Ever been stoked with a reduced die casting price estimate, but only to end up paying twice the amount in mold re-designs, counterfeit components, and transportation delays? Too many purchasing decision-makers have fallen into the “low-cost trap.” True cost optimization is so much more than quoting figures, it’s about gaining ultimate value throughout the product’s life cycle.

In this handbook, JS Precision specialists will uncover the die casting secrets, prevent you from falling into common traps, determine the ideal cost-performance balance, and make the best purchase decisions.

Key Answer Summary

| Core Dimensions | Traditional Low-Price Trap | JS Precision Value Proposition |

| Cost Concept | Pursues the lowest unit price and ignores hidden costs such as mold maintenance, defect rates, and delays. | Pursues the lowest total cost of ownership and ensures long-term project stability through robust processes and quality control. |

| Design Collaboration | Produces strictly according to drawings without providing suggestions, and design flaws are exposed during mass production, leading to a sharp increase in costs. | Provides free in-depth DFM analysis and optimizes from the source of design to reduce cost risks. |

| Mold Investment | Treats low-cost molds as cost items, makes compromises on steel quality and precision, resulting in short service life and high failure rates. | Treats molds as long-term assets and adopts high-quality steel and processes to ensure production stability and efficiency. |

| Quotation Transparency | Quotation documents are vague with many subsequent changes, making the total cost uncontrollable. | Makes the cost structure transparent and jointly analyzes cost drivers to let you know every expense clearly. |

| Supplier Role | Acts as a mere part processor with poor communication and slow response to problems. | Serves as your manufacturing partner, providing dedicated project management and technical support for a worry-free process. |

Why Trust? JS Precision’s Decade Of Hands-On Die Casting Expertise

When you seek a die casting partner, you want to have proven know-how and a proven record, rather than empty words. JS Precision has had a rich experience of die casting and precision metal casting for over a decade and has carried out over 500 successful projects. Its products are used in the automotive, communications, and premium consumer electronics sectors.

For example, we helped a European automobile component maker optimize the metal casting engine bracket design of its product. By redesigning the section of the part and applying innovative molding technologies, we reduced 15% of the part weight without a loss of strength, resulting in saving the supplier nearly $50,000 annually in materials and manufacturing cost.

We are not only proficient in operating our machines but also in predicting and resolving our customers’ problems. Our team of 20 engineers with an average experience of over eight years delivers over 200 detailed Design for Manufacturability (DFM) analysis reports annually, which help clients save 15% of average post-production costs and lower development time by 30%.

We know that precise metal casting price estimation is founded on rigorous attention to detail. It is this unerring dedication to technology and productivity that has placed us as a trusted, long-term strategic partner for our customers.

Select JS Precision and take advantage of a decade-long experience of die casting solutions. Let us offer you safe custom metal casting manufacturing solutions with a smooth project experience from the design to mass production.

Building The Fundamentals: An In-Depth Knowledge Of The Die Casting Process

What is Die Casting?

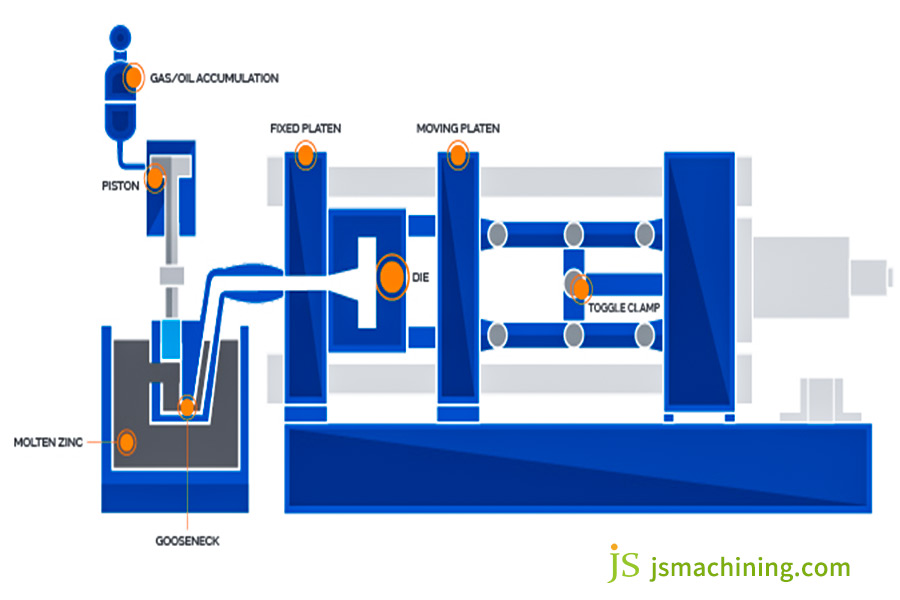

Imagine a very accurate metal syringe taking molten metal at high pressure and velocity and injecting it into a hardened steel mold cavity, filling all the detail in a split second before hardening and rapid cooling. That’s the basic high-pressure die casting process.

