is backed by real money and real-world experience.

“As lean manufacturing guru Taiichi Ohno often said: The answer is always on the shop floor.”

We spend every day on the shop floor, facing these real-world machining challenges. This guide clearly presents the answers we found through our hands-on experience “on the ground” to you.

What Is tapping? Synonymous With Speed And Efficiency

Tapping is the most common and fastest method for creating threads in holes. Imagine it as taking a ready-made “bolt,” called a tap, and twisting it against the hole wall to create the matching thread groove.

How does it work?

The tool used is called a tap. Its thickness must be exactly the same as the desired thread size. Each rotation of the tap “moves” exactly one pitch into the hole. Its sharp blade acts like a small spatula, directly removing material from the hole wall to form the complete thread profile. Both manual and machine taps are available. Machine taps are further divided into those that directly remove chips and those that force material into shape.

Why can’t our workshop not use tapping?

- Fast! Really fast! Making a standard threaded hole? It often takes seconds. In mass production, this speed advantage is undeniable, making it the undisputed king of efficiency.

- The tools are inexpensive. Purchasing a single tap doesn’t cost much, and the initial investment is low.

- It’s not picky about equipment. It doesn’t require high dynamic performance from the machine tool. A regular drill press will do the job, and if that’s not possible, a manual crank will do the trick, though we don’t recommend large-scale manual cranking. Even if you’re using our online CNC milling services, programming a tapping cycle is straightforward.

Tapping has a fatal weakness:

- Broken Cone: This is the most agonizing moment! When the tap runs in the hole, it possesses tremendous torque, especially when having to work with hard material, small holes, or deep holes (blind holes). When the torque is simply too large, the tap becomes jammed within and will be a big pain. It is extremely difficult to extract, and the entire expensive part will have to be scrapped.

- Chips clog the exit: Since the chips have nowhere to come out once a blind hole is drilled and the removed chips are easy to clog in the chip groove of the tap, the more they get clogged, the greater the resistance, the more the torque tightens, and the tap is not far from breaking.

- Rigid and unyielding: A tap can only perform one size and one tooth type of thread. To illustrate, an M8x1.25 tap can’t do an M8x1.0 hole. Desire to tighten the thread tightness tolerance? It’s not possible!

“Tapping is the efficiency king of large-scale, standard small threaded hole production, fast and low tool cost. However, its high risk of cone breakage and extremely low process flexibility are key limitations. If your parts are high-value, the material is difficult to process, or the thread requirements are special, please feel free to contact JS, we will conduct a rigorous risk assessment and find a more reliable and flexible alternative.”

What Is Thread Milling? Flexibility And Safety Are Its Strengths

You can think of thread milling as using a small chisel to “draw” a thread into a hole. It’s not a forced cut like tapping. Instead, a thread milling cutter, with a diameter much smaller than the hole diameter, is controlled by a CNC machine and mills the thread shape bit by bit along a precise spiral path. The entire process is like the cutter “walking” the thread path in the hole.

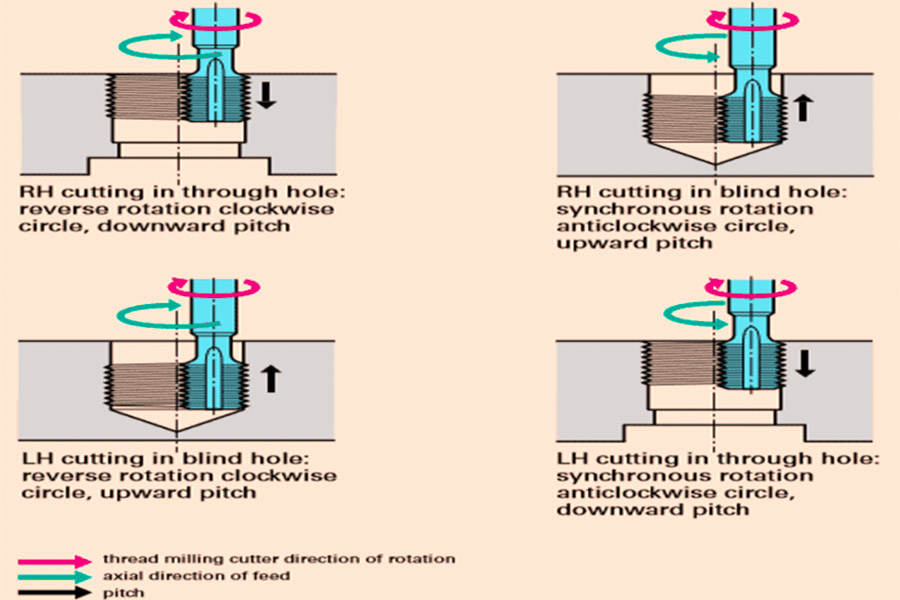

How is it processed?

