In manufacturing, every metal cast item must be of exact specifications, and investment casting excels in this respect. This ancient method, known as the “lost wax technique,” can create complicated detail parts with mirror-finish surfaces as well as complicated, branching forms such as those on living organisms, and turbine blades strong enough to drive airplane engines.

In our daily projects, our company has found that it not only ensures excellent dimensional accuracy and better surface finish, but also eliminates much material waste and downstream processing. In aerospace, medical devices, or car parts, investment casting offers unprecedented reliability and flexibility.

Despite its long history, the combination of newer methods like CAD/CAM and additive manufacturing achieves even more in terms of repetition of quality and cost savings. That is why we continue to use it for making difficult parts.

Key Answer Summary:

| Aspect |

Core Answer

|

| Process Name |

Investment casting (wax loss method).

|

|

Essence

|

A process of obtaining ceramic molds by melting disposable wax molds, and then pouring metal liquid to obtain precision castings. |

| Key Value | Manufacturing metal parts with extremely complex shapes, precise dimensions, and smooth surfaces that cannot be achieved by other processes. |

|

Applicable Materials

|

Widely used, from stainless steel and aluminum alloys to titanium alloys, cobalt based/nickel based high-temperature alloys, etc. |

| Typical Applications | Aerospace engine blades, turbochargers, medical implants, artworks, hardware, etc. |

|

Dimensional Tolerance

|

Extremely high, usually ± 0.13mm/25mm or CT level 4-6 (national standard). |

| Surface Roughness | Excellent, typically Ra 1.6-6.3 μm, polished to achieve mirror finish. |

|

Economy

|

The initial cost of the mold is moderate, and the cost per piece significantly decreases with increasing batch size, making it very suitable for medium to large-scale production. |

Why Trust This Guide? A Practical Review From The JS Team

Our JS team has worked decades in the trenches of foundry manufacturing. I have personally completed every step from design and simulation to mold making and melting. Our products are in the high-reliability applications of aviation, healthcare, and energy, not paper-stage developments.

As international casting expert Professor John Campbell said, “90% of problems in casting can actually be avoided during the design phase.”

This strongly resonates with us. Due to this, we placed particular emphasis on the initial-stage simulation and process control. For example, through our designed gating and riser design method, we reduced the scrap rate of a specific aviation component from the industry average of 12% to less than 3%. Moreover, in a high-temperature alloy blade project, fatigue life was greater than 50% above customer requirements.

There is no mystical rationale behind it, it’s an practical approach gained from real projects. Every sentence that we pen is grounded on practical experience supported by our own experience and pitfalls we’ve had. We merely hope that it will indeed assist you in solving problems and not make errors.

What Is Investment Casting? A Millennium-Old Precision Art

Investment casting is an exacting process molding used to shape complex, finely dimensioned metal parts. To us JS engineers, it is closer to a millennium-old “metal art”—by casting molten metal into a throwaway ceramic shell mold, we create near-net-shape parts requiring little or no follow-on machining.

