Has it ever occurred to you to be confused with SLS 3D printing service quotations? Quotes for ostensibly the same parts from different service providers might differ remarkably, and you’re left wondering why 3D printing price is so vastly in magnitude. A small change in design can triple or more the cost. It is not a whimsical pricing strategy on the service provider’s part, but a complicated system of open calculation.

Most companies seeking the services of custom 3D printing manufacturing are confused by a lack of understanding on how quotes are presented. This article will be your “quote decoder,” dissecting the cost structure of SLS 3D printing in detail, exposing little-known “hidden expenses” and “money-saving tips,” and ultimately showing you how to get a whole lot more value with an informed decision.

Core Answer Summary

| Cost Component | Typical % Range | What’s Included & Notes |

| Material Cost | 30% – 50% | It includes the mixed cost of the consumed new nylon powder and recycled powder (i.e., powder refresh rate). Specialty materials (such as PA11, PA-GF) will have a price premium. |

| Machine Time Cost | 30% – 40% | It is the equipment time fee occupied by laser sintering of parts, covering equipment depreciation, laser energy consumption, nitrogen consumption, equipment maintenance, and other items. It is directly related to the printing height (number of layers). |

| Post-Processing & Labor | 15% – 25% | It includes labor and time costs for steps such as removing parts from the build cylinder, recycling unsintered powder, sandblasting cleaning, and quality inspection. Special treatments (such as dyeing, polishing) are charged additionally. |

| Setup & Overhead | 5% – 10% | It is the cost allocation for preparation work such as 3D file review and repair, build layout, and machine preheating for the order. It also includes the indirect costs of enterprise operations. |

JS Team Reveals: How To Get a Quote For SLS Printing

JS possesses over 10 years of practical experience in SLS 3D printing, serving customers in new energy vehicle, medical device, and industrial automation fields. We have completed hundreds of high-tech projects, including huge vehicle structural components, high-precision medical components, and personalized industrial components.

We are aware of the cost characteristics of different SLS printers, learn how to implement specialty materials and cost-saving methods, and can help customers save 3D printing prices by optimizing the structure and design.

This guide is a summary of our experience in projects, and all the points of knowledge have been applied in real-world practice. You may trust it to read quotations and select the best online 3D printing services.

If you need professional SLS 3D printing quote advice, the JS team can provide you with appropriate analysis based on their extensive experience. From complex parts to specialty materials, we can provide reasonable 3D printing price advice for your custom 3D printing manufacturing project.

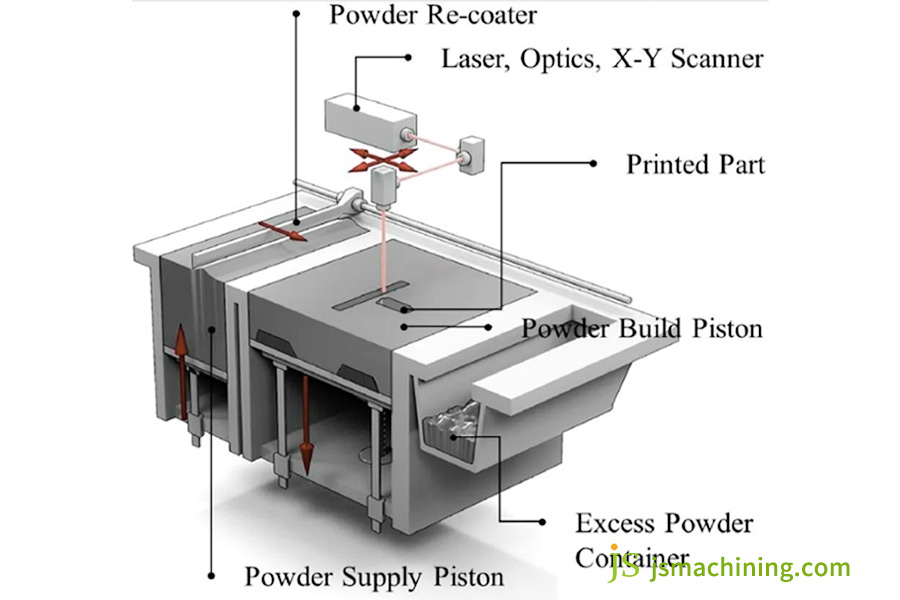

Knowing The Cost Center Of An SLS 3D Printer System

In order to achieve SLS 3D printing quotations, you should first understand where the printer costs are incurred, as such costs are ultimately incorporated into the 3D printing price. The basic cost drivers of SLS printers are centered in five main components:

Laser and Optical Systems

SLS 3D printing has the capability to sinter powder with CO₂ or fiber lasers. Laser has a lifespan of thousands of hours and high replacement costs. Furthermore, optical lenses must be clean and maintained regularly, further increasing the costs.

