When the heart of a high-pressure valve of a desalination plant needs to be changed every three months because it ‘seizes’ and incurs losses exceeding $28,000 per shutdown, when core components of medical equipment are sent back to factories by clients for failing to meet antibacterial standards, and when high-quality transmission components repeatedly fail because they’re worn too thin—are you conscious that an unsuitable selection of material not only erodes profit but also holds up project progress?

In precision production, the best products require rigorous material selection and processing techniques. CNC machining bronze, with its unique advantages, has become the preferred choice for many top products, and this is not accidental.

Summary Of Core Answers

| Consideration Dimensions | Bronze (CNC Machining) | Other Metals (e.g., Steel, Aluminum) | High-Performance Engineering Plastics |

| Core Advantages | Self-lubricating, corrosion-resistant, antibacterial, high toughness | High strength, high hardness, high temperature resistance | Low weight, low cost, chemical resistance |

| Main Uses | Bearings, bushings, sea parts, artistic castings | Structural parts, gears, housings | Housings, connectors, low-load parts |

| Life Comparison | Extremely long life in wear-resisting and corrosive conditions | Long life under lubrication | Susceptible to aging and creep, resulting in relatively short life |

| Cost Positioning | Processing and material are expensive, but lifecycle cost is less | Medium | Low |

This article will provide you with a thorough overview of the six reasons bronze is irreplaceable to the world’s finest manufacturers, thoroughly exploring how it surpasses all other materials. This will protect you from choice mistakes and guarantee that all your CNC machining parts stand the test of time and conditions of use.

Why Trust Us? JS’s Precision Machining

JS has over 15 years of real-world experience in CNC machining with a strong specialization in specialty machining of difficult-to-machine materials including bronze. We are not just proficient at CNC turning and milling alloys like tin bronze and aluminum bronze, but we also possess extensive experience in machining core components for use in desalination, medical devices, and high-performance transmissions.

We have provided individualized custom CNC machining fabrication services to over 500 companies, from raw material procurement to finished product delivery. Online CNC machining services offer quick turnaround times and precisely fulfill customers’ precision and deadline requirements for CNC machined parts.

This handbook is the JS team’s distillation of key technical points, taken from many years of project experience. From studying bronze properties to getting past machining challenges, all information has been field-tested, leading you away from common errors in material selection and machining operations and acting as a trusted companion to your CNC machining projects.

JS has a better understanding of bronze and your needs. After an online consultation, state your needs and we will give you a quote and customized solution in minutes. Upon confirmation, we will begin custom CNC machining manufacturing and deliver high-precision parts to you worry-free.

Five Major Reasons For High-Quality Products Choosing Bronze

Top-grade products meticulously consider whether or not their performance is proportional to their high expectations while deciding on materials. Bronze is favored because of the following five major advantages.

Reason 1: Better Self-Lubrication and Low Wear

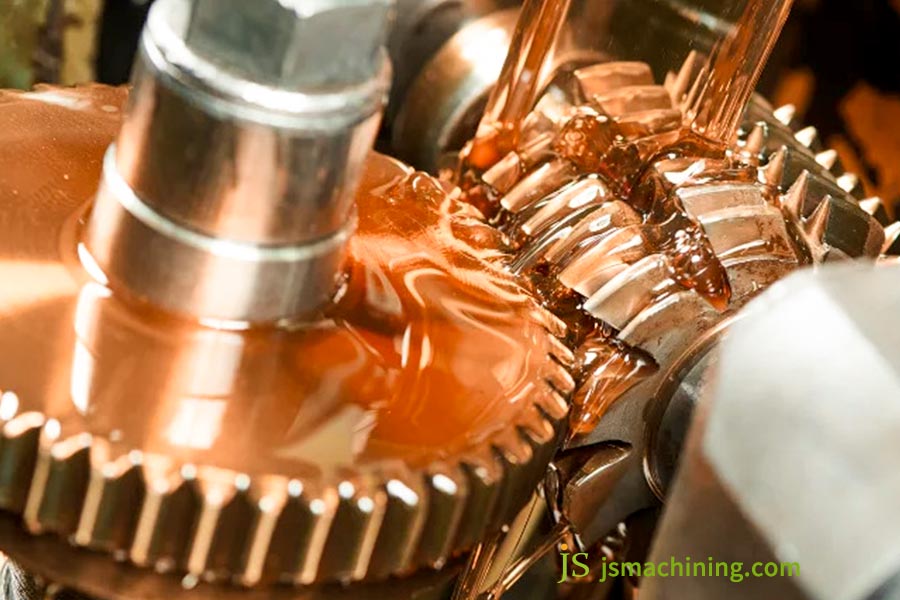

Bronze also has lubricating substances naturally, which form protective layers in the process of friction, and hence smoothness is obtained with no need for replenishing the lubricants. This reduces wear and increases the life of CNC machining parts significantly.