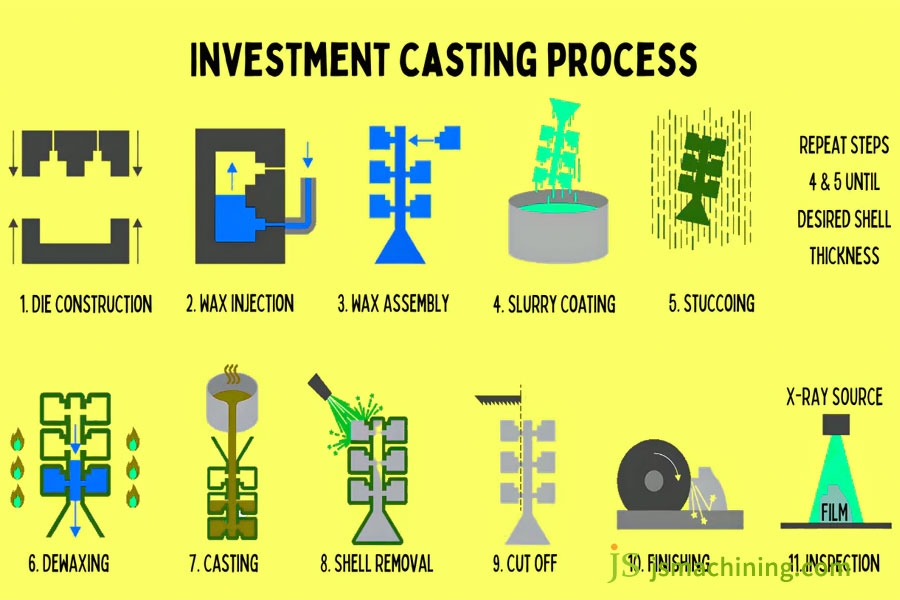

The basic process can be described in a few words:

- First, a wax pattern is created for the part and built up into a tree.

- Ceramic slurry is repeatedly applied to build up a solid shell mold.

- Heat-dewaxing is performed to create a hollow mold.

- High-temperature sintering is followed by filling with molten metal.

- Finally, the shell mold is broken open, and the casting is taken out and cleaned.

Its greatest strength is in generating extremely complicated geometries in a single step—such as internal channels, conical cutters, or intricate design ornamentation—that might be difficult to efficiently make with traditional machining. Due to this, it’s particularly well-suited for custom metal casting manufacturing in aerospace and medical implant applications, help us achieve high-precision control from material to shape.

Which Alloys Shine In Investment Casting?

In investment casting, we rely on a variety of high-performing alloys to create precise and detailed parts. The choice of these alloys directly impacts the performance and application of the finished metal casting parts.

The following are some of our most commonly used alloys and their typical applications:

|

Material Category

|

Specific brand examples

|

Main characteristics and application areas

|

|

Stainless steel

|

304, 316, 17-4 PH | Good corrosion resistance and the widest range of applications, from parts to medical equipment. |

| Alloy steel | 4140, 4340 | Extremely strong, commonly used for critical structural components. |

|

Superalloy

|

Inconel, Hastelloy | Resistant to high temperature oxidation, used in aviation engines and extreme environments. |

| Cobalt-Chrome | – | Good biocompatibility makes it the preferred choice for medical implants. |

| Aluminum alloy | – | Lightweight, used for components with high requirements for lightweight. |

| Copper alloy | – | Excellent conductivity and thermal conductivity, commonly used in electronic and industrial components. |

Lesser-known but equally important materials:

- Titanium alloys, which must be cast entire in a vacuum to avoid reaction with air, are a first choice for the aerospace and high-grade medical industries.

- Jewelry and special industrial catalysts are also produced using investment casting from precious metals such as gold and silver.

We hope this guide will help you make better material selections. If you require custom metal castings for your project, feel free to contact us, we will offer you JS professional services.

Irreplaceable: Which Complex Components Are “Essential” For Investment Casting?

In our daily business, some complex components are “naturally” suited to investment casting. They typically have complicated structures and demanding performance requirements, which render them difficult to produce by other means. They belong to the following categories:

