From deep space probes to surgical robots, the core of such sophisticated devices can potentially be the seemingly unobtrusive gear. However, the reality is that standard-gears are generally found to be inadequate when they meet with extraordinary performance, demanding space or specific material specifications. It is because of this reason that prominent industries such as the medical, aerospace, and industrial automation rely heavily on custom gear manufacturing.

At JS, we help customers overcome such problems every day. Whether it’s perfecting existing designs or designing new solutions from scratch. Our goal is simple: harness experience and advanced tools to make the gears you get not only precisely meet the application requirements, but also improve overall performance and eliminate the dangers of misaligned custom gears. Don’t settle for “almost” standard parts, let’s talk about your unique needs.

Core answer summary:

| Industry field | Why do we need customized gears | Common custom gear types |

| Aerospace and defense | Extreme environment, ultimate lightweight, absolute reliability, non-standard materials. | Planetary gears, harmonic gears (components), high-precision small module gears, titanium alloy/PEEK gears. |

| Robots and automation | Zero backlash, low noise, compact integration, high transmission ratio. | Custom worm gears, custom plastic gears, and micro gearboxes. |

| Medical equipment | Miniaturization, biocompatibility, quiet operation, and high precision. | Stainless steel micro gears, PEEK gears, customized gear systems for surgical tools. |

| Automobile and racing sports | Capable of withstanding maximum torque and speed, customized transmission ratio, and rapid prototyping. | Helical gears of high strength, custom level gears, and custom transmission gears. |

| Energy industry (wind energy/oil) | Heavy-duty type, large type, heavy-duty type, and long-term reliability. | Large planetary gears, herringbone gears, and corrosion-resistant alloy gears. |

| Industrial and Special Machinery | Unique mechanical functions, integration with existing equipment, specific load cycles. | Various non-standard gears, sprockets, and custom brass gears. |

Why Do Special Equipment Have To Customize Gears? A Practical Review From JS

In the fields served by JS, industries such as new energy vehicles, robots, and special equipment have particularly high requirements for customized gears. Our team has a deep accumulation in mechanical design and materials, and can help you optimize the tooth shape to the extreme, accurately calculate the gear force under complex working conditions, and strictly control the most advanced process of manufacture.

All this is to ensure that each customized solution is at the forefront of technology. We have passed strict certifications such as ISO 9001 and IATF 16949, our research results have also been published in top industry journals, and we have been cooperating with top research institutions.

“As engineer Henry Royce often said: Small things make perfection.”

That’s what we do: we meticulously implement international standards such as AGMA, ISO, and DIN, and establish a full-process quality tracking system from design to production. Before each set of gears is delivered, we will provide detailed life test, noise analysis, and precision inspection reports. Ultimately, we do all this to provide you with the most solid, reliable, and precision core components in your transmission system.

Aerospace And Defense: Failure Is Not An Option

In the aerospace and defense industry, equipment often operates at tens of thousands of meters in the air or even in space. You and I know that in such extreme environments, there are drastic temperature changes, strong vibrations, and a near-vacuum state. A problem with a gear is not just a matter of stopping for maintenance, the consequences can be catastrophic. Standard gears can hardly withstand these harsh conditions.

That’s why the gears here are almost all “tailor-made”. To be absolutely reliable, we have to use special materials of aviation grade, such as ultra-light but ultra-strong titanium alloys, special aluminum alloys, or high-performance engineering plastics like PEEK. Moreover, the space inside the equipment is extremely precious, and the shape and size of the gears must be stuffed into the specified position exactly, with no extra space.

At JS, we deeply understand this “zero failure” requirement. The custom gears we design and manufacture are “customized” processed bit by bit according to specific mission requirements, and absolutely no carelessness is allowed, because human lives are at stake.

