The engine’s precision oil sump of automobiles, the high-duty hinges of computers, and even dental implant abutments – all these seemingly unrelated products are created by the same robust manufacturing process: die casting. Most people are still unaware of its definite uses and how to use it in order to facilitate productive output.

This guidebook will start from the JS company’s practical experience, guide you through exploring the magical world of die casting technology, help you provide complete answers to the fundamental question of ‘where is die casting used’, and provide clear references for your production tasks.

Summary Of Core Answers

| Key Aspect | Critical Info | Typical Applications | JS Advantages |

| Die Casting Processes | Hot chamber, Vertical/Horizontal cold chamber. | Toys, Auto engine blocks. | Professional process selection support. |

| Materials | Al/Zn/Mg alloys (2.5-5.5 USD/kg). | Auto chassis, Electronics enclosures. | Cost-efficient material recommendations. |

| Tolerances | ±0.1-±0.3mm (high precision). | Medical tools, Auto parts. | ISO-certified high-precision casting. |

| Industry Uses | Auto, Electronics, Home Appliances. | Battery housings, Motor end caps. | Industry-tailored fast delivery. |

Why Trust This Guide? Practical Experience Of JS Die Casting

Prior to studying the true application of decompression casting, you may wonder if information presented in this guide is trustworthy. In fact, the credibility of this guide relies merely on JS’s over 15 years of practical experience in the custom metal casting manufacturing field.

JS has provided customized chassis aluminum alloy die casting parts to leading new energy vehicle makers in the automotive industry, eradicating the problem of heavy traditional stamped parts. JS also provides online metal casting services and has shipped small batch sample within 72 hours for a medical equipment company to meet customers’ emergency test needs.

This book is a distillation of the JS team’s experience from thousands of real die casting jobs. Everything we recommend in process selection through cost control has been validated by actual production, so you can have complete confidence in this book.

Choose custom metal casting manufacturing service, JS Precision Manufacturing is your best friend! Our experience in the field has been transformed into a mature service system, providing professional support for small-scale sample requirements and mass production plans.

More Than One Approach: Exploring The Development And Expansion Of Die Casting Technology

With the diversification of manufacturing needs, die casting has evolved into various branches with individual emphasis on usable material, production efficiency, and product form. Knowledge of the various branches will allow you to choose an effective process.

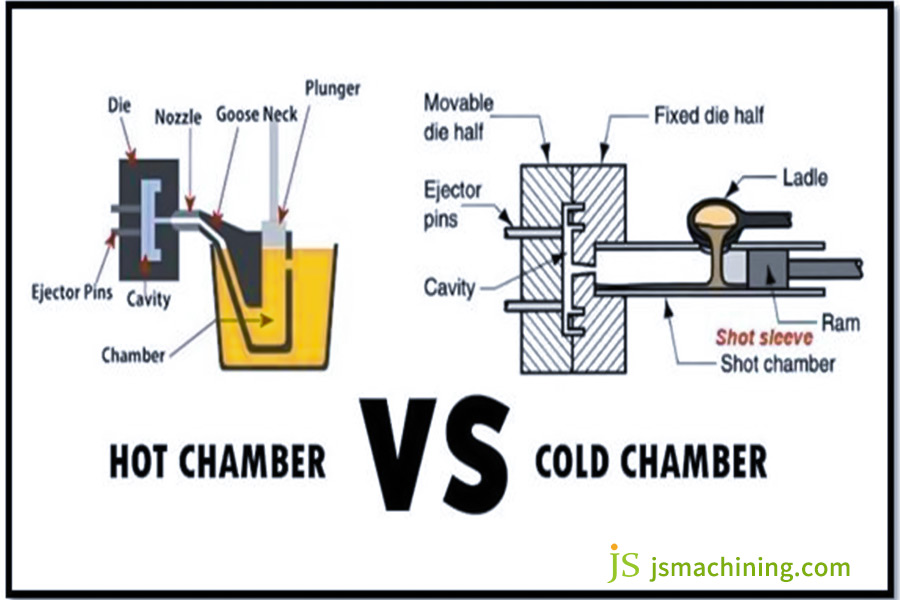

Comparison of Main Branches of Die Casting Process:

