Composite materials are composed of multiple layered materials such as carbon fiber, Kevlar, glass fiber, and resin matrix. They are stacked layer by layer to form a composite material that is as light as a feather but as strong as steel. Processing this material is like using the same surgical knife to perform orthopedic and ophthalmic surgeries.

Traditional tools in cutting not only wear down quickly but also pull fibers and induce delamination, rendering the expensive material useless in a matter of seconds. In opposition to this, composite-specific tools in cutting have to be utilized to provide precise, clean cuts and maximize the material’s performance.

Here we will talk about how difficult it is to machine composite materials and delve deeply into the special cutting tool design to help you resolve actual machining problems. Whether choosing cutting tools or CNC machining, you can find authoritative recommendations here.

Key Answer Summary

| Challenge Dimension | Traditional Tools (e.g., HSS) | Specialized Composite Tools |

| Core Mechanism | Relies on plastic deformation to “tear” materials. | Compression shear: cuts fibers instantly like scissors to minimize tearing force. |

| Tool Material | Ordinary cemented carbide and high-speed steel. | Polycrystalline Diamond / Diamond coating for extreme wear resistance. |

| Geometric Design | General helix angle and small chip flute. | High helix angle/straight edge, large chip flute, and mostly left-hand edge design to prevent delamination. |

| Cutting Result | Burrs, delamination, fiber pull-out, and fast tool wear. | Smooth edges, no delamination, extremely high precision, and long tool service life. |

| Applicable Scenarios | General metal/wood machining. | Specialized for carbon fiber, glass fiber, Kevlar, CFRP/GFRP, etc. |

Why Is It More Difficult For Tooling To Machine Composite Materials? JS Precision Shares Practical Experience

JS Precision has gained vast experience in CNC machining composite materials for more than a decade, having machined more than 5,000 customers across the aerospace, automotive, and medical industries.

We have successfully finished more than 200 composite CNC machining parts jobs, such as high-accuracy carbon fiber reinforced polymer (CFRP) aircraft engine parts and glass fiber reinforced polymer (GFRP) body panels in the automotive industry.For example, for an aerospace customer, we machined 1,000 CFRP drone parts with ±0.02mm machining accuracy and the lifespan of tools in cutting has been extended by 15 times compared to standard tools in cutting.

This article summarizes our experiences on thousands of CNC machining operations. Everything that we have recommended has been field-tested in actual production and could be used safely to fix composite cutting issues. If you need to machine thin-wall composite CNC machining parts or high-strength CFRP parts, our experience is a good fallback.

JS Precision expertise is composite CNC machining. Are you looking for custom CNC machining manufacturing service? Please contact us and we will provide you with full solutions and competitive CNC machining prices.

Why Are Composites “Tool Killers”?

Composite material has always been referred to as “tool killer” primarily due to its four inherent features, which pose phenomenal challenges in CNC machining and tools in cutting.

Anisotropy and Heterogeneity

The composites are not only extremely anisotropic but also extremely heterogeneous, the strength being enormously different in fiber direction. The strength, for example, could be 5-10 times greater in the direction of the fibers compared to the direction perpendicular to the fiber. This causes extremely unstable and extremely fluctuating CNC machining cutting forces with the tool facing various resistances according to cutting direction.

Severe Wear Resistance

The hard glass and carbon fibers of composite materials are far too hard in comparison to common metals like steel and aluminum. During CNC machining, these hard fibers will continue to wear down the blade, causing tools in cutting to quickly passivate. Normal carbide cutting tools used in machining CFRP last only for 10-20 minutes, which is far less than in machining metal CNC products.

Risk of Delamination and Burr

When composite materials are being machined, cutting forces in the upward direction can readily cause layers to separate, or “delamination.” Besides that, cut-through of the fibers on a partial basis can cause burrs. These defects not only physically disfigure CNC machined parts but also weaken structural integrity, making them unacceptable for high-precision applications such as aerospace.

Thermal Management Challenge

Warming up in CNC processing can soften composite materials’ resin and impair material properties. In addition, the softened resin will adhere to cutting tools and form built-up edge, which further impairs cutting quality and facilitates tool wear.