For example, in transmission parts where accuracy is a must, CNC machining bronze parts experience much less wear compared to parts machined from conventional materials.

Reason 2: Unmatched Corrosion Resistance

Bronze forms a dense oxide layer on its surface which protects the metal from exposure to outside corrosive media. The layer is stable in humid environments and dilute corrosive liquids and is therefore less susceptible to corrosion damage.

Bronze parts CNC-machined are an excellent choice for application where maximum corrosion resistance is required, such as marine engineering and chemical apparatus.

Reason 3: Natural Antibacterial and Safety

Bronze has intrinsic antibacterial ability, killing over 99% of common pathogenic bacteria, such as Escherichia coli and Staphylococcus aureus, inhibiting bacterial growth and multiplication effectively.

For areas with strict sanitation and safety requirements, such as medical equipment and food processing equipment, CNC machining bronze parts can guarantee effective prevention of bacterial transmission.

Reason 4: Excellent Toughness and Impact Resistance

Bronze also possesses greater toughness and impact strength. It is resistant to breakage or shattering from outside forces because it deforms and absorbs energy. Compared to other brittle materials, it is also better able to withstand sudden external forces.

For example, in machine transmission systems, bronze parts machined by CNC are better able to protect the system against sudden loads impacts and reduce the risk of breakdown.

Reason 5: Better Thermal Conductivity and Heat Resistance

Bronze’s high thermal conductivity allows for rapid heat transfer, preventing overheating in localized areas that would compromise component performance. Bronze is also more resistant to heat, maintaining better mechanical properties above 200°C and resisting softening and distortion. CNC-bronze parts perform uniformly under high-heat applications such as engine components and high-heat molds.

JS respects the hardness of bronze and can make CNC machining components as per your specification. We provide instant proposal and CNC machining quote after online consultation, and start manufacturing immediately after confirmation of order, enabling you to get high-quality components efficiently.

Bronze Family Revealed: Core Alloy Grades Available For CNCMachining

Popular bronze alloys used today for CNC machining in industry all have some specific characteristics and applications:

| Alloy Type | Core Characteristics | Applications | Processing Considerations |

| Tin Bronze

(Cu-Sn) |

Excellent machinability and superior surface finish | Bearings, gears, and precision transmission components | Can be CNC milled/turned, widely applied in online milling/machining services |

| Aluminum Bronze

(Cu-Al) |

Excellent wear resistance and strength | Wear-resistant parts for ship propeller and mining machinery | Carbide tools are required, and machining costs 20%-30% above tin bronze |

| Lead Bronze (Cu-Pb) | Low cutting resistance and good self-lubrication | High-speed machine tool guideway bushings and bearings | Requires compliance with environmental standards of lead and limited cutting temperatures in machining |

| Silicon Bronze (Cu-Si) | Strong corrosion resistance and excellent weldability | Chemical piping and light structure parts for marine exposures | No additional corrosion protection is required following machining, cost-saving in the future |

It is to be noted that precision of different bronze alloys in CNC machining is different: Lead bronze and tin bronze can tolerate within ±0.01mm. Since the hardness of aluminum bronze is greater, the tolerance should be relaxed within ±0.02-0.03mm.

If choosing online CNC machining services, company owners need to define the alloy type and precision requirements of the part clearly to obtain an exact CNC machining price quotation and resultant CNC machining parts to meet your needs.

JS knows the characteristics of various bronze alloys and may help you select the right grade as well as estimate a suitable CNC machining cost. After finishing online communication, we can arrange processing instantly and send you qualified CNC machining parts.

Bronze Vs. Other Materials: Which Has The Longest Life?

In selecting materials, lifespan becomes one of the top priorities. To visually distinguish the advantage of bronze, we are comparing it against stainless steel (304/316), aluminum alloy (6061), and engineering plastics (POM, PA66+GF). This will identify the ‘longest lifespan winners’ in different situations and can also assist companies in selecting the right material.

Bronze vs. Stainless Steel (304/316)

| Comparison Parameters | Bronze | Stainless Steel (304/316) |

| Self-lubrication | Excellent, no additional lubrication required | Poor, requires regular lubrication |

| Wear Resistance | High,low wear rate | Moderate, wears faster without lubrication |

| Antibacterial Properties | Naturally antibacterial, kills many bacteria | No natural antibacterial properties, surface susceptible to bacterial growth |

| Service Life (for transmission components) | 5-8 years | 3-5 years |

| CNC Machining price | Relatively high (material properties + machining process) | Relatively low (mature process) |

For self-lubrication uses, antibacterial use, and wear resistance, bronze lasts much longer than stainless steel. For transmission components, particularly, bronze parts have longer lifetimes. Although more expensive to machine, bronze CNC machining proves cost-effective in the long term.