| Die Casting Process Type | Suitable Alloys | Production Speed (pcs/h) | Typical Products | Advantages | Disadvantages |

| Hot Chamber Die Casting | Zinc Alloy, Lead Alloy | 30-90 | Toy Car Bodies, Connector Housings | High efficiency, low metal loss | Cannot process high-melting-point alloys |

| Vertical Cold Chamber Die Casting | Aluminum Alloy, Magnesium Alloy | 20-60 | Small Motor End Caps, Sensor Housings | Small footprint, low investment | Poor metal filling stability |

| Horizontal Cold Chamber Die Casting | Aluminum Alloy, Magnesium Alloy | 25-70 | Auto Engine Blocks, Chassis Parts | Uniform filling, high part quality | Large equipment size, high workshop space demand |

Doubtful of which die casting process to employ? JS’s online metal casting services can help you break it down! We provide process simulation testing to allow you to know the impact on production first and go ahead confidently with the project.

Designed for Die Casting: Unleashing the Full Potential of Mass Production

Once having selected the die casting process, the reasonableness of part design will directly influence whether or not manufacturing is able to proceed. The following five design points should be treated, which also are basic principles verified by practice projects in the die casting industry:

Draft Angles

When cooled, the metal liquid will contract and stick tight to the mold, and the absence of draft angles is sure to lead to deformation of the parts at will. Suggest a slope of 0.5° -3° for aluminum alloy parts and 0.25° -1° for zinc alloy parts.

Equal Wall Thickness

Unequal wall thickness could create non-uniform cooling, thick one suffering shrinkage and thin one suffering under-filling. Die casting part thickness is generally 1.5mm-6mm, and this must be varied according to size and alloy.

Fillets and Radii

The right angle of the component is prone to stress concentration that results in cooling cracks and also hinders the flow of molten metal. The fillet radius should not be smaller than 0.5mm in normal cases, and the load-carrying features (e.g., car suspension brackets) should be R3mm or bigger.

Reinforcing Ribs and Bosses Columns

Ribs are strengthened to offer increased part stiffness without any increase in wall thickness, and boss columns are used for screw installation.

Design guidelines: The reinforcing rib must be less than 70% of the main wall thickness and no more than 5 times the thickness in height. The boss column must have a diameter of 1.5-2 times that of the screw and not more than ≤ 3 times the diameter in height.

DFM (Design for Manufacturing)

DFM stands for the application of die casting requirements to pre-design. It can reduce mold costs while improving production efficiency and avoiding risks during the design phase.

Do you need top-notch metal casting parts? JS provides DFM design optimization services to help you make changes and ensure parts meet performance standards and mass production specifications. You’re welcome to consult and work together.

Material Science: Choosing The Most Suitable Metal Alloy

A well-designed die casting must be accompanied by the right metal alloys so that the parts meet the use criteria along with cost control. The strength, corrosion resistance, density, and cost of different alloys are all very different, and a wrong choice will render the parts unusable or extremely costly.

The following is a presentation of the specific requirements in the table below, and you can choose suitable metal casting parts materials from there.

Typical Metal Alloys Used for Die Casting Comparison:

| Alloy Type | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Cost (USD/kg) | Typical Applications |

| Aluminum Alloy | 2.7 | 200-350 | Good (needs surface treatment) | 2.5-3.5 | Auto Chassis, Laptop Casings, AC Compressor Housings |

| Zinc Alloy | 6.5 | 180-300 | Average (easy to oxidize) | 1.8-2.2 | Toy Parts, Door Lock Fittings, Phone Charging Bases |