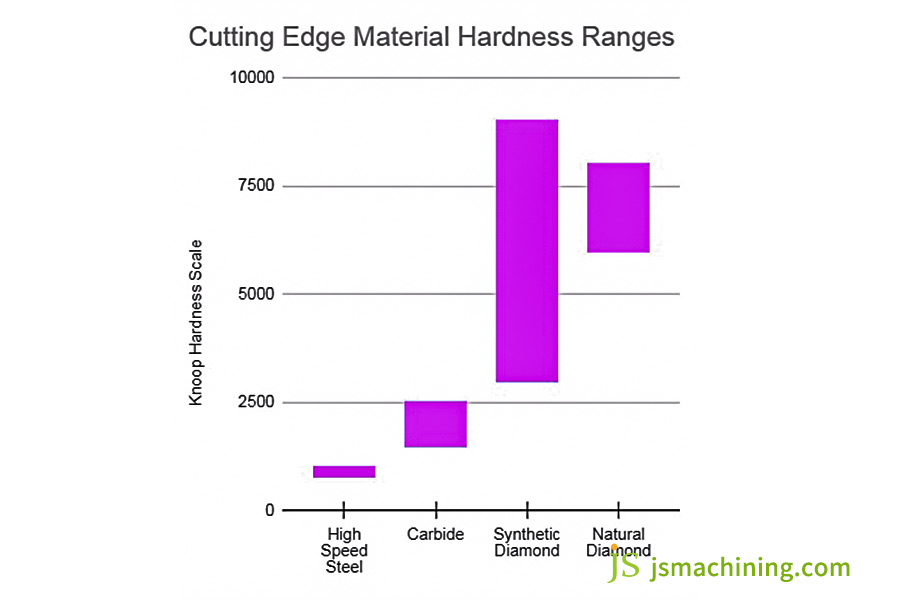

The “Core” Of The Tool: Special Requirements On Material Selection

Accurate selection of a suitable tool material is the guarantee of successful composite cutting. Materials differ widely as regards their hardness, toughness, and cost, and their scope of application also differs.

| Material Type | Hardness Characteristic | Toughness Performance | Applicable Scenarios | Cost Range (USD per tool) |

| Cemented Carbide (Fine Grain) | Relatively high with good abrasion resistance. | Moderate, can resist certain impact. | Medium-batch GFRP processing and rough CFRP processing. | 50-150 |

| Powder Metallurgy HSS | Moderate, easy to grind. | Relatively high with strong impact resistance. | Special-shaped tools in cutting and rough CFRP processing. | 30-80 |

| PCD (Polycrystalline Diamond) | Extremely high with unparalleled wear resistance. | Relatively low, prone to chipping and requires careful use. | Mass production of precision CFRP machining and high-quality CNC machining parts. | 300-800 |

Ultra-High Hardness is the Foundation

Ultra-high hardness is the cornerstone for cutting tool composites. Since wear resistance of composite fibers is excellent, the cutting tool must possess adequate hardness to withstand wear. The mainstream is carbide, and finer-grain or ultrafine-grain is superior since it is more wear-resistant compared to usual carbide.

Toughness Balance

In pursuit of hardness, cutting tools also need to possess some degree of toughness to resist impact and chipping. Powder metallurgy high-speed steel is still used in some rough machining or specially shaped cutting tools. Its high toughness can prevent tool damage when machining uneven composite surfaces.

Peak Performance: Polycrystalline Diamond (PCD)

Polycrystalline diamond (PCD) is the peak performance of composite cutting tools. Why is it called the “king”?

- PCD is unparalleled in terms of hardness and wear resistance—a single PCD cutting tool can machine thousands of CFRP CNC machining parts, while dozens of parts can be machined by conventional carbide tools.

- In terms of cost, although PCD cutting tools are 5-10 times more expensive than carbide tools, they also last 20-50 times longer and thus incur a lower cost per CNC machining part.

JS Precision offers composite material cutting tools in various materials. If you need custom CNC machining manufacturing, we can recommend the most cost-effective cutting tool alternative based on your need and provide definitive CNC machining price.