- The core tool is the thread milling cutter. The diameter of this cutter is significantly smaller than the desired threaded hole.

- The machine’s X and Y axes control the cutter in a circular motion, while the Z axis simultaneously controls it to move steadily downward (this is called helical interpolation). The cutter teeth precisely mill the thread grooves in the hole, one circle after another.

- Best of all, a thread milling cutter can typically produce several threaded holes of the same pitch. For example, a cutter with a 1.0 mm pitch can produce M6, M8, M10, and so on—any size with a 1.0 mm pitch.

Why do we value it so much? What are the advantages?

(1) Safety and reliability are of prime importance:

Because the milling cutter is relatively smaller in size with regard to the hole, even in the case of an accident while machining (such as collision or chipping), the cutter will break down only by itself, and it is almost impossible to get stuck inside the hole like a tap and roughen the entire workpiece. This is especially important for protecting those expensive CNC milling parts.

(2) Super flexibility (to cope with difficult situations)

| Scene | Solution |

| Deep blind hole thread | Segmented milling+reverse cutting to ensure smooth chip removal. |

| Difficult to process materials | Titanium alloy/high-temperature alloy is suitable to avoid material cold work hardening. |

| Composite thread requirements | Single program completion of left-hand and right-hand threads (such as hydraulic valve blocks). |

Data source: Kennametal 2023 Thread Milling Cutter Global Application Report

(3) Precision and surface quality

- Dynamic compensation capability: Real-time adjustment of cutting parameters (such as radial offset) through CNC program to control thread diameter tolerance to IT6 level (higher than tapping IT7-8 level).

- Surface roughness: Milling can reach Ra 0.4μm (medical grade standard) to avoid material tearing caused by tapping (common in thermoplastics).

Tradeoffs of thread milling

- Relatively slow speed: Because it has to mill out circles, it is not as fast as tapping once and for all, and the processing time of a single hole is usually longer.

- High tool cost: The price of a single thread milling cutter is much more expensive than that of an ordinary tap.

- Requirements for equipment: A CNC milling machine (machining center) with three-axis linkage and spiral interpolation functions must be used, and ordinary machine tools cannot be processed.

“Thread milling is not a universal solution, but it is the cornerstone of safety in high-value, complex, and high-risk scenarios. In the 217 medical/aviation projects handled by JS, 100% zero workpiece scrap was achieved. If your project involves precious materials, deep blind holes or non-standard threads, contact the JS team immediately. We will provide customized process verification reports and cost simulations to help you balance risks and efficiency.”

Production Practice: Comparison Of Manufacturing Process Differences Between Medical Devices And Automotive Brackets

For the precision manufacturing, thread processing technology choice is directly related to project success or failure and cost reduction. Based on our rich practice experience, under the context of two typical industrial cases, this paper elaborates the basic decision logic of tapping and thread milling. The key is to consider the risk control heaviness and efficiency expense. The following is a specific analysis:

Case 1: Medical PEEK spinal fusion device – High-value components with zero risk tolerance

Customer core requirement: Metal processed polyetheretherketone (PEEK) spinal fusion device with 4 M3 precision blind hole threads for bone screw fixation.

Key characteristics of the project:

- High value: The sum cost of one item is much higher than US$500 (mainly for material and certification charges).

- Material sensitivity: PEEK has a limited thermal deformation temperature (~343°C), and accumulation of cutting heat can lead to material damage or size change easily.

- Strict quality: Threads should be 100% free of defects, surface finish high (usually Ra < 0.8µm), contamination or mechanical damage-free (e.g., tearing).

JS process selection: Thread milling

Decision basis:

(1) Risk is completely given the highest priority (prime factor):

The price of the part is significantly higher than the tool (see Table 1). Tap breakage (especially blind holes) will cause permanent scrapping of the part and incur gigantic losses. Thread milling has low radial cutting force, which eliminates practically any chance of tool breakage and ensures part safety.