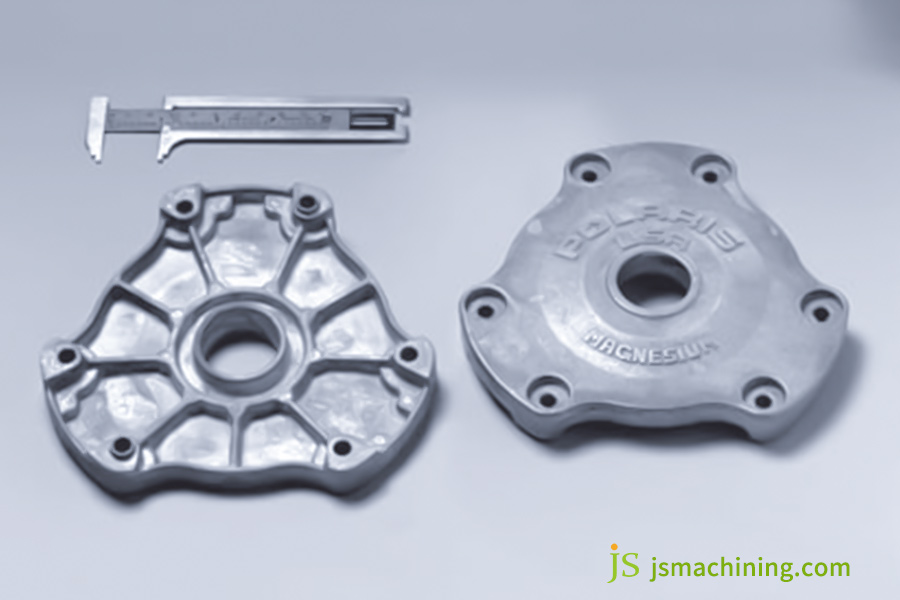

| Magnesium Alloy | 1.8 | 220-320 | Poor (needs anti-corrosion treatment) | 4.0-5.5 | Aerospace Seat Frames, Drone Bodies |

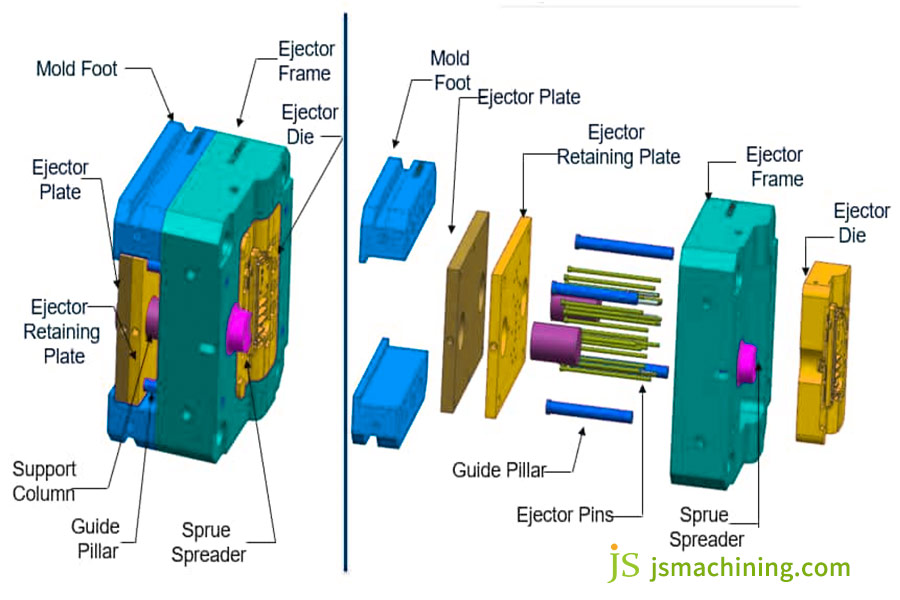

Mold: The Central Part Of Die-Casting Technology

Die casting mold is the core production plant of die casting, not only a tool but also a precision value asset with hundreds of thousands to million of times. It controls the part’s precision, surface, and production efficiency directly and further affects the metal casting price.

The precision of the die casting mold is extremely critical, like consumer electronics connector housing molds, the precision is up to ± 0.03mm, and assembling parts can be directly done without reprocessing.

The molds’ cost is the main starting cost: small zinc alloy parts molds costs around 5,000-15,000 US dollars, middle aluminum alloy parts molds costs around 20,000-80,000 US dollars, and large automobile parts molds costs around 100,000-500,000 US dollars. The cost will be shared for the parts, and with the larger the batch of producing, the lower the cost sharing per unit.

Everywhere Applications: Which Industries Rely On Die Casting?

Die casting, with its accuracy, efficiency, and mass production, has taken over different industries and become a significant process in the manufacturing of many products.