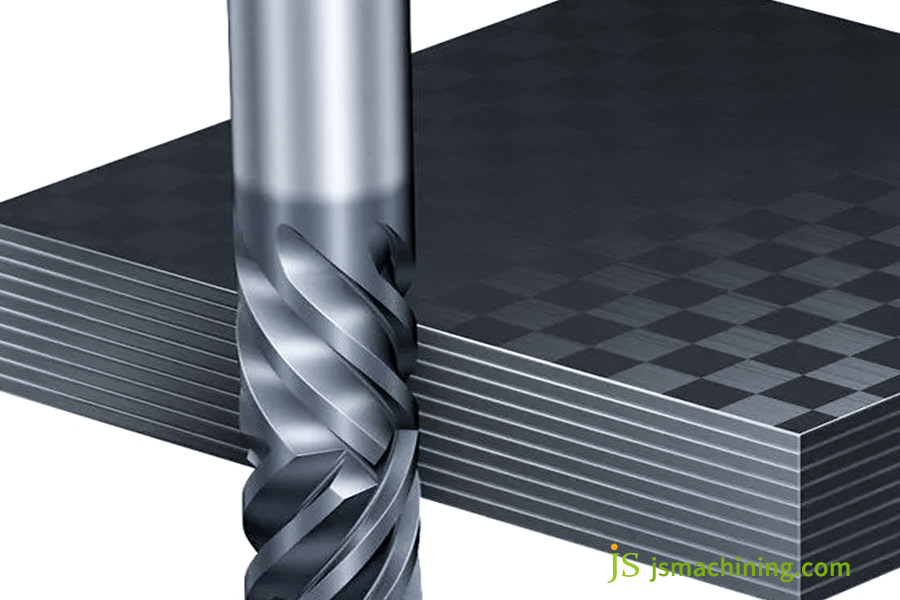

Cutting Edge Geometry: Special Design Of Cutting Tools

Geometric design of tools in cutting directly affects cutting forces, chip removal, and surface quality of CNC machining parts. When machining composite materials, all the geometry details of cutting tools must be optimized.

Cutting Edge Design

Cutting-edge design is critical in composite material cutting. A positive rake angle that is sharp reduces cutting forces and encourages a clean cut, and a reinforced cutting edge (micro-T-edge) discourages chipping. This combination can achieve complete fiber cutting while protecting the tools in cutting itself from damage.

Helix Angle and Tooth Profile

- Inclined helix angle (>40°) or straight edge (0°): Both of these designs reduce axial cutting forces and delamination is successfully avoided. High helix angle tools are suitable for contouring, while straight edge tools are more suitable for grooving.

- Right-handed (down-cut) or left-handed (up-cut) edges: Up-cutting tools move chips upward, enhancing chip evacuation but possibly raising the danger of delamination,down-cutting tools push the material downward, lessening delamination but enhancing chip evacuation.

Chip Flute Design

Chip flutes must provide enough chip space. As the composite chips are brittle and curled, wide flutes will ensure rapid chip removal, preventing blockage and secondary cutting. Not only does secondary cutting enhance tool wear, but it also causes secondary damage to the surface of CNC machining parts.

Decisive “Coating”: The Crushing Benefits Of Diamond Coatings

Coatings on cutting tools serve the fundamental purpose of increasing wear resistance and reducing heat generation. For composite materials, ordinary coatings are almost ineffective, and diamond coatings have become the preferred choice.

| Coating Type | Coefficient of Friction | Hardness | Reactivity with Composites | Applicable Scenarios | Service Life Improvement Multiple |

| TiAlN (Ordinary) | 0.4-0.6 | HV2800-3200 | Easy to react. | Metal machining and a small amount of rough GFRP processing. | 1-2 times |

| CVD Diamond | 0.05-0.1 | HV9000-10000 | Chemically inert. | Medium-batch CFRP and GFRP machining for CNC machining parts. | 8-15 times |

| AMCD Diamond | 0.03-0.08 | HV9500-10500 | Chemically inert. | Mass production and high-precision CFRP machining for CNC machining parts. | 15-25 times |

Limitations of Conventional Coatings

Conventional coatings such as TiAlN are less effective for abrasive wear of composite materials. During CFRP cutting, TiAlN-coated tools lose their coating within 10 minutes and the cutter body subsequently wears rapidly.

Why is diamond coating a perfect match?

- Its extremely low coefficient of friction reduces cutting heat and resin softening to a minimum.

- Its extremely high hardness provides it with excellent resistance to carbon fiber and glass fiber abrasion.

- Its chemical inertness prevents it from reacting with composite materials and contaminating CNC machining parts.

CVD Diamond Coating vs. AMCD Diamond Coating

- CVD diamond coatings are formed by depositing diamond particles on the surface of the cutting tool. They have better wear resistance with a comparatively rough surface.

- AMCD coatings have smaller grains, resulting in a smoother surface, improved adhesion, and better performance.AMCD-coated cutting tools are more suitable for high-precision machining of composites, e.g., aerospace CNC machining parts.

JS Precision supplies composite cutting tools with AMCD and CVD diamond coatings. Our online CNC machining services meet high-precision requirements and offer cost-effective CNC machining price based on project requirements.

Composite Machining Challenges: Typical Defects And Solutions

In spite of applying the right cutting tools, composite machining is still susceptible to defects. Understanding the causes of these defects and adopting certain measures are the keys to improving the quality of CNC machining parts.

Defect 1: Delamination/Burr

Problem Analysis: Tools in cutting passivation will increase cutting force and cause delamination.Low feed rates cause tools to dwell on the surface of the material for a long period of time, resulting in burrs.Improper clamping causes CNC machining parts to vibrate, resulting in uneven cutting.Wrong cutting edge type causes inability to cut fibers completely.