Heating System

To facilitate sintering without any hindrance and deformation-free powder formation, the build cylinder must be preheated to a temperature of 150-200°C. Higher build cylinders consume more energy, and this type of energy expense is a significant cost.

Precision Machinery and Control Systems

Laser position accuracy and uniformity of powder spreading influence 3D printing part quality, leading to expensive procurement and maintenance of related precision machinery and control systems.

Inert Gas Shielding System

Nitrogen must be fed throughout the entire sintering process to prevent oxidation and burning. Gas consumption is costly in long-term, bulk operations and is often overlooked.

Powder Recovery and Screening System

The equipment used for sintering back unsintered powder and cleaning it for recycling is also a massive upfront cost, as well as wear and tear.

When you’ve got the cost center of an SLS printer, JS can calculate each cost item for you with accuracy. It provides you with a better understanding of the cost structure of your 3D printing business when you choose an SLS 3D printing service so you don’t end up with unnecessary expenses.

Item-By-Item Analysis: What’s Included In Your SLS Quote?

With the printer’s cost center known, let’s analyze what you’re getting for an SLS quote. These are the same items as aforementioned cost centers, and once you know them, you’ll be able to evaluate the cost-effectiveness of online 3D printing services.

Setup Fee

This also covers pre-print preparations such as machine commissioning, powder placement, and file processing. It is charged on a per-order basis.Small batch orders have relatively high 3D printing prices due to lower initial cost sharing.

Volume Cost

This is calculated on the basis of the volume of the part bounding box, not the actual volume. This is because hollow parts take up space in the build cylinder without any room for other parts. This is standard industry practice and influences the cost of manufacturing custom 3D prints.

Machine Time Cost

Calculated based on the total hours of laser sintering, it is directly related to the height (number of layers) of the parts. Taller and more complex parts require more sintering time and are therefore more costly and thus a higher 3D printing price.

Material Cost

Depending upon the powder used, the amount used, and the mix of new and remelted powder, prices vary substantially for different powders, and loss of support powder and unsintered powder must be adjusted for.

Post-Processing Charge

Charged based upon the quantity of parts and the processes. Standard powder cleaning, sandblasting, coloration, and polishing vary in cost. Utilization of more than one process will contribute to custom 3D printing manufacturing cost.

Powder Enters The Market: The Art Of Mixing Materials Pricing

Prices of powder constitute a significant portion of the expense of SLS 3D printing materials. SLS 3D printing costs factor in aspects like the ratio of virgin to recycled powder, variation in type of material, and loss of mechanical performance. All these factors affect material cost and add to the total 3D printing price.

Virgin Powder vs. Recycled Powder:

Unsintered powder can be recycled and sieved for reprinting. Service providers can use a mixture of virgin and recycled powder for printing. Virgin powder content is higher to achieve more stable 3D printing parts, but at increased cost. High-end service providers typically have a percentage of virgin powder 30%-50%.

Material Type Premium:

Prices vary widely for different materials, as set forth in the table below:

| Material Type | Cost Range (USD/kg) | Main Application Scenarios | Cost Characteristics |

| Standard Nylon 12 (PA12) | 50 – 80 | General parts, structural parts. | It has low cost and high cost-effectiveness. It is a commonly used material in custom 3D printing manufacturing. |

| Nylon 11 (PA11) | 80 – 120 | Flexible parts, impact-resistant parts. | Its cost is higher than that of PA12, and it has good flexibility and impact resistance. |

| Glass Fiber Reinforced Nylon (PA-GF) | 100 – 150 | High-strength structural parts, automotive parts. | Its cost is relatively high, and it has high strength, making it suitable for load-bearing parts. |

| Flame-Retardant Nylon | 120 – 180 | Electronic parts, automotive interior parts. | It has the highest cost and flame retardancy, meeting safety standards. |

Powder Performance Degradation:

Used powder will also deteriorate with successive use, affecting the quality of 3D printing parts. Quality service providers track usage and dispose of used powder, and this cost needs to be charged over on the material price.