The industry emphasizes and JS services based solely on die casting are as follows:

Automotive Industry

Die casting’s largest application field is in the automotive sector with requirements for an enormous number of light and high-strength metal parts (e.g., engine cylinder blocks and gear housings). JS provides online metal casting services to new energy car makers, producing battery boxes, and dispatching emergency orders within at least 5 working days.

Electronic Industry

The electronics market has high requirements for precision and miniaturization of parts, which can be achieved by die casting (such as charging base shells and shaft brackets). JS previously performed customized connector housing in the consumer electronics business and, through optimization of the process, brought down the fault rate in parts from 5% to below 1%.

Home appliance industry

Home appliance industry has a great demand for components and high die casting efficiency is perfectly suitable (e.g., washing machine motor end caps, air condition compressor housings). JS provides home appliance customers with tailored die casting solutions, developing processes for minimum costs to reduce part prices by as much as 15% on average.

Industrial equipment industry

Industrial machinery requires good wear resistance and strength of components, and hydraulic valve blocks, pump housings, etc., can be manufactured by die casting. JS provides DFM analysis, mold manufacturing, and die casting production as one-stop solutions to industrial machinery customers from design to mass production, so it is convenient for customers to reduce the project cycle.

Die Casting vs. Other Processes: How To Make Informed Decisions?

While die casting is advantageous, when used in actual production, it should be compared to other methods. The wrong selection is easily able to produce greater expense or low quality.

Comparison between Die Casting and Other Manufacturing Processes:

| Feature | Die Casting | Plastic Injection | Sand Casting | Investment Casting | CNC Machining |

| Material | Non-ferrous metals (Zn, Al, Mg) | Plastics (PP, ABS, PC) | Ferrous/non-ferrous metals | Ferrous/non-ferrous metals | Almost all materials |

| Tolerance | ⭐⭐⭐⭐ (High) | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐ (Low) | ⭐⭐⭐⭐ (High) | ⭐⭐⭐⭐⭐ (Highest) |

| Surface Quality | ⭐⭐⭐⭐ (Good) | ⭐⭐⭐⭐⭐ (Excellent) | ⭐ (Rough) | ⭐⭐⭐⭐ (Good) | ⭐⭐⭐⭐⭐ (Excellent) |

| Cost Driver | High mold cost, very low unit cost | High mold cost, low unit cost | Low mold cost, medium unit cost | Medium mold cost, high unit cost | No mold, very high unit cost |

| Optimal Applications | High-volume complex metal parts | High-volume complex plastic parts | Low-volume large metal parts | Medium-volume high-precision complex metal parts | Prototypes/low-volume high-precision parts |

Have no idea which manufacturing process to choose? JS Precision Manufacturing‘s custom metal casting production service includes process comparison analysis! We will recommend the best option for you to balance cost and efficiency in production.

Integrated Die Casting: How Tesla Reshaps Automotive Manufacturing? Real Case Studies From JS

Challenge

- Long manufacturing cycle: One rear bottom plate takes 1-2 hours, which is difficult to meet Tesla’s requirement for mass production.

- Costly: over 70 sets of molds (over 2 million US dollars)+over 30 welding robots (approximately 5 million US dollars).

- Heavy weight: The heavy weight of the conventional steel rear floor is approximately 50kg, which is not conducive to lightweighting and durability.

- Large footprint: The production line takes up a 2000 square meter factory building, so the site cost is higher.

JS Solution

- Adding a 6000 ton ultra large die casting machine (Giga Press) for single-shot die casting of aluminum alloy parts for the bottom plate.

- Develop the aluminum alloy formula to the best level and employ high-strength alloys with a tensile strength of 320MPa to meet safety standards.

- Implementation of DFM optimization design: Replace the welded joint with an integral structure, achieve a 1.5 ° draft angle and R3mm fillet, and shorten the cooling time from 20 minutes to 5 minutes.

- Installed with automatic production lines, such as automatic feeding, die casting, testing, and handling equipment, to accomplish complete process automation.

Results

- Weight loss and performance: Aluminum alloy rear bottom plate is reduced by 35kg (30% less), Model Y’s driving distance is increased by 7.5 kilometers, and torsional stiffness is enhanced by 20%.

- Cost savings: More than 70 parts reduced to 1, eliminating more than 70 sets of molds (1.8 million)+30 robots (4.5 million), saving 60% of labor costs, and unit prices from 200 to 80 US dollars.