It is a highly efficient and precise metal casting technique. High-pressure die casting is proportionally more suited than other metal casting techniques such as gravity casting for bulky, complex shape manufacturing, thin-walled parts with high surface quality requirements.

Its intrinsic merits are that it possesses its very high production efficiency, ability to produce complex geometries, high dimensional precision, and improved surface quality, in certain applications even requiring no substantial post-processing for direct applications.

Die Casting Materials in the Mainstream: Choosing the Right Material for Your Project?

Material selection is the first consideration to remember regarding performance and cost balance. What follows is a rundown of the top three mainstream die casting materials so you can gain an understanding base in a hurry.

| Material Type | Core Characteristics | Typical Applications | Cost Considerations |

| Aluminum Alloy | Good strength-to-weight ratio, corrosion resistance, electrical and thermal conductivity. | Automotive engine components, transmission housings, electronic device casings, structural frames. | High cost-effectiveness, relatively stable raw material prices, and the most widely used. |

| Zinc Alloy | Excellent casting fluidity, high strength and hardness, easy to plate. | Locks, precision gears, connectors, high-end hardware, bathroom accessories. | Moderate material cost, can form more complex thin-walled parts due to good fluidity. |

| Magnesium Alloy | The lightest commercial structural metal, high specific strength, good damping properties. | Aerospace components, laptop casings, camera bodies, portable tools. | Higher raw material cost, but the value brought by extreme lightweighting is significant. |

Design Determines 80% Of Cost: Your Die Casting Design Guide

Golden Rules of Design for Manufacturability

First-class die castings begin with first-class design. Following design for manufacturability principles can reduce costs and improve quality at its source. To observe the impact of design decisions on cost and quality, look to the following comparison:

| Design Features | Poor Practices | Optimization Suggestions | Core Value Delivered |

| Wall Thickness | Uneven thickness with large variations. | Maintain uniformity as much as possible with gradual transitions. | Avoids shrinkage holes and deformation, and improves structural consistency. |

| Draft Angle | Ignored or insufficient draft angle. | Ensure sufficient draft angle (usually 1-3 degrees). | Protects the mold, ensures smooth part demolding, and achieves a perfect surface. |

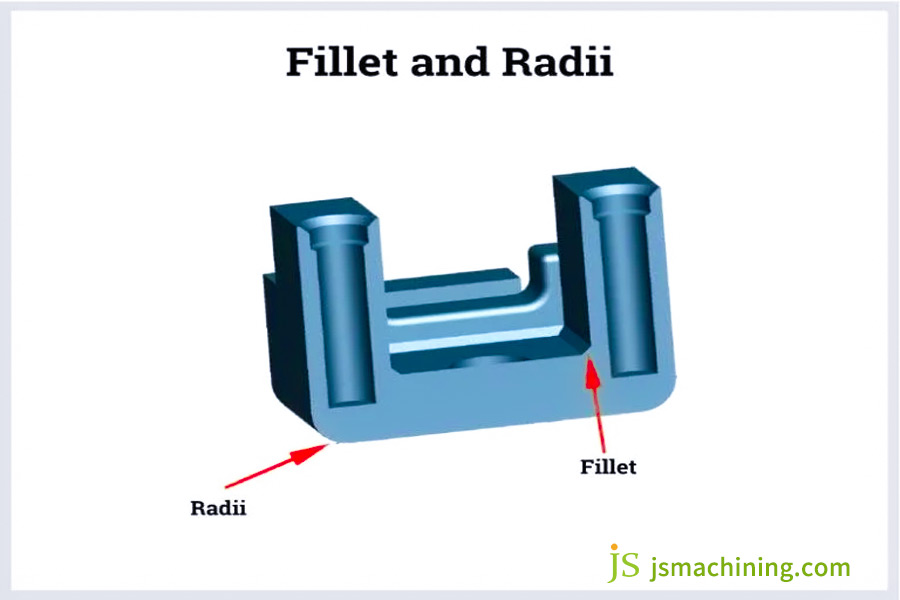

| Fillet Radius | Sharp internal and external corners. | Use appropriate radius fillets for all corners. | Significantly reduces stress concentration and extends mold life. |

| Ribs | Excessively thick, with the same thickness as the main wall. | Set thickness to 50-70% of the main wall thickness. | Achieves maximum rigidity with minimal weight, reducing overall weight. |