Bronze vs. Aluminum Alloy (6061)

| Comparison Parameters | Bronze | Aluminum Alloy (6061) |

| Density | 8.8-9.2g/cm³ | 2.7g/cm³ |

| Corrosion Resistance | Excellent, resistant to various corrosive environments | Good, susceptible to corrosion in extreme conditions |

| Toughness and Impact Resistance | Excellent, resistant to fracturing on impact | Fair, susceptible to deformation and fracturing on extreme impact |

| Service Life (for structural parts | 8-10 year | 4-6 years |

| Cost of CNC machining | High (material cost + complexity of machining) | Low (material cost + simplicity of machining) |

For such applications requiring high structural toughness, resistance to corrosion, and longevity, bronze clearly excels over aluminum. While aluminum is light in weight and inexpensive to machine, premium products prefer the durability of bronze in the long term.

Bronze vs. Engineering Plastics (POM, PA66+GF)

| Comparison Parameters | Bronze | Engineering Plastics (POM, PA66+GF) |

| High Temperature Resistance | Excellent (stable operation above 200°C) | Poor (performance degradation at 100-150°C) |

| Load Capacity | High (withstands high compressive loads) | Medium (tends to creep under high long-term loads) |

| Aging Resistance | Good (minimal long-term performance shift) | Poor (prone to aging and brittleness with long-term use) |

| Service Life (for high-temperature, high-load components) | 6-8 years | 1-3 years |

| CNC machining Price | High (high material and process demands) | Low (quick processing and low cost) |

In high-temperature, heavy-duty uses, bronze parts live with an incredibly longer life compared to engineering plastics. Though engineering plastics are inexpensive and easy to process, they cannot offer the long-term stability required in high-quality products.

In summary, in most cases where performance and lifespan are of prime importance, bronze leads the way, supporting diligently the choice of CNC-machined bronze for premium products.

JS guides you to accurately compare the advantages and disadvantages of the material. Refer online to application situations, and we will propose cost-effective solutions and customize CNC machining parts to make your project more reliable.

Tool Choice And Technique Tips For CNC Machining Bronze

In order to gain the maximum from bronze and produce high-quality parts, effective tool choice and scientific machining practice are crucial. Not only does this influence part quality and accuracy, but even the cost of machining.

Golden Rules for Tool Selection

Select tool material based on the grade of bronze alloy: for lead bronze and tin bronze, low-cost high-speed steel tools are recommended, for aluminum bronze, high-hardness carbide tools, good wear resistance but expensive, are recommended. Select tool geometry appropriately, and consider tool coatings (e.g., TiN and TiAlN coatings) for improvement in wear resistance and tool life.

Core CNC Machining Methods

CNC turning is best suited for rotational parts such as sleeves and shafts, with precise machining and favorable surface finish. CNC milling is best suited for non-rotational parts such as boxes and those with complex curves, enabling multi-face machining and complex structure formation.

JS has the tools and process know-how in bronze machining. Once we have negotiated part requirements over the internet, we can immediately come up with machining plans efficiently and accurately so that you can easily obtain CNC machined parts.

Common Problems In CNC Machining Bronze And JS’s Solutions

The majority of common issues arise in CNC machining with bronze. Such issues affect not only the precision and quality of CNC machined parts, but also reduce machining efficiency and increase expenses.

Being a seasoned production expert in custom CNC machining, JS has resolved such challenges by enforcing certain measures for assuring stable and efficient machining.

Challenge 1: Material Adhesion to Tools

During machining of lead bronze and tin bronze, hot metal chips easily adhere to the tool’s cutting edge, resulting in built-up edge (BUE), creating surface scratches, size deviation, and high tool wear.

JS precision metal cutting solution:

Cutting by alloy characteristics. Cut the lead bronze at 120-150 m/min and 0.1-0.15 mm/r feed. Use a use of an emulsion with extreme pressure additives to reduce friction and heat effects, critically reducing adhesion problems.

Challenge 2: Work Hardening

In bronzemachining, the surface top layer hardens due to plastic deformation. It is especially so for aluminum bronze, whose hardness is considerably enhanced with hardening. This renders it more difficult to perform follow-on machining and can even lead to chipping of tools and cracking of fragments.

JS precision machining solution:

Three-pass machining process of ‘roughing – semi-finishing – finishing’ is employed. Semi-finishing is employed separately to remove the hardened layer. Ultra-fine-grain carbide cutters are employed in order to maximize machining efficiency as well as tool life.