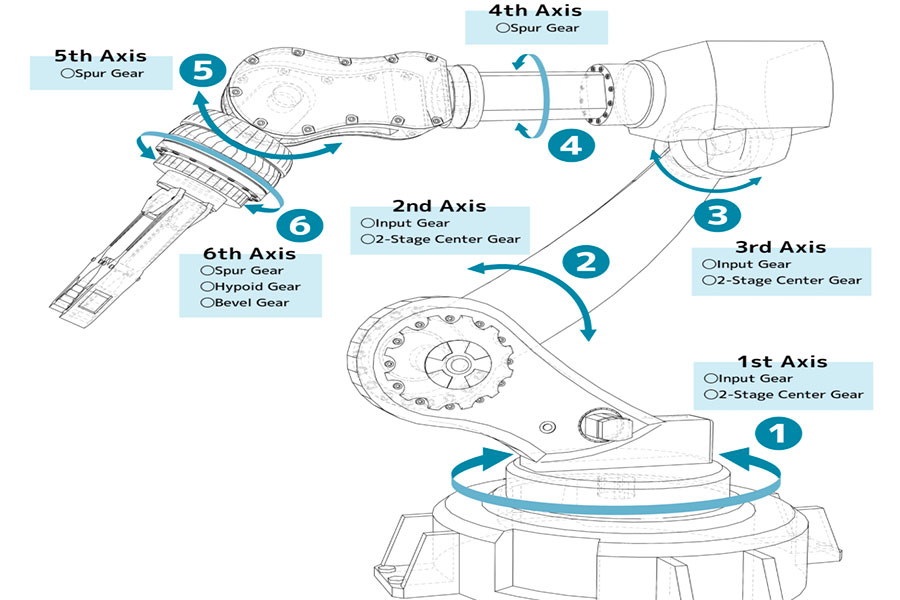

Robotics And Automation: The Art Of Motion Precision

Let me talk about the requirements for gears in the field of robotic automation, especially those gear machining parts that require us to carve them meticulously:

(1) Core demand: Precision is the lifeline!

You see the silky movements of the collaborative robot arm, or the robot on the production line can accurately grab the parts and put them in place every time. The most critical thing behind this is the matching accuracy of the gears. What is most important to us is the “backlash” control, which is the small gap when the gears are meshed. In this industry, we often pursue “zero backlash” because even a little looseness will accumulate and make the robot unable to stop in the correct position, and the entire automation process will be messed up.

(2) Quiet operation is important:

In the factory workshop, no one likes to listen to the squeaking of the machine all day long. Therefore, many robots, especially collaborative robots that need to work close to people, have high requirements for gear noise. This often uses our customized engineering plastic gears, which are inherently much quieter than metal gears and have less friction noise.

(3) Strong power and space saving:

The space in the robot joint is very tight, but it needs to output a lot of power (high torque) or achieve fine motion control (high transmission ratio). At this time, our specially customized worm gear combination comes in handy. This structure can achieve a large reduction ratio in a small space, turning the small power of the motor into a large force of the joint. Of course, this high-precision worm gear itself is a very technical gear machining parts.

Collaborative robot gear: choose standard parts or JS customization?

| Key items | Common problems with general/standard gears | JS customized gear core advantages |

| Accuracy | The back clearance is too large (≥ 3 arc min) → inaccurate positioning. | Near zero backlash (≤ 1 arc min) → precise movement. |

| Noise | Noise Metal gears are noisy (≥ 65 dB), whereas plastic gears are prone to damage. | Ultra quiet (<55 dB) and durable → safer human-machine collaboration. |

| Space & Power | Standard parts take up space → limit joint design. |

Small volume, high torque → unleashing joint potential.

|

| Long term stability | Fast wear and tear → requires frequent calibration/replacement → high cost. |

Wear resistant upgrade → less maintenance, low total cost.

|

Data source: IFR – Cobot Task Force 2024

“The high performance of collaborative robots is hidden in every gear machining part. General solutions often have compromises, JS customization allows you to choose without making any trade-offs. Contact us now and let your robot win at the starting point!”

Medical Equipment: The Miracle Of Life Between Millimeters

In the field of medical equipment, gears are not just mechanical, they often affect the rhythm of life. The gears inside are challenging the limits of “miniaturization” and “absolute reliability”.

(1) Size is life, precision is the bottom line:

Medical equipment space is extremely precious, and gears often have to be very small, but no matter how small, the size must be accurate. Think about the precise movements of surgical robots, or the tiny drug delivery mechanism in insulin pumps, which rely on the ultra-high precision manufacturing of our gear machining parts.