The Value of Early Collaboration with the Engineering Team

The best projects begin with early involvement of the suppliers. If your production supplier for custom metal casting manufacturing is involved early on, they can provide manufacturing-focused optimization suggestions and avoid costly design mistakes.

JS Precision strongly recommends that its customers get in touch with us at the conceptual design phase. Our designers provide professional Design for Manufacturability (DFM) analysis reports, highlighting issues and suggesting improvement solutions. This saves customers up to 15% in follow-up expenses and shortens development cycles considerably.

Make JS Precision your design partner. Designing with us early on may improve your design and reduce metal cast prices by quite a margin. Get our free DFM analysis through our online metal casting services for your design drawings.

Cost Deconstruction: Correct Budgeting And Quoting Analysis

Five Important Parameters that Influence the Die Casting Cost

To analyze the cost of a quote, we have to analyze the cost. The cost per unit is largely made up of the following.

- Material cost is not merely by metal weight but by yield (net weight of casting vs. weight of pour). Better yield will have less scrap and lower material cost.

- Production costs include machine tonnage (larger, more expensive), cycle time (shorter, more efficient), energy consumption, and labor.

- Post-process costs such as deburring, machining, and surface finishing (e.g., painting, electroplating) contribute to unit cost.

- Mold costs must be amortized over accumulative production amount. With the increase in production amount, the mold cost per unit comes down.

- Quality control costs include in-process checking and final testing to assure supplied product specificationally suitable.

Die Casting Mold Quote Demystification: How to Effectively Interpret and Evaluate die casting Mold Quotes

The molds are the region of utmost significance in die casting manufacture and have the highest initial capital expense. A quote for a mold would typically include cost of high-grade mold steel, sophisticated CAD/CAM engineering, precise CNC milling, heat treatment to enhance hardness and life cycle, and simple mold trialing.

It should be remembered that “you get what you pay for.” Mold life may be reduced by using lower-cost steel or by using a less complex design, resulting in mold failure during manufacturing and incurring further losses. A well-constructed mold must be of long life and with open maintenance costs.

Fluctuations in Raw Material Prices: How to Obtain a Stable Quote

Both zinc and aluminum are global commodities, and their prices depend on demand and supply in the market. JS Precision addresses this risk by using long-term strategic sourcing agreements, creating buffer inventories of raw materials, and using price formulas or floating clauses in our quotations.

Our objective is to provide our clients with the most accurate and stable metal casting prices possible, avoiding uncertainty that is typically initiated by volatile market rates and project budgets.

JS Precision has an open metal casting price estimate breakdown. You will be able to see precisely where each dollar is going and have actual cost control as our partner. Arrange for a consultation today for your custom metal casting manufacturingproject budget.

Leverage Value: Maximize Value While Minimize Cost

Value Engineering Thinking: Not Cheapest, but Most Economical

Canny buyers want “most economical” rather than “cheapest.” That is, away from “cost per part” thinking and towards “total cost of ownership” thinking.

Cost of ownership is the total of purchase cost, cost of quality risk (down time loss due to faulty components), cost of delayed delivery, and cost of after-sales service. A supplier who delivers a bit more but is always on time with no faults will have significantly lower cost of ownership than a supplier who delivers less but has recurrent problems.

Fine Cost Optimization Practical Strategies

The strategies through which you can cost-effectively reduce expenses are:

- Optimize material selection with prudent trade-offs, choosing the cost-effective material with performance requirements.

- Loosen tolerances wisely. Wise loosening of tolerances on non-critical dimensions can reduce dramatically processing effort and cost.

- Pursue functional consolidation, where varied pieces are integrated into a single die-cast component in an effort to minimize assembly operations and components.