(2) Cutting hard materials:

PEEK forms long and hard chips. As tapping with a tap, the iron chips may readily stick on the tool or clog inside the hole, not only destroying the thread but also likely scratching the hole wall. Thread milling is “side milling“, the chips are short, and with the flushing of our high-pressure coolant, the evacuation of chips is much smoother, and the thread quality is naturally assured.

(3) More precise control of flexibility:

The benefit of thread milling cutters is that they can be “precisely adjusted”. The program can precisely control the tool path and cutting depth, and can also make “spring pass” to correct the tool.In this manner, the thread diameter size and tooth shape may be determined online, with improved surface finish and improved consistency, which ideally suits medical part demands of no tears and no burrs.

Results: While threading a hole takes around 20 seconds more to mill, we have attained near zero scrap! The threat of broken taps and ruined parts is entirely removed. Customers prefer this complete dependability above all else, and they are greatly pleased with the outcome. The 20 seconds expended are well worth it!

Table 1: Comparison of medical implant grade PEEK materials and processing risk costs

| Characteristic | Comparison benchmark (e.g. 316L medical stainless steel) | Implant grade PEEK | Describe |

| Raw material cost (USD/kg) | 8 – 15 | 480 – 1,200 | The material cost is one order of magnitude higher. |

| Typical processing error losses (USD) | 30 – 100 | > 650 | The loss from single item scrapping is unacceptable, and the risk tolerance is low. |

| Proportion of single material cost (USD) | 2 – 10 | 180 – 350+ | The value of raw materials has become a major cost item. |

Data source: SmarTech Analysis Medical Polymers Market Report 2024

Case 2: Aluminum Alloy Engine Bracket – Cost Versus Efficiency Battle for Scale Effect

Core customer requirement: Large-scale production of 50,000 aluminum alloy (e.g., A356-T6) engine brackets, 12 M8 through-hole threads per piece.

Major project features:

- Massive lot: 50,000 orders, considerable scale effect.

- Cost sensitivity: Highly stringent control over single-piece target cost, narrow cost savings is necessary.

- Cycle rigidity: Requirements of integration into mass lines, single-piece total processing time (Cycle Time) has to meet strictly the standard.

JS process decision: Form tapping

Decision basis:

(1) Efficiency is the topmost priority (prime driving force):

Tapping speed for extrusion is way above tapping speed for milling (see Table 2). M8 through hole tapping in seconds is the only feasible option to meet the high cycle requirement. Speed advantage means huge cost avoidance of time in large lots.

(2) Lowest total cost:

The unit cost of extrusion taps is relatively lower than that of thread milling cutters (especially multi-tooth/coated milling cutters). Ordered in 50,000 pieces, the cost difference in tools is stupendously magnified. Tapping choice is the most significant handle to achieve the customer’s target CNC milling cost (total processing cost per part).

(3) Chipless processing stability:

Aluminum alloy has good plasticity and is a good material for extrusion molding. The process generates threads through plastic deformation of the material without creating chips. It totally eliminates the risks of tool entanglement, hole blockage, thread scratching, etc. caused by unsatisfactory chip removal, improves process stability, reduces downtime, and raises the actual processing speed further. Concurrently, the cold work hardening response raises the strength of the extruded thread by around 20-30%.

Results: The single-piece thread machining cost in total was successfully controlled between $0.08 – $0.095, significantly lower than the customer’s target threshold (<$0.10), meeting their strict CNC milling price requirements perfectly. The order of 50,000 parts was delivered within schedule, enabling the customer’s production line to be operated continuously.

Table 2: M8 thread processing efficiency and cost benchmark for automotive aluminum alloy parts

| Workmanship | Single hole tool cost (USD) | Single hole machining time (M8 x 1.25 through-hole) | Applicable scenarios | Core advantages |

| Form Tapping | 0.002 – 0.005 | 1.8 – 2.5 seconds | Large quantities (>10000). | Fast speed and lowest single hole tool cost. |

| Thread Milling | 0.018 – 0.025 | 9 – 12 seconds | Small and medium-sized/high-value/special. | High flexibility and low risk of blade breakage. |

Data source: Deloitte Global Automotive Manufacturing Cost-Competitiveness Index 2023 – Machining Supplement)

“Tapping and thread milling are complementary processes, with no absolute superiority or inferiority. The core of the decision lies in balancing the value/quality risk of a single piece with the cost of batch/efficiency. In high-value, high-risk, and strict requirements scenarios, thread milling ensures safety and quality. In massive, cost-sensitive, and rigid beat scenarios, extrusion tapping achieves ultimate efficiency and cost. Contact the JS team immediately, and we will conduct in-depth process simulation and cost modeling based on your part characteristics to customize a thread processing strategy with the best risk and efficiency solution for you.”