(2) Safety first, materials are the key:

When used in medical equipment, especially those that come into contact with the human body or are implanted, the gear material must be absolutely safe and harmless. We most commonly use special engineering plastics such as medical-grade 316L stainless steel or high-performance PEEK. They are not only strong and durable, but more importantly, they have passed strict human compatibility tests to ensure that they will not cause rejection or safety issues. This is not something that ordinary gear materials can handle.

(3) Quiet and stable, related to experience and recovery:

In a quiet ward or operating room, if the gears make noise or shake violently, the patient will feel uncomfortable and may interfere with precision operations. Therefore, the gears of medical equipment must run super quietly and extremely smoothly. This involves every detail from design to manufacturing, and deep customization is required to achieve the effect. Standard parts are difficult to meet the standards.

“Building gears for medical equipment is to escort life. JS focuses on providing safe, accurate and quiet micro-precision gear processing parts solutions. Contact us now to create miracles of life between millimeters together!”

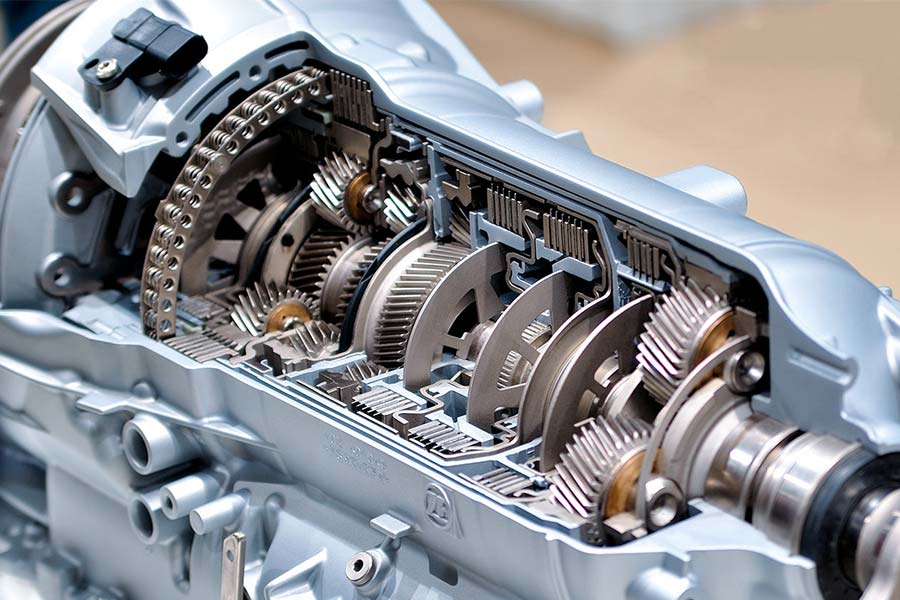

Cars And Racing: Squeeze Every Bit Of Performance

Every day, our JS company “tailors” the heart parts-gears for various wheels. Whether it is the F1 racing gearbox that pursues the speed limit or the truck differential that does heavy physical work, if you want to squeeze out every bit of performance, you can’t do without our carefully designed custom gears.

Customers’ needs are varied: how the engine is powered, the specific conditions of the track, how the driver wants to drive, all of which determine that we must create a unique gear combination. To put it bluntly, it is to let the power be delivered in the most appropriate way at the most appropriate time.

This job is not small. These gears have to withstand huge impacts and instantaneous high temperatures, and they can’t fall off at all. Therefore, we JS pay special attention to materials. The core of our customized gears is made of high-strength special steel, and coupled with our unique heat treatment and surface strengthening process, they are hard and tough, and especially durable. This is the confidence that we can help customers push performance to the extreme.

Beyond Standards: The Core Advantage Of Customized Gears

Let me discuss why custom gears are more helpful than standard parts in most critical situations:

To put it briefly, standard parts sometimes can’t quite fit some requirements. The best thing about custom gears is that they can fit your requirements perfectly. Whether it is the precise transmission of torque, specific speed requirements, or the optimization of transmission efficiency, we can “tailor-make” for you, not just accommodate it.