Comprehensive Comparison: Top SLS 3D Printing Service Providers

Knowing the quote style and material cost, the choice of a suitable online 3D printing service becomes most critical. Here is the comparison table that provides leading figures of top service providers, which highlights JS’s advantages of custom 3D printing manufacturing.

| Service Provider | Pricing Transparency | Process Expert Support | Post-Processing Capability | Material Range | Minimum Order Quantity | Core Advantage |

| JS Precision Manufacturing | High (itemized quotation breakdown). | One-on-one full-process support, providing design optimization suggestions. | One-stop (powder cleaning, sandblasting, dyeing, polishing, etc.). | Full range (PA12, PA11, PA-GF, flame-retardant nylon, etc.). | 1 piece | Strong cost optimization capability and high printing success rate. |

| Protolabs | Medium (details of some items not disclosed). | Email support with fast response. | Basic post-processing (powder cleaning, sandblasting). | Mainstream materials (PA12, PA-GF). | 1 piece | Fast delivery speed. |

| Xometry | Medium (automatic quotation with brief details). | Online customer service support with slow response to complex issues. | Basic post-processing; customized post-processing requires additional negotiation. | Multiple materials; some specialty materials need to be purchased externally. | No minimum limit | High degree of order process automation. |

| Rapiddirect | Medium (quotation details require application). | Project team support with advance appointment required. | Basic + partial customized post-processing. | Mainstream materials; specialty materials optional. | 1 piece | Moderate cost-effectiveness. |

| 3erp | Low (overall quotation package with vague details). | Technical support requires additional fees. | Basic post-processing; complex post-processing outsourced. | Limited materials (mainly PA12). | 5 pieces | Price advantage for bulk orders. |

| Waykenrm | Medium (some material costs not disclosed). | Online technical consultation with limited in-depth support. | Basic post-processing; additional fee required for dyeing. | Mainstream materials; PA-GF requires customization. | 1 piece | Stable delivery cycle. |

To other SLS 3D printing service providers, JS has the advantage of open pricing, process support, and cost savings. From small-batch prototype to mid-volume production, our online 3D printing services offer cost-effective custom 3D printing manufacturing services with simple and hassle-free ordering.

Cost Multipliers: Five Key Factors Affecting The Final Price

Even when you notice the quote format and contrast service providers, the actual 3D printing price will still differ depending on some “cost multipliers.” Being aware of what these are will allow you to reduce cost before designing and ordering.

Part Placement and Layout

Improper placement will increase the volume of the enclosure box, and poor layout wastes space, both of which increase the 3D printing price. Proper placement and high-density layout may reduce cost.

Number of Layers (Part Height)

Taller parts and more layers contribute to the laser operation time, machine labor, and 3D printing price. Unnecessary height should be controlled during design.

Cavity Design

Inefficient cavities can increase material consumption and print time, or make post-processing difficult, increasing cost. There must be a balance between weight saving and manufacturability.

Necessity of Supports

SLS printing typically does not require supports, but may be necessary when there are special overhanging structures or high surface quality requirements.It will increase material and post-processing costs, and raise the 3D printing price.

Post-Processing Options

There are different post-processing options with different costs. Use of multiple or high-precision post-processing options can be very expensive, and therefore the choice to be made based on the actual part needs.

From component design through post-processing functionality, JS will help you keep SLS 3D printing expenses under control from start to finish so you can receive high-quality 3D printing parts at a reasonable price.

Money-Saving Tips: 5 Design Techniques To Significantly Reduce Printing Costs

For every cost-incrementing factor, there exists a cost-reducing tip. With optimal design and printing optimization, you can reduce the cost of SLS 3D printing without compromising the quality of your 3D printing parts.

“Hollowout” is the First Rule of Thumb:Where the component structure allows, position hollowouts to reduce material usage and bounding box volume to reduce print time, material cost, print volume cost, and machine labor cost. Consider minimum wall thickness requirements.

Optimize Build Vault Fill:Print multiple components with the build vat full, averaging up-front cost and maximizing space use. JS’s online 3d printing services can achieve near-100% fill rates.

Optimize Part Orientation:Reduce part height to reduce the number of layers and print time, lower machine labor costs and post-processing requirements.

Uniform Wall Thickness:Maintaining uniform wall thickness prevents deformation and cracking, reduces the chance of print failure, facilitates easier scanning of the path, speeds up printing rate, and reduces costs.

Split Complex Parts:Separate large, complex parts into small parts, print them separately, and assemble them, reducing the cost of individual parts and 3D printing complexity and increasing success rates.

Want to achieve affordable high-quality 3D printing services? JS will incorporate these cost-saving techniques into your custom 3D printing manufacturing productions. Our ordering process is smooth and simple, allowing you to easily gain benefits from cost-effective online 3D printing services.

Why Should JS Offer You The Best Value SLS Print Solutions?

Knowing the quote structure, cost factors, and how to save money, JS can give you the best value SLS 3D print solutions. This is because we understand all processes and know what customers need.

Transparent Pricing:Our itemized quote explicitly includes all costs, no hidden costs and basis of calculation explanation, to ensure that you know the underlying 3D printing price.

Process Expert Support:We offer complimentary design reviews, print status monitoring in real time, and post-processing solution recommendations to ensure the quality of your 3D printing parts.