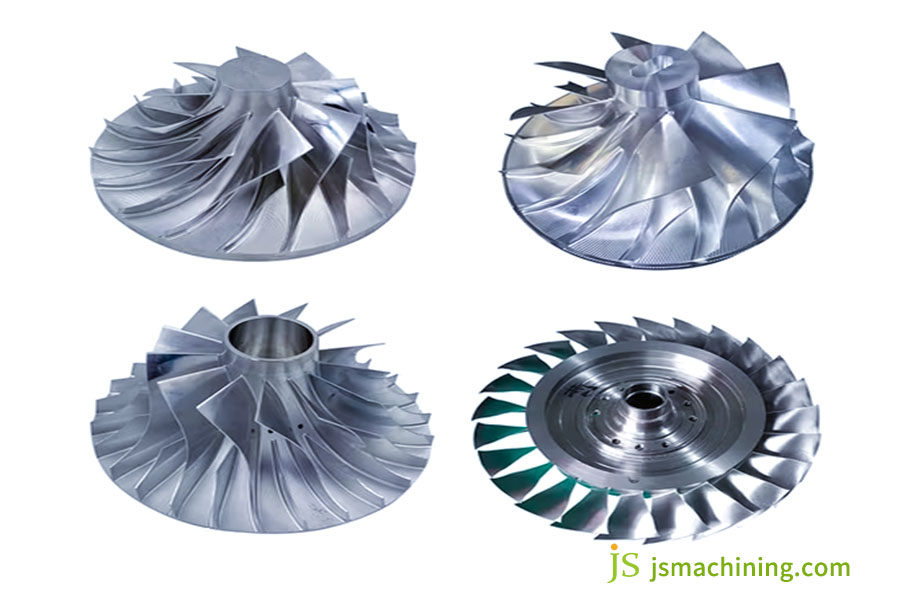

- Aerospace: For example, turbine blades in an engine are filled with complex cooling channels. These complex internal voids are very critical to engine efficiency and must be cast in a single operation.

- Medical implants: Artificial hips and knees, for example, must fit precisely into the human body, often with complex and tailored shapes. Investment casting is a great method for achieving this.

- High-performance automotive applications: Turbocharger impellers are a typical example, requiring extreme balance and heat resistance to withstand high engine speeds.

- High-end industrial applications: Some pump casings and valve bodies, for example, have complex internal flow path geometries that directly affect the efficiency and reliability of the overall system.

The commonalities of these parts are: Complex structure, extremely high demand for accuracy, and integral casting demand. Through our process, a number of parts can be integrated into an integral metal casting part, thereby avoiding assembling defects, reducing weight, and significantly improving the reliability of the end product.

Investment Casting vs. 3D Printing: Competitors Or A Perfect Partner?

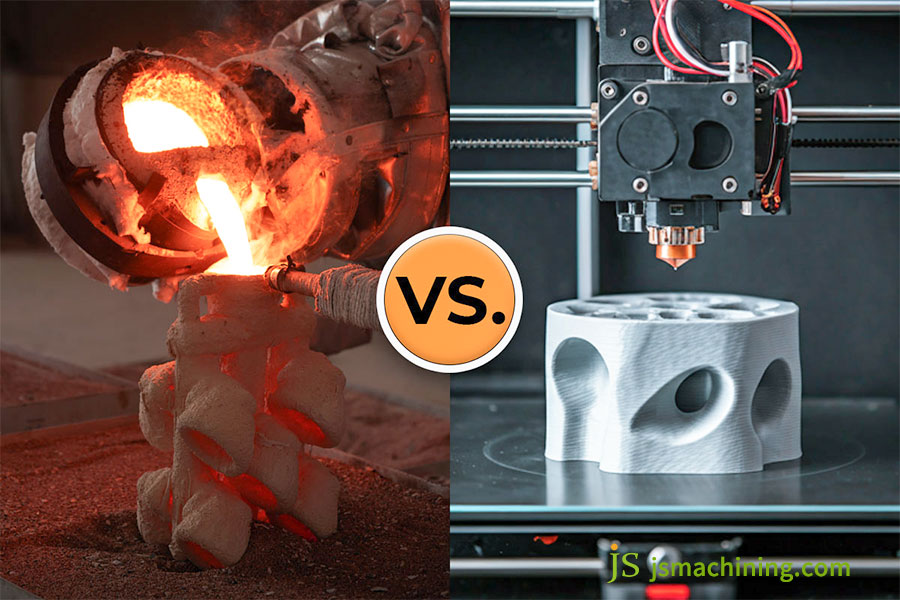

I often help customers choose between investment casting and 3D printing. Actually, they are not usually rivals, they’re actually more often complements.

When is investment casting less expensive?

For large orders: Usually over 50-100 pieces, the cost per part of investment casting is significantly lower than that of 3D printing.

When considering performance and materials: Especially with traditional, evolved alloys, the properties are homogeneous and the costs are negligible for casting, compared to 3D printing, which might not be as strong in every direction.

So, when is 3D printing more suitable?

For rapid prototyping: This eliminates the step of opening the mold and allows faster production of the initial example.

For highly complex structures: For example, with conformal cooling or complex topology, 3D printing allows for the employment of a single-shot molding process, eliminating demolding problems.

In manufacturing, we prefer to combine the two in a process of 3D printing to produce the resin mold to cast and investment casting to produce the metal part. This process offers velocity and volume advantages and is best suited for our online metal casting services that economically supports small-batch customization needs.