You have full freedom in material choice. With our internet-based gear machining services, you are free to prioritize weight reduction, corrosion resistance, or stability under extreme high temperature environments based on the real application, and select the most corresponding high-performance materials without being limited by the stock of ordinary parts.

In terms of integration, custom gears mean that the size, shaft hole, keyway and other details are manufactured completely according to your design drawings. There is no need to change the entire machine structure to accommodate a gear, which saves worry and effort.

More importantly, it can achieve unique functions that standard parts cannot provide. Whether it is a special number of teeth, non-standard tooth shape design (such as cycloidal teeth), or the need to integrate a small cam on the gear, these non-standard designs are pain points that custom gears can solve.

How To Choose The Right Custom Gear Manufacturer ?

As an engineer at JS, I often need to purchase custom gear machining manufacturing services. Finding a supplier is not about who is close, but who can really do it well. If I want to trade smoothly and get reliable gears, I mainly look at the following points:

(1) Evaluate technical docking capabilities:

Can the other party’s engineers really understand my drawings? Suppliers who can actively propose optimization suggestions are efficient to cooperate with and have fewer problems in the later stage. This is the basis for worry-free and labor-saving transactions.

(2) Confirm core processing equipment:

High-precision gears cannot be handled by ordinary machines. There must be accurate gear hobbing machines, gear shaping machines, and gear grinding machines. Complex shapes must rely on 5 axis machining centers. If the equipment is not good, I dare not place an order no matter how cheap it is.

(3) Investigate material application experience:

There are many types of gear materials, from ordinary steel to special plastics, with great differences in characteristics. Good suppliers are very clear about the processing difficulties and heat treatment of various materials, and can ensure that the performance of the finished products meets the standards and avoid transaction disputes caused by materials.

Verify the quality control system: Precision is the lifeline of gears and the core of transactions. Suppliers must be equipped with three-coordinate measuring machines (CMM) and professional gear testing equipment. Each batch of goods is strictly tested and reports are provided. The data speaks for itself, and I feel at ease when I pay.

(4) Emphasis on response efficiency and service process:

Nowadays, good suppliers have online platforms, and drawings can be sent to them for quick quotes and clear delivery dates, and global services are no problem. Suppliers with smooth communication and transparent processes can ensure that transactions are completed on time much better than a slow local workshop.

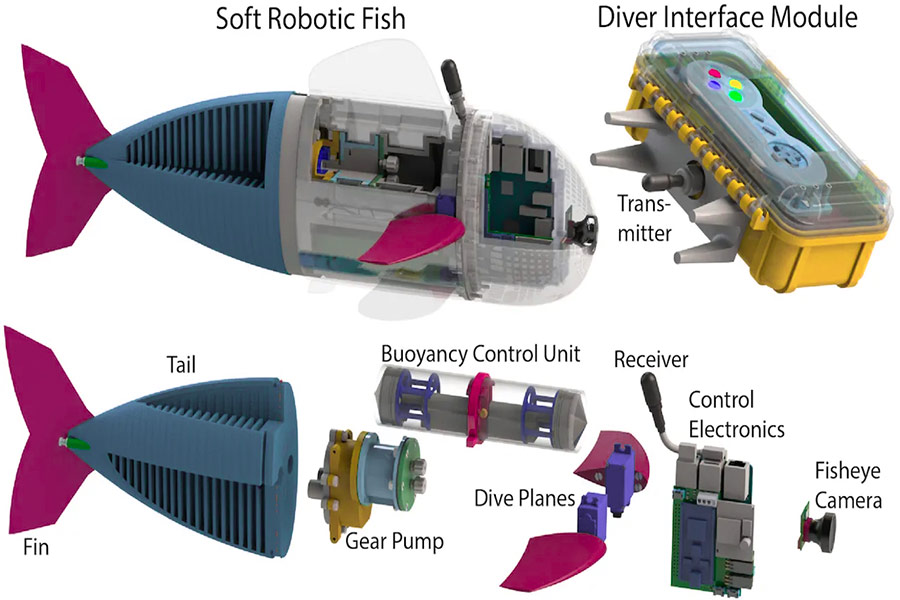

Case Analysis: Customizing Corrosion-Resistant Bevel Gears For Underwater Robots

Let me share a real case, how we helped a marine exploration company solve the problem of underwater robot steering.