Solution: Replace with new, sharp tools or diamond cutting tools,increase the feed rate to 1500-2500 mm/min depending on the material,enhance the clamping method, such as vacuum fixture, and choose compression spiral or straight edge end mills.

Defect 2: Premature Tool Wear

Problem Analysis: Wrong material choice (other than diamond) is not able to resist fiber wear,too low spindle speed increases the contact time between the cutting tool and the material, while too high spindle speed causes overheating,lack of cooling favors coating wear.

Solution: Application of diamond-coated or PCD tools for cutting operation is mandatory, follow recommended cutting parameters (e.g., 15,000-20,000 rpm during machining CFRP), employ air cooling (air blowing) or minimum lubrication.

Defect 3: Burning/Melting of Resin

Problem Analysis: Excessive heat in the cutting area leads to resin melting and burning,poor chip removal leads to chip accumulation and heat build-up.

Solution: Employ higher cutting speed to reduce the tool-in-cutting contact time with the material,ensure chip flutes for free chip removal,use compressed air cooling to remove the heat right away.

Practical Guide: How To Select The Most Appropriate Tool Type?

The right selection of cutting tools based on the machining process and material type can enhance machining efficiency and reduce cost.

Choose by Process

| Machining Process | Recommended Tools in Cutting Type | Applicable Materials | Advantages |

| Milling (Contour, Slotting) | Diamond-coated cemented carbide end mills (solid/brazed edge). | CFRP, GFRP | High precision and low wear. |

| Drilling | Custom composite drills (special apex angle), PCD drills. | CFRP, Kevlar | No burrs and high hole position precision. |

| Cutting/Trimming | Diamond-coated small-diameter end mills, diamond grinding wheels. | GFRP, Kevlar | Neat edges and high efficiency. |

Choose by Material Type

| Material Type | Preferred Recommended Tools in Cutting | Alternative Tools in Cutting |

| CFRP | PCD tools in cutting, AMCD diamond-coated tools in cutting. | Ultra-fine grain cemented carbide tools in cutting. |

| GFRP | High-quality diamond-coated cemented carbide tools in cutting. | Fine-grain cemented carbide tools in cutting. |

| Kevlar | Diamond-coated tools in cutting with extremely sharp cutting edges. | Ultrasonic cutting tools. |

JS Precision can recommend the most suitable cutting tools based on your machining process and material. Our custom CNC machining manufacturing services cover a wide range of composite CNC machining parts and provide clear CNC machining price.

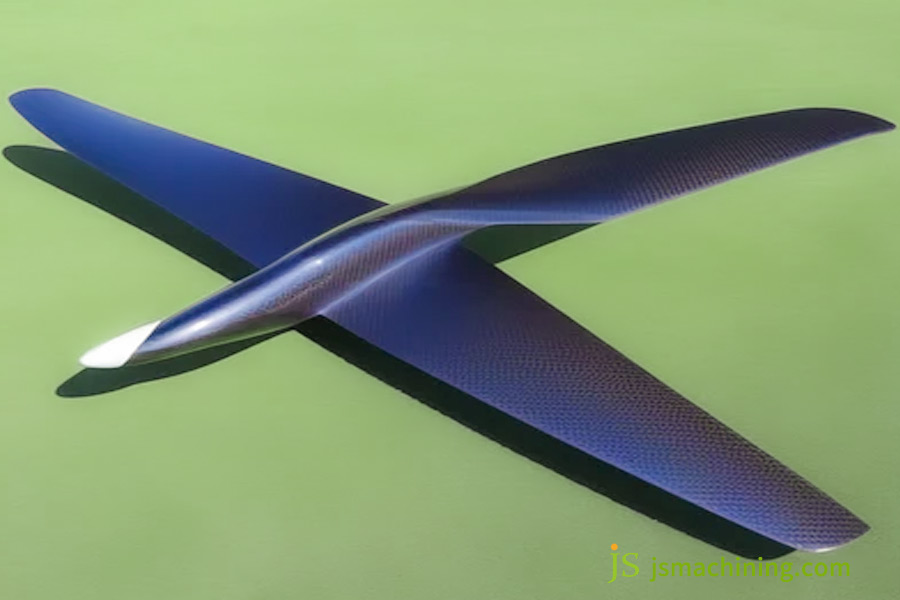

Practical Case: High-Speed Precision Milling of Aviation-Grade Carbon Fiber Composite Components

Case Background

An aerospace company needed to machine the edge of the carbon fiber composite skin of a specific drone wing. These CNC-machined parts, essential parts of drones, must have absolutely no delamination or burrs, and extremely high surface quality (surface roughness Ra < 0.8μm).