Challenge 3: Internal Stress Induced Deformation

Internal residual stress as a result of previous bronze machining can be redistributed through CNC machining material removal, leading to over-deformation of thin-walled or complex components, and scrap.

JS precision machining solution:

Low-temperature aging as raw material and relaxation of internal stress. Precision components are subject to a second aging treatment after roughing machining. Symmetrical machining is utilized for even elimination of material to avoid deformation inside precision tolerance.

JS does not have an issue of solving bronze machining issues. Inform us about your requirements for parts online and we will promptly offer you a solution. After machining commences, we deal with quality control, so you worry less.

Case Study: A Million-Dollar Decision-Material Selection For Seawater Desalination Valves

Case Background

The core of the high-pressure regulating valve of this desalination plant is a core part which must be capable of withstanding 1.6 MPa high pressure and repetitive, low-speed micro-motions under seawater conditions of over 35,000 mg/L salinity.

The core of the valve was originally designed of super duplex stainless steel (2507). Whereas stainless steel maintained its performance in normal corrosive conditions, it suffered ‘seizure’ after three months of operation in this instance due to poor lubrication between the valve seat and valve core.

Seawater salt also accelerated crevice corrosion, which ruined the sealing surface of the valve core. Every replacement required 48 hours of downtime, and this came at a cost exceeding $28,000 in maintenance and reduced the daily production of desalinated water by 500,000 tons.

JS Analysis and Intervention

Upon receiving the request, JS Precision Manufacturing first examined the broken component and discovered that the cause of failure for the stainless steel valve core was that it was not self-lubricating. Boundary lubrication conditions resulted in metal-to-metal contact and adhesive wear (seizure).Besides, seawater chloride ions penetrated into the passive film of stainless steel and promoted localized corrosion.

According to the above properties of aluminum bronze, JS recommended high-aluminum bronze (C95500) as a substitute material and provided custom CNC machining manufacturing services. CNC turning strictly regulated the valve core sealing surface tolerance to ±0.01mm, besides CNC milling to form the complex flow path structure.

In addition, to reverse the work hardening of the aluminum bronze, the above ‘three-step machining process’ was employed to ensure the precision of the part.

Results of Implementation

The new valve core has been performing satisfactorily for more than 36 months after installation, only through routine cleaning and maintenance every six months without any seizure or corrosion problem.

In terms of costs, even assuming the CNC machined cost of high-aluminum bronze valve cores is 30% greater than that of stainless steel, the lifecycle cost is merely a quarter of that of stainless steel solutions. It avoids a total of over $700,000 in downtime loss fully illustrating how cost-effective and dependable CNC-machined bronze is in severe working conditions.

CNC machining of bronze boasts a superb treasure chest of successful applications of bronzes machining. Contact us online for guidance on your project requirements. We can leverage our know-how and design a solution to your specifications, efficiently supply high-quality CNC machining parts, and minimize your risk.

FAQs

Q1: Why is CNC machining bronze relatively expensive?

1.Material cost: The price of bronze raw materials is higher than that of stainless steel and aluminum alloy.

2.Tool wear and tear: Bronze processing tools are prone to wear and tear, increasing the cost of consumables.

3.Process complexity: It is necessary to address issues such as adhesion and hardening what extend working hours.

Q2: Will JS increase prices on small lots of specialty CNC machining bronze pieces?

JS has mature solutions for processing small batches of bronze parts, and will accurately calculate the CNC machining price based on the alloy type and process difficulty, without additional charges. After communicating the requirements online, you can obtain a transparent quotation.

Q3: Can 3D printing be used instead of CNC to manufacture bronze parts?

Okay, but the performance is different. Metal 3D printed bronze parts are porous, and their density, mechanical properties, and corrosion resistance cannot reach the level of CNC machining of forging blanks. CNC is the ultimate choice for pursuing performance.

Summary

Premium products demand long-term stability, high-performance operation, and a high-quality experience, and CNC machining bronze precisely provides these demands. Though its CNC machining price may be slightly more expensive than common materials, its long-term worth, dependability, and stable quality render it an ideal choice for high-end products, providing a high-quality material solution for custom CNC machining manufacturing.

JS has been engaged in CNC machining bronze industry for 15 years, providing one-stop online CNC machining services. After defining your needs through online consultation, we can quote instantly and customize the process to allow you to obtain CNC machined parts with increased lifespan as well as better performance, ensuring the protection of high-quality products.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: How Can You Tell If Aluminum Is Anodized? - JUSHENG

Pingback: Does Your Project Require Zero Tolerance Precision Machining? - JUSHENG