Challenge: When underwater robots encounter the “impossible triangle”

A marine exploration company we cooperated with encountered a difficult problem: their underwater thruster steering mechanism needed to meet three points at the same time:

- 1) The space is smaller than you think.

- 2) Long-term durability in highly corrosive seawater.

- 3) Achieve 90-degree efficient power steering.

Standard gears are almost completely defeated by these three conditions.

JS’s solution:

(1) Choose the right gear type:

The customer clearly requires 90-degree steering, and custom bevel hears is the best partner. It is naturally suitable for processing this project, with a compact structure and high efficiency.

(2) Material is the key to success or failure:

Ordinary steel cannot withstand seawater, and rust is a fatal injury. We decisively recommended phosphor bronze. We are very familiar with this material. It is particularly good at dealing with seawater corrosion and has its own lubricating properties. It is wear-resistant and smooth when paired with stainless steel shafts, greatly extending its service life.

(3) How to customize the 90-degree steering?

To achieve a smooth 90-degree transmission direction, ordinary spur gears shake violently. We use 5 axis CNC machine tools to finely cut and create spiral bevel gear surfaces, which are quiet and efficient when biting. This custom gear machining manufacturing process is not only fast, but also ensures that there are no burrs in each tooth gap to avoid jamming problems.

Final result:

In the end, this steering system is not only completely resistant to seawater corrosion and compact in size, but also more efficient than customers expected. After two years of trial use, there were no failures and the life was 50% longer than they thought. This is not just a machining part, but a full-process solution provided by our JS company, which solves their core headache.

“Don’t let corrosion or space limitations hold up your project. Contact us JS company. We professionally customize gear solutions to ensure high efficiency and durability. Let’s solve the challenge together!”

Our Commitment: You Design, We Make It

(1) Flexible response to needs: Do you want to make a sample to try? Or do you want hundreds or thousands of sets for formal production? No problem, we can take it, and each custom gear project is special.

(2) Break the trouble of traditional manufacturing: We use our own machines and team experience to solve the procrastination and communication difficulties in the old manufacturing process, and our goal is to make you worry-free.

(3) Make production simple and reliable: From the moment you give us the drawings to the moment you receive qualified gears, we will monitor the whole process and finally deliver you reliable gear products.

FAQs

Q1: Can you make plastic gears?

Of course! We often make gears made of engineering plastics such as Delrin (POM), Nylon, and PEEK. They can help you solve the needs of weight reduction, noise reduction, or less lubrication. Please send us your requirements to discuss which material and how to make it.

Q2: How much more expensive are custom gears than standard gears?

Looking at a single gear, the price of custom parts is indeed higher. But foremost is to give thought to the whole!

Customized gears can make your equipment run smoother and last longer, and even save the trouble and cost of major design changes to accommodate standard parts. In this way, the total cost of ownership is more cost-effective. How much can you save? You are welcome to bring along your requirements, and we will help you calculate this account in a detailed manner.

Q3: What do I need to provide to get a quote?

To get an accurate quote quickly, it is best to provide a 3D model (such as a STEP file) or a 2D drawing with clear dimensions, tolerances, and materials. If the information is not complete, it doesn’t matter. Feel free to talk to our engineers about your ideas. We can also help you estimate it first to save you the trouble.

Q4: How long is the delivery cycle?

Thanks to our online platform and optimized production process, the delivery speed is usually better than that of conventional processing plants. The specific cycle depends on the complexity of the gear, material selection, and order quantity. You only need to upload the drawings through the online system to get a real-time estimated delivery time reference.

Summary

From aircraft carrier deck elevators to the watch you wear, gears quietly move the world. But it is often custom gears that are tailored to solve specific problems that really drive innovation. When your project needs to go beyond the limitations of standard parts, it is crucial to find a partner who understands design and precision manufacturing.

At JS, we understand what a perfectly matched gear means to your design. Don’t let generic parts hold your project back. Take action now:

Please upload your gear design to our secure and reliable online platform. You will not only get a clear and competitive gear machining price immediately, but also a commitment from our team of engineers to use our expertise and precision manufacturing capabilities to accurately and reliably transform your unique design into reality.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com