- Maximize production volume and take advantage of economies of scale to minimize unit cost. Use the most economical post-processing operation.

- Developing strategic partnerships with suppliers such as JS Precision, rather than one-time transactions, will usually lead to lower prices and priority service.

JS Precision vows to give the highest back on your investment with value engineering. Our die casting experts will design a cost-saving plan for you. Contact us to experience a one-of-a-kind online metal casting service.

Beyond Price: Five Key Dimensions For Judging Die Casting Suppliers

If a group of suppliers quotes similar prices, the choice is made on “softer qualities” aside from price. The following five dimensions will help you to have a genuine long-term partner.

1.Engineering support is vital. You should evaluate if the firm’s engineering personnel can provide proactive DFM analysis and not just modify drawings. For example, do they provide pre-suggestions regarding the reduction of wall thickness to obtain strength at a lower cost?

2.The quality control system takes precedence. Apart from certification validation like ISO9001, you need to check whether there are advanced-technology testing machines and closed-loop quality control procedures, for instance, whether X-rays are employed in the case of internal non-destructive testing in order to eliminate potential defects.

3.Production and capacity are biggest. You have to be aware of the condition of equipment, its frequency of maintenance, and terms of flexible capacity so that you can accept changes in your orders.

4.Project management and communication are the grease. A dedicated and professional project manager provides you with smooth information flow, timely warnings, and bug fixing, which provides you a confidence guarantee.

5.Previous experience and previous case histories within the industry are worth recommendation. Look for similar success cases for your business. This will assist a great deal in reducing project technical risks as well as accelerating mass production.

JS Precision has built systemic competencies in all the above areas. We not only supply highest quality metal casting parts but also offer value-added services across the product lifecycle.

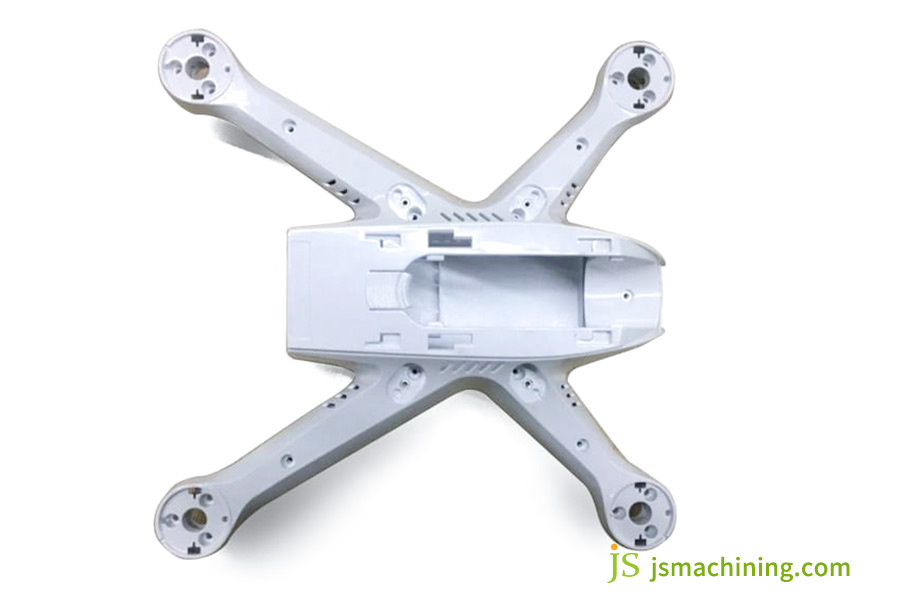

Case Study: How JS Precision Helped A Drone Manufacturer Achieve A 30% Weight Reduction And An Overall Cost 20% Lower

Client Background

A new drone producer was developing a flagship industrial drone. The greatest challenge lay in the main airframe structure. The initial design employed numerous aluminum CNC machining parts bolted together, leading to a high number of components, intricate assembly, heavy total weight, and expensive overall production cost, which hindered market competitiveness.

JS Precision Solution

JS Precision team was invited to intervene in the early stages of the project. Our engineers collaborated with the customer’s R&D department to redesign the original design in-depth. The solution arrived at integrated and condensed the original seven individually machined pieces into a structurally consolidated yet highly complex aluminum alloy die casting.