One-Stop Post-Processing:We have an entire post-processing production line, eliminating the need for multi-processes. Our experts ensure uniform post-processing results.

Effective Cost Optimization:We create customized optimization solutions, such as part splitting and layout optimization, to help you reduce your 3D printing price.

Reliable Delivery Time:A few high-speed SLS printers ensure efficient production planning and prompt delivery of parts.

An “Impossible” Budget – How JS Printed A$100,000 Automotive Intake Manifold Functional Test Part For $50,000

Client Background

A startup firm that was designing a new energy vehicle had a newly developed engine and needed to produce a large, complex nylon glass fiber (PA-GF) intake manifold for bench testing. The 500mm × 300mm × 200mm manifold with a complex internal air path was to be used at a temperature of 150°C and pressure of 0.8MPa and had to be shipped within two weeks.

The client contacted some online 3D printing services, but all provided quotations of $90,000 to $100,000, which was way above the budgeted amount of $50,000, putting the project on hold.

JS’s Solution and Cost Optimization

Design Optimization: On the basis of their model analysis, JS’s process specialists recommended the part be cut into three pieces and be assembled using a combination of snap-fits and adhesives. This effectively reduced each individual part’s bounding box volume, removing printing risks and reducing printing costs.

Intelligent Layout: The three deconstructed components were precisely nested with other 3D printing parts of other customers in little batches within the build cylinder, for near-100% utilization of space and spreading of initial and space costs.

Material Recommendation: A “PA-GF + PA12” hybrid strategy was recommended, where PA-GF was used in stress-bearing regions and PA12, a 40%-lower-cost material, in non-stress-carrying regions, for performance with reduced material cost.

Process Parameter Optimization: The scanning speed of the laser was increased by 15%, and the heating temperature profile was optimized to minimize the print time from 72 hours to 60 hours, meeting delivery schedules and reducing labor costs on machines.

Cost Results

The total project cost was $52,000, a bit higher than the customer’s budget of $50,000 but about 50% lower than other service vendors. The part printed successfully in the first attempt, and the performance of the printed part completely satisfied testing conditions, enabling the customer to finish the project within schedule.

Inspiration: Choosing an SLS service provider is not only about buying machine time, but also about buying process knowledge and optimization capabilities.JS Precision Manufacturing, with its optimized knowledge, is the number one source for SLS 3D printing for many of its clients.

FAQs

Q1: Does minimum detail affect the SLS 3D printing quotation?

Yes. It is because ultra-high-precision details require laser scanning speeds to be slower in order to achieve a perfect build, increasing labor cost for machines. Furthermore, high precision also places extremely stringent requirements on the powder, which increases the cost of material. Moreover, high-accuracy parts are more difficult to post-process, which will increase post-processing expenses. All these factors are more expensive for 3D printing.

Q2: Why are we charging based on bounding box volume rather than actual volume?

In SLS 3D printing, hollow parts also occupy space in the build cylinder. Billing by actual volume if we do it will result in pieces with smaller actual volume that occupy the same volume being underbilled and pieces occupying greater volume being overbilled, not reflecting on machine resource usage. Charging by bounding box volume is therefore the way the industry works to have fair pricing for online 3D printing services.

Q3: Will my last powder be used to print with the following customer?

JS has a rigorous powder management policy. Your last powder will not be used in printing with the following customer. Each customer order is printed using a dedicated batch of powder. After the print, any remaining recycled powder is stored in a different area and labeled with the order information, and not mixed with other customer powder. We also subject the recycled powder to testing, and only tested powder is used for future orders,protecting your custom 3D printing manufacturing projects.

Q4: What happens if my part does not print? How will it be billed?

If the printing failure is caused by JS equipment failure or incorrect process parameter settings, we will bear all losses and reprint for free.Our system has a robust online monitoring and quality inspection that detects abnormalities and real-time adjustment to minimize the chances of failure. We recommend that you make use of our free design review service prior to ordering to reduce errors caused by problems related to the design.

Summary

The first step to an intelligent purchase is knowing SLS pricing. It must not be a cryptic bill, but a fair deal founded on value provided and science-based estimations. Getting a partner who deeply understands cost and willing to permit optimization results sharing with you matters more than attempting to own the lowest price.

JS can create cost-effective solutions through professional process support and cost optimization.Whether small-batch 3D printing parts sample prototypes or mid-volume custom 3D printing manufacturing, we have transparent pricing and great service so you can be confident to receive good parts at a reasonable price. This is the value of JS’s professional online 3D printing services.

Disclaimer

The content of this website is for reference only. JS services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Nylon Is Just The Beginning: 5 High-Strength 3D Printing Materials Revealed - JUSHENG

Pingback: Can 3D Printing Automotive Parts Replace Traditional Manufacturing Today? - JS Precision