The choice is premised on some requirements. For low-cost, high-volume projects, casting is the right technique, for complex, urgent projects, 3D printing is the right technique. A combination of both is typically better. If you would like a detailed analysis of your project, please feel free to contact JS!

Comparison Between Investment Casting And Mainstream Casting Processes

In choosing a process of casting for your project, are you stuck between precision, efficiency, and expense? What makes investment casting superior to other casting processes? Today, I’ll utilize some critical facts to inform you about the main differences between it and three commonly practiced processes.

Comparison with Sand Casting: The Trade-off between Precision and Cost

Think of it as the difference between “precision craftsmanship” and “mass production.” Our investment casting technique uses ceramic molds, with smoother surfaces and tighter tolerances. Complex shapes can be done in a single pass, with minimal follow-up finishing. Sand casting uses sand molds, with a rougher surface and suited for mass production of simpler parts.

The downside, though, is higher mold costs. Sand casting of wooden or metal molds is much cheaper. So, if you need thousands of simple, unproblematic parts, sand casting costs less than metal casting. For small- to medium-volume, complex-shape, and high-precision parts, however, our investment casting process has lower overall costs because it reduces post-processing and material costs significantly.

Comparison with Die Casting: The Trade-off Between Materials and Performance

Die casting is a “quick gun,” favorably suited to large-volume production of non-ferrous metal products, such as zinc alloy and aluminum alloy cellphone enclosures, and boasts high efficiency. It is beset with material limitation and cannot handle high-melting-point steel.

Our investment casting method, on the other hand, employs a “slow and steady” technique and can cast nearly all alloys, including stainless steel and tool steel, high-performance materials. Therefore, our parts typically deliver improved overall performance in strength and resistance to high temperatures. Of course, our production efficiency cannot be compared with the high-speed automation of die casting.

Comparison with Lost Foam Casting: Different Paths, Different Objectives

Many people have the feeling that investment casting and lost foam casting are very similar, both using a “vanishing” mold. The primary difference, however, lies in the mold itself.

Lost foam casting uses a foam mold, which is vibrated and sand-filled before pouring. The foam is evaporated and is absorbed by the molten metal. The method readily develops carbon defects on the casting surface and is highly dependent on the sand for dimensional accuracy.

Investment casting utilizes a wax pattern, and being a process, it possesses extremely high surface quality. A decent ceramic slurry is deposited several times to create a hard mold shell, and finally, dewaxing is performed to create a clean cavity. This ensures that our products tend to have higher precision and surface quality.

Key performance comparison between investment casting and mainstream casting processes:

|

Characteristic indicators

|

Investment casting

|

Sand casting

|

Die casting (aluminum)

|

Lost foam casting |

|

Typical tolerance (mm)

|

±0.003 | ±0.015 | ±0.0025 | ±0.010 |

|

Surface roughness Ra (μm)

|

1.6 – 3.2 | 12.5 – 25 | 0.8 – 1.6 | 12.5 – 25 |

|

Requirements for draft angle

|

Usually not required

|

Need (3°±) | Need(1°-2°) | Need (1°-2°) |

|

Minimum achievable wall thickness (steel parts, mm)

|

0.7 | 3.0 | – | 2.5 |

|

Minimum achievable aperture

|

Φ 1.2 mm (blind hole)

|

Φ5.0 mm | Φ1.5 mm (through-hole) | Φ3.0 mm |

Data Source: Modern Casting, International Report, Euro Investment Casters’ Study

There is no such process as the optimal one, but rather the most suitable one. And if you require outstanding precision, complicated designs, and broad material compatibility, then please do reach out to our JS team and we’ll create the most precise casting solution for you.

JS Real Case Study: The Creation Of A Turbocharger Impeller

I’m a JS engineer, and recently we were given a challenging assignment: designing a turbocharger impeller for a high-performance automotive manufacturer. Their requirements were extremely specialized: light, balanced, able to tolerate extremely high speed and extremely high temperature, and with a very complex surface profile.

Why did we ultimately choose investment casting?

- Traditional machining cannot produce such complex surfaces.

- Die casting cannot withstand high temperature and is not durable.

- 3D printing would be expensive and time-consuming for production in quantity.