We used advanced conformal cooling channel technology during the design of the mold to achieve improved and consistent mold cooling and efficiently reduced production cycle time by 15%. For the material, we employed high-strength aluminum alloy with excellent strength to offer thin-walled design support in the major zones as well as overall rigidity and structural integrity.

Results

The main fuselage structure of the drone efficiently reduced its total weight by 30%, improving its flight endurance. By eliminating all assembly operations completely and significantly reducing secondary machining needs, the total cost of manufacturing parts was reduced by approximately 20% from the original design.

Through single-piece molding, reliability and structural integrity were greatly enhanced. Due to JS Precision’s world-class manufacturing process and project delivery, the product was delivered two weeks earlier than scheduled, gaining precious time to understand market opportunities.

Why JS Precision Should Be Your Go-To Project?

We at JS Precision are passionate believers in that the quality in custom metal casting manufacturing begins in an intimate relationship. To that end, we stand before you as your design and engineering partner, an expansion of the in-house know-how of production of your team, rather than a mere slave-order taker. It shows from our practice:

We are absolutely committed to technology and quality, constantly investing in new die casting and testing equipment and creating process specifications in-house that exceed industry standards.

We also believe in full cost transparency and are happy to sit down with you and analyze in great detail each aspect of metal casting price and how we can make it better, instead of building barriers to information.

From the moment you utilize our platform for online metal casting services until delivery of the end product, we have full-fledged project management, with dedicated professionals at each step, to give you a seamless, reliable, and efficient experience.

JS Precision choice is a choice of a strategic partner with a full-fledged knowledge of your needs and continuously facilitating your product success.

FAQs

Q1: What is the minimum wall thickness of a die-cast part?

This generally differs with die casting material and part size. For die casting of aluminum alloys, the smallest wall thickness would usually be about 0.8 mm to 1.2 mm. Zinc alloys, with their fluidity characteristics, are capable of making even lower wall thicknesses, down to a minimum of 0.5 mm. We would need to evaluate your unique part on the basis of its size and geometry. JS Precision engineers can provide precise recommendations in DFM analysis.

Q2: What is a typical mold development cycle?

Development cycles for mold are longer depending on its complexity and size. A fairly simple mold would be four to six weeks. For complex, large, or difficult molds, the development cycle may be eight to twelve weeks or more. Before commencing the project, JS Precision will provide a comprehensive mold development schedule so that there is a workable and clear project plan.

Q3: What are the primary distinctions between aluminum die casting and zinc die casting? How do I choose between them?

Their principal distinctions are in material properties. Die castings in aluminum are lighter, have greater strength-to-weight ratio, and are more corrosion-resistant. Zinc die castings are stronger and harder, more dimensionally stable, have better surface finishes, and are easier to apply to surface treatments such as electroplating. Your product requirements are what decide, for instance, aluminum for light weighting, zinc for strength, hardness, and excellent surface. Cost and application are of equal importance.

Q4: Are small-batch trial runs accommodated? How are tooling costs handled?

Yes, we fully support small-batch trial runs. This is necessary to ensure customers validate their designs and market conditions. Tooling fees are typically borne by the customer as a one-time engineering fee. In subsequent high-volume production, tooling fees are amortized on agreed-upon volumes or charged to the part cost. We offer flexible solutions to accommodate different customer needs.

Summary

Making a astute die casting purchasing choice is a trade-off of conditions that influences not just the price quoted, but the cost of ownership. It requires a good understanding of die casting process, an acceptance of design for manufacturability, and a mutual partnership with a proven supplier who has a high degree of engineering sophistication.

JS Precision is such a strategic partner dedicated to maximizing long-term value for customers.We look forward to bringing our skill and experience to your next great innovation.

Get your personalized value optimization plan today! Upload your 3D drawings below, and our senior team will provide a complimentary first-cut evaluation report within 24 hours with Design for Material Design (DFM) analysis and transparent pricing. Let’s work together to bring your ideas to life at the best possible price.

Disclaimer

The content of this website is for reference only. JS Precision Services expressly disclaims any representations or warranties, express or implied, as to the accuracy, completeness or validity of the information provided. Any performance parameters, geometric tolerances, design features, material specifications or processes mentioned should not be considered as any commitment or guarantee by JS Precision for products offered by third-party suppliers or manufacturers on its network or other channels. Buyers seeking quotes for parts are responsible for confirming their specific needs and product suitability. If you have any questions or need further information, please contact JS Precision directly.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:jsmachining.com