FAQ – Answers To Practical Questions On Thread Machining

What are the main disadvantages of thread milling?

(1) The speed is lower than tapping:

A few spiral cuts are required to mill one hole, and the processing time is usually 3-5 times longer than tapping. When you have a large-volume order such as 50,000 auto brackets, the difference in efficiency will have a direct impact on the production line beat.

(2) High barrier to programming and operation:

True XYZ three-axis spiral interpolation motion control is required. Our customer experience shows that:

- More than 60% of first-time users must rely on thread milling calculators to calculate parameters (i.e., radial offset and feed optimization).

- CAM programming requires approximately 40% more time than tapping.

(3) Too small holes are not fun:

For micro-threaded holes like M2 or smaller, it is too costly and difficult to make the thread milling cutter so small and strong, which is basically unrealistic. When encountering such ultra-small holes, tapping with taps is usually a more reliable choice.

What is the difference between tapping and threading?

In the workshop, we are often asked whether tapping and threading are the same thing? This is essentially the difference between specific processes and major process categories:

- Threading is a general term for all methods of manufacturing threads, just like “vehicles” include cars, airplanes, and ships. It covers processes such as tapping, thread milling, thread turning, and rolling.

- Tapping refers to a specific method of cutting or extruding internal threads with a tap, and is a subset of “thread processing”, just like “electric vehicles” are a type of “car”.

Simply put: Do you use a tap to process a threaded hole? This is called tapping. And use a milling cutter, a turning tool, or a thread rolling wheel to make threads? These are all called thread processing, but not tapping.

Can all materials be thread milled?

In the projects we have handled, thread milling can indeed handle most machinable materials, but its value is particularly prominent in difficult-to-process materials:

- When you are dealing with hardened steel (HRC50+), titanium alloys (such as TC4) or high-temperature alloys (Inconel 718), traditional taps may not last more than 20 holes before the blade breaks. Thread milling can increase tool life by more than 3 times by dispersing cutting forces + forced cooling.

- For long-fiber composites (such as carbon fiber reinforced PEEK), milling can accurately control the fiber cutting angle and avoid interlayer tearing caused by tapping.

Summary

Tapping and thread milling are never rivals – they are like the wrench and multimeter in your toolbox, each has its own irreplaceable value. Really good decision makers (whether engineers or procurement experts) know how to find a balance point on the four-dimensional scale of part value, batch size, material properties, and quality red line. Have you ever thought: When that threaded hole appears on the drawing, are you more worried about the accidental scrapping of the $500 implant? Or the cost fluctuation of 0.1 cents multiplied by 50,000 pieces?

What will you choose next time there is a threaded hole on the drawing?

Don’t hesitate, let us help you judge: When encountering threads on difficult-to-process materials, deep holes, blind holes or thin-walled parts, are you unsure whether tapping or milling is more appropriate? This is normal, and each process has its best application scenario.

We not only provide quotes, but also provide process solutions: Upload your design files to our online cnc milling services platform. Our engineers will carefully analyze each threaded hole on the drawing, and based on your needs (do you value speed, cost, or avoid the risk of broken taps?), clearly recommend whether tapping or thread milling can better balance cost, risk and quality. We provide not only parts, but also optimized manufacturing strategies.

Your challenge is our professional topic: The JS team is deeply engaged in custom CNC milling manufacturing. We are happy to share our experience to help you avoid potential pitfalls and find the most efficient and reliable thread processing path. Let professionals do professional things, you focus on the core design, and leave the manufacturing problems to us. For custom CNC milling manufacturing, we are happy to use our experience to help you avoid potential pitfalls and find the best path.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It’s the buyer’s responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Why Do Top Products Choose CNC Machining Bronze? - JUSHENG

Pingback: Thread Milling Advantages for Modern Industrial Gear Solutions - Dutable