The firm had previously attempted to use regular carbide cutting tools, but the CNC machining parts had such severe delamination,requiring replacement of tools in cutting every 5 pieces, far below production requirements.

Machining Challenges

The workpiece was a thin-walled structure with only 1.2mm thickness, with poor rigidity and easily vibrated during CNC machining. The quality requirement was high, and visible defects such as delamination, burrs, and scratches caused CNC-machined parts to be scrapped. The 99.9% pass rate was required.

JS Precision Solution

Tool Selection: A two-flute end mill with ultra-fine-grain carbide substrate and AMCD diamond coating was selected, which features a high 15° rake angle and a wavy edge special design. The high rake angle reduces cutting forces, and the wavy edge allows even cutting of fibers and prevents burrs.

CNC machining parameters: Spindle speed 18,000 rpm, feed rate 2,000 mm/min, radial cutting depth 0.5 mm, single axial cutting (minimizing the risk of delamination by not cutting repeatedly).

Cooling method: The entire process is cooled with 0.6MPa high-pressure compressed air to promptly remove cutting heat and prevent resin softening.

Fixture and programming: The deformation and stability of CNC machining parts are ensured by a special vacuum fixture. Adopting the forward milling method, the path is optimized as a circular arc advancing and retreating knife to minimize the effect of the tool in cutting on the edges of the CNC machining parts during cutting.

Results

The machined parts are smooth on edges, delamination free as inspected by endoscope industrial and ultrasonic test. Surface roughness is up to Ra 0.5 μm, exceeding customer requirements.

The life of a single tool in cutting is over 20 times that of the regular carbide tools-in-cutting (can produce 100 CNC machined parts). Overall machining cost is 35% lower than the customer’s original solution. This project has earned JS high recognition from the aerospace company and made it a long-term partner.

The example shows JS Precision’s ability for CNC machining of composite materials. Here, if you require high-precision CNC machining parts, our online CNC machining services offer high-efficiency, high-quality outcomes at low CNC machining prices.

FAQs

Q1: How to prevent cracking in extremely thin carbon fiber sheets (<1mm)?

In addition to using a compressed spiral-edge end mill, having a good quality bottom pad (e.g., 5mm thick PVC or high-density wood) to provide even support—thin sheets easily deform without support—is essential. Furthermore, minimizing cutting forces by using higher spindle speeds (20,000-25,000 rpm) and smaller radial depths of cut (0.2-0.3mm per cut) can readily prevent cracking from high forces.

Q2: Is it necessary to use cutting fluids when machining composite materials?

It is not generally recommended to use conventional cutting fluids. The resin of composite materials tends to absorb cutting fluid easily, which influences the mechanical properties of the material. Recommended is a dry machining method with effective air cooling (air blowing). Not only does this remove the heat generated during cutting without any damage to the material, but it also prevents chip clogging due to cutting fluid and chip mixing.

Q3: Discuss why most composite milling cutters are two-fluted.

There are two reasons for this: First, two-flute end mills have larger chip flutes than three- or four-flute end mills, allowing for faster removal of brittle and curly composite chips, preventing accumulation and secondary cutting. Second, at a fixed spindle speed, two-flute end mills allow for a higher feed rate per tooth, which improves machining efficiency and reduces the end mill’s dwell time on the material surface.

Q4: Why is there a harsh squealing sound when machining composite materials?

This is usually a sign of vibration or resonance. Vibration causes uneven contact between the end mill and the material, resulting in irregular cutting and a harsh sound. This can be caused by improper clamping (such as a loose fixture), inappropriate cutting parameters (excessive feed or low spindle speed), or insufficient rigidity of the end mill. Solution: Tighten and inspect the fixture, adjust parameters to be within the recommended range, and change the cutting tools to larger diameters to increase rigidity.

Summary

Composite materials are challenging to cut, but with the right cutting tools and some sophisticated CNC machining capability, the challenges can be overcome. From diamond’s unparalleled hardness to the sophisticated geometry of the compressed spiral edge, every design feature is meant to transform machining challenges into a competitive advantage for your product. Don’t let unsuitable cutting tools become a stumbling block on your innovation journey anymore.

Whether you’re machining CFRP for aerospace or GFRP for automotive, the right cutting tools and partners are the secret to success. JS Precision offers quality cutting tools, reliable online CNC machining services, and fair and affordable CNC machining prices.Contact us to start a project and we’ll ensure that your CNC-machined parts meet the highest quality standards.

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com