- Efficiency Revolution: Production time reduced from 1-2 hours to 3-5 minutes, efficiency improved 24 times, daily output of 96-160 units.

- Space saving: The manufacturing process only occupies 500 square meters, 75% less space compared to traditional methods.

Inspiration

This is the successful application of die casting, which turns traditional manufacturing upside down. It is proof that die casting can produce enormous structural components, with structural innovation, efficiency, and cost advantages.

Want to manufacture efficiently like Tesla? JS’s die casting business can provide you with an integrated solution! We all help you streamline processes, reduce metal casting price, and make product manufacturing competitive.

Starting Your Die Casting Project: The Road To Success From Concept Through Mass Production

After familiarizing yourself with the value and uses of die casting, if you are ready to start a project, you can proceed through the following three basic stages to successfully achieve the implementation from concept through mass production:

Initial planning and design optimization

Specify the basic requirements of the parts, design and optimize the draft angle, wall thickness, etc. according to the requirements, and select proper alloys and surface treatment.Implementing DFM analysis to minimize risk and reduce subsequent change cost.

Prototype Verification and Mold Development

After finalizing the design, the prototype (die casting 10-50 pieces or CNC maching 1-10 pieces) will be created. After testing successfully, the production of the mold will commence (from H13/S136 steel). After fine-tuning the trial mold, the cycle will be 4-16 weeks, ready to set the stage for mass production.

Debugging of trial production and delivery of mass production

Trial production of 100-500 units after mold completion, quality and parameter (pressure, temperature) control, process adjustment to correct faults such as porosity.Mass production will be executed after the success of trial production, planning and standards will be established, and molds will be maintained in order.

JS is able to provide automation line support to meet the need of 100,000 pieces per month and also make timely delivery.

FAQs

Q1: What is the minimum hole and wall thickness that can be achieved in die casting?

Zinc alloy die casting, with high-precision machinery and high-quality dies, is capable of accurately controlling the minimum wall thickness to 0.4mm and the minimum aperture to about 0.8mm. Aluminum alloy, due to its relatively lower material flowability, typically needs a minimum wall thickness of 0.8-1.0mm and slightly bigger minimum aperture, which has to be set in consideration of the product structure and die-casting process.

Q2: What are ‘slow injection’ and ‘fast injection’?

The two are two significant continuous processes in high-pressure die casting:

- Slow injection is correct speed control to gently propel the molten metal to the gate without causing bubbles through the fast movement of liquid and air trapping.

- Rapid injection injects and fills the entire mold cavity with molten metal at fast speed, ensuring that the casting is finished and the measurement is accurate.

Q3: What are the surface treatments that can be done on die casting parts?

- Spraying and powder coating can be used to improve appearance and weather resistance.

- Zinc alloy is suitable for electroplating to impart decorative properties, and aluminum alloy is suitable for anodizing to improve hardness and corrosion resistance.

- In addition to this, there are electrophoresis, wire drawing, sandblasting, etc.

Q4:Why should we emphasize the uniformity of wall thickness in die-casting component design?

Uniform wall thickness is the most important aspect of ensuring die casting component quality: non-uniform wall thickness will produce unevenness in solidification speed of molten metal, and thick wall is prone to loosen and shrink, it may also cause surface indentation, cracking, and other defects, and speed up local mold wear, decrease mold life, and affect stable production.

Summary

Die casting is right in our own backyard. It is not a distant factory term, but a ‘manufacturing cornerstone’ that keeps together production of many industries such as automobiles, electronics, household appliances, and machinery. If you want metal parts to be made in-house, you may want to try to understand die casting,it may be your best choice to break through production bottlenecks and enhance the competitiveness of products.

JS Precision Machining, as a professional custom metal casting manufacturing enterprise with rich experience and professional online metal casting services. From process planning, design optimization to mass production delivery, our expert team will accompany you step by step to help you make your product manufacturing target come true. We’re glad to cooperate with you for a win-win scenario!

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: What Casting Method Should Be Chosen For Precision Castings? - JUSHENG

Pingback: The Composition Of Brass Material:Why It's Not 100% Copper - JUSHENG