JS’s Solution:

We employed investment casting to complete this difficult metal casting parts. Here is what we did:

- First, we created the impeller shape with CAD and cast the process using MAGMASOFT® to foresee in advance the potential defects and to avoid a significant amount of trial and error time.

- Second, the inner airflow passages of the impeller are extremely complex, calling for a high-performance ceramic core to be cast accurately without decreasing the aerodynamic performance.

- Finally, the entire casting was performed under vacuum conditions using a heat-resistant alloy to prevent oxidation and ensure purity of materials. This resulted in a fully functional impeller that was diligently up to standard.

This case fully illustrates that for some custom metal casting manufacturing with special structures and strict performance, investment casting still has irreplaceable advantages.

If you also have such demands for metal parts with ultra-high precision and performance, please feel free to contact us, JS can help you meet your demand in a timely manner!

Why Do We Need To Choose A Professional Supplier Like JS?

For most of the projects we have completed, clients prefer to work with professional partners like us because we can handle fundamental problems. If you’re thinking about online metal casting services, the following descriptions may place our value:

1. Detailed Engineering Cooperation: We go above order-based production and actually work with your design. Our engineers provide comprehensive design and manufacturability studies to help you make structure more streamlined, alter details, preclude risks, save you money, and improve product quality.

2. Expert Material Handling Skills: Not all factories are equipped to handle expertise materials like titanium and high-temperature alloys. Our process experience, acquired over decades of working in the field, ensures superior casting of such challenging materials.

3. Full-Process Closed-Loop Quality: Quality is not some end-of-line check, but is built into every process. From raw material spectroscopy to in-cast X-ray nondestructive testing (NDT) and CMM final inspection, we have a complete control system in place to ensure that every metal casting you receive is consistent and reliable, as demanded.

4. One-Stop Integrated Production: We offer complete services including precision casting, heat treatment, finishing, and surface treatment. This minimizes having to deal with multiple suppliers, significantly simplifying management processes and further guaranteeing product delivery time and overall quality.

FAQs

Q1: How is the surface roughness of the investment castings?

Our investment castings typically have a surface roughness of Ra 1.6-6.3μm. The lower the Ra, the smoother it is. For a higher shine surface, polishing can achieve a near-mirror finish.

Q2: What is the initial cost of the mold (wax pattern)?

Mold opening expense usually ranges from a few hundred to a few thousand dollars, depending on how complex it is. It’s a one-time expense, and we will prorate it based on the volume of your order as a whole. The greater the volume, the less expensive per piece. We can only quote the actual expense after viewing the drawings. Please feel free to inquire further.

Q3: What dimensional tolerances can investment castings achieve?

Our investment castings possess decent dimensional control. Overall, for sizes below 25 mm, we are able to obtain an allowance of approximately ±0.13 mm. For larger sizes, the tolerance is adjusted proportionally by an increase or decrease by about ±0.13 mm for every 25 mm. The actual precision will naturally be affected by the part shape and material as well. We are able to provide an accurate assessment at the design stage.

Q4: What will be the investment casting trends in the future?

Investment casting will become more precise and efficient through rapid tooling with 3D printing and optimizing the manufacturing process through smart manufacturing, and venturing into new applications for alloy casting in high-tech fields like aerospace.

Summary

Investment casting is an “art of manufacturing” of combining proven craftsmanship with high technology. It does indeed facilitate the efficient translation of complex designs to high-performance metal parts. Whether you’re working with aerospace high-temperature alloys or medical implant-grade components, this process is the perfect solution.

Do you work with a metal component having complex geometry and high-performance requirements? Are you struggling to keep the final metal casting cost to overall quality?

With JS Precision Manufacturing technology, you can achieve both ultimate performance and mass economy. Our team provides professional pre-manufacturing analysis to help you optimize your design and control costs.

Upload your CAD file for a complimentary design for manufacturing (DFM) manufacturability analysis and rapid quote. Let us help you rapidly and accurately transform your creative designs into quality products.

Disclaimer

The content of this website is for reference only. JS series expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS directly.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com

Pingback: Where Is Die Casting Used? - JUSHENG

Pingback: What Casting Method Should Be Chosen For Precision Castings? - JUSHENG